High-temperature moving spherical rearview mirror glass suction device

A suction device and rear-view mirror technology, applied in transportation and packaging, manual conveying devices, furnaces, etc., can solve the problems of scrapped spherical glass, falling gaps in contact positions, affecting the air tightness of vacuum adsorption, etc., to ensure quality. and stability, avoid contusion, avoid the effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

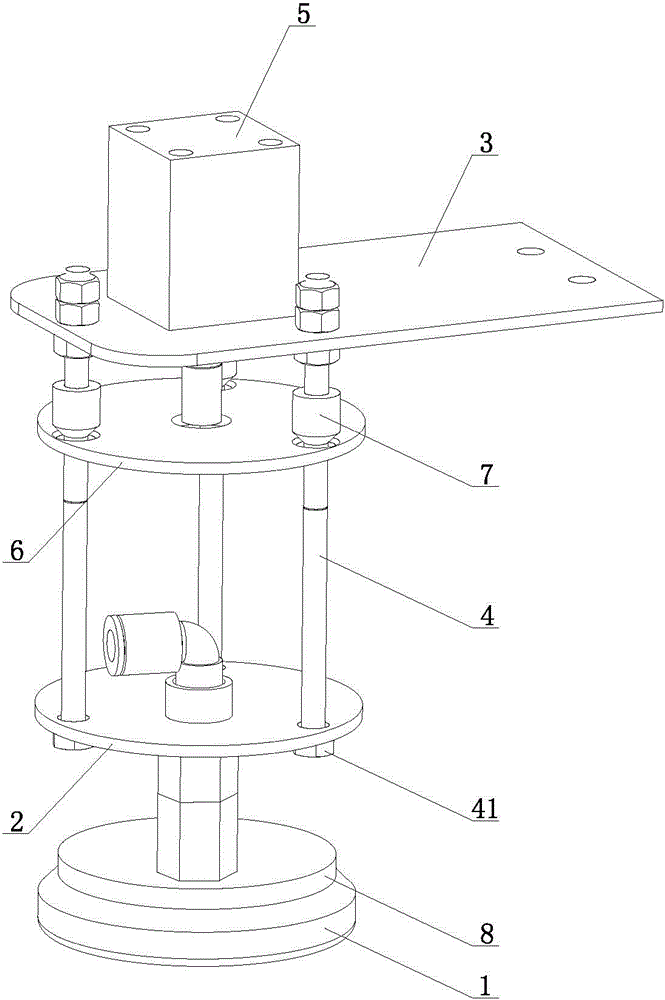

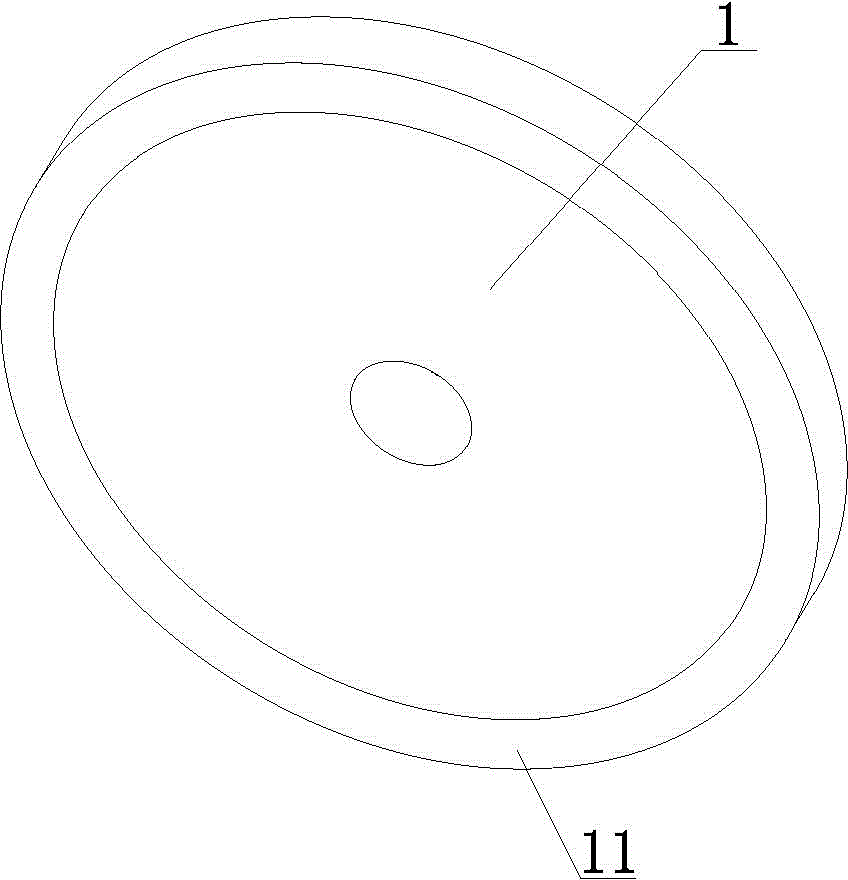

[0020] Such as Figure 1~2 As shown, a kind of high-temperature sports spherical rearview mirror glass suction device of the present invention comprises a floating control device and a metal vacuum chuck 1, and the floating control device includes a lower floating plate 2, an upper fixed plate 3 and a floating connecting rod 4, and the lower floating plate 2. A lower floating hole with an aperture larger than the diameter of the floating connecting rod 4 is provided. The bottom end of the floating connecting rod 4 is provided with a round table 41, and the top end of the floating connecting rod 4 passes through the lower floating hole and is non-tightly connected with the upper fixing plate 3. , the lower floating plate 2 abuts against the round platform 41 , and the metal vacuum chuck 1 is located under the lower floating plate 2 and connected with the lower floatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com