A Rapid Measuring Method of Blade Curved Surface

A measurement method and blade technology, applied in measurement devices, instruments, etc., can solve the problems of difficulty in improving measurement accuracy, low measurement efficiency and reliability, shorten the processing and manufacturing cycle, avoid low measurement efficiency, and reduce the number of measurement points. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

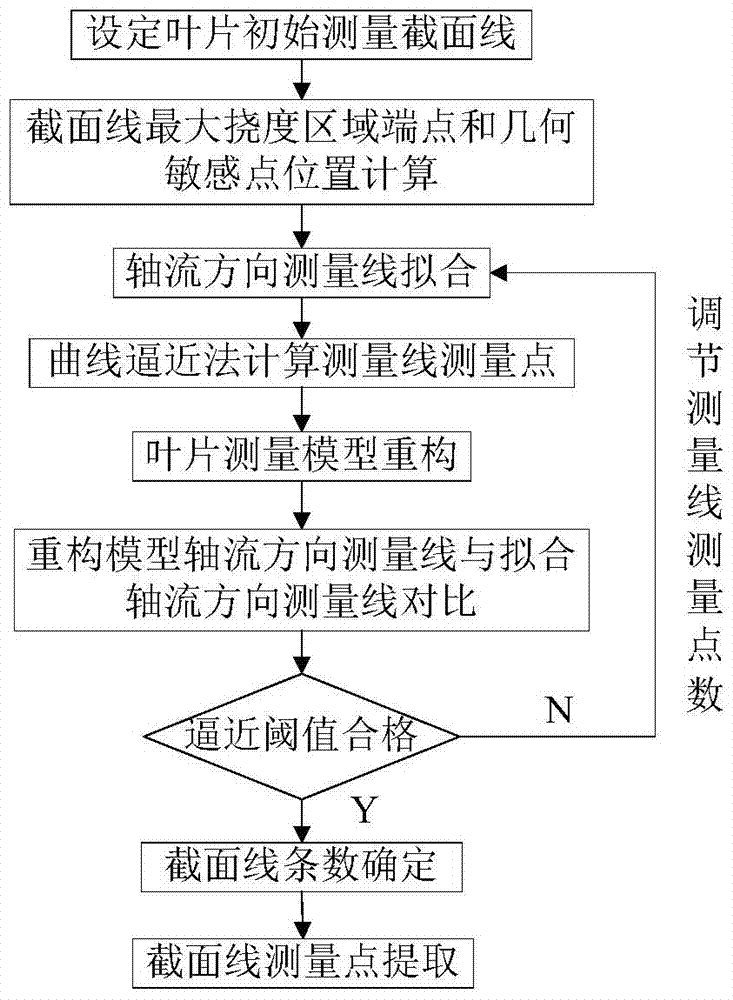

[0038] Include the following steps:

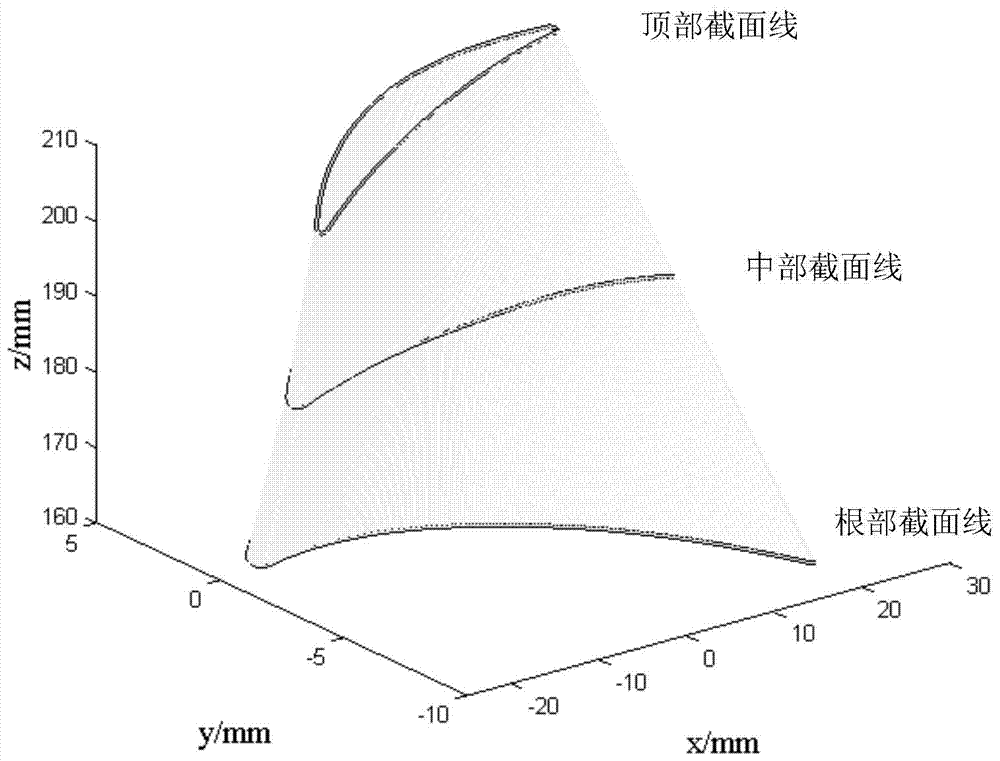

[0039] (1), in the direction perpendicular to the Z axis, intercept 3 section lines at equal intervals at the top, root and middle of the blade, and use a three-coordinate measuring machine to collect the measurement points of the section lines;

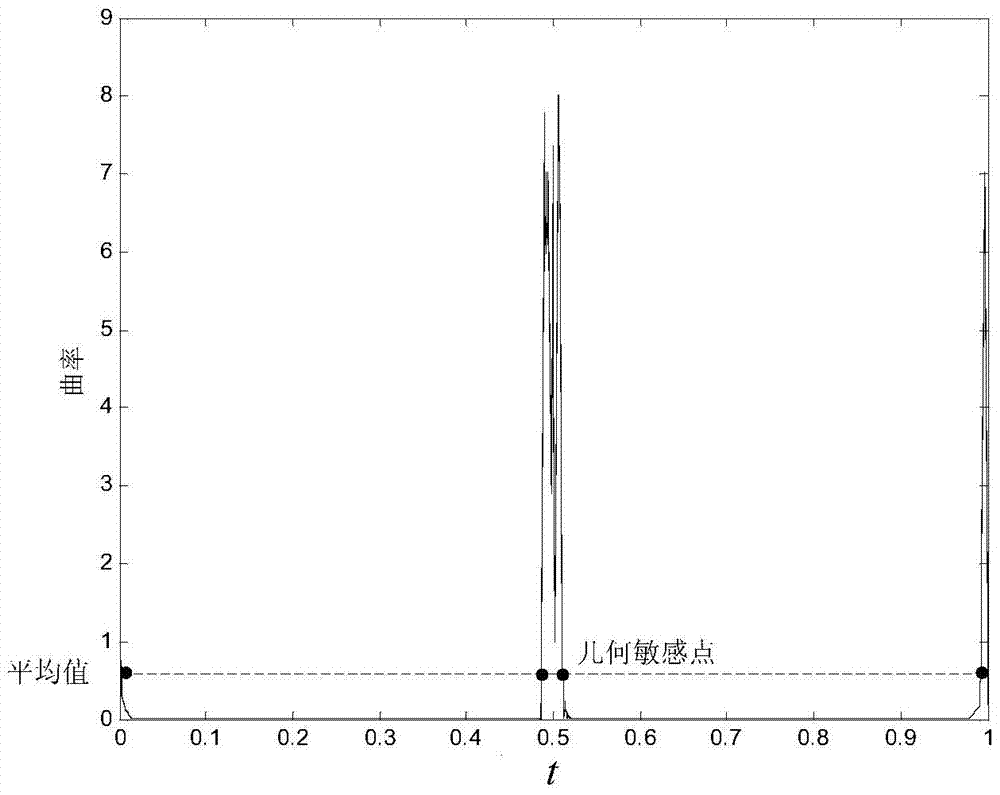

[0040] (2) Calculation of geometrically sensitive point positions: respectively perform 3 times of B-spline curve fitting on the measurement points of the above-mentioned cross-section lines, derivate the obtained 3 times of B-spline curves, and bring the first-order derivative and second-order derivative into the curvature Formula, calculate the curvature of the measurement point, calculate the average value of the curvature of the three B-spline curves, the intersection point of the average value and the curvature value is the geometrically sensitive point sought;

[0041] (3) Calculation of the maximum deflection area endpoints: Calculate the maximum deflection of the leaf back and leaf basin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com