Graphite substrate for improving wavelength uniformity of epitaxial wafer

A graphite substrate, uniformity technology, applied in the direction of single crystal growth, crystal growth, from chemically reactive gases, etc., can solve the problems of aggravated difference, uneven distribution of Mo sources, consumption, etc., to achieve volume reduction, uniform distribution, The effect of improving wavelength uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

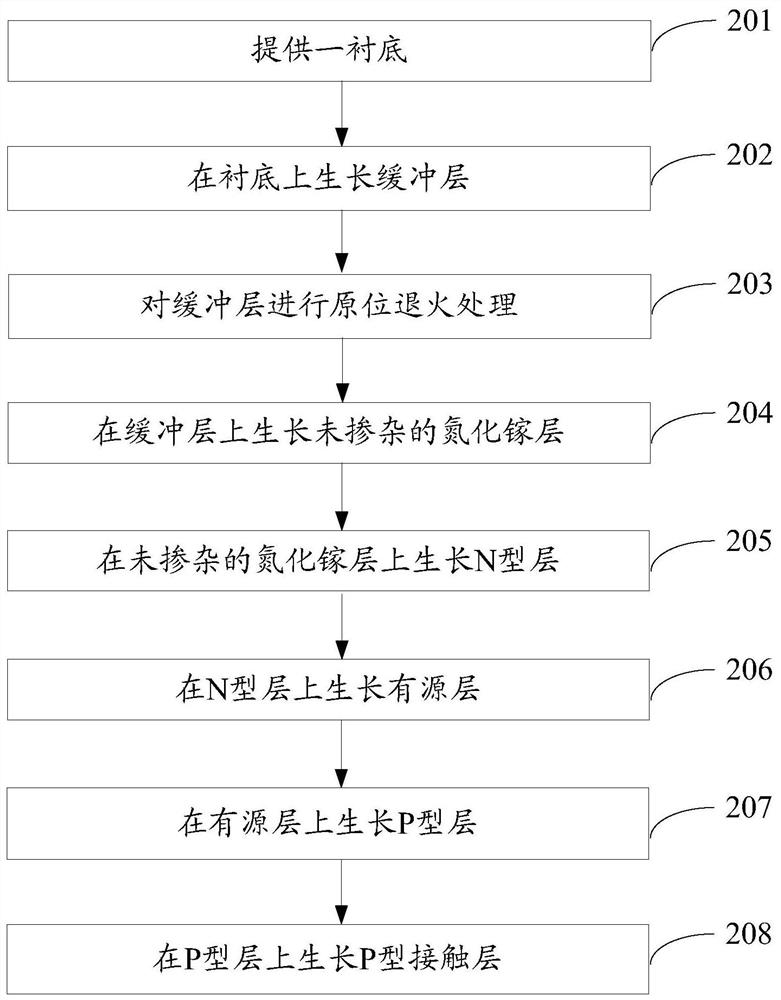

[0031] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

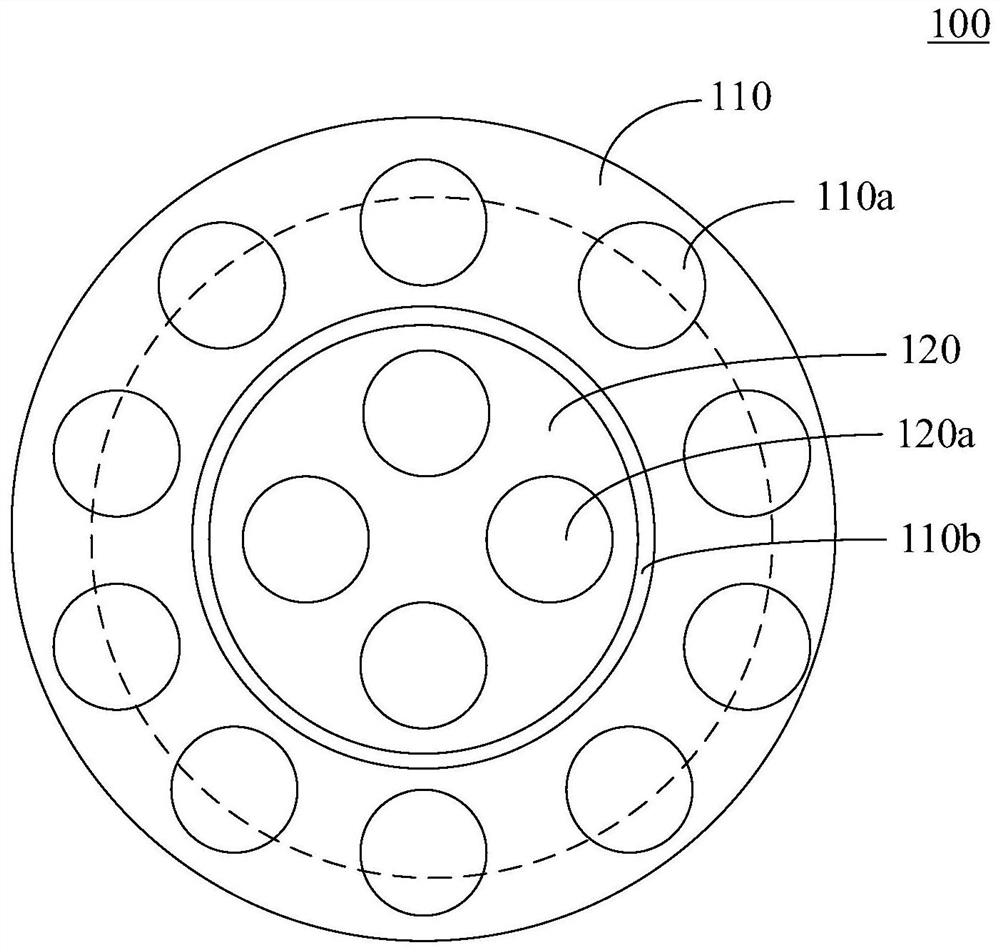

[0032] figure 1 It is a top view of a graphite substrate used to improve the wavelength consistency of an epitaxial wafer provided by an embodiment of the present disclosure, as shown in figure 1 As shown, the graphite substrate 100 includes a first substrate 110, a second substrate 120 and an exhaust device 130, and both the first substrate 110 and the second substrate 120 are discs.

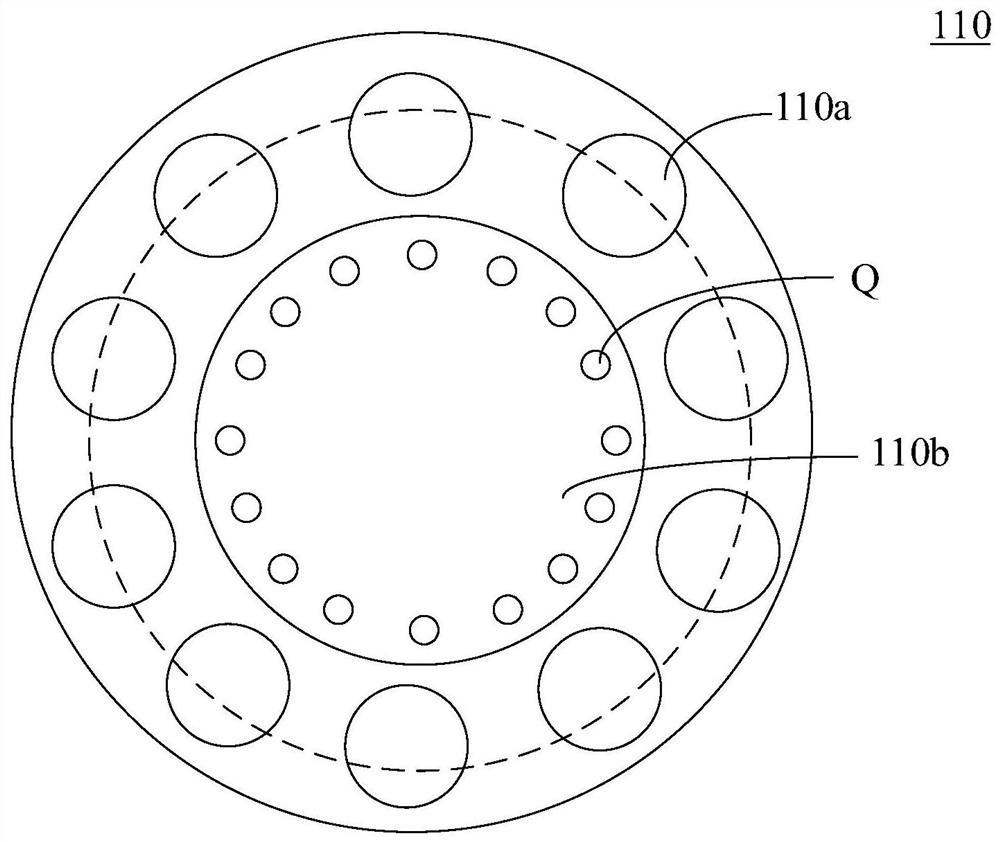

[0033] figure 2 is a top view of a first substrate provided by an embodiment of the present disclosure, such as figure 2 shown, combined with figure 1 , the upper surface of the first substrate 110 has multiple turns of first grooves 110a for accommodating the substrate, and the multiple turns of first grooves 110a are arranged on the first sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com