A diesel engine oil pressure sensor device and control method

A sensor device, diesel engine technology, applied in the direction of pressure lubricated safety devices, etc., can solve problems such as overturning, pressure sensor cannot be replaced, diesel engine and ship operation have risks, etc., and achieve mobile and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

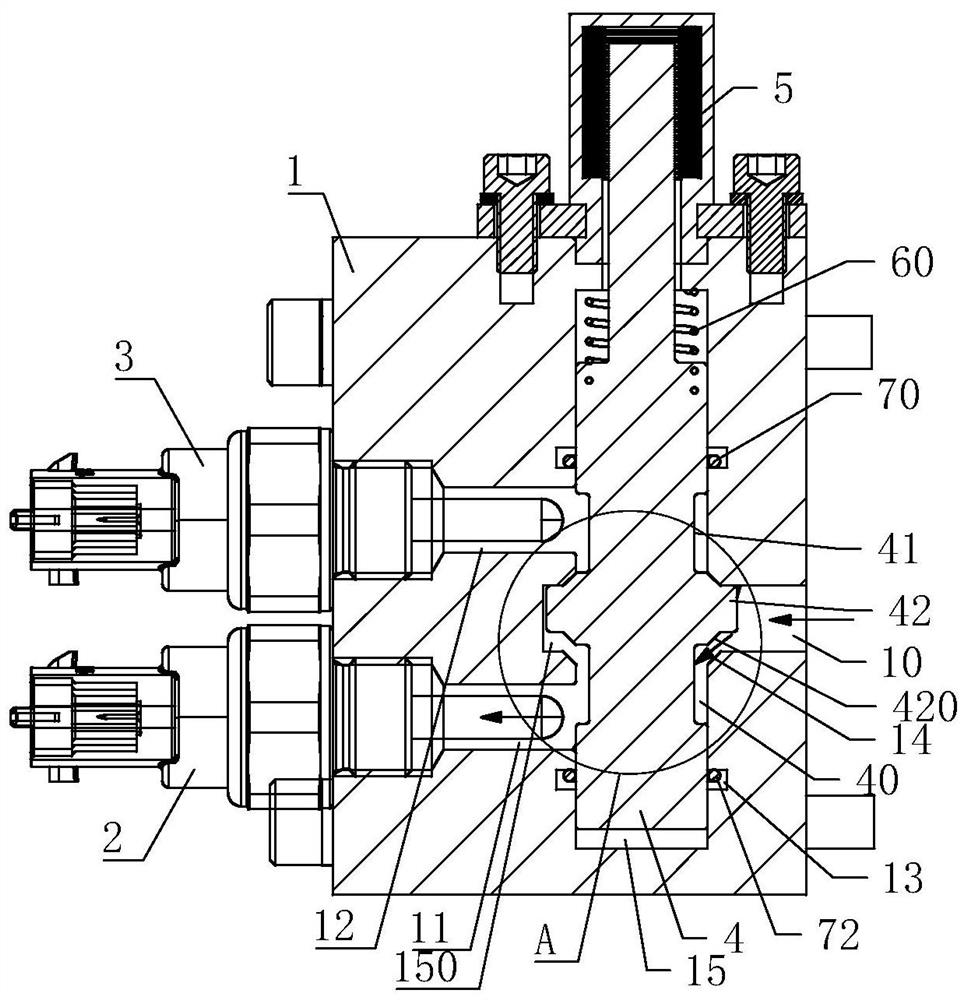

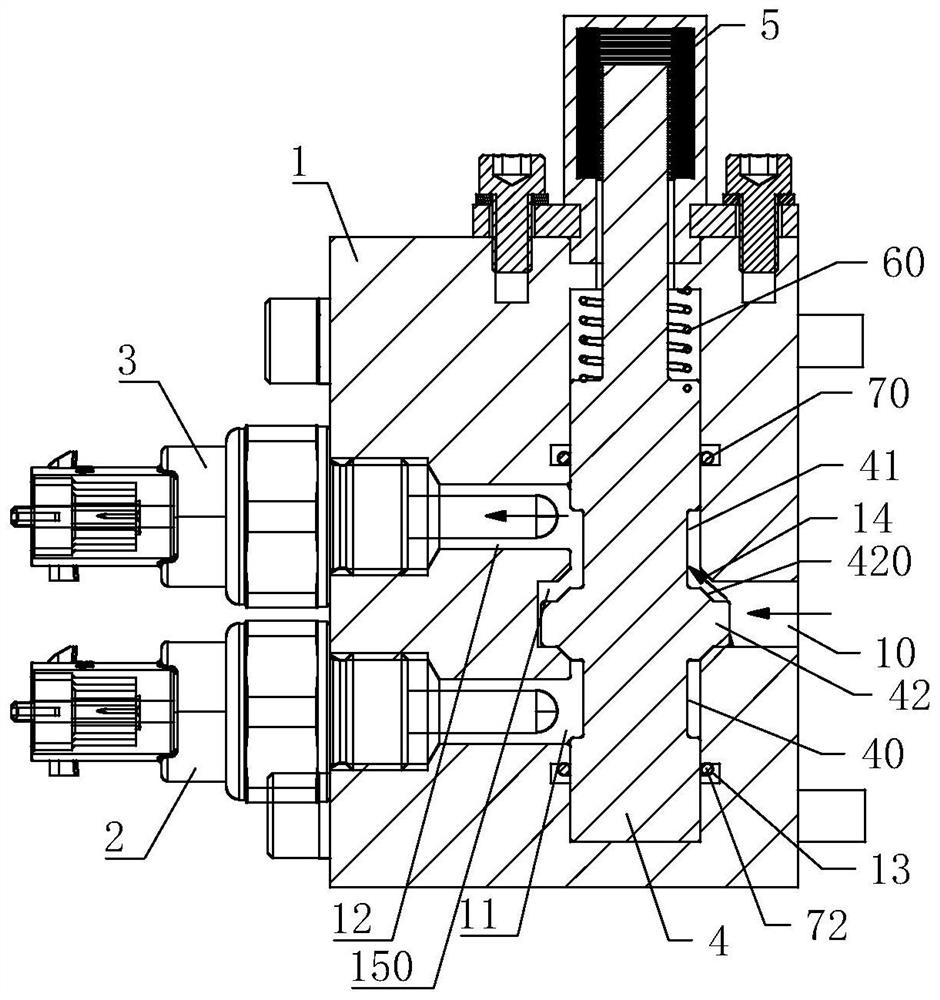

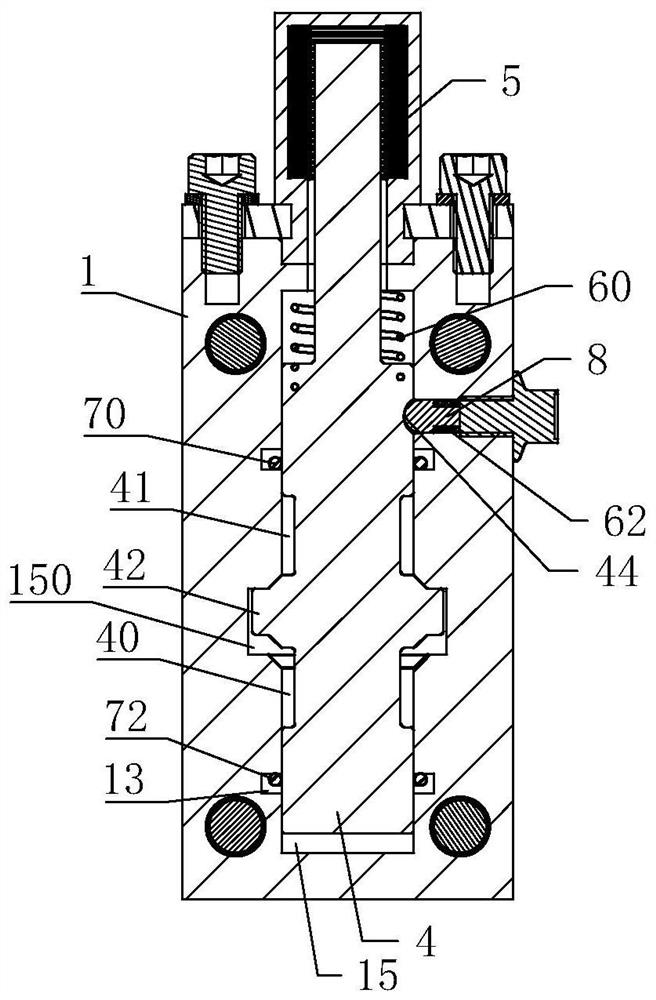

[0050] like Figure 1 to Figure 4 As shown, a diesel engine oil pressure sensor device includes a base 1, a first pressure sensor 2 and a second pressure sensor 3 arranged on the base 1, and the base 1 is provided with a first detection channel 11, a second Two detection passages 12, communication passages 15 and medium entry passage 10; the detection end of the first pressure sensor 2 is set in the first detection passage 11; the detection end of the second pressure sensor 3 is arranged in the second detection passage 12; in the communication passage 15 The communication shaft 4 is provided, and the length of the communication channel 15 is greater than the length of the communication shaft 4; the base 1 is also provided with a power mechanism, and the power mechanism acts on the communication shaft 4 to move in the communication channel 15 to communicate with the first detection channel 11 and The medium enters the channel 10 or communicates with the second detection channel...

Embodiment 2

[0063] like Figure 5 As shown, a control method of a diesel engine oil pressure sensor device, the diesel engine oil pressure sensor device is the diesel engine oil pressure sensor device described in Embodiment 1, and in the initial state of the diesel engine oil pressure sensor device, the first pressure sensor Putting into use, the second pressure sensor is not in use, of course, the second pressure sensor can be put into use in the initial state, including the following steps:

[0064] Step S1, obtaining the medium pressure value collected by the first pressure sensor;

[0065] Step S2, judging whether the medium pressure value is within a preset range, the preset range is a pre-calibrated amount, and the case of not being in the preset range includes the case that the medium pressure value is too low or not collected;

[0066] Step S3, if no (the medium pressure value is not within the preset range), generate a corresponding control signal; if the medium pressure value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com