Sub-motor-driven wire drawing machine

A wire drawing machine and separate motor technology, which is applied in the direction of wire drawing dies, transmission boxes, mechanical equipment, etc., can solve the problems of high maintenance cost, large consumption of lubricating oil, high manufacturing cost, etc., and achieve the effect of reliable sealing and isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

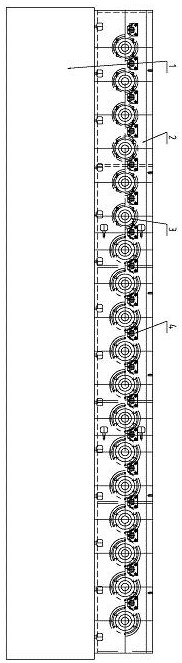

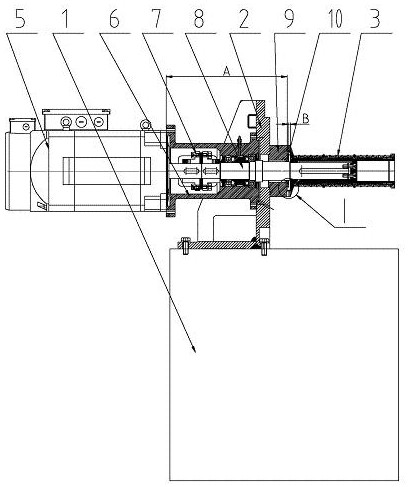

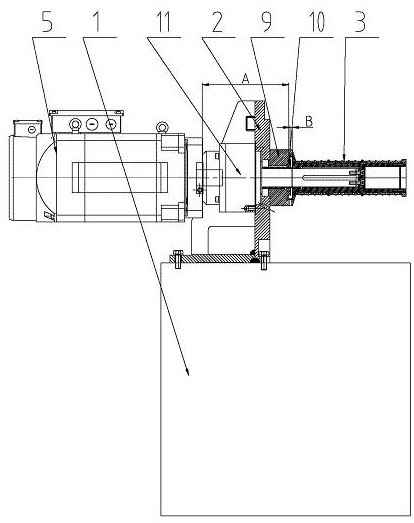

[0024] exist figure 1 with figure 2 In the motor-driven wire drawing machine shown, the machine base 1 is in the shape of a cuboid box, which is the basic supporting member of the wire drawing machine. The vertical plate 2 is fixedly connected to the machine base 1, and the cross section of the vertical plate 2 is square-shaped. , its bottom surface is fixedly connected with the machine base 1, and the vertical plate 2 can be an integral structure, but it is preferably formed by splicing and combining a plurality of discrete plates along the length direction through connecting bolts, and three or four groups are arranged on each discrete plate Or five or six or seven wire drawing assemblies form a modular assembly, which can be easily combined into wire drawing machines with different numbers of wire drawing wheels. A wire drawing die assembly is arranged between the two wire drawing wheels 3, and the wire drawing die assembly includes a wire drawing die and a wire drawing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com