Hermetic door for vacuum pipe system

A technology of vacuum pipelines and airtight doors, which is applied in the field of airtight doors, can solve the problems of hydraulic and pneumatic restrictions, inconvenient piping and pipe penetration, etc., and achieve the effects of saving space, good sealing and isolation effects, and large degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

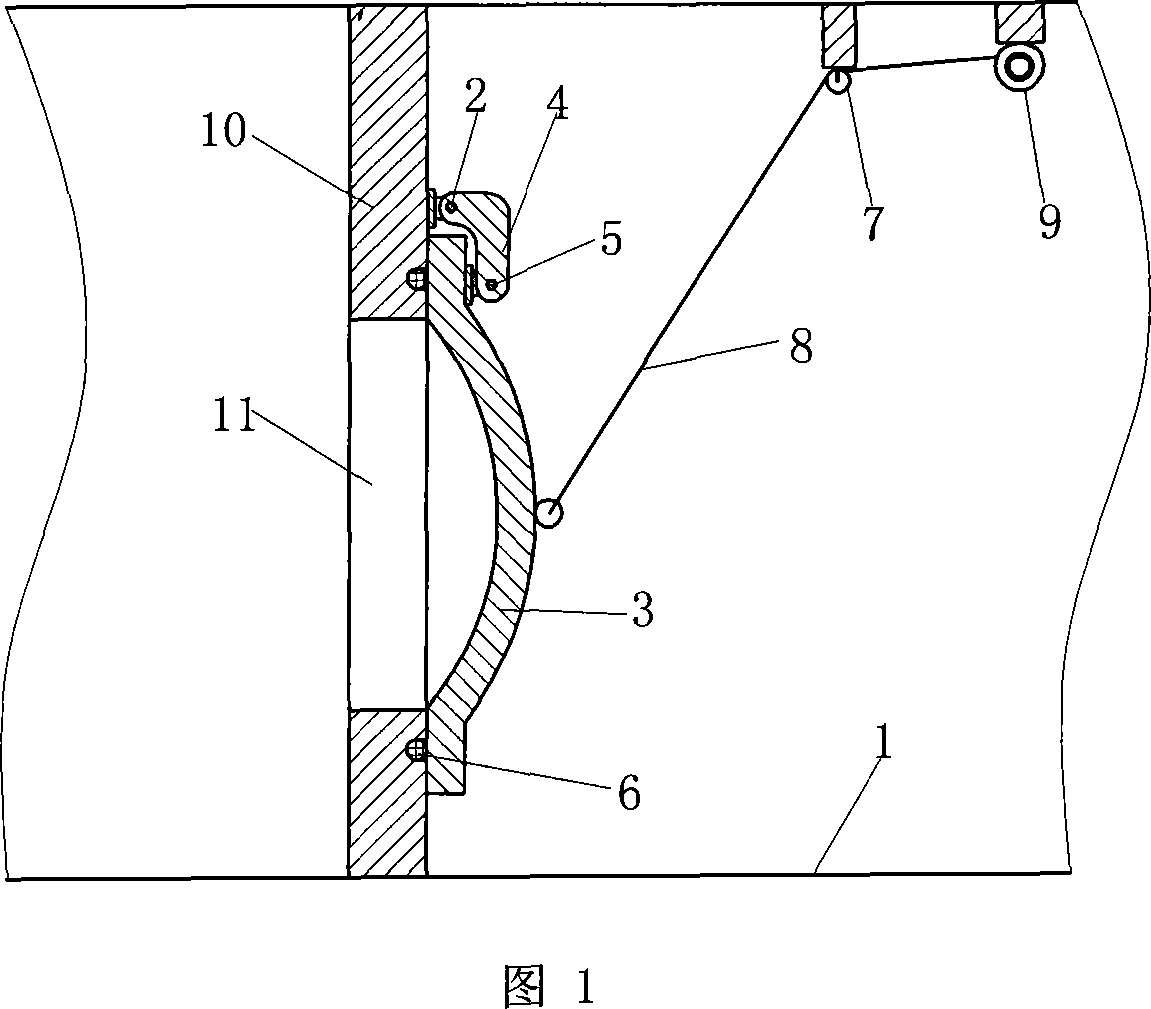

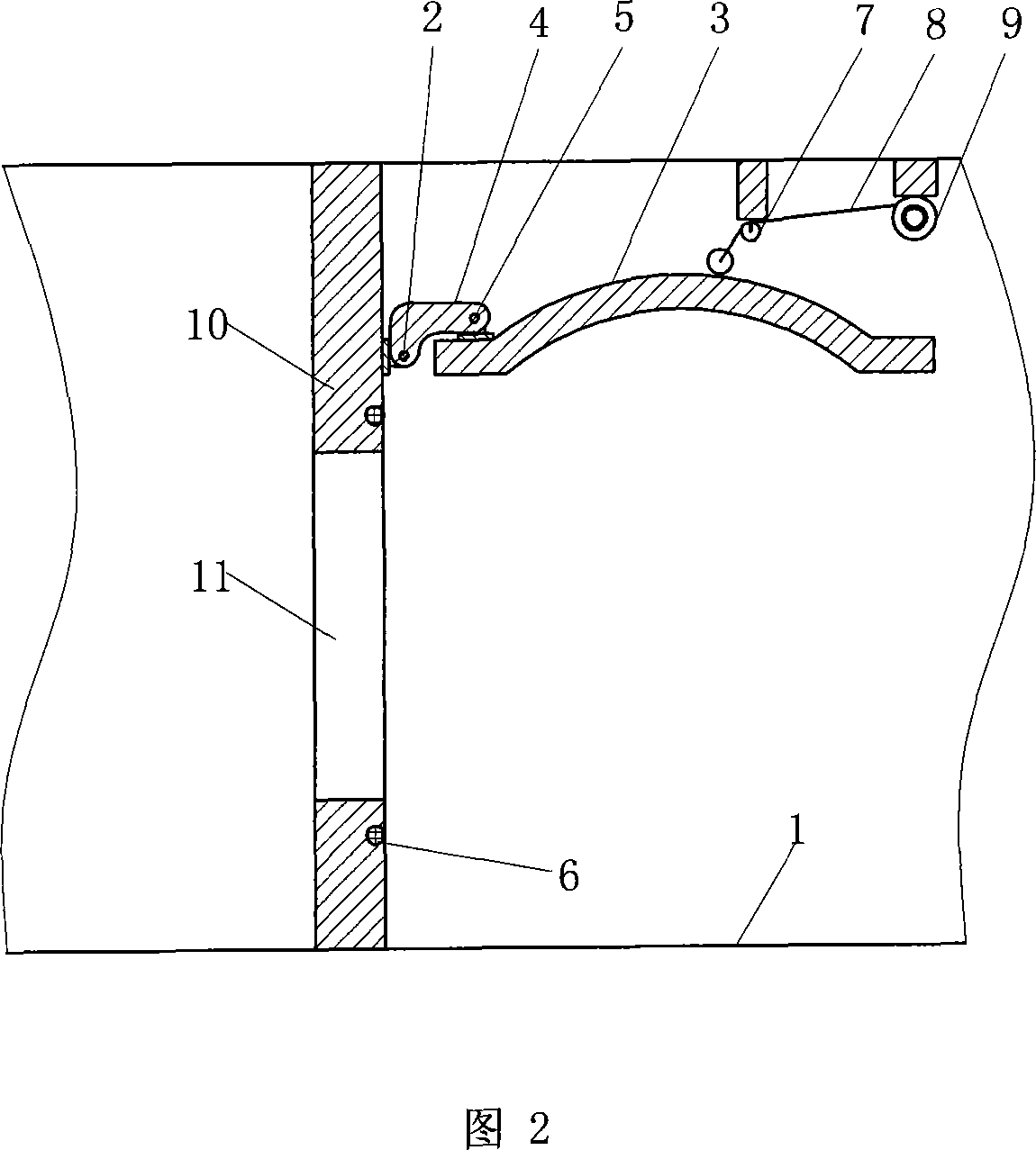

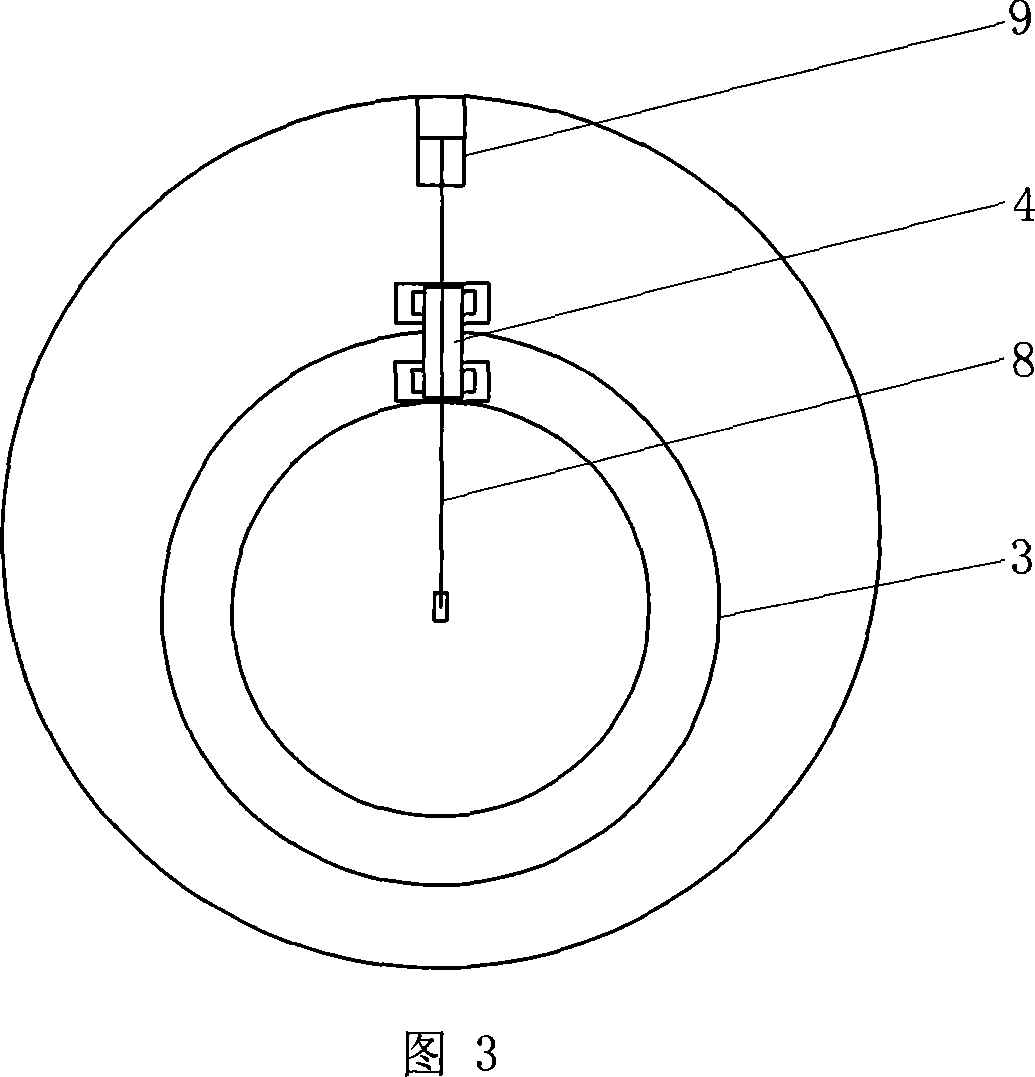

[0022] Figures 1-3 show that a specific embodiment of the present invention is: a hermetic door used in a vacuum pipeline system, including a partition wall 10 set in the vacuum pipeline 1 and a door opening 11 and a door cover on the partition wall 10 3. Partition wall 10 metope is hinged by one end of pin 2 and L-shaped hinge bar 4, and the other end of L-shaped hinge bar 4 is hinged with the back side of door cover 3 by pin 5. Its door cover 3 back side connects steel cable 8, and the other end of steel cable 8 links to each other with the winch 9 of door cover 3 back tops. The connection of steel cable 8 and door cover 3 back sides can adopt modes such as buckle, hook to connect flexibly, is convenient to the replacement of steel cable 8 like this.

[0023] The L-shaped hinge bar 4 of this example is positioned at the top of the door opening, and the winch 9 is positioned at the top of the door cover 3 backs. Also be provided with a Sui wheel 7 between door cover 3 and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com