Pump

A pump chamber and canned pump technology, applied in the field of pumps, can solve the problem of high installation cost, and achieve the effect of simple manufacturing technology, saving space and reducing installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

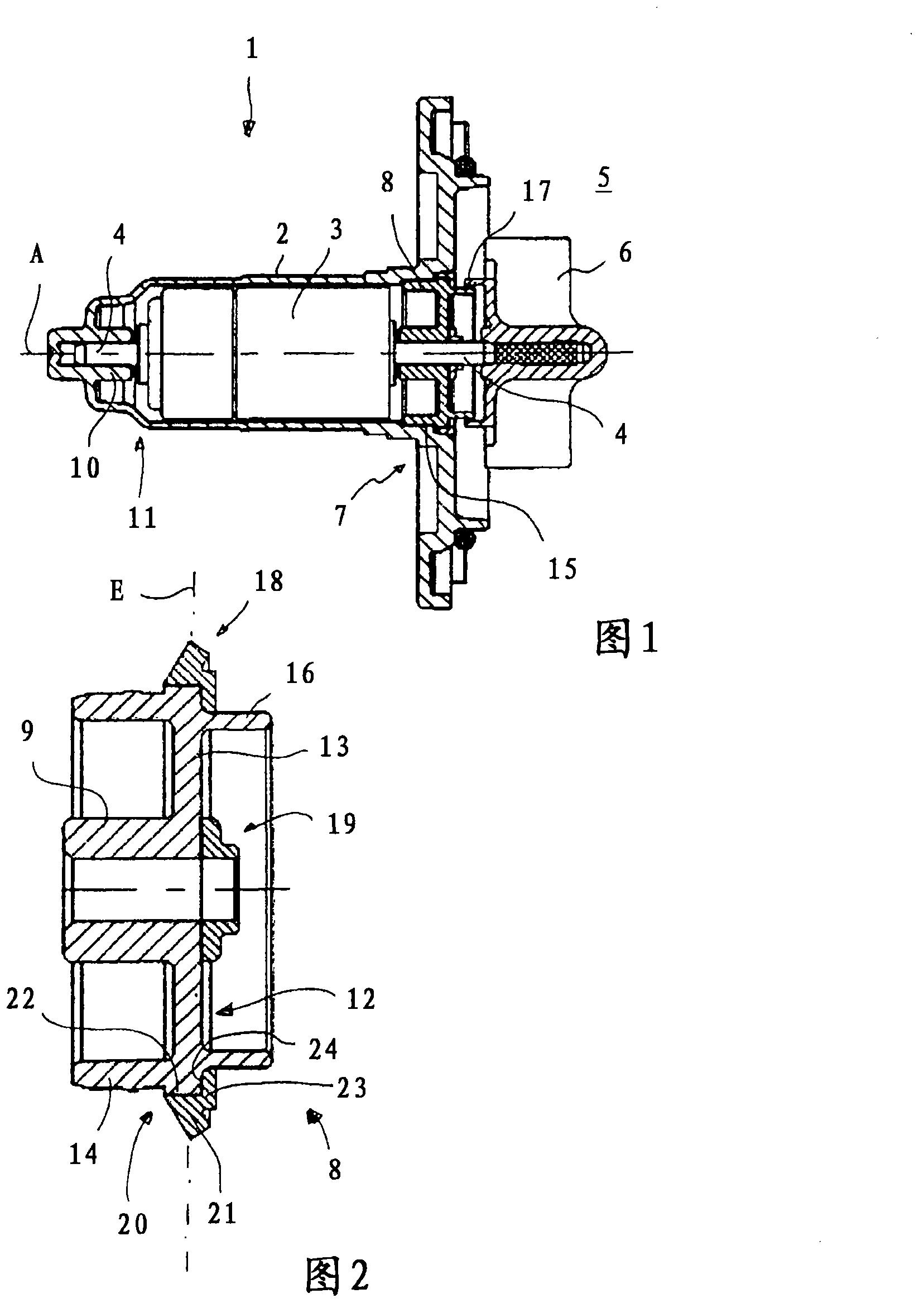

[0016] The pump according to the exemplary embodiment of the invention shown in the drawing forms a canned pump 1 that can preferably be used in domestic appliances that operate with water, such as dishwashers or the like.

[0017] The canned pump 1 has a canned tube 2 as a motor housing, in which a rotor 3 of a synchronous motor and a drive shaft 4 connected to the rotor 3 in a non-rotatable manner are mounted. The not shown stator of the synchronous motor can be arranged outside this shielding tube 2 .

[0018] The drive shaft 4 is non-rotatably connected to the impeller 6 of the pump, which is arranged in the pump chamber 5 . Alternatively, the drive shaft 4 can also be connected to the impeller 6 of the pump via a freewheel or via a flywheel.

[0019] In the region of the first end face 7 of the shielding tube 2 facing the pump chamber 5 , a sealing carrier 8 is arranged, which has a supporting and sealing function. from figure 2 As can be seen more clearly in , the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com