Patents

Literature

44results about How to "Reduce labor production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel welding material

ActiveCN101844281AIncrease the cost of useProne to galvanic corrosionArc welding apparatusWelding/cutting media/materialsMartensiteImpurity

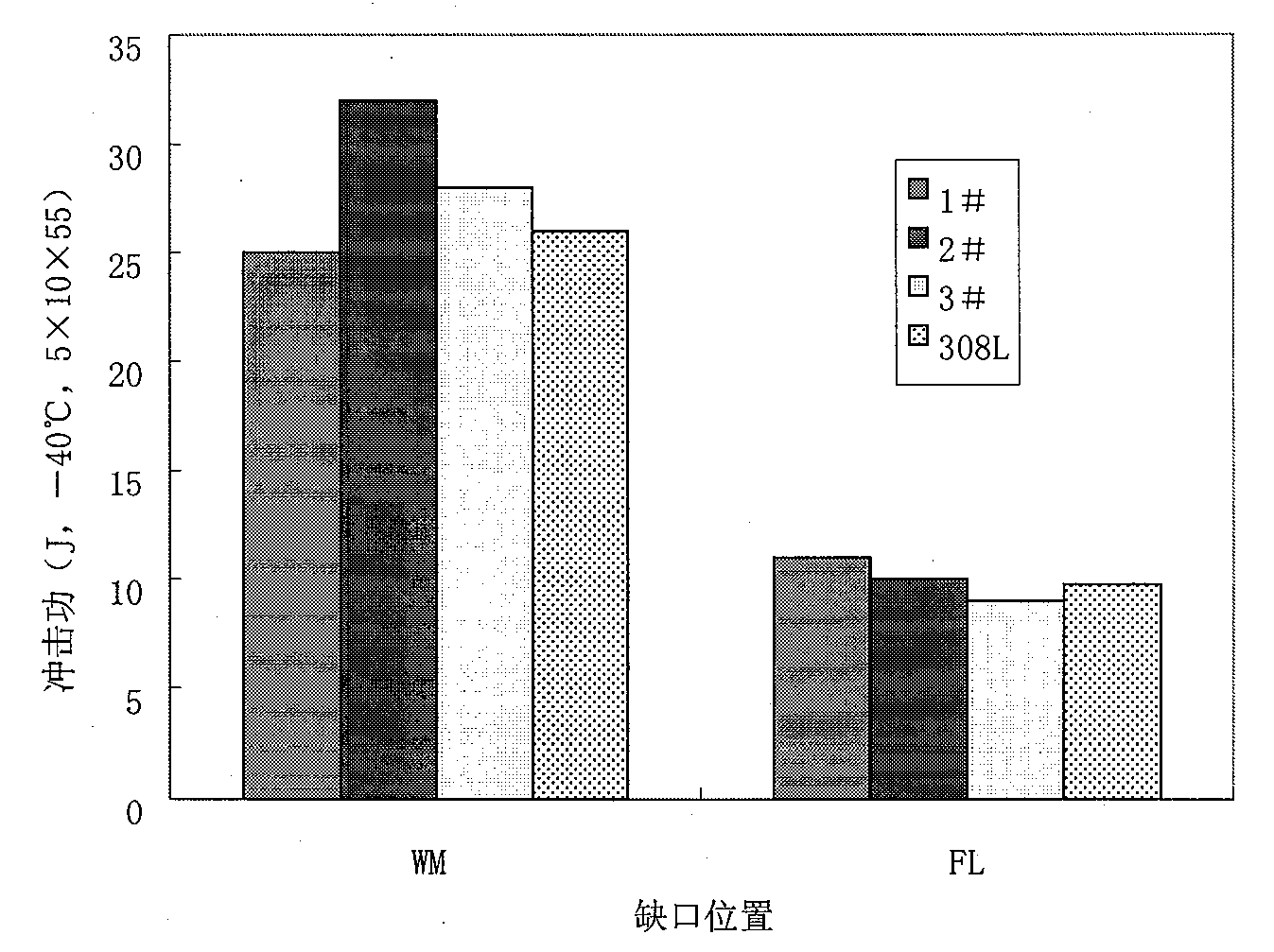

The invention relates to a stainless steel material, a welding wire and a welding wire coil; and the material comprises the following components in percentage by weight: 0 to 0.03 percent of C, 0.5 to 1.0 percent of Mn, 0.5 to 1.0 percent of Si, 12.5 to 14.5 percent of Cr, 0.2 to 0.3 percent of Ti, 5.5 to 6.5 percent of Ni, 0 to 0.015 percent of S, 0 to 0.02 percent of P, and the balance Fe and other inevitable impurity elements. When being applied in ferritic stainless steel and martensitic and ferritic dual-phase stainless steel welding, the stainless steel welding material can replace austenitic stainless steel. The stainless steel welding material is applicable to welding under the condition that the heat input is 5 to 7kJ / cm.

Owner:BAOSHAN IRON & STEEL CO LTD

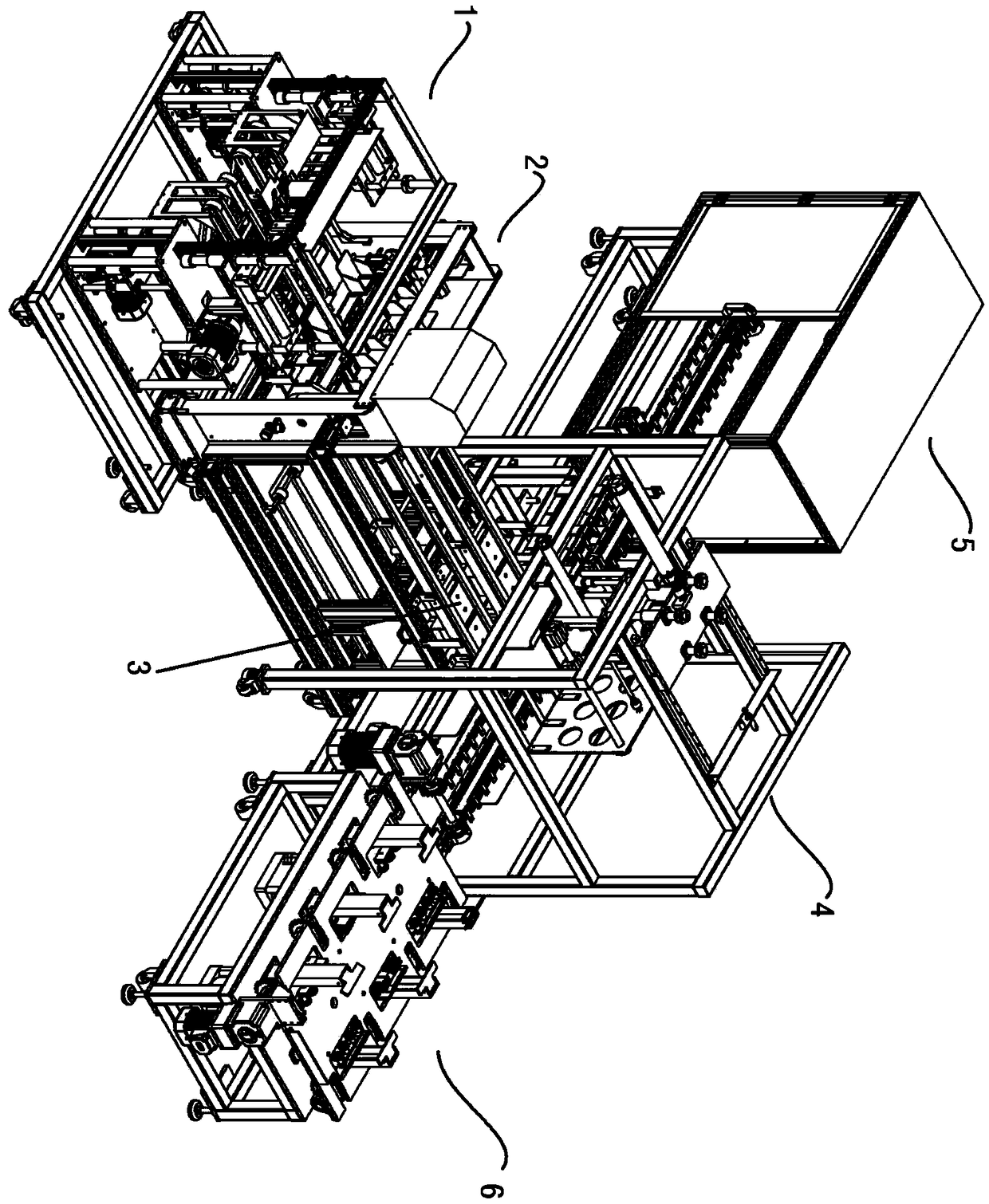

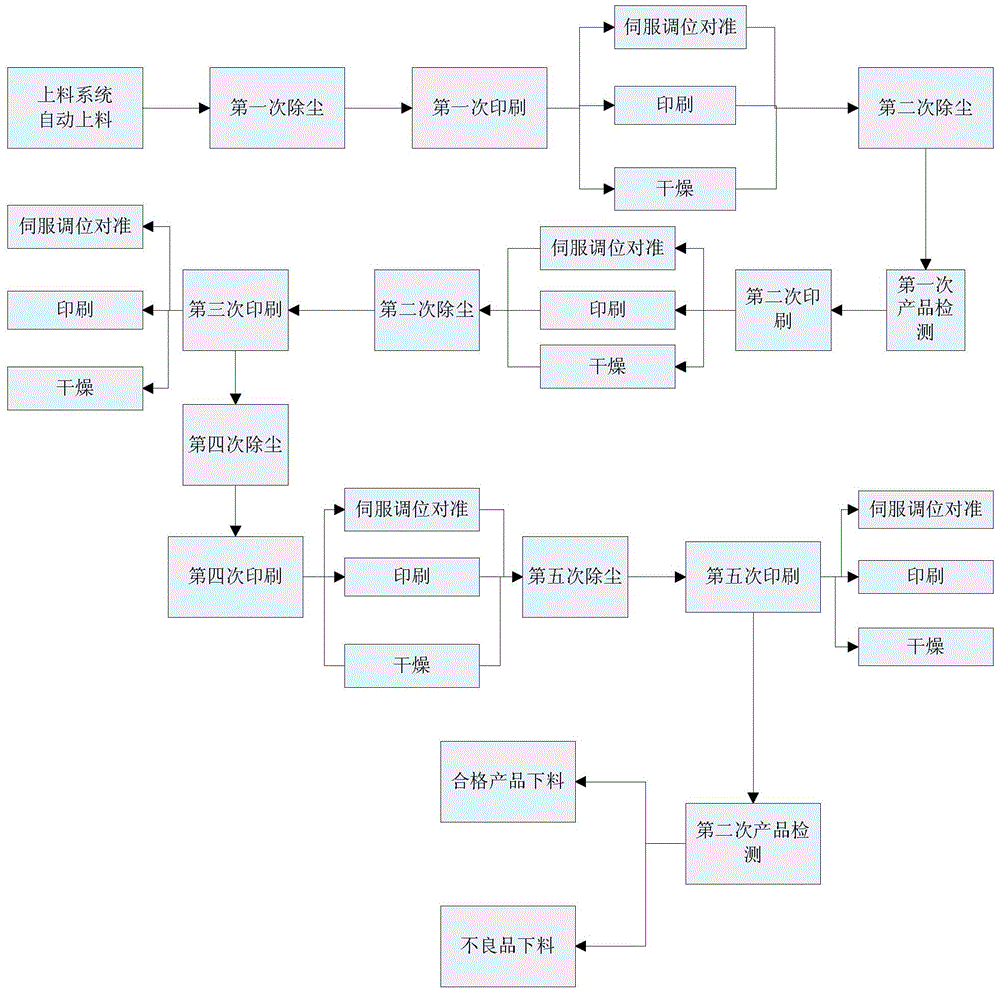

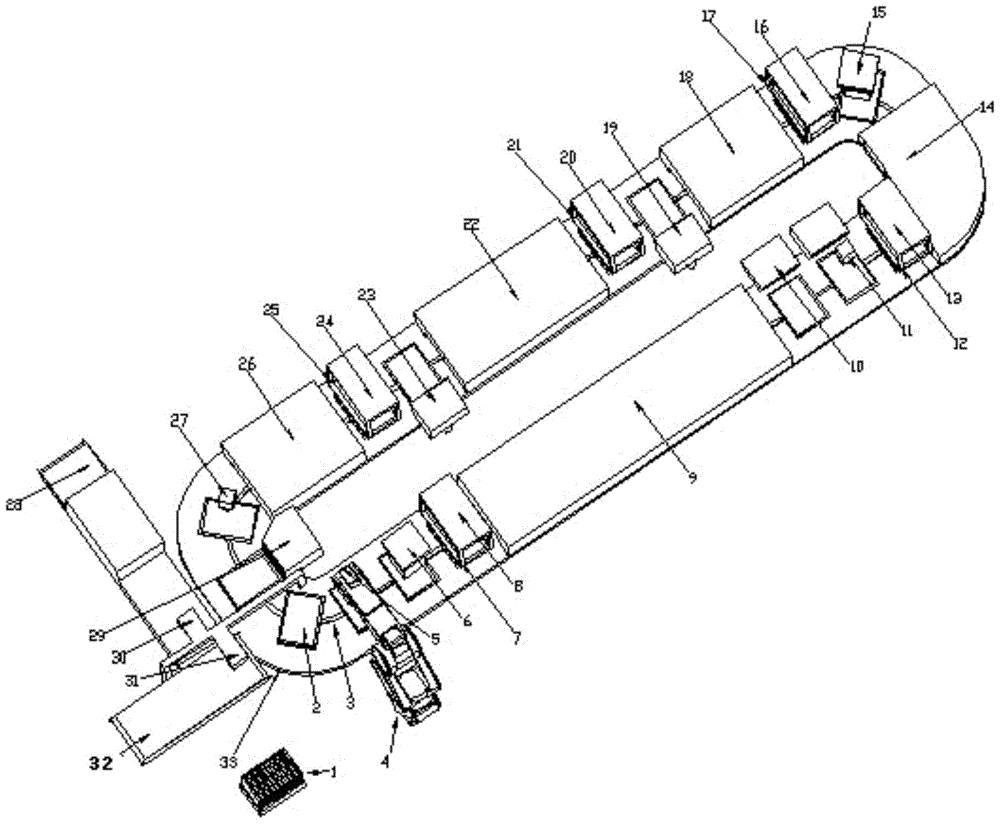

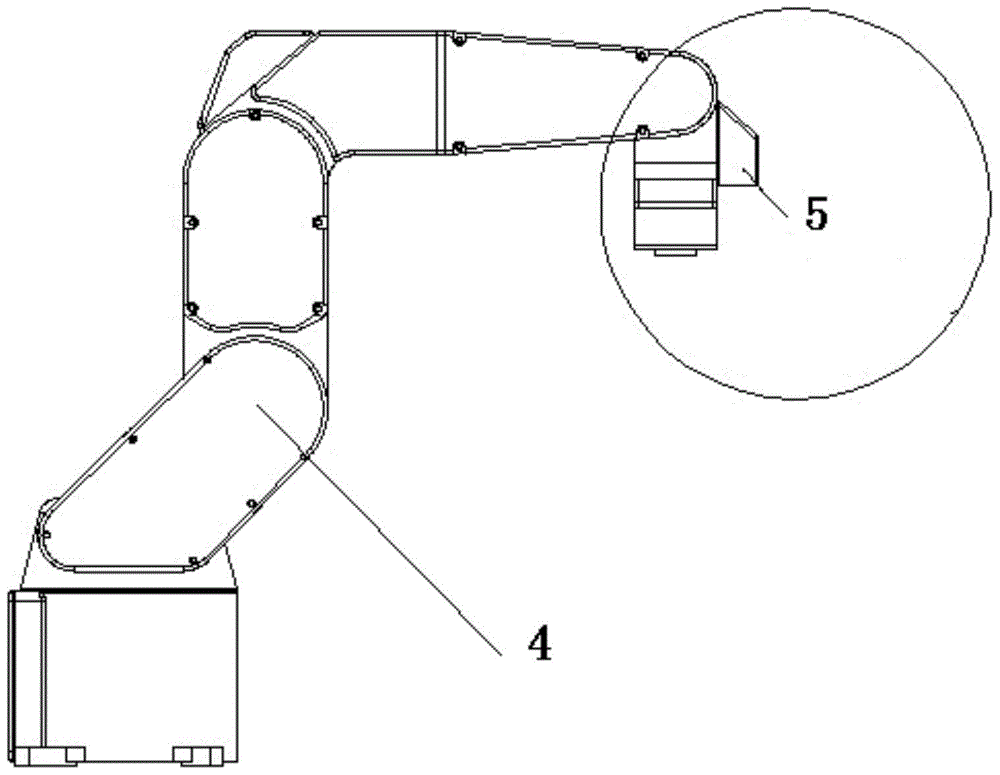

Full-automatic printing machine with touch screen

ActiveCN104441936AReduce manufacturing costAvoid defective productsScreen printersPrinting press partsManipulatorEngineering

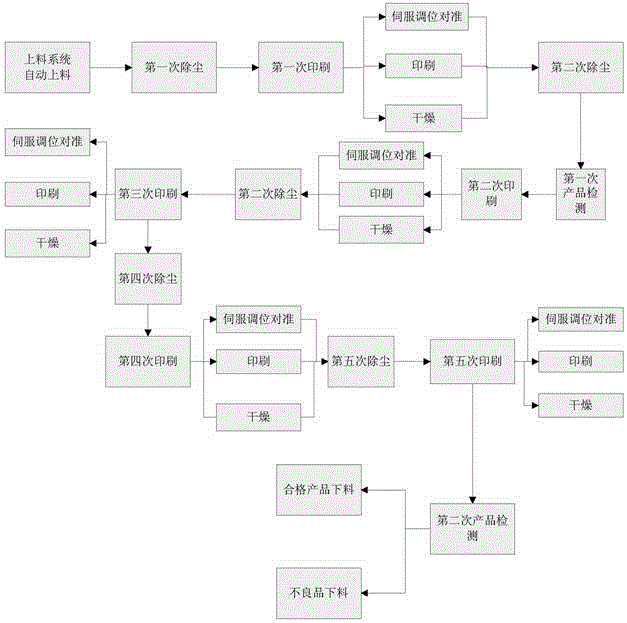

The invention discloses a full-automatic printing machine with a touch screen. According to the technical scheme, the full-automatic printing machine with the touch screen comprises a base, working tables, a feeding device and at least two machining devices; the multiple working tables are installed on the base and are in sliding fit with the base, and the touch screen is accurately driven by a divider to the specified machining procedure; the feeding device comprises a mechanical arm and a CCD detection device installed on the mechanical arm; the at least two machining devices include a silk-screen printing device and a servo position adjustment device; the servo position adjustment device is installed on the silk-screen printing device, the silk-screen printing device is adjusted through the touch screen position fed back by the CCD detection device, and therefore it is guaranteed that the silk-screen printing device directly faces the machining position. The full-automatic printing machine has the advantages that the full-automatic production procedure is achieved; meanwhile, as the multiple silk-screen printing-drying machining devices are arranged, multicolor chromatography can be achieved through one production line, the production efficiency can be greatly improved, and the production cost can be greatly reduced.

Owner:广州泰行智能科技有限公司

Anti-corrosive powder paint for steel support frame

InactiveCN101434806AImprove effective utilizationAvoid harmAnti-corrosive paintsPolyurea/polyurethane coatingsLimited resourcesOrganic solvent

The invention relates to an anticorrosive powder coating used for steel supporting frames, belonging to the technical field of powder coating; the coating is mainly characterized in that: according to the mass percentage, the anticorrosive powder coating comprises 35-58 percent of thermosetting resin, 4.5-35 percent of curing agent, 20-35 percent of pigment and filling material and 2-5 percent of auxiliary agent. The anticorrosive powder coating can avoid the environmental pollution and the damage on health of people caused by the use of solvent based coating, also can save the limited resource organic solvent, improves the effective utilization ratio of the coating, improves the labor productivity, can achieve the required coating thickness and the anticorrosive performance by one-time coating, saves the labor production cost, has good safety performance during the production and avoids the unsafe factors such as fire, and the like caused by the use of the organic solvent.

Owner:扬州三川实业有限公司

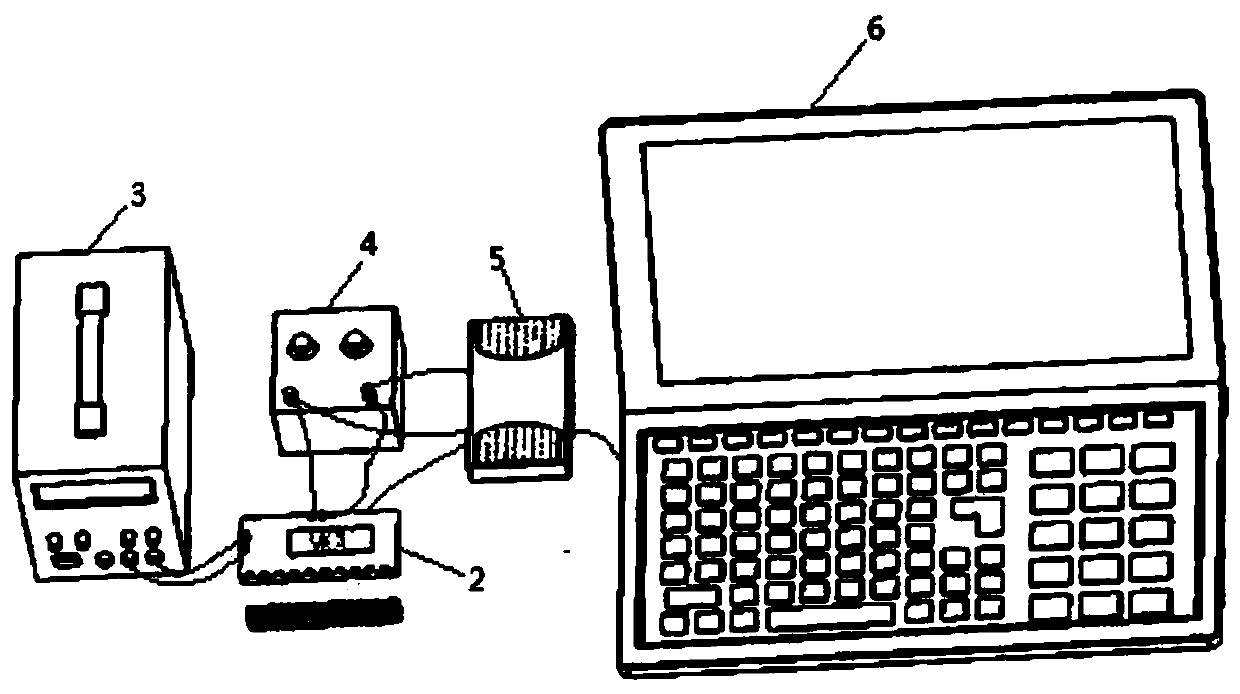

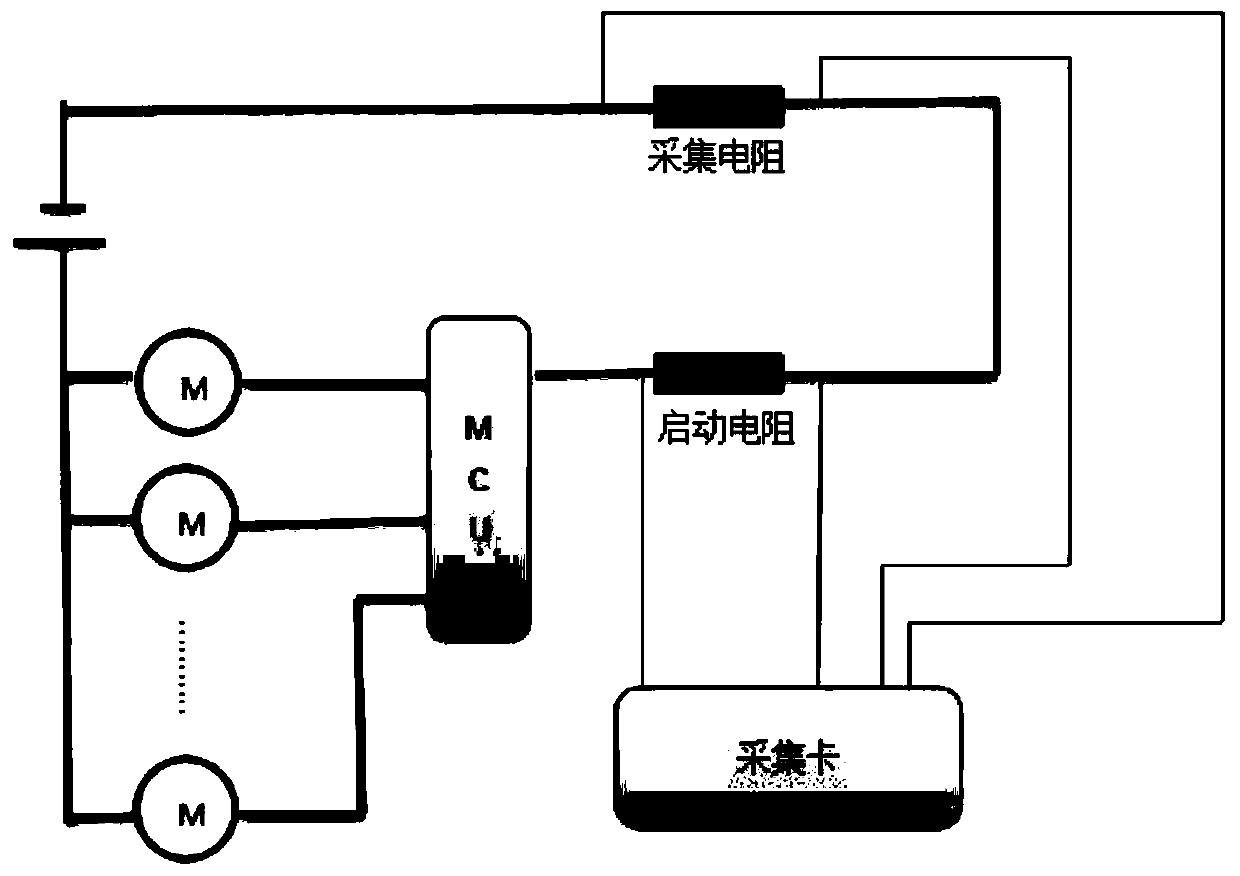

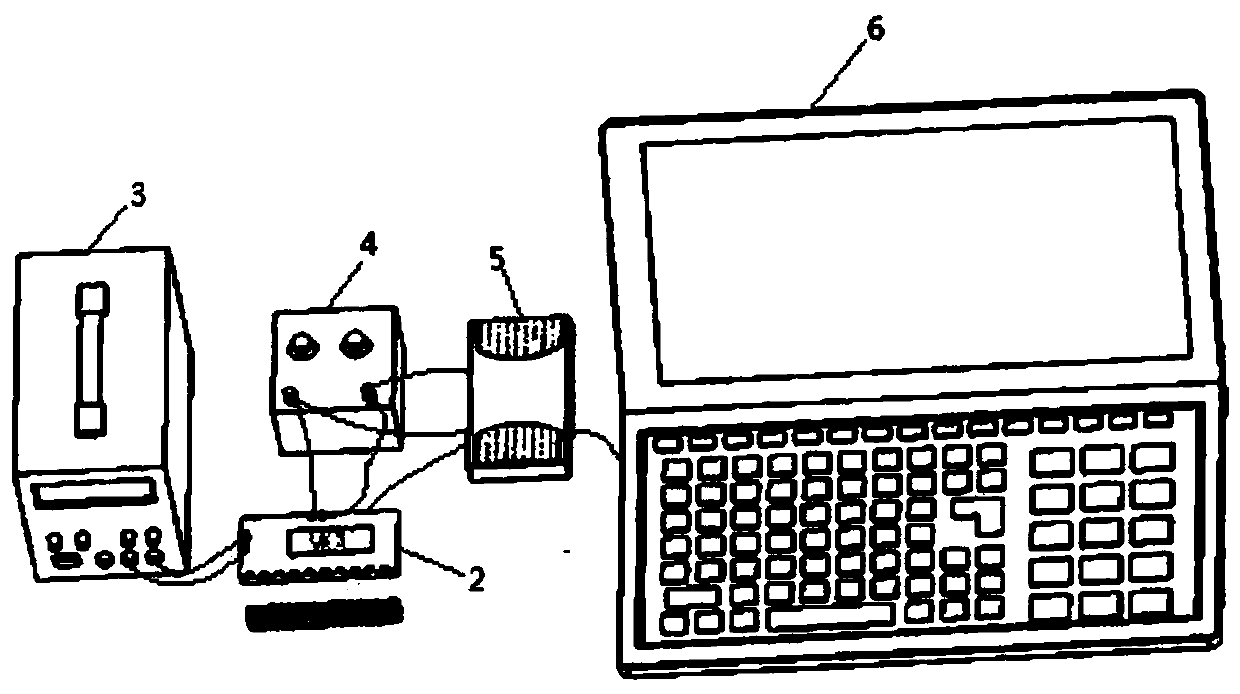

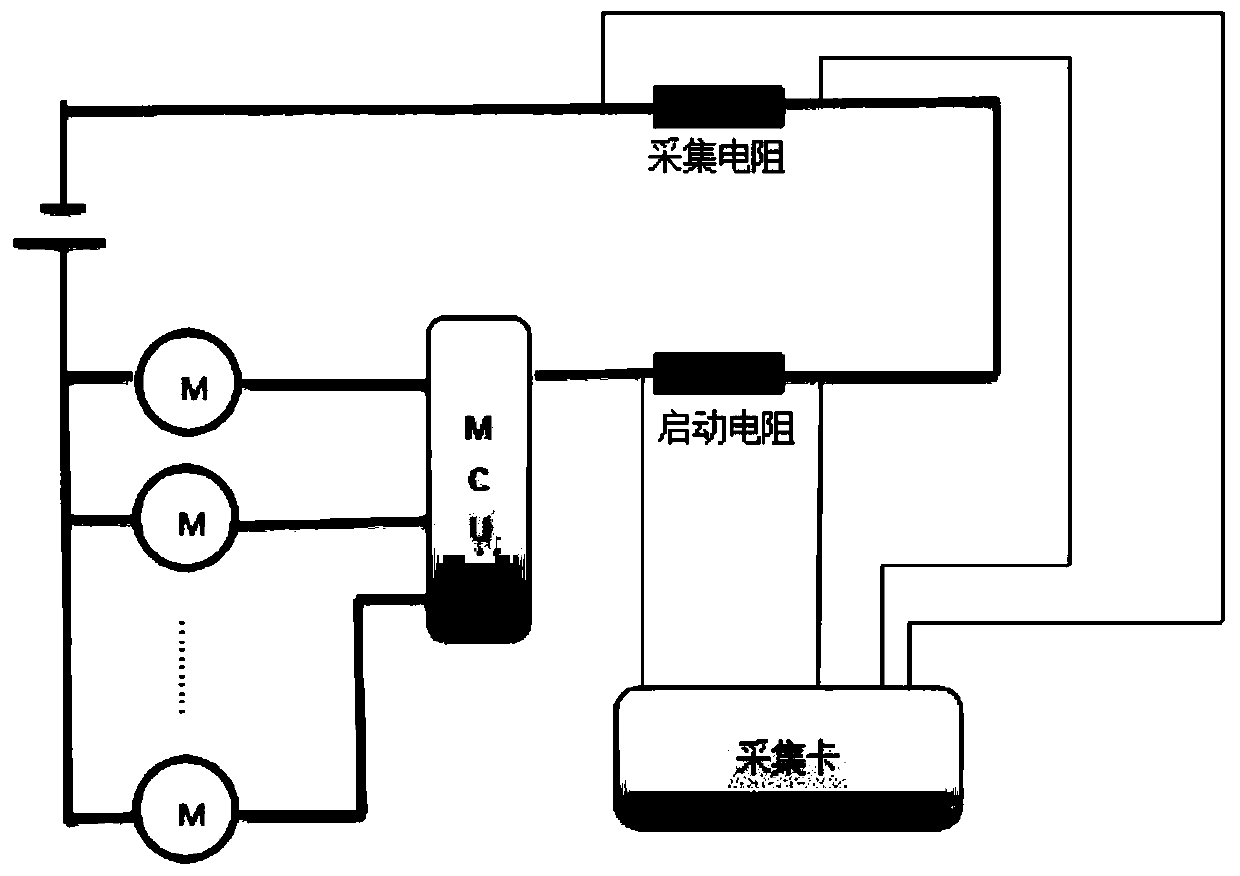

Micro-vibration motor defect failure classification method and device based on convolutional neural network

ActiveCN109946606AQuick checkHigh-precision detectionImage enhancementCharacter and pattern recognitionElectrical resistance and conductanceGeneration process

The invention discloses a micro-vibration motor defect failure classification method and a micro-vibration motor defect failure classification device based on a convolutional neural network. Voltage signal images acquired at the two ends of an acquisition resistance connected in series with a micro-vibration motor electrifying loop are input into a trained convolutional neural network model, accurate identification of the micro-vibration motor defect varieties can be realized, the whole process is automatic identification operation, staff does not need to take part in the whole generation process too much, the detection efficiency is greatly improved and the labor production cost is reduced.

Owner:SICHUAN UNIV

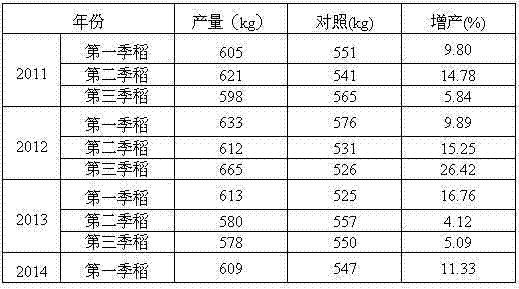

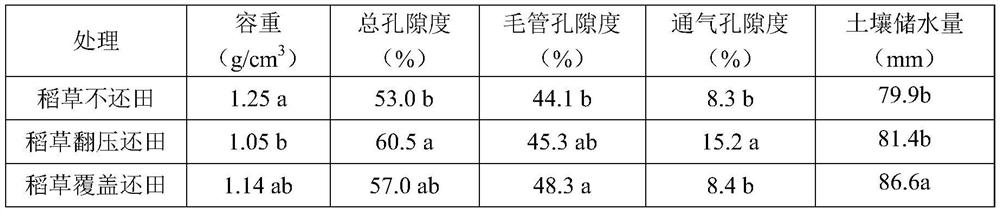

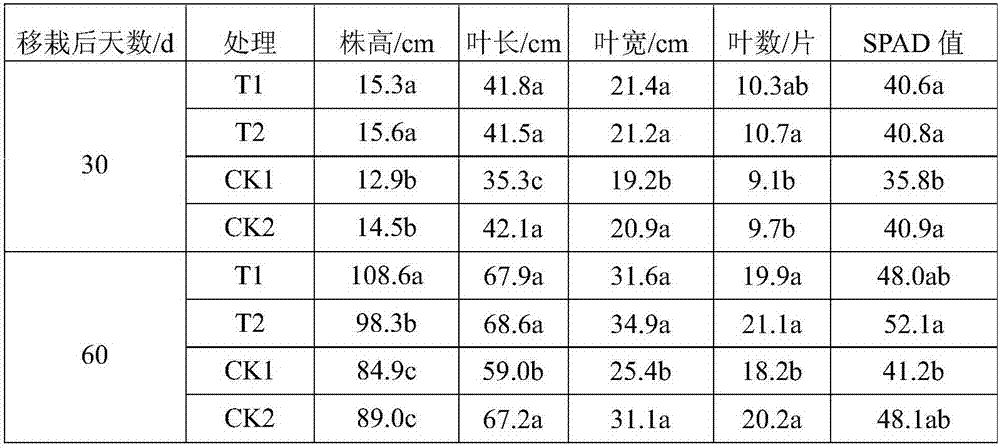

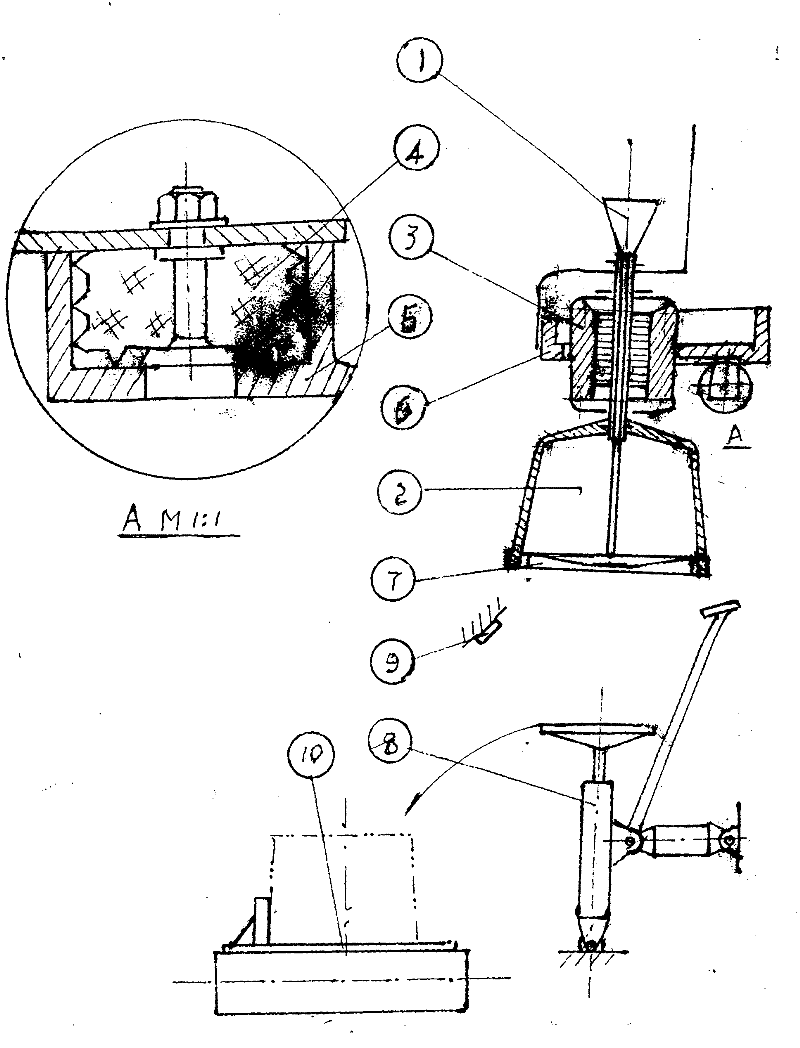

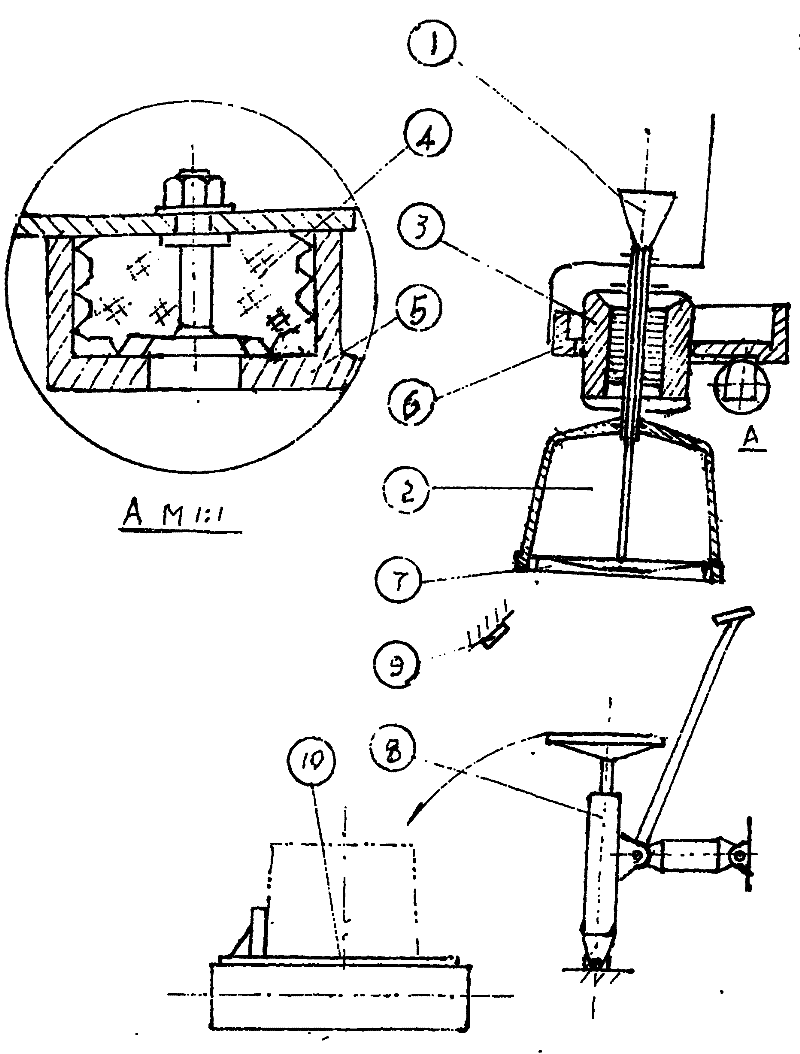

Rice ridge-pulverization ecological and efficient cultivation method

InactiveCN104115713AIncrease fertilizer and water retention performanceIncrease productionRice cultivationEnvironmental resource managementEngineering

The invention discloses a rice ridge-pulverization ecological and efficient cultivation method. The rice ridge-pulverization ecological and efficient cultivation method comprises the steps that an auger-bit machine enters soil and vertically rotates, wherein the machine enters the soil to the depth of 25-30 cm; ridge-pulverization soil drilling and fertilization are carried out at the same time, and the land is not harrowed so that bottom deep-layer soil will not be disturbed afterwards; meanwhile, ridge-pulverization deep rotary tillage does not need to be conducted again when second rice crop is planted, no tillage or only 3-4 cm shallow tillage is needed, stratification and air permeability of the bottom soil are kept, and field farm operation such as cultivation, weed control, fertilization, pesticide application and water management is conducted in a cooperative mode. The rice ridge-pulverization ecological and efficient cultivation method can effectively solve the problem that a traditional farming mode easily causes soil environmental degradation, effectively improve labor efficiency of ridge-pulverization cultivation, achieve the effect that deep ploughing is not needed within 3-4 years each time ridge-pulverization is conducted, and keep the stable yield and the yield increase of rice continuously, thereby having important value and significance in the field of rice cultivation.

Owner:广西壮族自治区农业科学院经济作物研究所

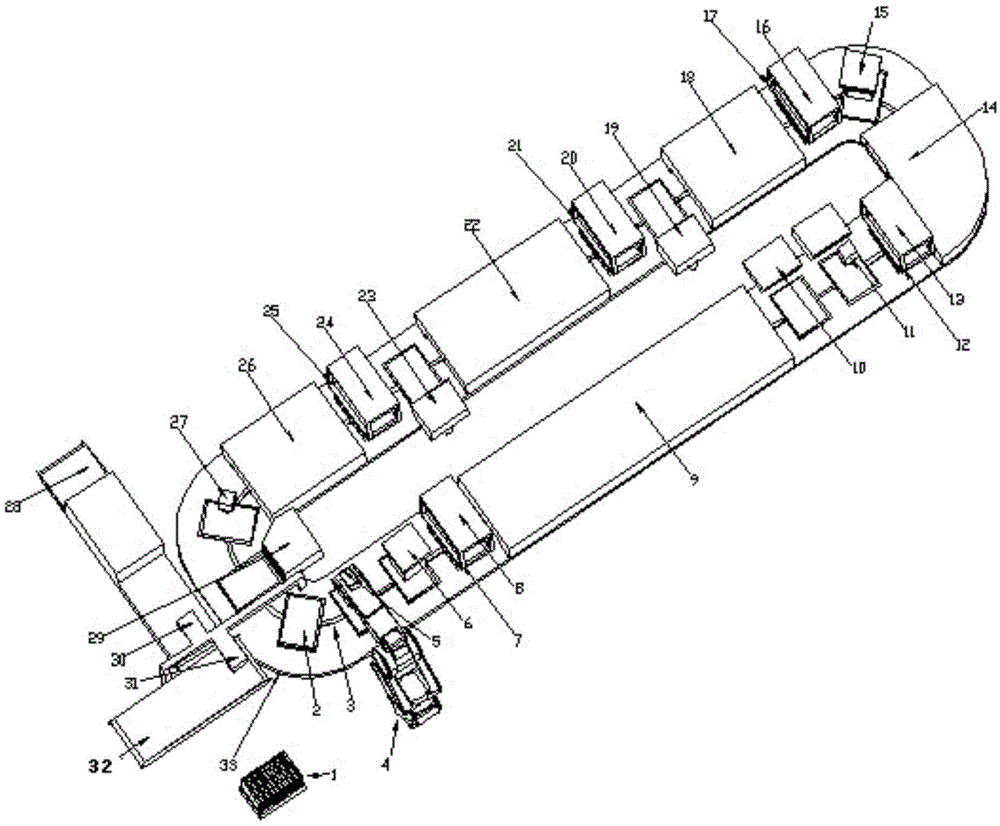

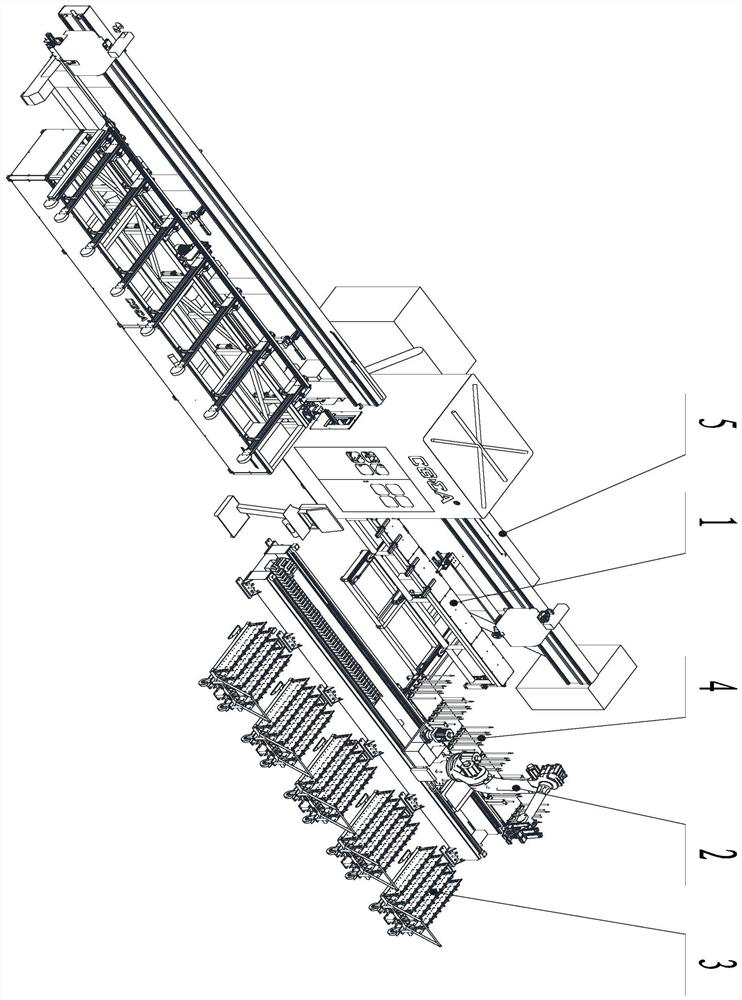

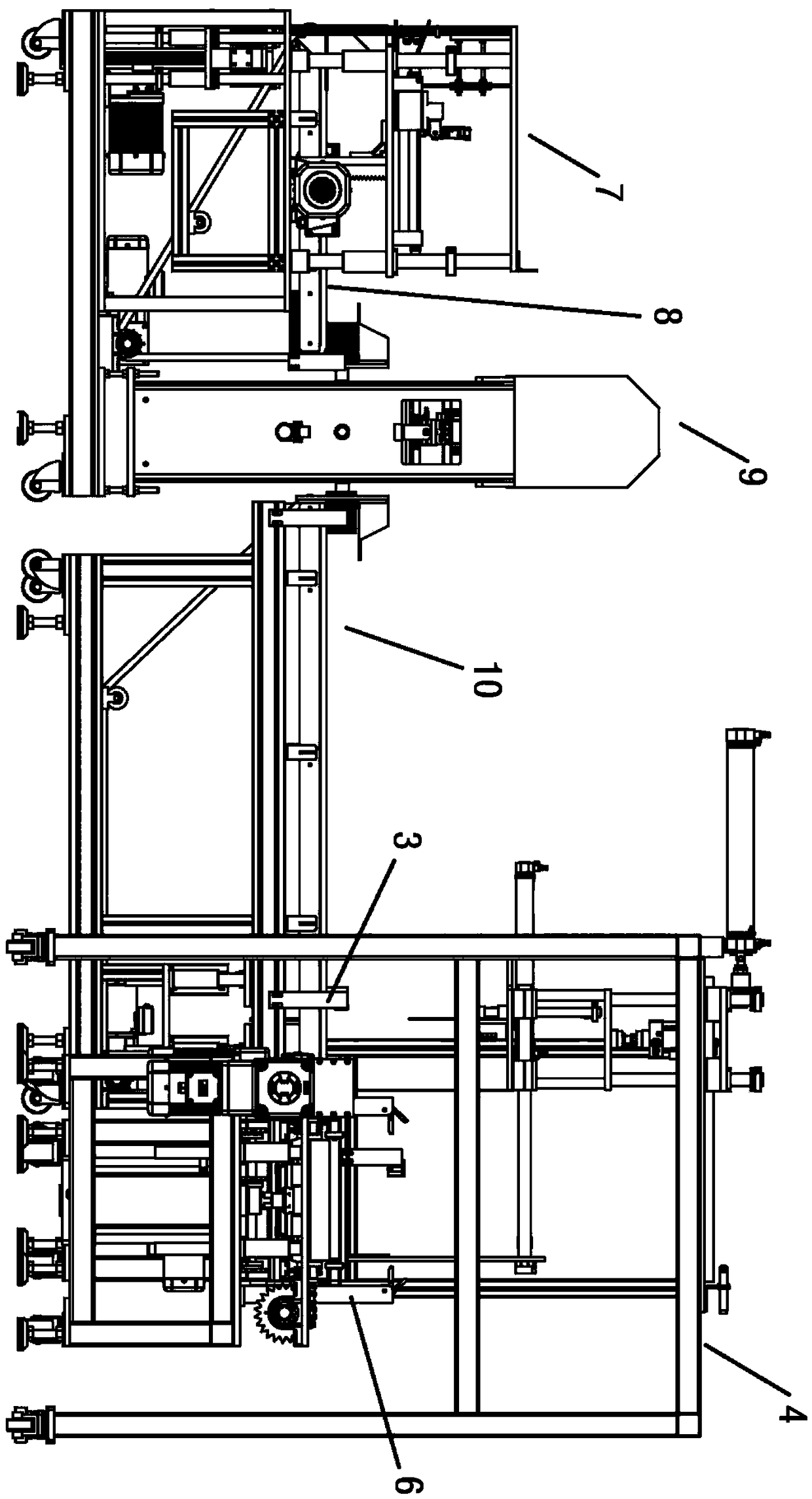

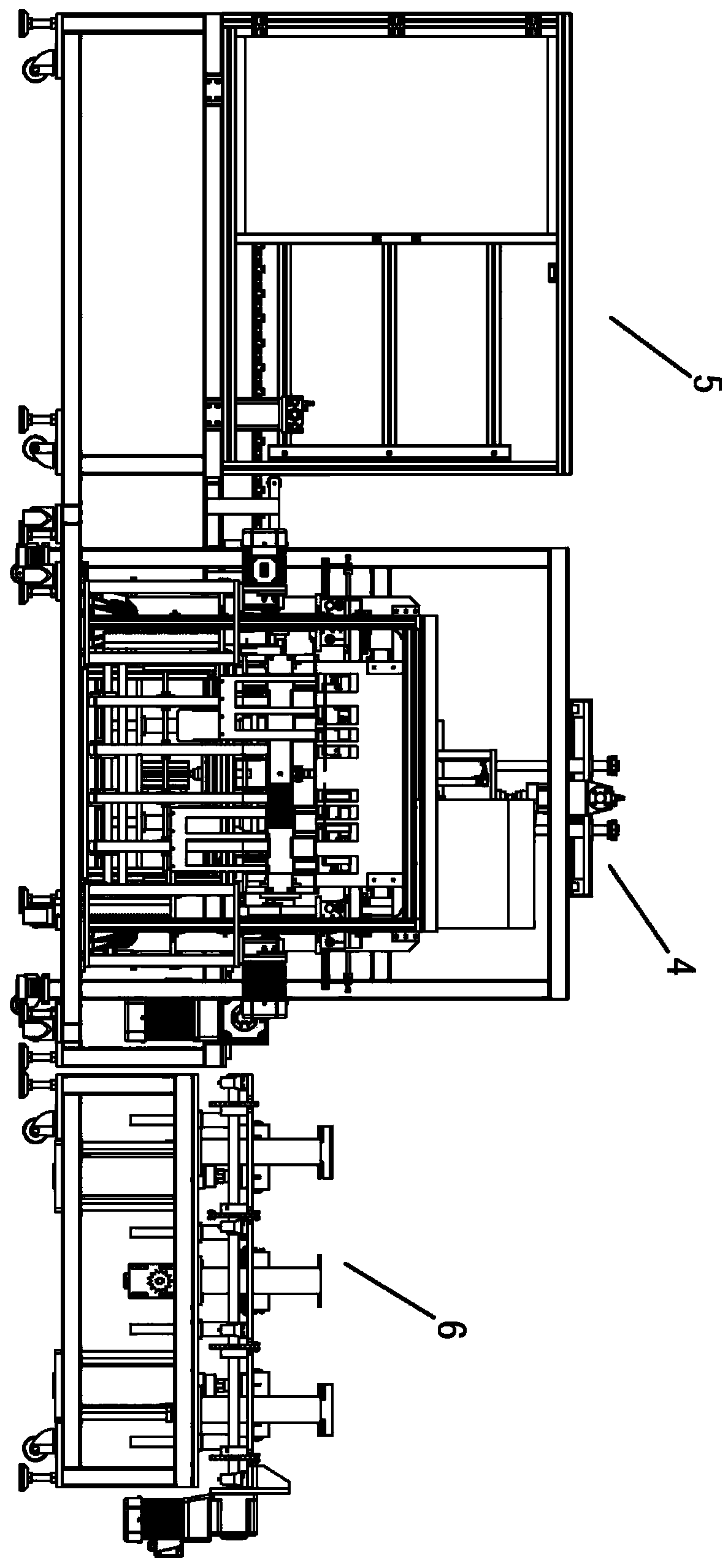

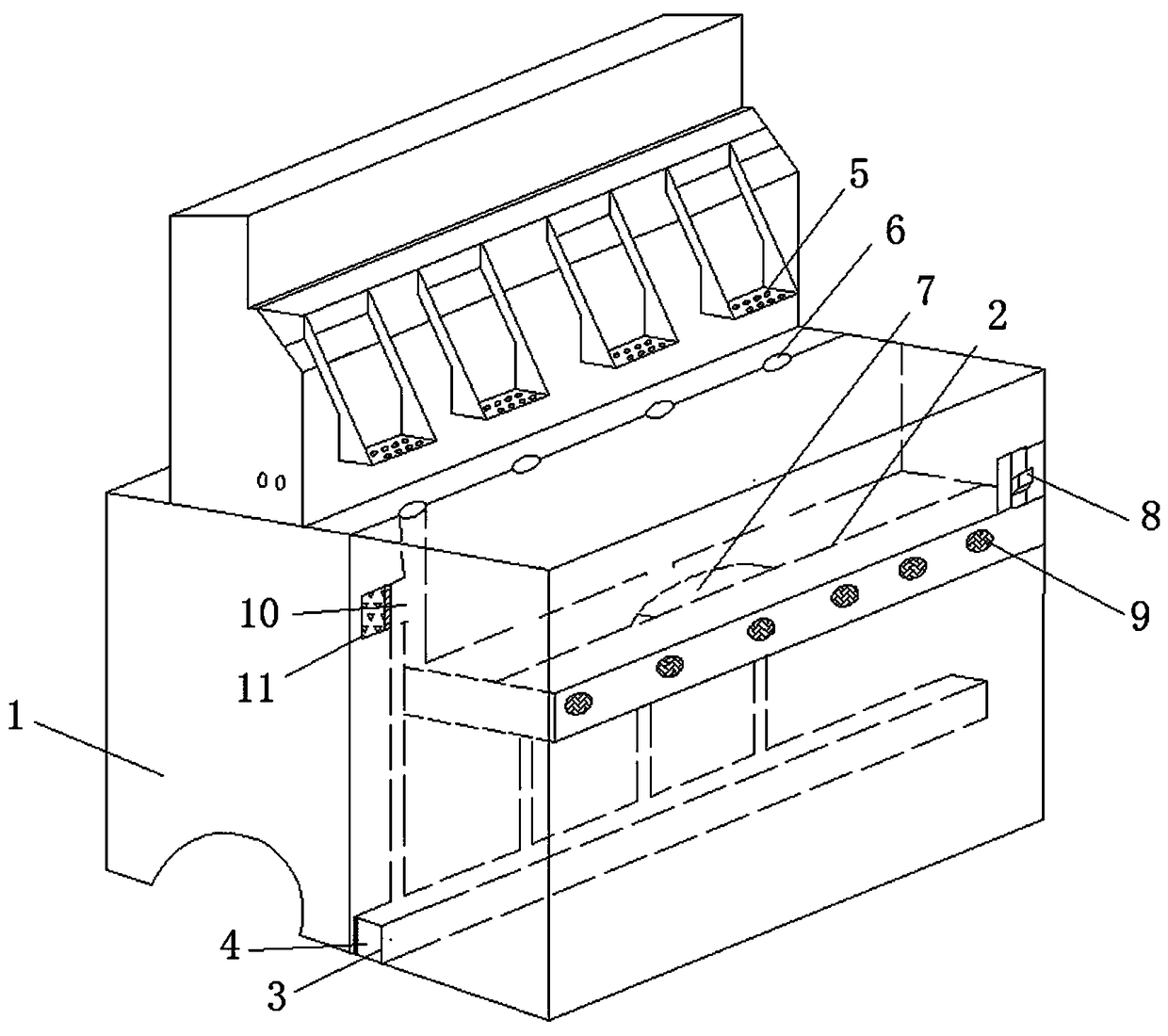

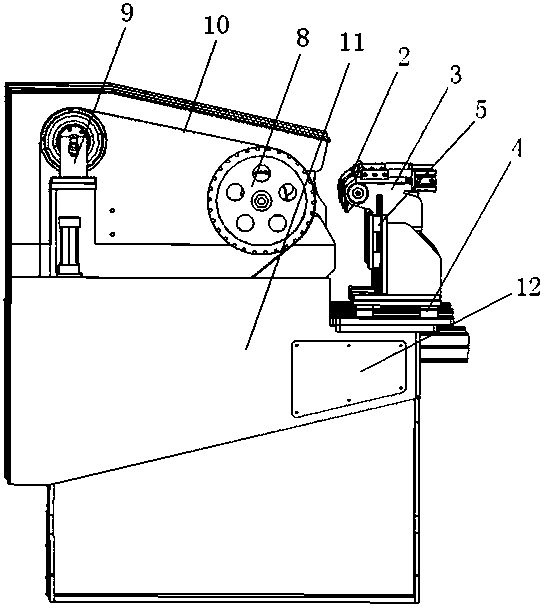

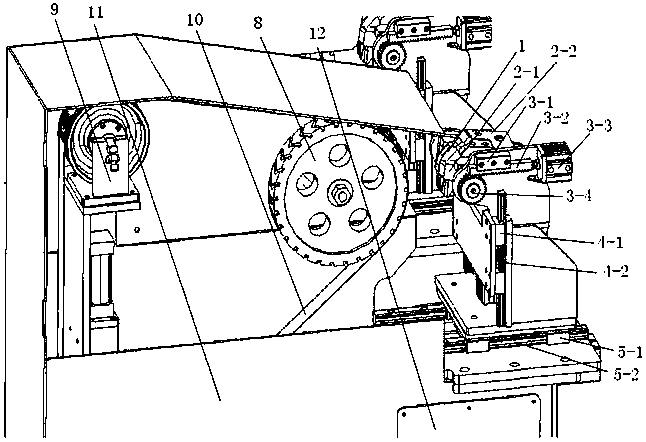

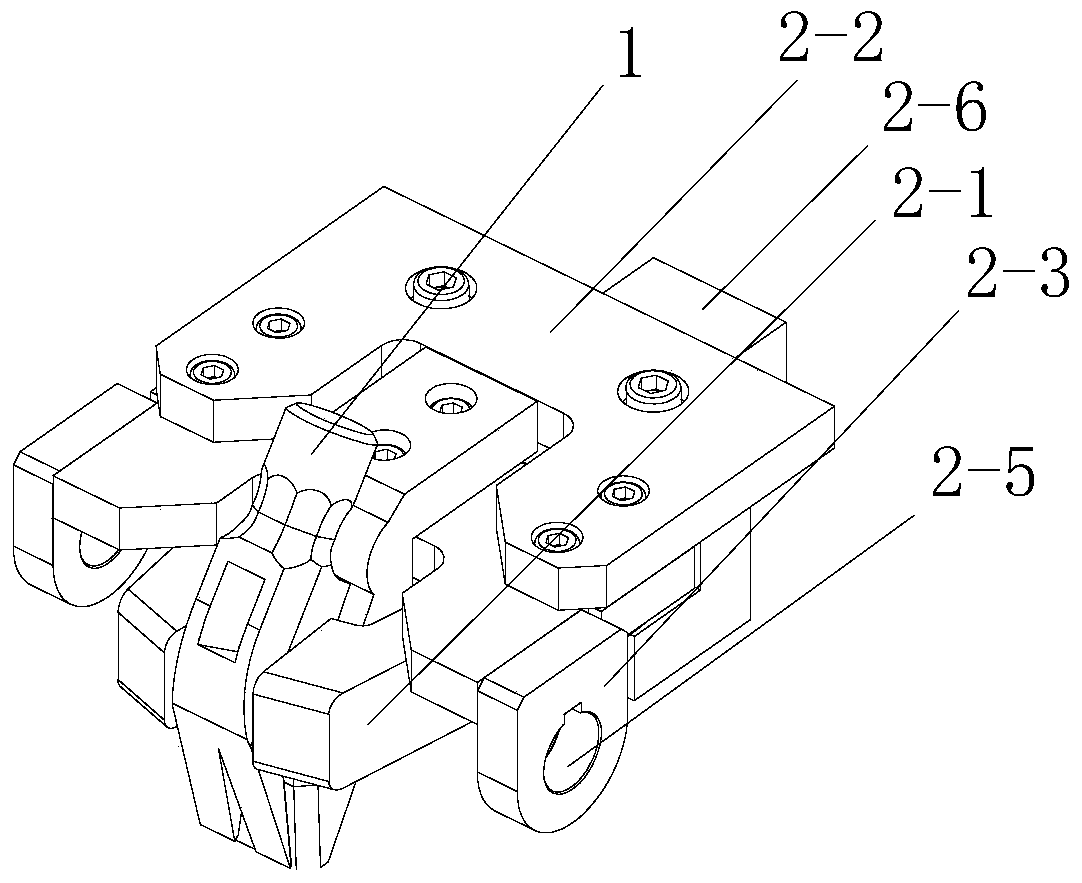

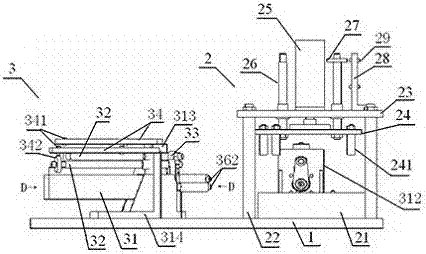

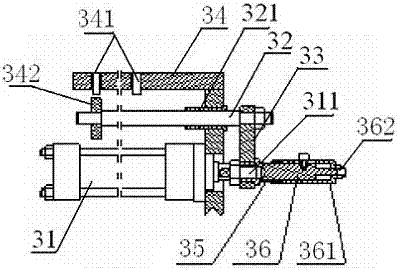

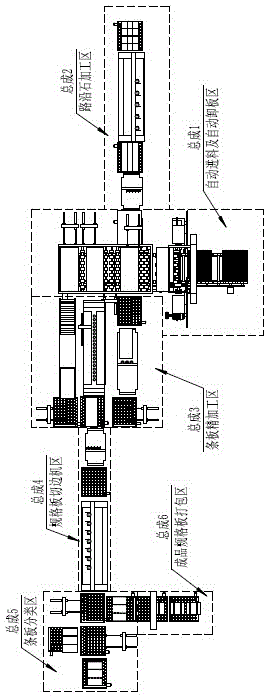

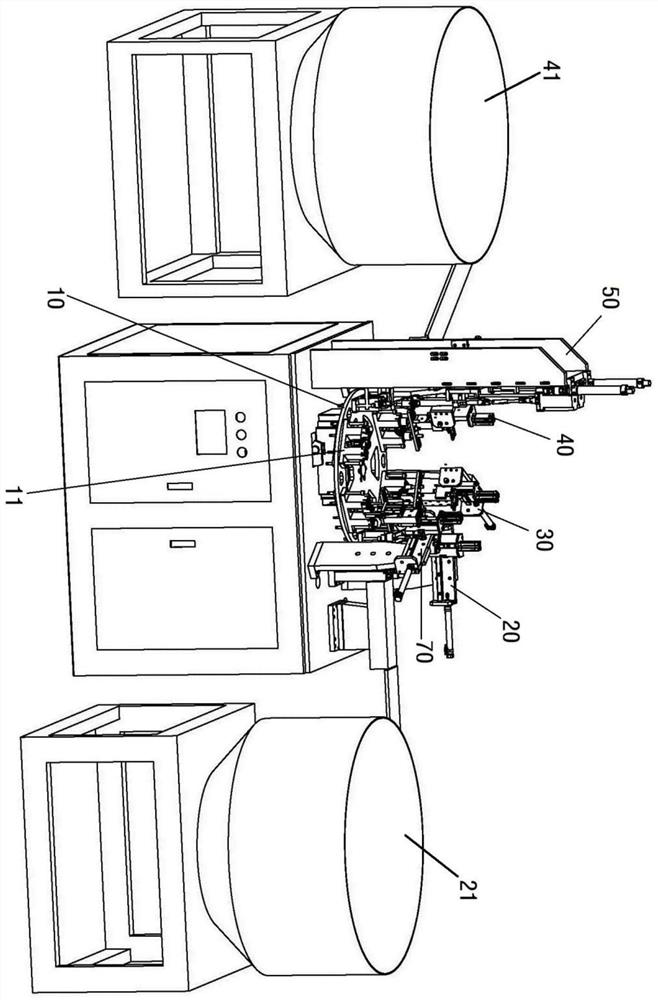

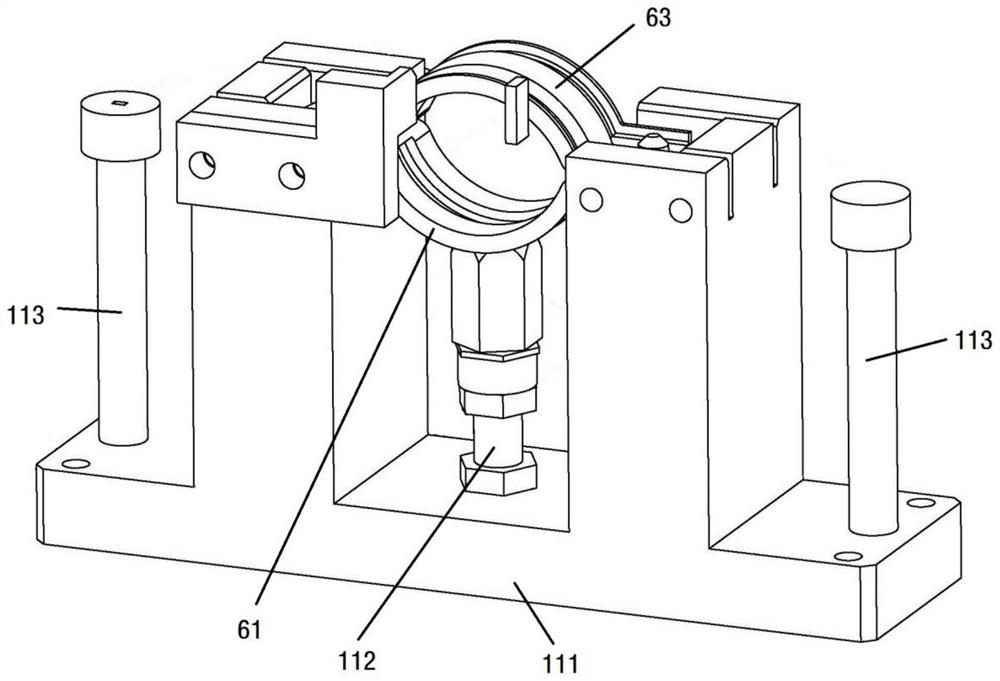

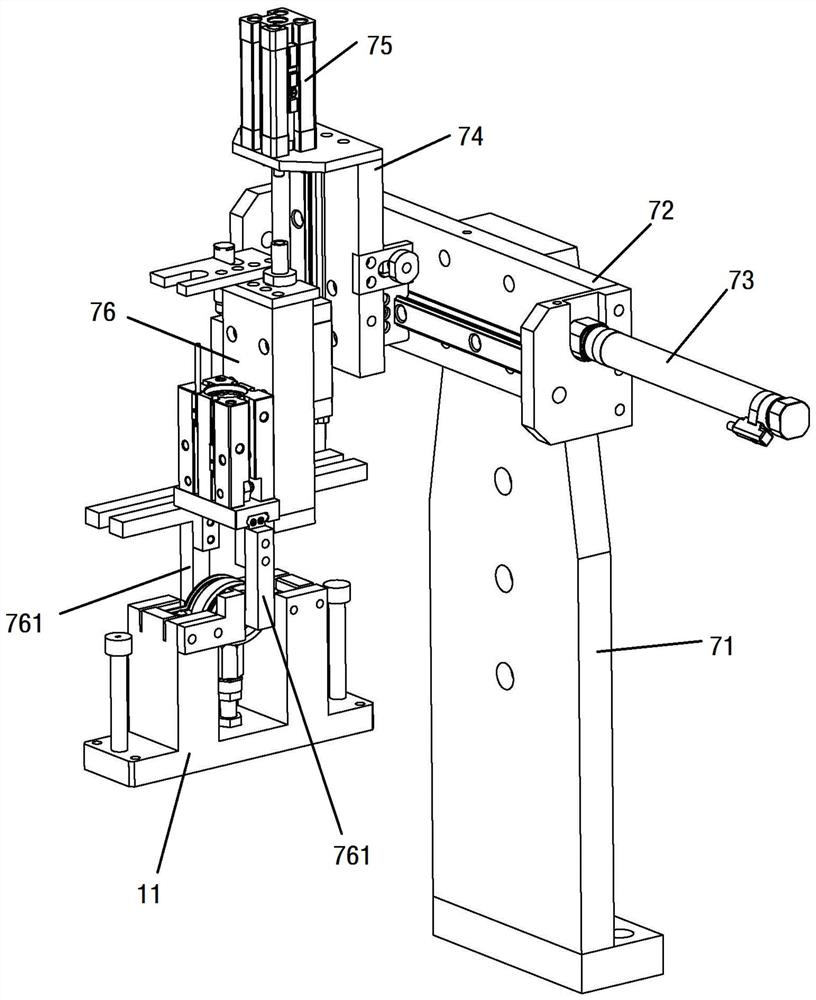

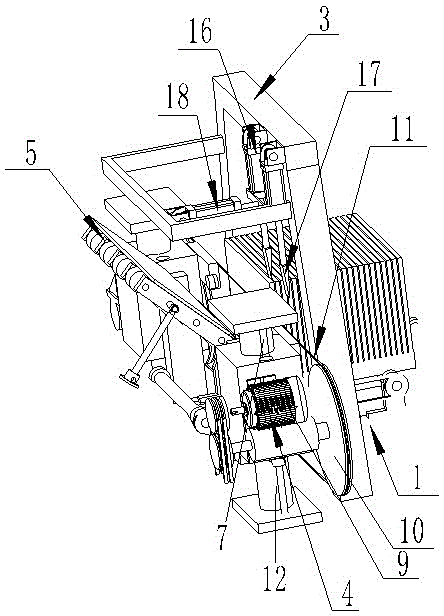

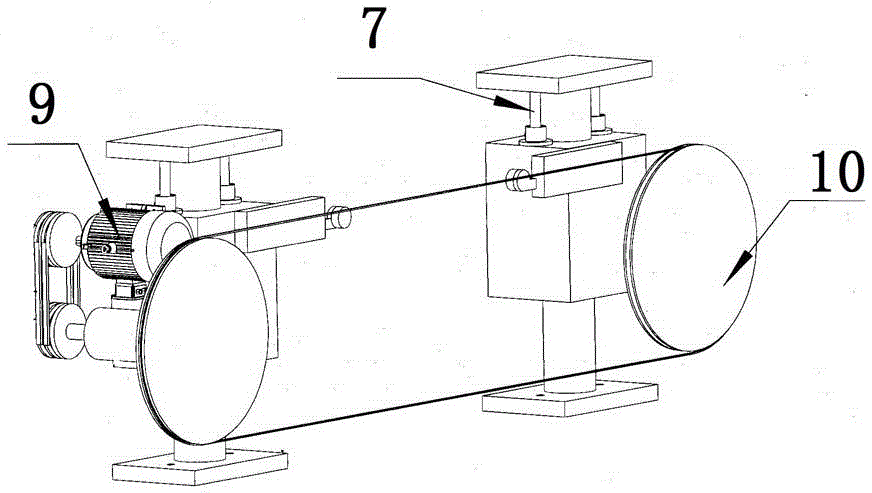

Full-automatic bottom hot-spinning and forming production line for steel cylinder

ActiveCN105537426ACompact structureEasy to useShaping toolsMetal-working feeding devicesProduction lineHigh volume manufacturing

The invention provides a full-automatic bottom hot-spinning and forming production line for a steel cylinder. The full-automatic bottom hot-spinning and forming production line for the steel cylinder sequentially comprises a heating and pushing device, a turning and receiving device, a clamping device, a gas auxiliary heating device, a deslagging device and a bottom pressing device in the machining sequence of the steel cylinder. The full-automatic bottom hot-spinning and forming production line for the steel cylinder is compact in structure, easy to use and convenient to operate; product forming is stable, the unqualified rate is decreased, and the production line is suitable for automatic volume production; the labor production cost is reduced, and the market competitiveness of products is improved.

Owner:潍坊泰克机械有限公司

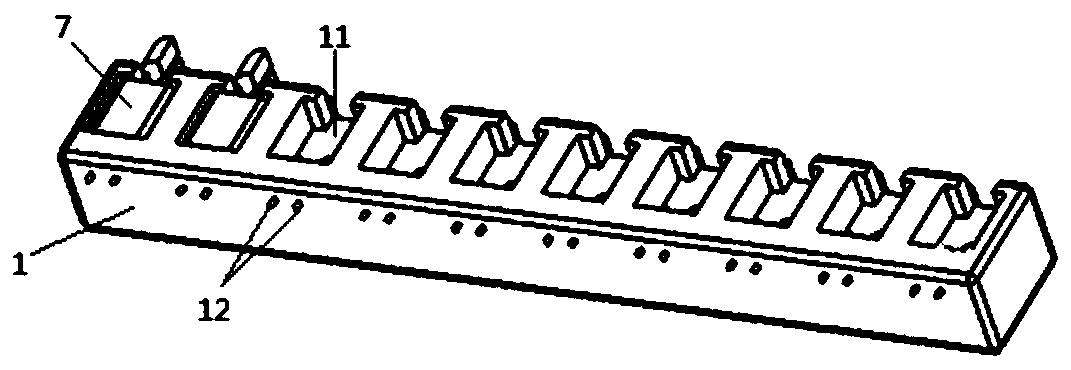

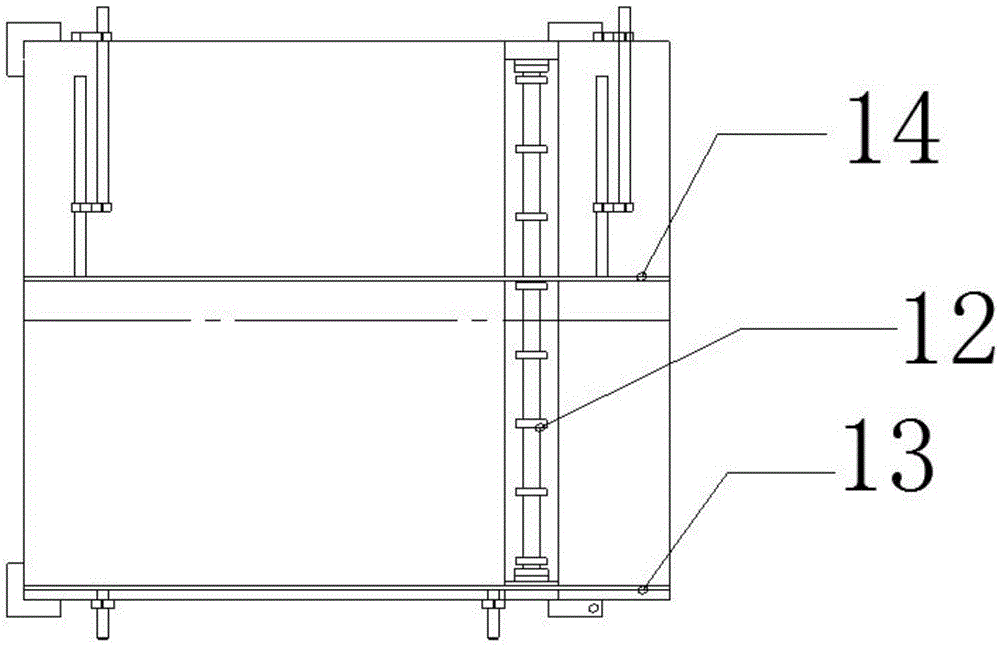

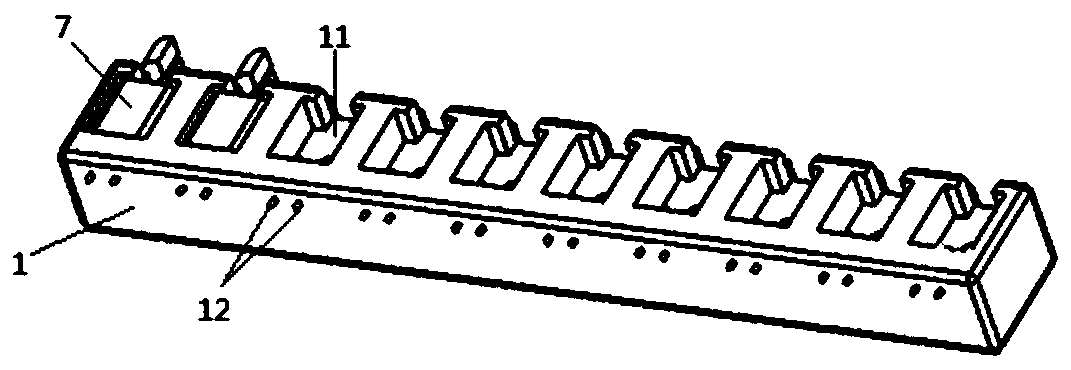

Electrode plate automatic tidying device

PendingCN109795862AImprove stacking efficiencyNo need for manual stackingStacking articlesConveyor partsEngineeringSingle electrode

The invention discloses an electrode plate automatic tidying device, and belongs to the technical filed of battery production. The electrode plate automatic tidying device comprises a first conveyingmechanism, a second conveying mechanism, material receiving mechanisms and a third conveying mechanism; the first conveying mechanism sequentially conveys at least one row of electrode plates placed in a single-layer mode; the second conveying mechanism is connected to the lower course of the first conveying mechanism in a suspended mode and rotates synchronously with the first conveying mechanism, and single electrode plates conveyed by the first conveying mechanism are adsorbed in sequence and are conveyed to the next mechanism through the second conveying mechanism; the material receiving mechanisms are used for collecting the single electrode plates conveyed by the second conveying mechanism to form an electrode plate aggregate; and the third conveying mechanism is arranged under the material receiving mechanisms and is used for receiving the electrode plate aggregate collected by the material receiving mechanisms and is used for conveying the collected electrode plate aggregate toa discharging position. According to the electrode plate automatic tidying device, the functions of automatic tidying and aligning of the electrode plates are achieved, scattered electrode plates arestacked into the electrode plate aggregate, manual stacking is not required, the electrode plate stacking efficiency is improved, the electrode plate aggregate can better enter into a next step, andthe labor production cost is further reduced.

Owner:中山慧能科技有限公司

Current type fault diagnosis apparatus and method for micro-vibration motor

ActiveCN110161406AAccurate identificationImprove detection efficiencyMeasurement instrument housingVibration testingFailure diagnosisEngineering

The invention discloses a current type fault diagnosis apparatus and method for a micro-vibration motor. A current change condition in a power-on circuit of the micro-vibration motor is reflected by an acquired voltage signal of a sampling resistor connected to the power-on circuit of the micro-vibration motor in series, the interference of physical measurement is avoided, relevant characteristicvalues are extracted from the acquired voltage signal, a fault of the micro-vibration motor is pre-diagnosed, and then the fault of the micro-vibration motor is finally diagnosed according to Booleanlogic, so that the fault type of the micro-vibration motor can be accurately recognized, and furthermore, the whole process adopts automatic identification operation, a worker does not need to excessively participate in the whole generation process, the detection efficiency is greatly improved, and the labor production cost is reduced. According to the apparatus and the method, judgment can be carried out for 100 times within 0.7 second, so that the fault diagnosis accuracy is ensured, and meanwhile, the fault diagnosis efficiency is greatly improved.

Owner:SICHUAN AWA SEIMITSU ELECTRIC CO LTD +1

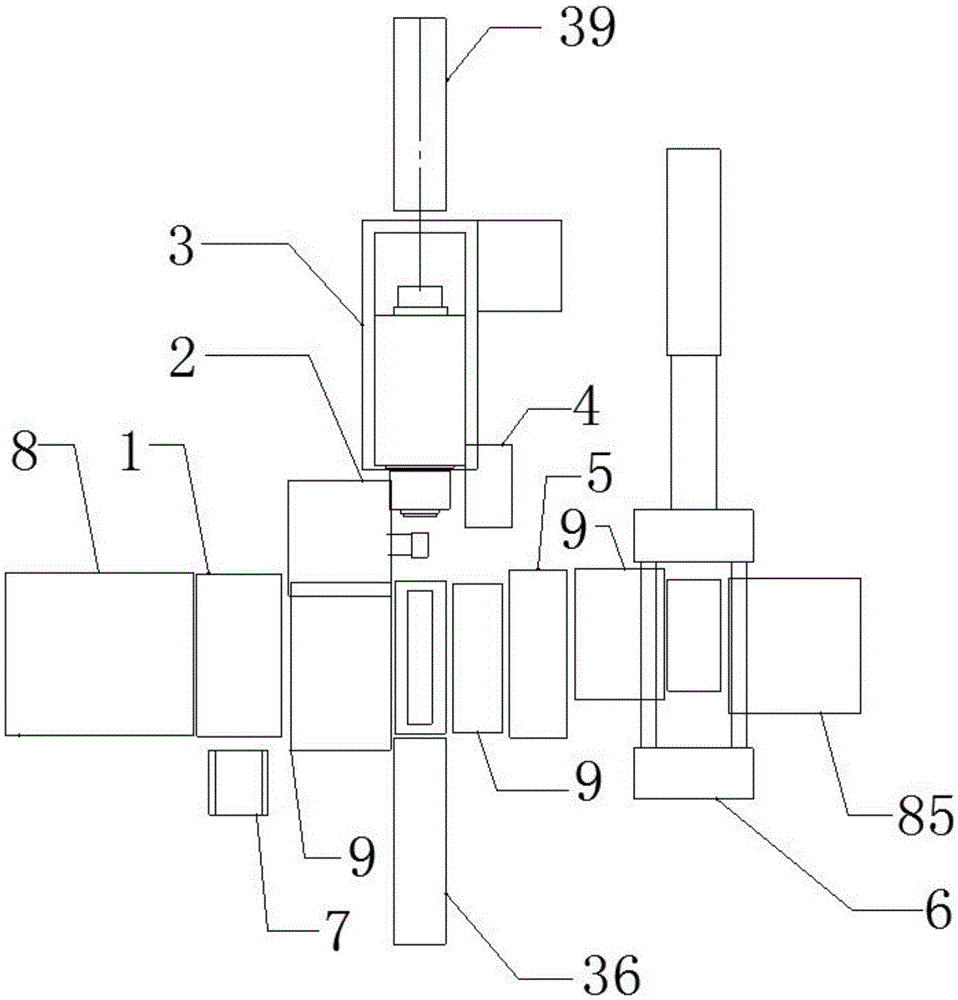

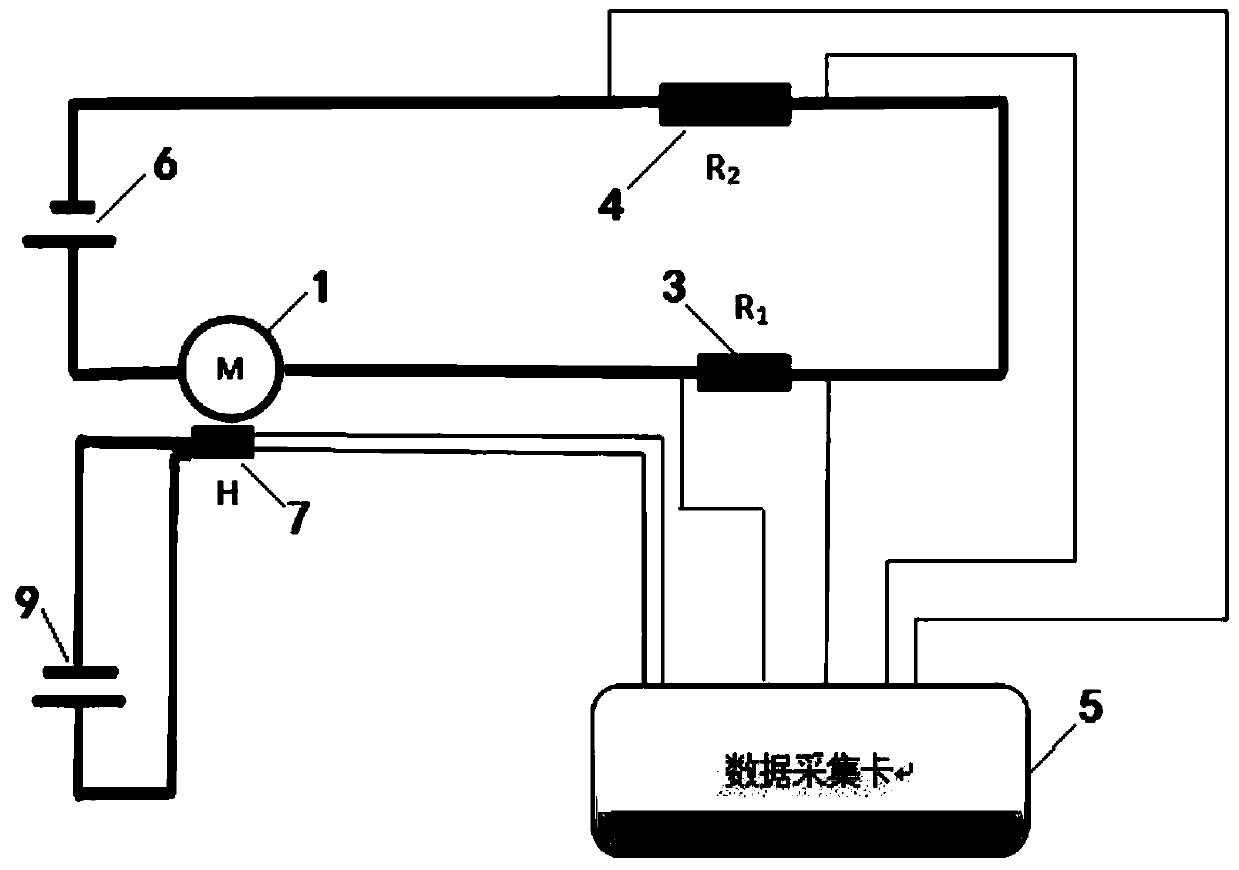

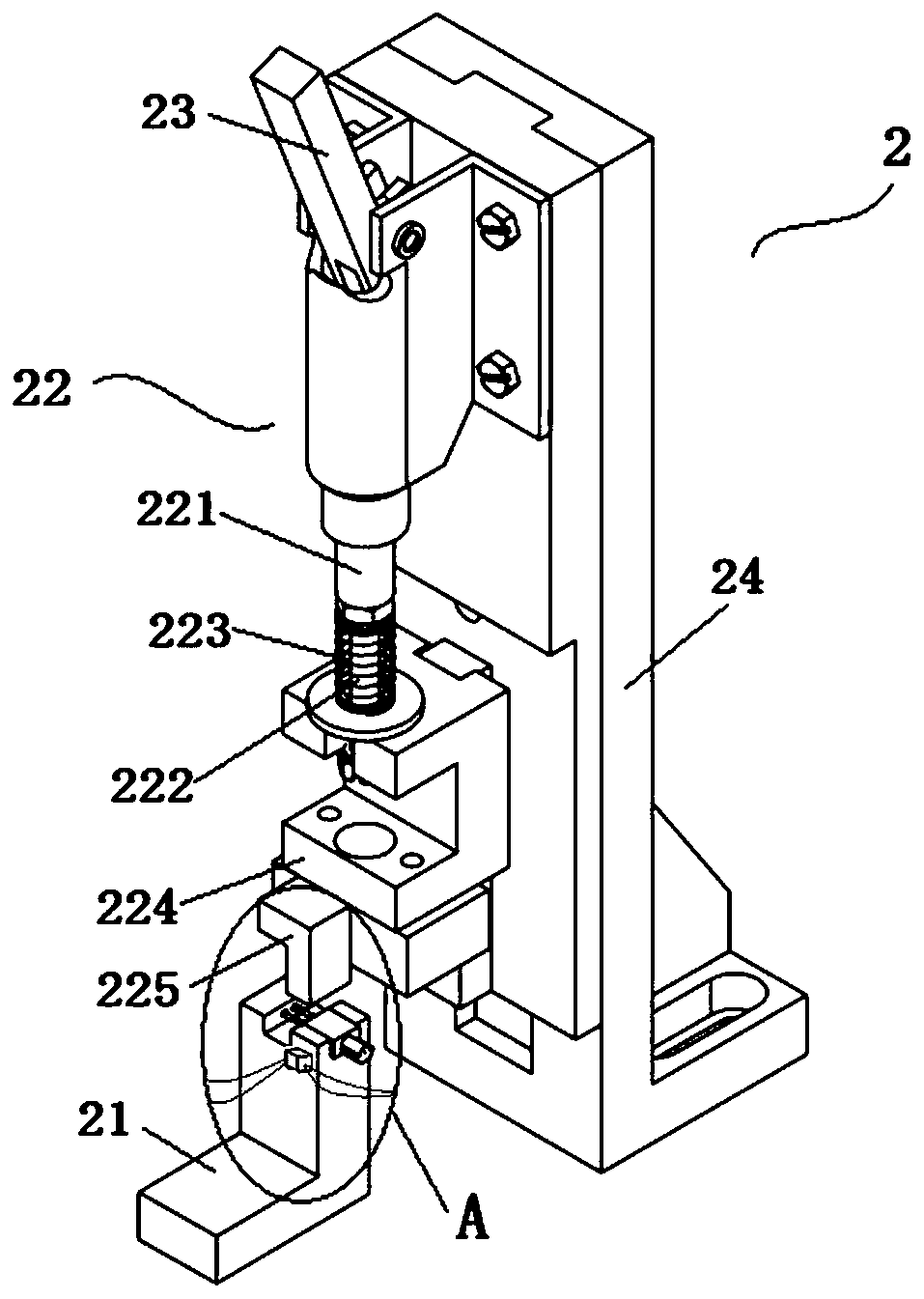

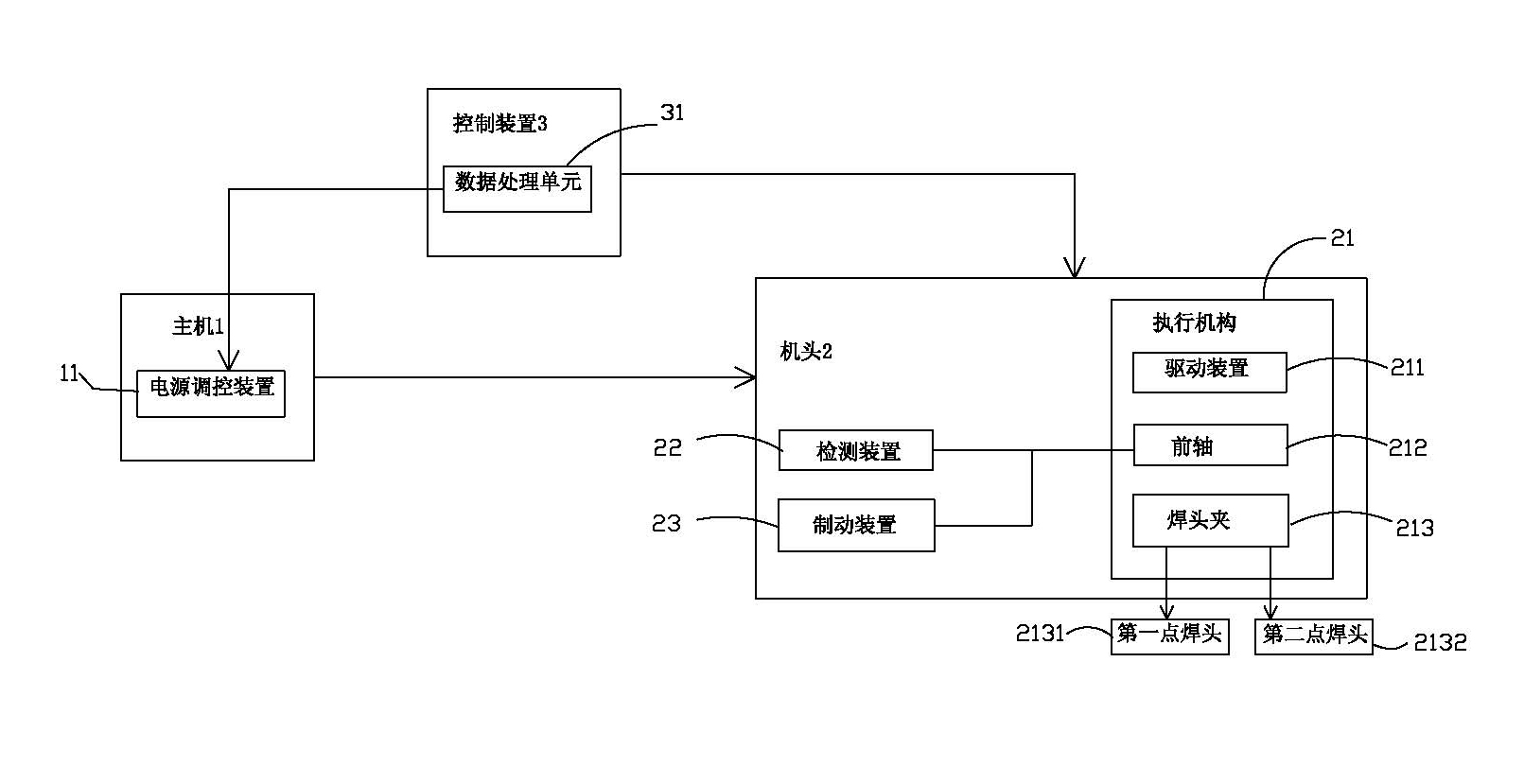

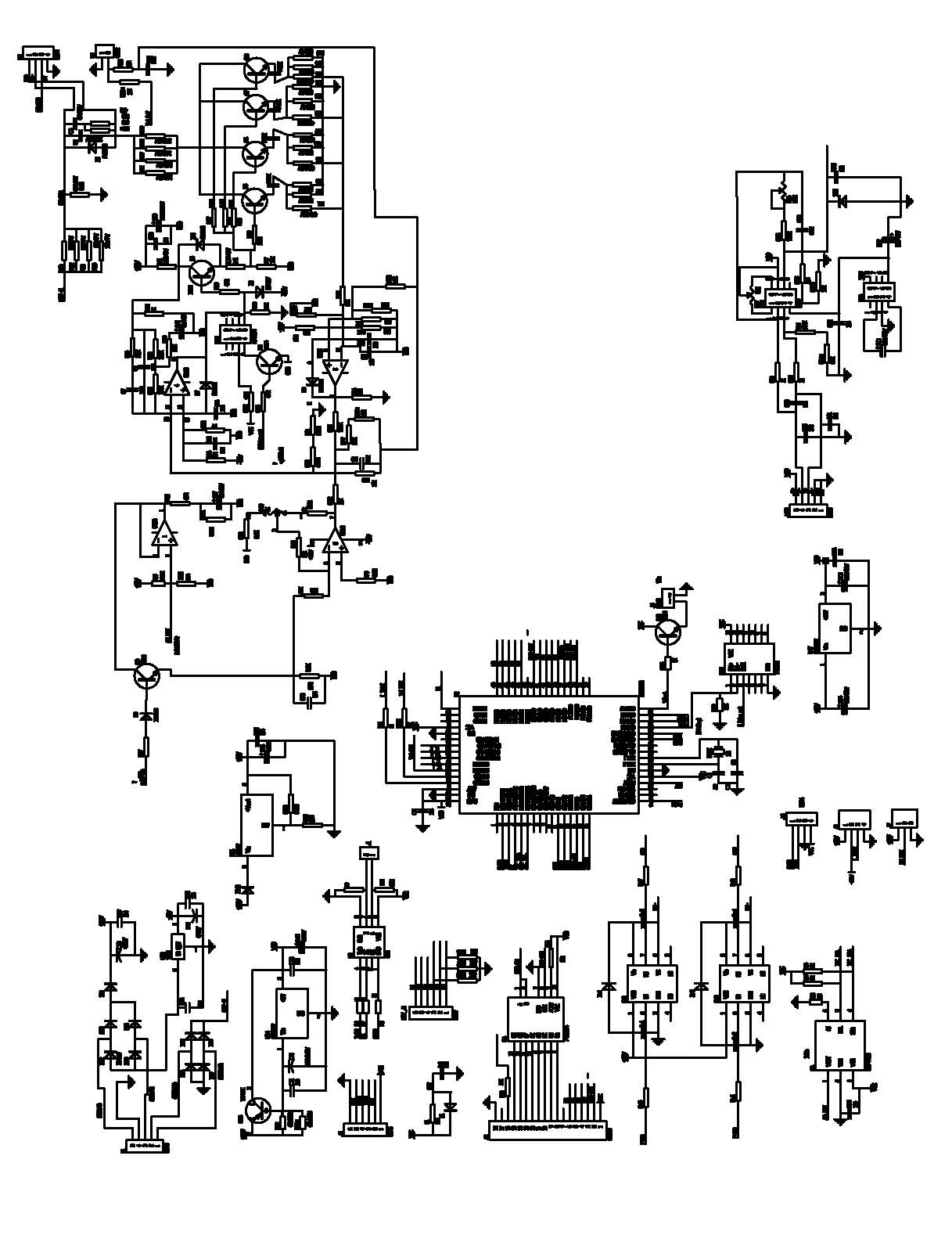

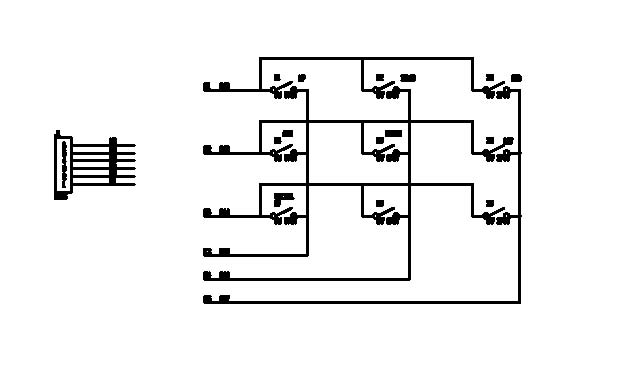

Electronic spot welding machine with double spot welding heads

InactiveCN102319946AExtended service lifeReduce labor production costsWelding electric supplyEngineeringSpot welding

The invention provides an electronic spot welding machine with double spot welding heads, and the machine provided by the invention comprises a mainframe, a machine head and a control device, wherein the machine head comprises an executing mechanism, a detection device and a brake device, the executing mechanism, the detection device and the brake device are electrically connected with the control device, and the control device is used for controlling the motion of the machine head and executing welding actions; the detection device is electrically connected with a data processing unit; the executing mechanism comprises a driving device, a front shaft and a welding head clamp arranged at the lower end of the front shaft, the front end of the welding head clamp is fastened and connected with a first spot welding head and a second spot welding head respectively, and the detection device and the brake device are respectively connected with the front shaft; and the control device can enable the first spot welding head and the second spot welding head to simultaneously move up and down through the driving device, the detection device is used for transmitting obtained data to the data processing unit in real time, and the first spot welding head and the second spot welding head can simultaneously execute the welding actions through the mainframe. The electronic spot welding machine with the double spot welding heads can be used for improving the production efficiency and reducing the labor force.

Owner:珠海精易焊接设备有限公司

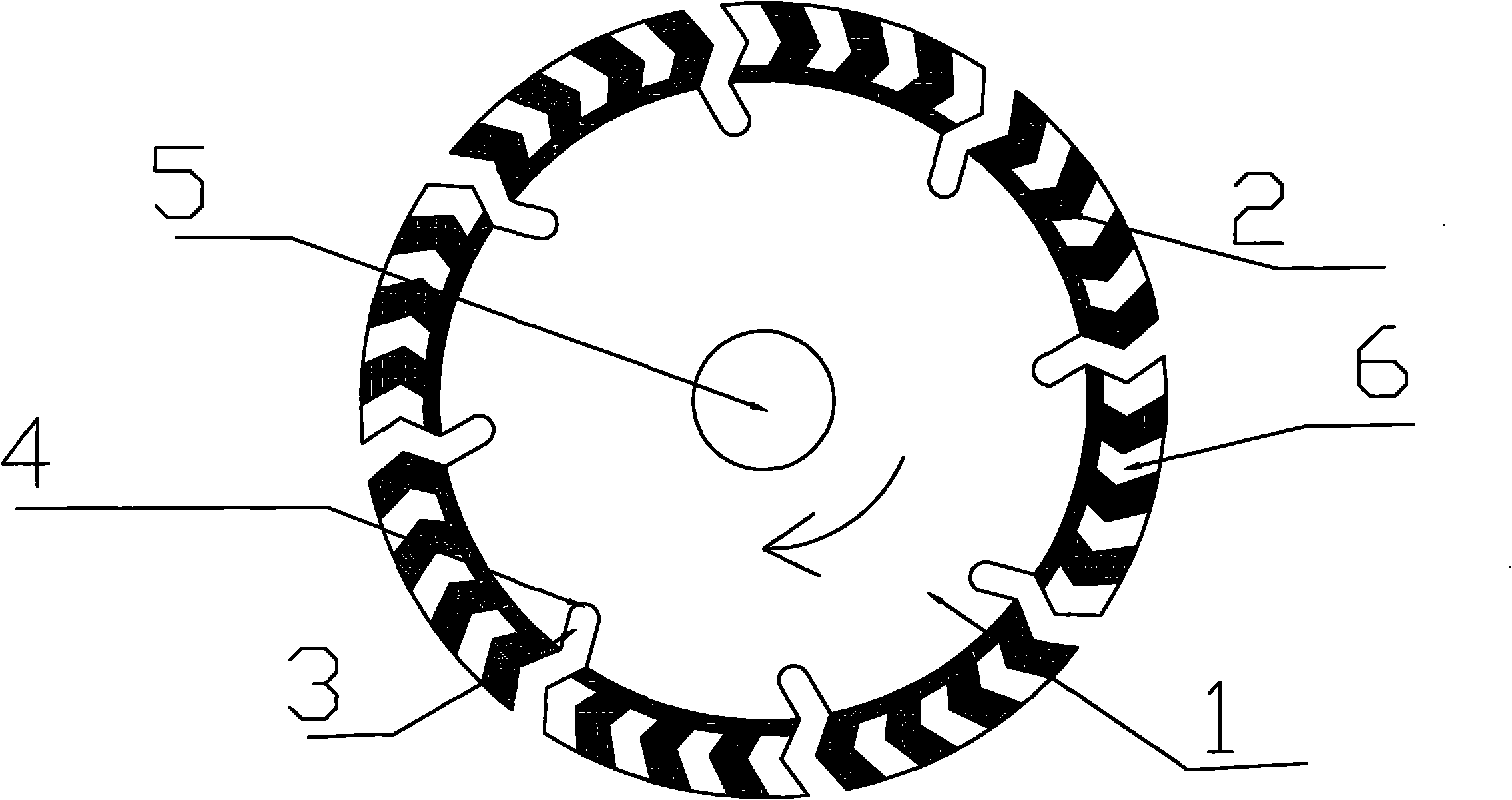

Diamond circular saw blade with nock-type tool bits

InactiveCN102328134AGuaranteed stabilityPlay a role in coolingMetal sawing toolsTool bitCircular saw

The invention provides a diamond circular saw blade with nock-type tool bits and belongs to a processing tool. The diamond circular saw blade with the nock-type tool bits is formed by a matrix and the tool bits. The tool bits are of a nock shape and are formed in a mode that >-shaped blocks are alternately connected in a concave-convex mode along the same direction. The direction of the >-shaped blocks is the rotating direction. Water tanks on the matrix are deflected towards the direction of the >-shaped blocks and are respectively at an included angle of 20 to 30 degrees with the longitudinal direction. The bottom parts of the water tanks are in circular arc transition. When the tool bits are connected with the matrix, the odd number of the >-shaped blocks and the even number of the >-shaped blocks in the same direction are arranged alternately. When rotating at high speed, the saw blade has a good cooling effect and is easy to discharge chips. Due to the existence of grooves, the resistance of the saw blade is reduced, the sharpness of the saw blade is obviously improved, and the diamond circular saw blade with the nock-type tool bits is widely suitable for the industries of stone processing and the like.

Owner:湖北昌利超硬材料有限公司

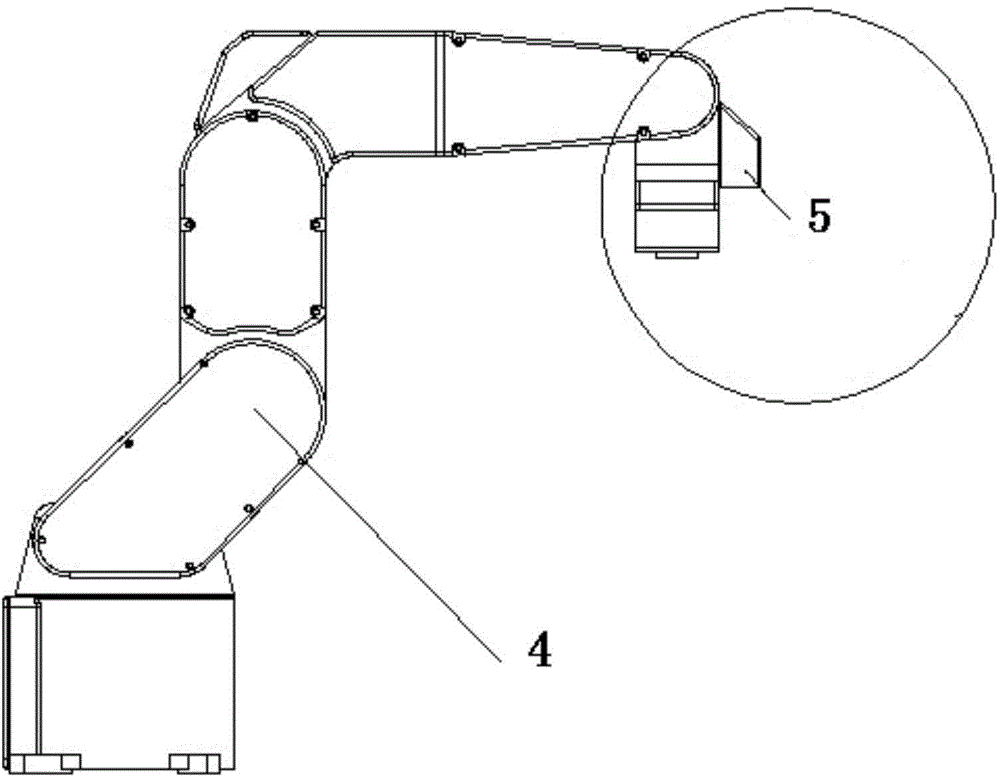

Automatic discharging device of aluminum alloy sawing center robot

PendingCN112296730AIncrease productivityLabor savingMetal working apparatusNumerical controlEngineering

The invention relates to the technical field of aluminum alloy door and window and curtain wall machining equipment, in particular to an automatic discharging device of an aluminum alloy sawing centerrobot. Radio frequency cards are installed on a profile material trolley and an excess material trolley, a card reader is installed on a joint robot mechanism, size information of an aluminum profileneeding to be machined is input into an industrial personal computer, an aluminum profile numerical control sawing center can automatically cut the profile into the needed size, a material pumping mechanism pumps the sawn aluminum profile to a discharging workbench mechanism, and the discharging workbench mechanism conveys the profile to the position to be grabbed, the joint robot mechanism automatically grabs the profile from the discharging workbench, then puts finished profile into the profile material trolley and puts excess material profile into the excess material trolley, and meanwhile, the card reader of the joint robot mechanism writes corresponding profile information into the radio frequency cards of the corresponding profile material trolley and excess material trolley. The automatic discharging device has the beneficial effects that automatic discharging of the robot of the aluminum profile numerical control sawing center is achieved, the production efficiency is improved, the labor force is reduced, and the labor production cost is saved.

Owner:JINAN CGMA CNC MACHINERY CO LTD

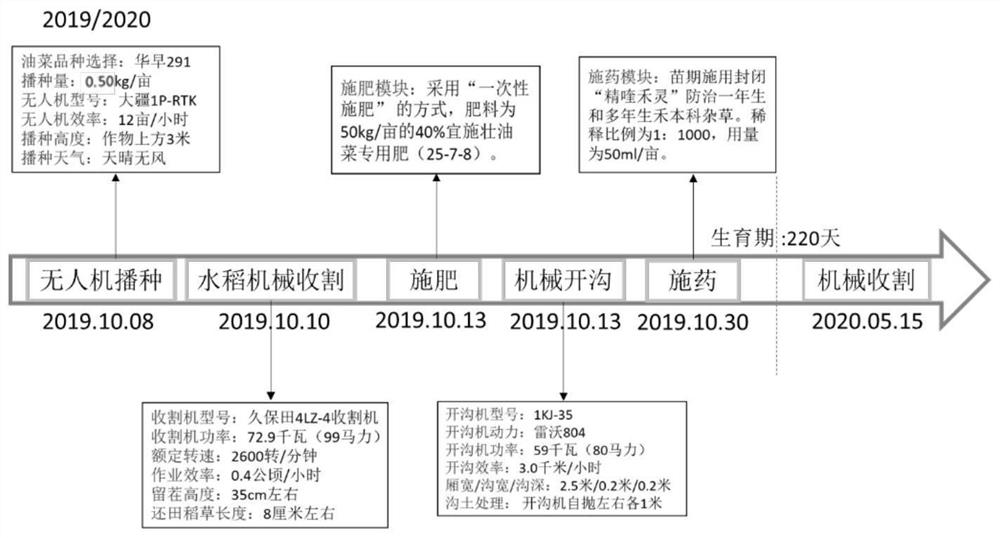

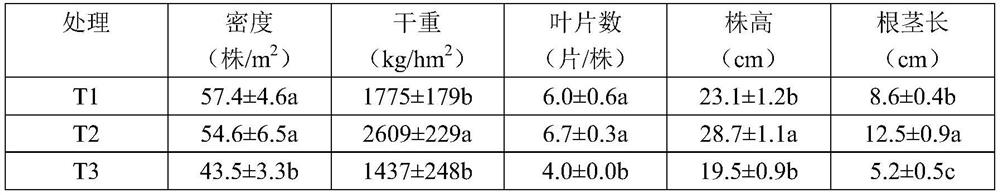

Simple and efficient oilseed rape planting method based on no-tillage aerial seeding and full straw returning

PendingCN112262717AReduce labor production costsImprove work efficiencyMagnesium fertilisersAlkali orthophosphate fertiliserRice strawSoil science

The invention discloses a simple and efficient oilseed rape planting method based on no-tillage aerial seeding and full straw returning. The simple and efficient oilseed rape planting method comprisesthe following steps of (1) conducting aerial seeding of oilseed rape seeds by an unmanned aerial vehicle 1-3 days before rice harvesting; (2) mechanically harvesting the rice, leaving 30-50cm of ricestumps, smashing rice straw to 5-10 cm, and spreading the crushed rice straw on the field surface; (3) conducting fertilization, specifically, spreading special fertilizer for the oilseed rape 1-10 days after aerial seeding; (4) after base fertilizer is applied, carrying out ditching operation by utilizing a machine, and separately throwing ditch soil to compartment surfaces; and (5) spraying foliar fertilizer by using the unmanned aerial vehicle in an oilseed rape bolting phase or initial flowering phase, wherein the foliar fertilizer consists of monopotassium phosphate, calcium nitrate, magnesium sulfate and boric acid. According to the simple and efficient oilseed rape planting method, by combining multiple simplified technologies such as aerial seeding, tillage avoiding, straw returning, leaf fertilizer special for the oilseed rape and mechanization, under the condition that it is guaranteed that the yield of the oilseed rape is not reduced, the labor production cost is effectively reduced, the operation efficiency is improved, and the simple and efficient oilseed rape planting method is suitable for large-area operation and application.

Owner:HUAZHONG AGRI UNIV

Production process for primer-free plastic thermal transferred pattern film of bamboo and wood products

InactiveCN102371798AReduce labor production costsEnergy savingDuplicating/marking methodsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention provides a production process for a primer-free plastic thermal transferred pattern film of bamboo and wood products, which comprises a material preparing stage and a thermal transferring stage, wherein a release agent and a protective agent are diluted and mixed with ethyl ester and medical alcohol; a printing ink is diluted and mixed with the ethyl ester and the medical alcohol; a pet (polyethylene terephthalate) film thermal transferring glue is taken as the glue used in the production process and is diluted and mixed with the ethyl ester and the medical alcohol; and in the thermal transferring stage, the transferred pattern film can be realized, without painting the surface of the bamboo and wood products. The required pattern is firmly transferred according to an original transferring process, thereby greatly lowering the labor and production costs. Besides, the production process has the advantages of energy conservation, environmental protection, high quality, directness, high speed and convenience.

Owner:彭云飞

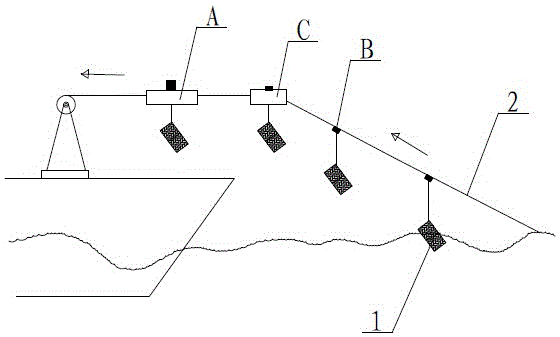

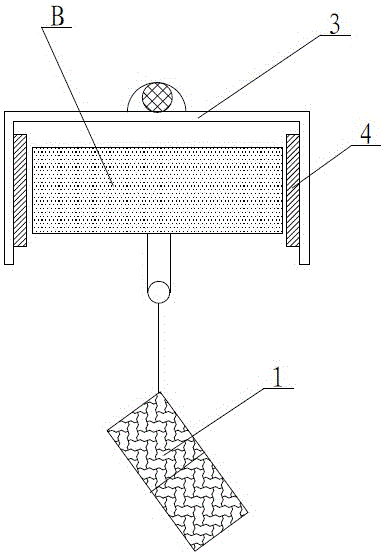

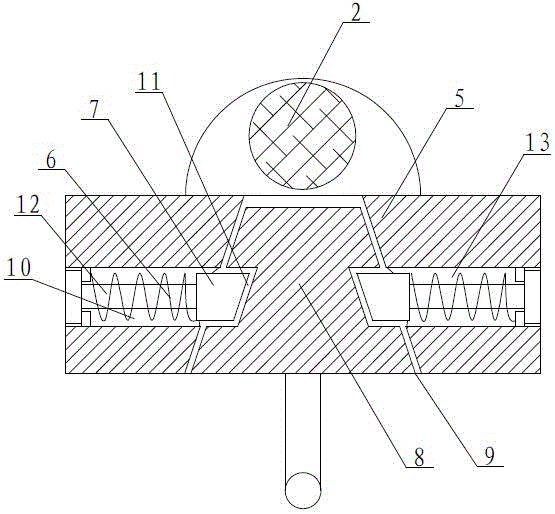

Automatic cage pulling device of cage type operation in fishery production

InactiveCN105104318AStrong reliabilityReduce manufacturing costFishingMarine engineeringEconomic benefits

The invention relates to an automatic cage pulling device of cage type operation in fishery production. The technical problems that for a traditional fishery cage picking mode, the labor intensity is high, the manpower consumption is large, the technique is high, the cost is high and the risk is high are mainly solved. The automatic cage pulling device of the cage type operation in the fishery production comprises a power source, a trapping cage, a main rope and an unhooking mechanism, the unhooking mechanism comprises a fixed frame, a driving part and a connector, the connector comprises a shell, an elastic part, a lock tongue and an inner core, the shell is provided with a chute which is communicated with an inner cavity of the shell, the lock tongue moves in a sliding mode along the chute, a locking notch is formed on the portion, corresponding to the chute, of the side face of the inner core, the lock tongue is clamped in the locking notch, and the driving part pulls the lock tongue to slide out of the locking notch of the inner core. Due to the fact that the automatic cage pulling device of the cage type operation in the fishery production adopts a mechanical structure to achieve unhooking, the mechanism reliability is strong, the manufacturing cost is low, use of the structure is easy, and the the automatic cage pulling device of the cage type operation in the fishery production is specially suitable for marine fishery production operation; the operation efficiency is greatly improved, the labor production cost is greatly reduced, the operation safety is improved, and the extremely high production benefit and economic benefit are achieved.

Owner:ZHOUSHAN TIEMUHAN FURNITURE CO LTD

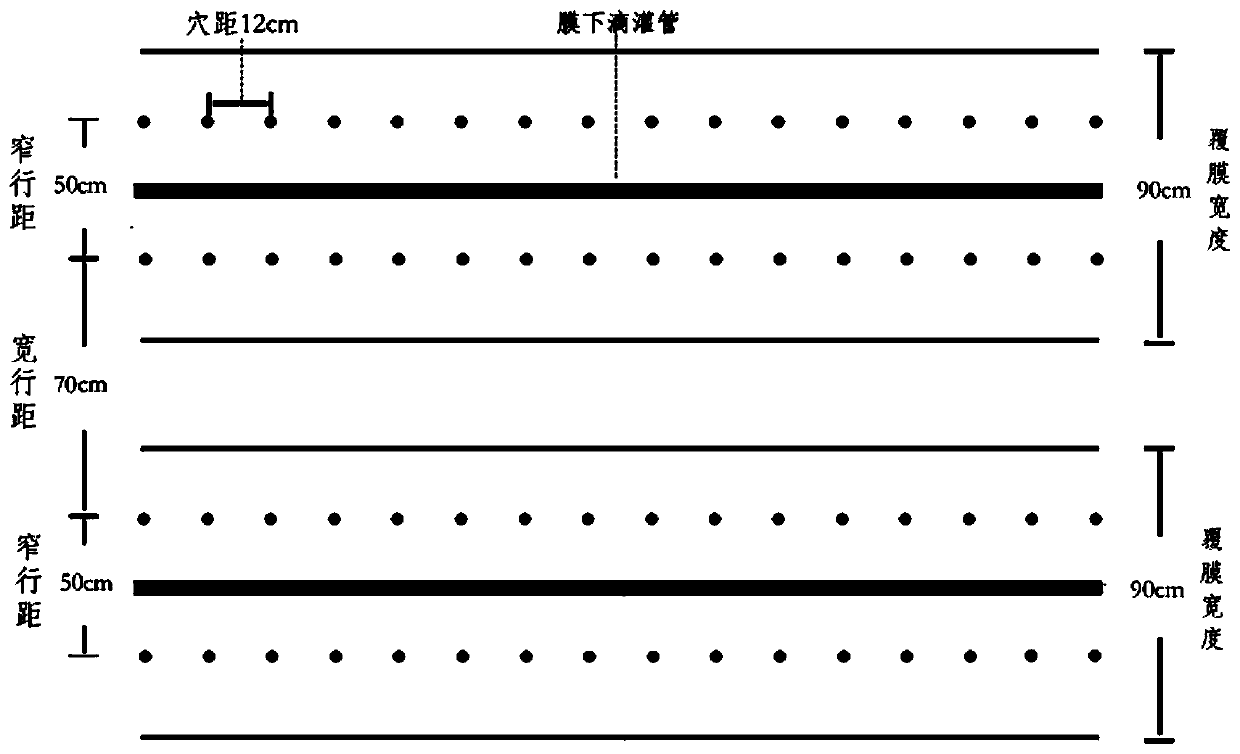

Water and fertilizer integrated planting method of foxtail millet through drip irrigation under films

InactiveCN111492747APromote growth and developmentImprove yield per unit areaFertilising methodsCereal cultivationBulrush milletDrip irrigation

The invention relates to the technical field of agricultural planting, and specifically relates to a water and fertilizer integrated planting method of foxtail millet through drip irrigation under films. The planting method includes the following steps: performing preparation before seeding; selecting varieties and performing seed treatment; performing seeding, selecting a film-mulching hill planter to perform flat planting, achieving operation of fertilization, pipe paving, film mulching, seeding and compaction for one time, fertilization per hectare being 300-400 kg of compound fertilizer containing nitrogen, phosphorus and potassium, mulching two rows with one film, paving a drip irrigation between the two rows, drilling holes to perform hole sowing, the distances between holes being 12cm and per hectare having about 130,000 holes, selecting the foxtail millet seeds whose germination rate is more than 85%, the using amount of the seeds per hectare being 3-4 kg, and seeding 4-6 seeds in each hole, the seeding depths of the foxtail millet being 3-5 cm; and performing field management. Through the provided planting method, watering and fertilization can be synchronously carried out, so that the invalid loss of water and fertilizer can be reduced, and production efficiency can be enhanced; the planting method is simple in operation and easy to operate; and the production costsof labor force can be saved, the utilization efficiency of the fertilizer and water can be increased, the yield per hectare of the foxtail millet and the seed quality of the foxtail millet can be enhanced, and the maximum economic benefits can be obtained.

Owner:JILIN ACAD OF AGRI SCI

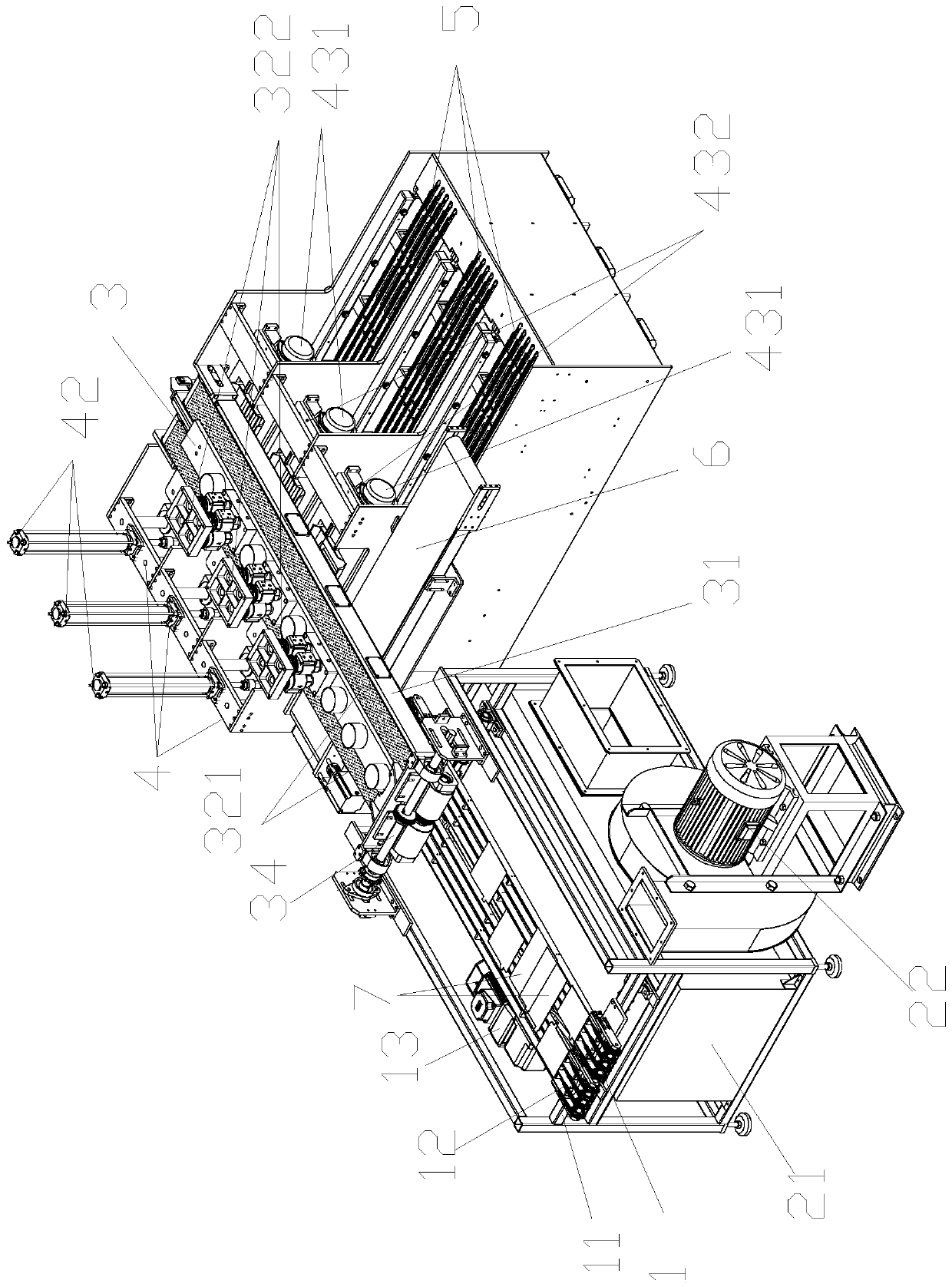

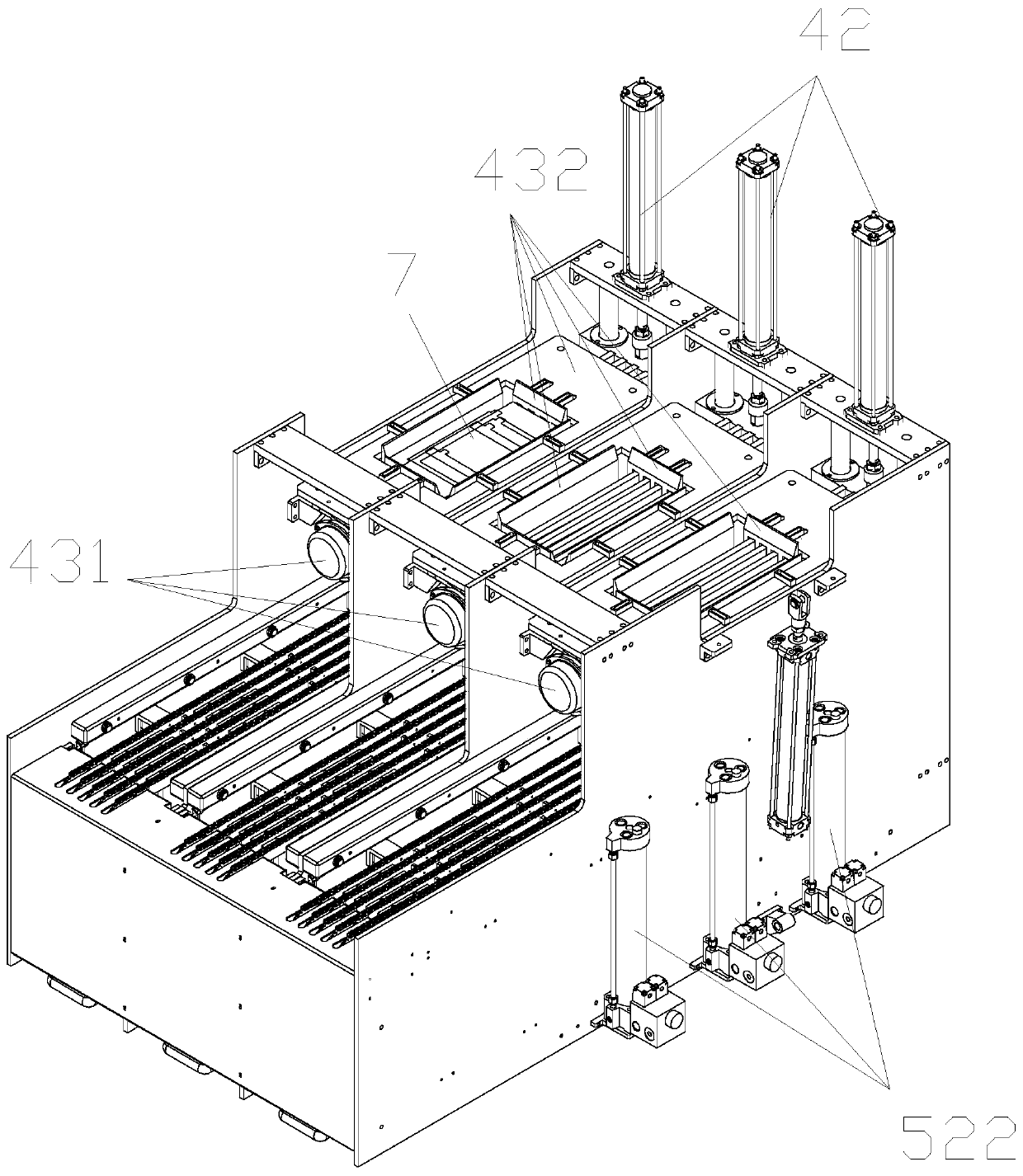

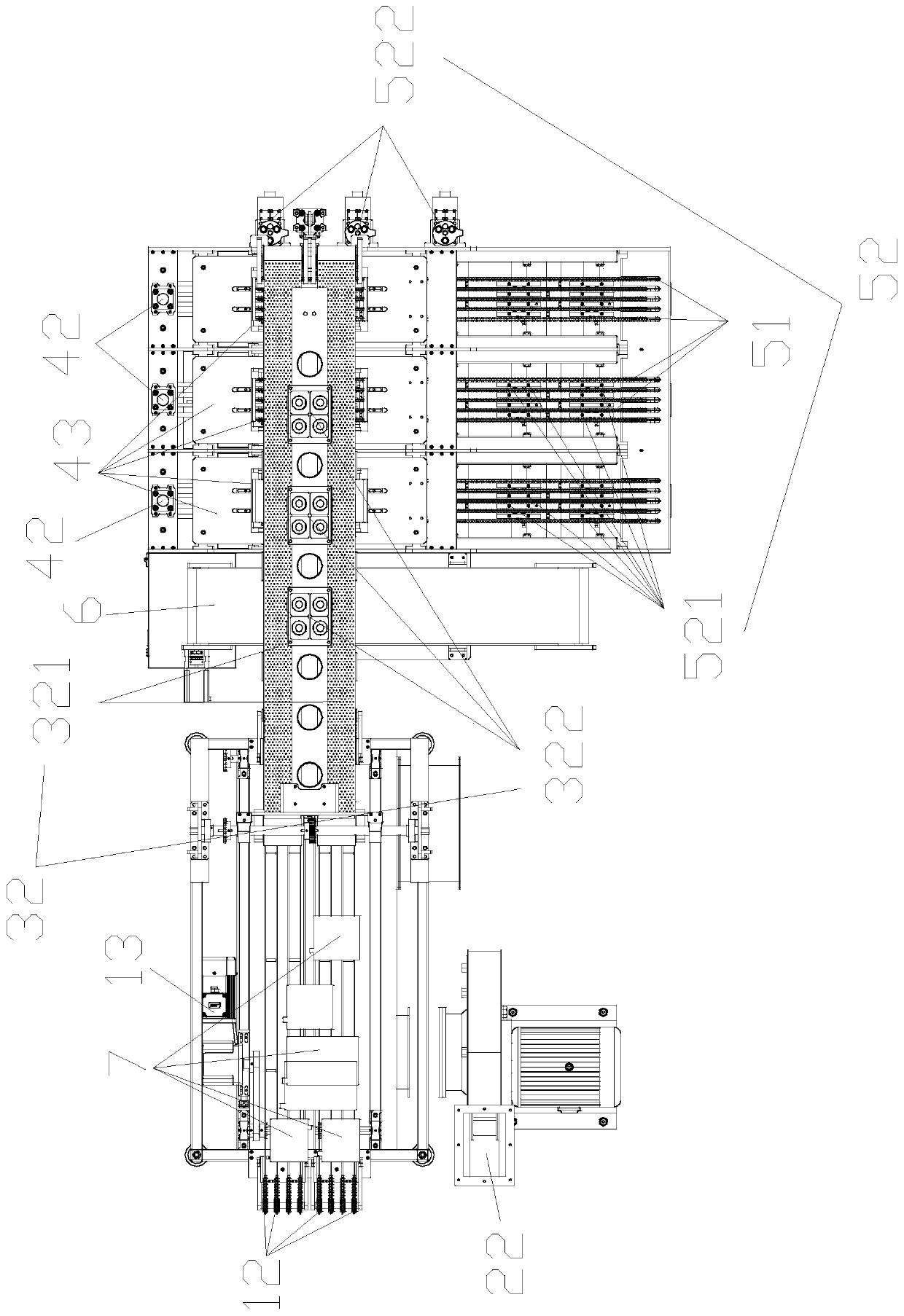

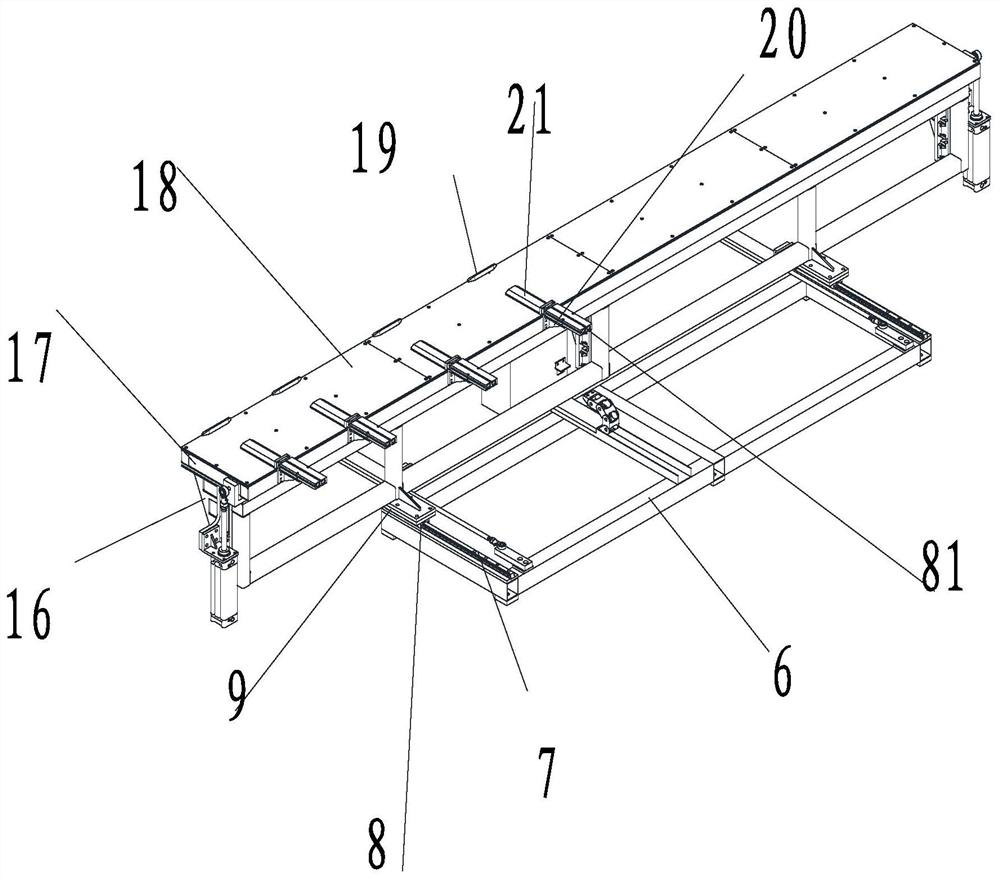

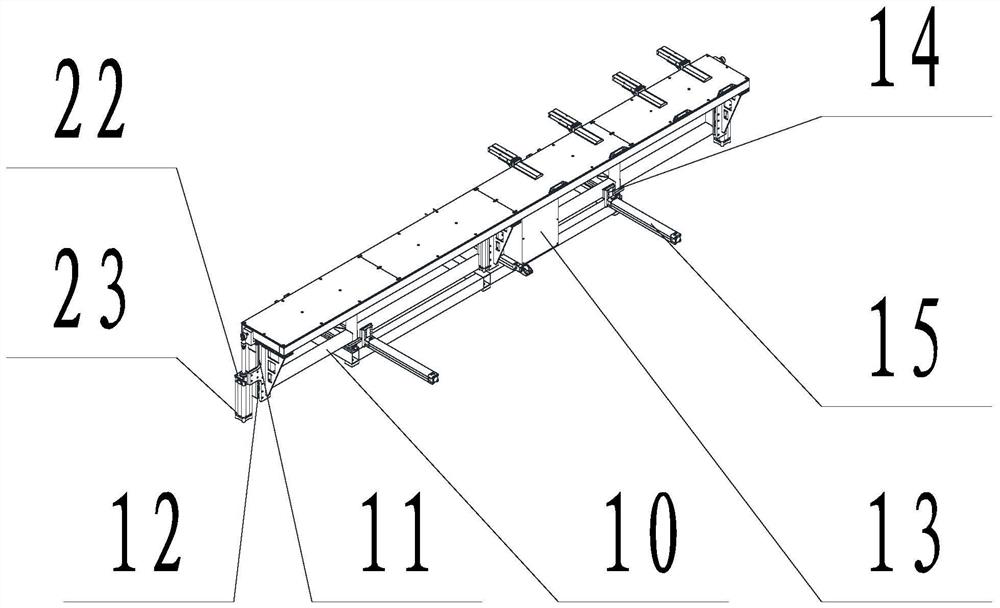

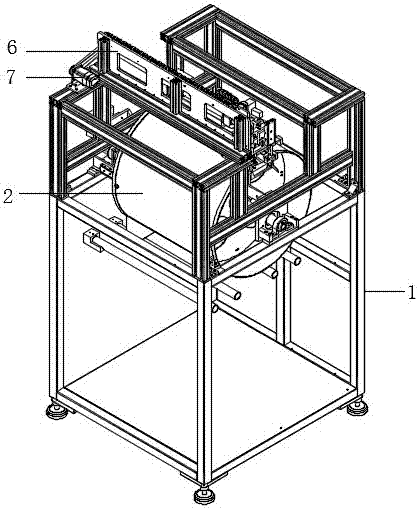

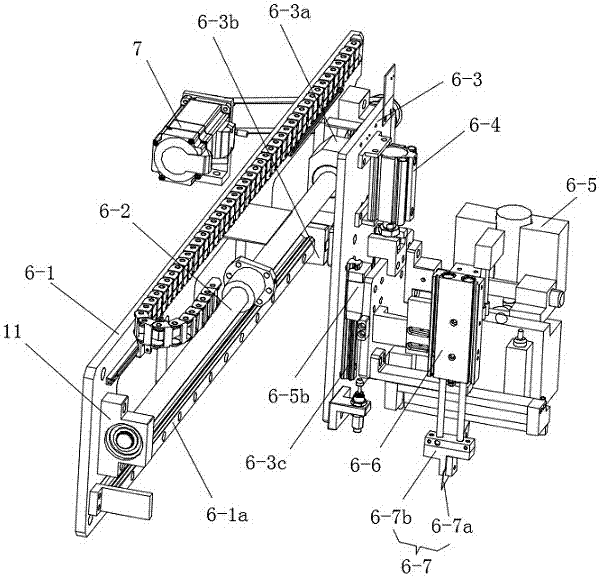

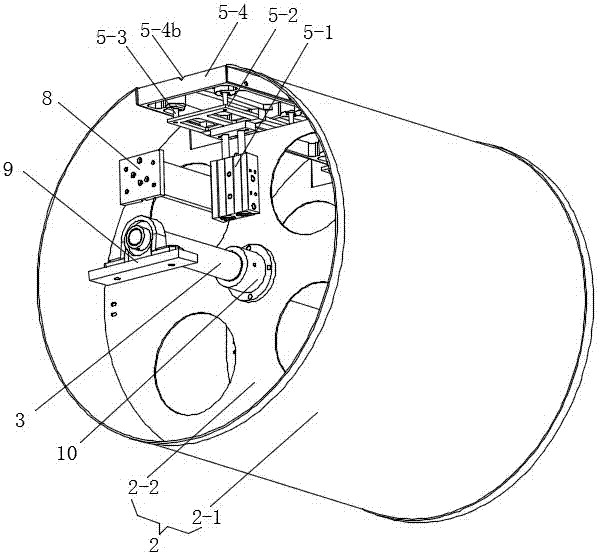

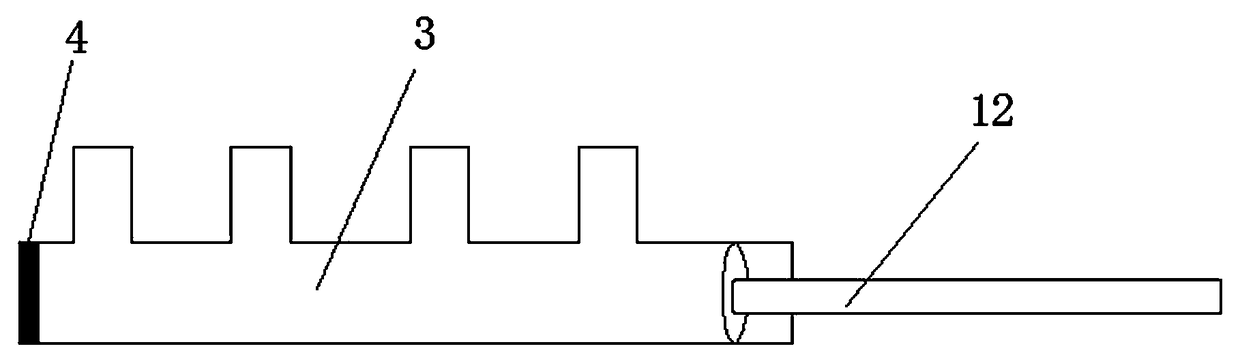

Film filament arranging, winding, gluing and cutting integrated mechanism

PendingCN107310975ANeatly arrangedHigh degree of automationLiquid surface applicatorsFilament handlingElectric machineryStructural engineering

The invention discloses a film filament arranging, winding, gluing and cutting integrated mechanism. The film filament arranging, winding, gluing and cutting integrated mechanism comprises a machine frame, a winding roller, a winding roller shaft, a filament clamping assembly, a filament jacking assembly, a gluing and filament cutting assembly, a winding motor and a lead screw motor. The winding roller comprises a hollow roller. Two reinforcing partitions are arranged on the inner side of the hollow roller. The winding roller shaft penetrates through the hollow roller and the two reinforcing partitions and is connected with the machine frame and the two reinforcing partitions. The filament clamping assembly and the filament jacking assembly are both located inside the hollow roller and connected with the hollow roller and the machine frame. The gluing and filament cutting assembly is located above the hollow roller and connected with the machine frame. The winding motor and the lead screw motor are fixed to the machine frame. The winding motor is connected with the winding roller shaft. The lead screw motor is connected with the gluing and filament cutting assembly. The film filament arranging, winding, gluing and cutting integrated mechanism has the advantages that film filaments are wound and arranged in order, the automation degree is high, the practicability is high, and the production cost is low. The film filament arranging, winding, gluing and cutting integrated mechanism is beneficial for long-term sustainable development of an enterprise.

Owner:ZHEJIANG AET INTELLIGENT TECH

Automatic collection, arrangement and transfer equipment and method for lead-acid accumulator plate

PendingCN108706304ALow efficiencyImprove production efficiencyStacking articlesConveyor partsEngineeringMechanical engineering

Owner:中山慧能科技有限公司

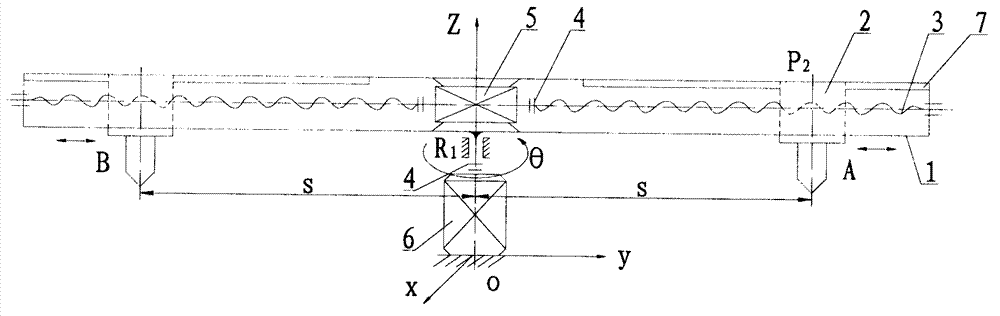

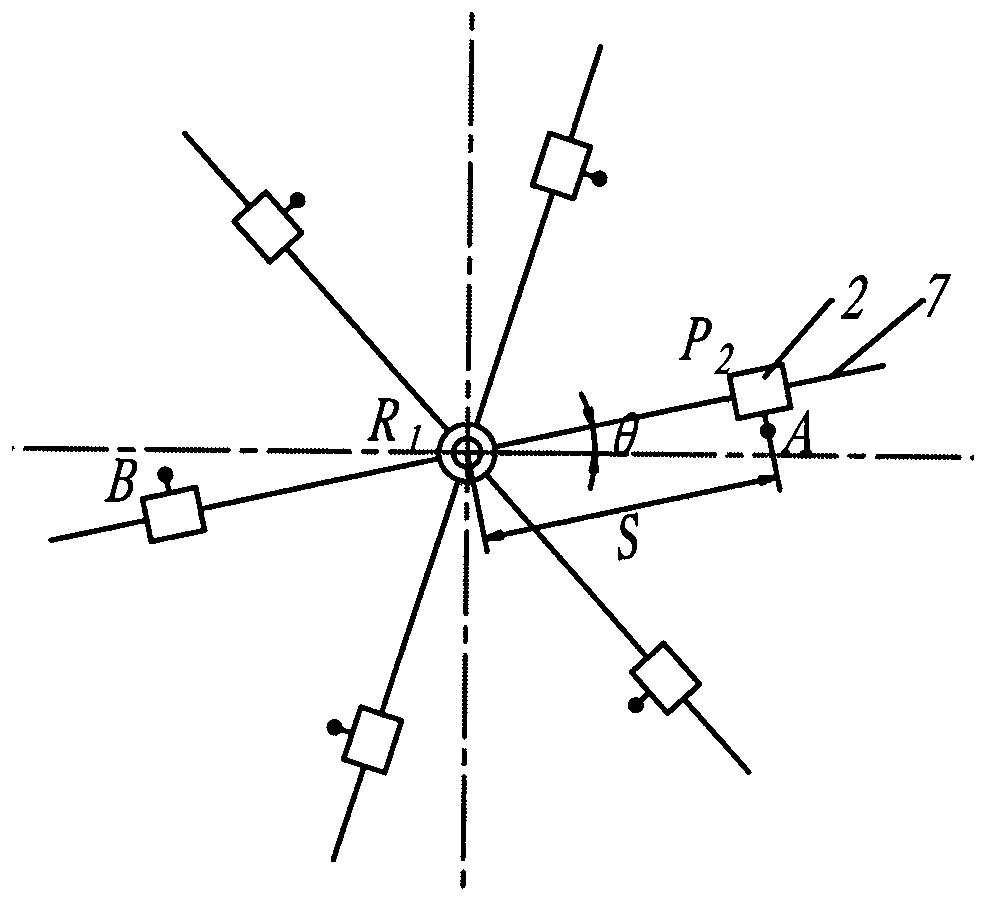

Curve tracer in symmetrical process

InactiveCN102785237AImprove work efficiencyQuality improvementOther workshop equipmentCouplingControl theory

A curve tracer in a symmetrical process comprises a frame (0), a main arm (1), nut sliders (2), screw rods (3), couplings (4), an auxiliary motor (5), a main motor (6) and a guide rail (7). The main arm (1) and the frame (0) form a revolute pair (R1) connected with the main motor (6) through the couplings (4), a pair of transmission systems which are opposite in rotation direction and consist of the screw rods (3) and the nut sliders (2) are mounted on two sides centering on a rotary shaft (Z) of the main motor (6) in the length direction of the main arm (1), the screw rods (3) are connected with the auxiliary motor (5) through the couplings (4), the auxiliary motor (5) is positioned in the center of the main arm (1) and provided with two output shafts, and the nut sliders (2) and the guide rail (7) arranged on the main arm (1) to form a moving pair (P2). The axis of the main motor (6) is perpendicular to that of the auxiliary motor (5), the transmission systems which are opposite in rotation direction and consist of the screw rods (3) and the nut sliders (2) are identical in screw pitch, lead and lead angle, and the curve tracer can be in central symmetry relative to the revolute pair (R1) and overlapped and combined for use. The curve tracer in the symmetrical process is simple in structure, easy to control and high in efficiency and tracing quality.

Owner:CHANGZHOU UNIV

Tobacco basal fertilizer and topdressing integrated fertilizer, and preparation method and application thereof

InactiveCN107245015AImprove qualityPromote growth and developmentMagnesium fertilisersAlkali orthophosphate fertiliserPhosphateAmmonium sulfate

The invention discloses tobacco basal fertilizer and topdressing integrated fertilizer, and a preparation method and application thereof, and belongs to the technical field of fertilizer. The tobacco basal fertilizer and topdressing integrated fertilizer is prepared from three organic fertilizer cakes, potassium humate, controlled release compound fertilizer, monoammonium phosphate, ammonium sulfate, potassium nitrate, potassium sulfate, polyaspartic acid, functional microbial flora, magnesium sulfate monohydrate and boric acid. According to the tobacco basal fertilizer and topdressing integrated fertilizer disclosed by the invention, slow release and controlled release are combined, nutrients are balanced and comprehensive, the demands on the nutrients of nitrogen, phosphorus and potassium in all stages of tobacco plant growing can be met, the soil structure is improved, the labor production cost is reduced, and the economic benefit of flue-cured tobacco planting is increased. In addition, the preparation method of the tobacco basal fertilizer and topdressing integrated fertilizer, disclosed by the invention, is simple in operation, short in technical steps, convenient in application, suitable for industrial production and easy to be popularized in flue-cured tobacco planting and fertilizer application.

Owner:HUNAN TAIGU BIOTECH

Dust collection and removal device of textile machine

InactiveCN108998865AReduce labor production costsProtect your healthAuxillary apparatusKnittingElectrostatic adsorptionImpeller

The invention discloses a dust collection and removal device of a textile machine. The device includes a textile machine body, a dust collection device, a dust removal device and an electrostatic adsorption device; the dust collection device is embedded in the middle of the textile machine body; the dust removal device is embedded at the bottom of the textile machine body; and the electrostatic adsorption device is embedded in the edge on the left side of the textile machine body. Through the rotation of a centrifugal fan impeller in the dust collection device, floccular dust generated duringa working process of a textile machine can be adsorbed into dust inlets; and through the collection and processing of the adsorbed dust by the dust removal device, labor production costs of enterprises can be reduced, body health of textile workers can be protected, and the wind power flown out of air outlets is good for releasing the bodies and minds of the textile workers; and thus, the device has market promotion values.

Owner:广西鑫阳机械设备制造有限公司

Multifunctional automatic CNC polishing machine

ActiveCN105500158BEffective protectionIncrease productivityBelt grinding machinesNumerical controlAutomatic control

The invention relates to a multifunctional automatic numerical control polishing and burnishing machine, comprising an engine base; the engine base is provided with a polishing and burnishing wheel, a tensioning mechanism, a polishing belt, a transverse walking mechanism, a longitudinal walking mechanism, a turnover mechanism and a clamping mechanism; the clamping mechanism is provided with a positioning seat; a machined workpiece is pressed and fixed on the mounting seat; the turnover mechanism controls the machined workpiece to rotate by an angle; the longitudinal walking mechanism drives the clamping mechanism and the machined workpiece to vertically move; the transverse walking mechanism drives the clamping mechanism and the machined workpiece to horizontally move; the polishing belt contacts with the outer ring of the polishing and burnishing wheel driving the polishing belt to rotate fast; the tensioning mechanism controls the tensioning and fast replacement of the polishing belt. The multifunctional automatic numerical control polishing and burnishing machine fully replaces manual operation, realizes full automatic control over a production process while greatly improving production efficiency and relieving personal labor intensity, machine production is closed, dust emission in field air is controlled, environment is effectively protected, labor production cost is greatly reduced, and economic benefits of an enterprise are improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

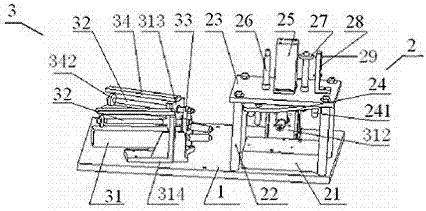

Crankcase plug riveting device

InactiveCN105598300BEnsure plug riveting assembly qualityEliminate damageMetal-working feeding devicesPositioning devicesCrankcaseEngineering

Owner:JIANGSU LINHAI YAMAHA MOTOR CO LTD

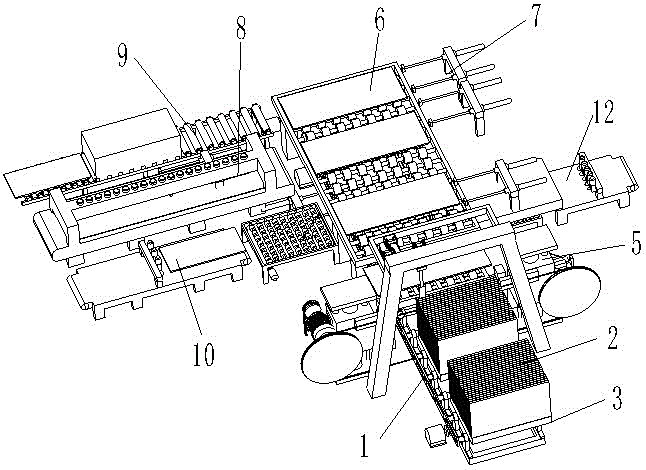

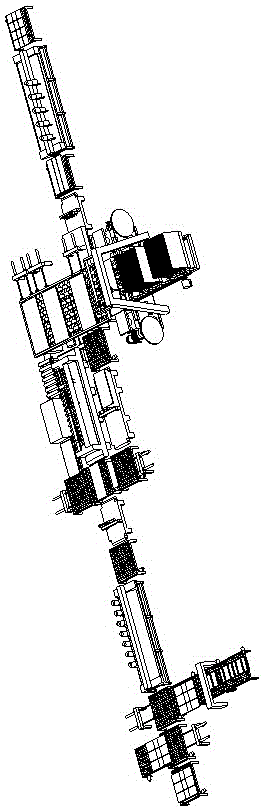

Full-automatic multifunctional complete set of stone processing equipment and processing method

ActiveCN105365053BHigh degree of automationImprove efficiencyConveyorsWorking accessoriesSmall footprintEngineering

The invention relates to a complete set of full-automatic and multifunctional stone processing equipment and a processing method. The processing equipment is characterized by comprising a machine body and a feed conveying belt arranged on the machine body for conveying quarry stones; a cutter for cutting off the connection between battens and the bottoms of the quarry stones is arranged on the feed conveying belt; a discharge conveying belt positioned on the upper layer of the feed conveying belt is additionally arranged on the feed conveying belt; a plurality of sets of oil cylinder push rods are arranged beside the discharge conveying belt; a stone polishing machine, a batten burning machine or a stone litchi surface processing machine is arranged on one side, opposite to the oil cylinder push rods, of the discharge conveying belt; oil cylinder push rods are also arranged on the feed conveying belt; and a baseplate output transitional frame is arranged on one side, opposite to the oil cylinder push rods, of the feed conveying belt. The complete set of full-automatic and multifunctional stone processing equipment has the following advantages: (1) the automation degree is higher, so that the working efficiency and the stability are greatly improved; (2) the floor area is small; (3) the energy is saved; (4) the needed workers are few; according to the yield of the same day, the equipment can reduce the labor number by at least 80% or above compared with a traditional processing mode, so that the labor production cost is largely reduced; and (5) the efficiency is high, so that the yield of the processing equipment is higher than the yield of the traditional processing mode by 5 or above times.

Owner:苏金溢

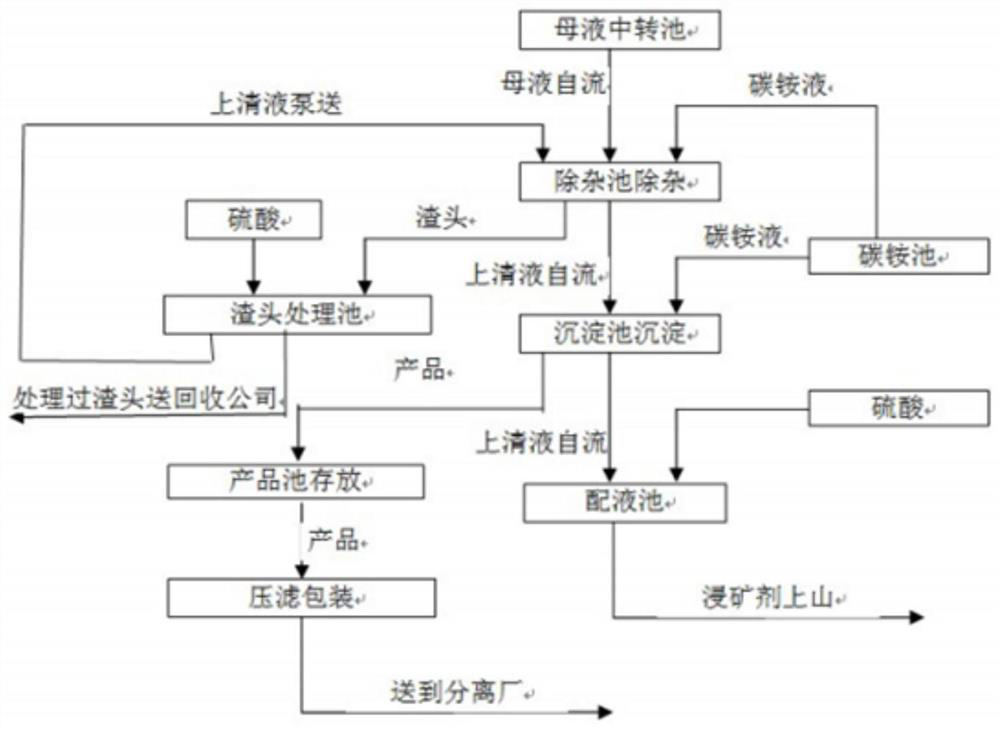

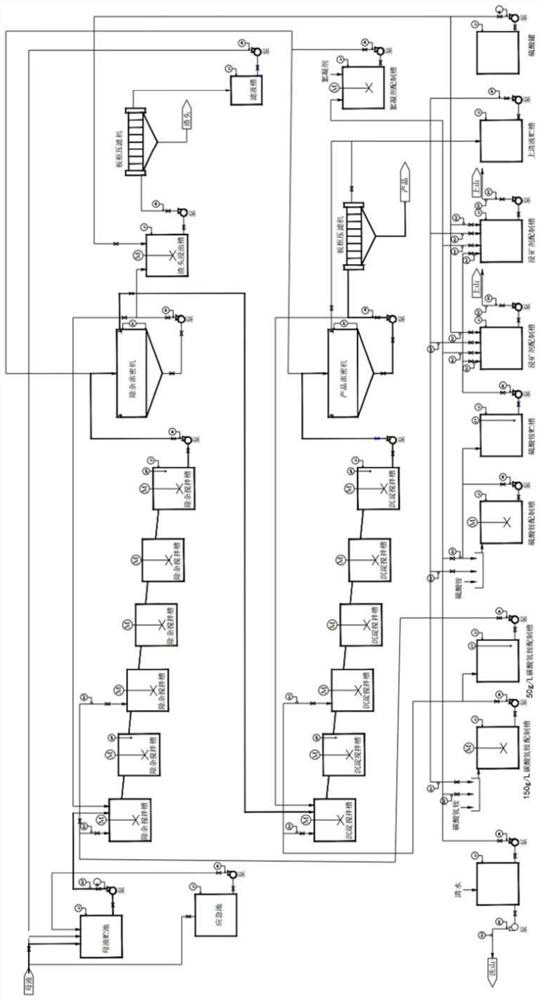

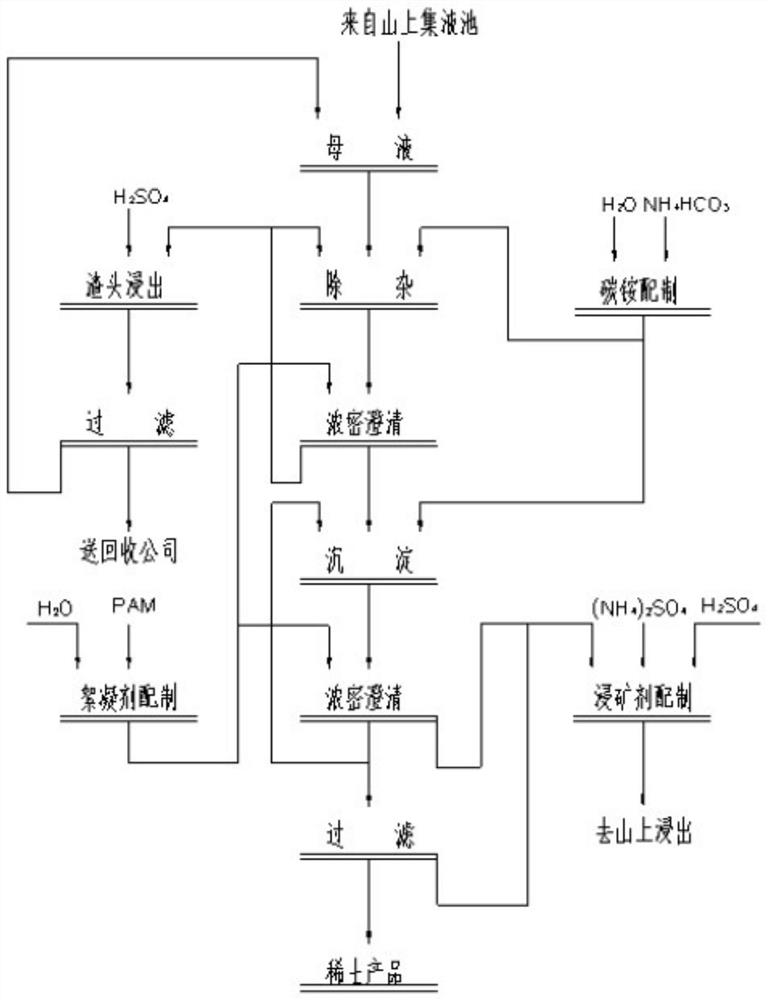

Intensive large-scale ion-type rare earth ore leaching mother liquor continuous treatment system and method

ActiveCN112961981BAvoid human errorEasy to controlProcess efficiency improvementProcess engineeringIndustrial engineering

The invention relates to an intensive large-scale ionic rare earth ore leaching mother liquor continuous processing system and method. The system includes an ammonium bicarbonate supply module, a flocculant supply module, a multi-stage series-connected impurity removal / precipitation stirring module, and an impurity removal / product thickener. , leaching agent preparation module, etc. Automatic operation, automatic adjustment and control of process parameters, and more accurate control; good impurity removal effect, better and more stable product quality, saving reagents and reducing production costs; highly intensive equipment and facilities, and a water metallurgy workshop with the same production capacity covers an area Compared with the existing technology, it is greatly reduced; large-scale production is realized, and the hydrometallurgical workshop with the same floor area, with highly integrated equipment and facilities, can obtain mother liquor processing capacity and product output production capacity far greater than the existing technology. Connect the in-situ leaching mine with the mother liquor treatment workshop, rationally plan the mining area, realize the orderly mining of the mine, rationally utilize the process solution, and regulate the water balance, which is conducive to the environmental protection management of the mine and realizes a green mine.

Owner:中稀(湖南)稀土开发有限公司

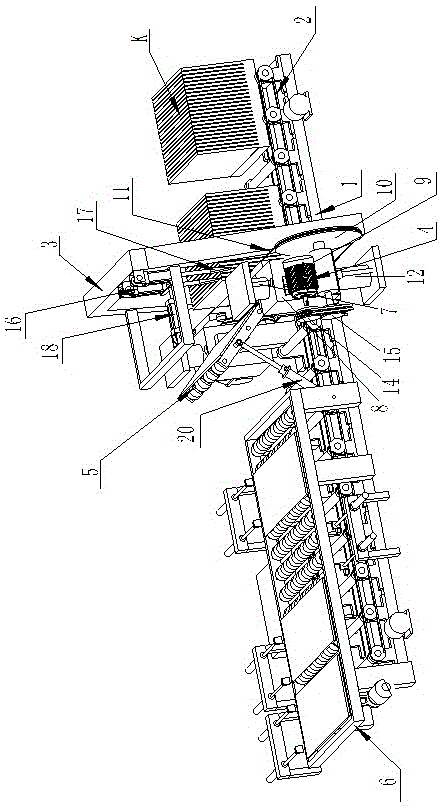

An assembly device and assembly method of an insulated cable clamp

ActiveCN109926819BImprove production efficiencySolve the difficulty of employing peopleAssembly machinesPositioning apparatusEngineeringStructural engineering

Owner:广东鑫太自动化设备有限公司

High-efficiency production-increasing codonopsis pilosula cultivation method

The invention discloses a high-efficiency production-increasing codonopsis pilosula cultivation method which includes the following steps of land preparation before seedling cultivation, seed preparation, sowing and quick breeding seedling culture. The quick breeding seedling culture includes that a. first-generation tissue culture seedlings are adopted as a breeding material; b. when the seedlings on a seedbed grows to 25cm and stem tips and stems are formed, the stem tips and the stems of the seedlings are taken down, the wound portions of the stem tips and the stems are immersed into 500-ppm rooting powder solution to be processed, then the stem tips and the stems are directly planted on a greenhouse hot bed of an agricultural facility and starts to survive in soil of the hot bed, and the stems tips and the stems grow for 30 days under the temperature of 28-35 DEG C to form second-generation complete plants; and c. continuously taking the stems and the step tips of the plants to conduct planting and breeding in the greenhouse hot bed of the agricultural facility after the second-generation complete plants are formed, third-generation plant seedlings are formed after 30 days, and the seedlings can emerge in the 30-day period to be planted. Autumn transplanting is a better choice in autumn sowing, and ridge planting or rest-balk planting is adopted. By means of the method, the seeds are large in seedling forming number, consumed time is short, seed quality purity is high, the production increase effect is remarkable and the method is suitable for large-scale planting.

Owner:安顺市西秀区鑫源药材种植园

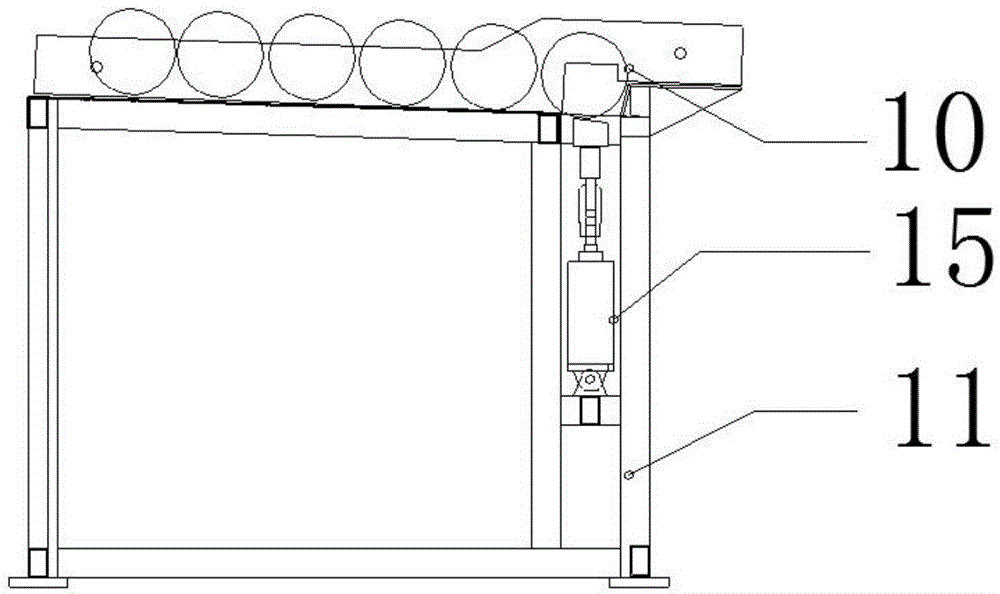

Slat automatic feeding and unloading mechanism and working method

ActiveCN105382937BHigh degree of automationImprove efficiencyConveyorsWorking accessoriesSmall footprintEngineering

The invention relates to an automatic batten feed and discharge machine and an operating method. The automatic batten feed and discharge machine is characterized by comprising a machine body and a feed conveying belt, wherein the feed conveying belt is arranged on the machine body and is used for conveying blocks, a discharge frame is arranged on the conveying belt, a cutter which is used for disconnecting a batten from the bottoms of the blocks is arranged on the discharge frame, a turnable batten support plate which is used for bearing the batten is arranged beside the discharge frame, and a batten discharge conveying belt is arranged beside the batten support plate. The automatic batten feed and discharge machine has the following advantages that (1) the degree of automation is high, and the working efficiency and the stability are greatly increased; (2) an occupied area is small; (3) energy is saved; (4) required workers are few, and for the yield of a day, compared with a traditional processing mode, the number of the workers can be reduced by more than 80%, and the labor and production cost is greatly reduced; (5) the efficiency is high, and the yield is higher than that of the traditional processing mode for more than five times.

Owner:福建省晋江市和盛机械有限公司

Ingot-suspended automatic spinning machine

InactiveCN102191577AExpand the use of surfaceGet rid of harmNew-spun product collectionHigher PowerPoor quality

Forty thousand viscose filament yarn spinning workers exist in China at present, but have to change jobs every 3-5 years as suffering from carbon bisulfide gas; and since the acid bath for the wet spinning technique of viscose filament yarn uses 240 g / l sulfuric acid which is seriously corrosive, a common spinning mechanism can not be easily available, and the spinning can only be carried out manually, which is a problem in the world. A full continuous spinning machine has appeared abroad; however, by using the full continuous spinning machine, the after-treatment technique of the spinning cake must be moved onto the spinning machine for monofilament treatment, and thus, the full continuous spinning machine has the defects of huge equipment, high power consumption and poor quality of rayon filament, and is hard to popularize. The ingot-suspended automatic spinning machine disclosed by the invention uses an energy-saving centrifugal cylinder CN200710071331,4 as the main body, can operate instead of human labor, and thus, relieves the workers of the damage from carbon bisulfide gas, thereby lowering the labor and production cost. By the aid of Patent ZL88104569 technology, the invention can increase the spinning speed by 20% as compared with the prior art, and can also save powder of electric ingot consumption by 30% on the basis of the energy-saving centrifugal cylinder. The spinning cake can be directly released from the factory, thereby widening the application range and benefiting the social production.

Owner:张钦桂

A fully automatic touch screen printing machine

ActiveCN104441936BAvoid the phenomenon of defective productsFully automatic production processScreen printersPrinting press partsScreen printingDry machining

The invention discloses a full-automatic printing machine with a touch screen. According to the technical scheme, the full-automatic printing machine with the touch screen comprises a base, working tables, a feeding device and at least two machining devices; the multiple working tables are installed on the base and are in sliding fit with the base, and the touch screen is accurately driven by a divider to the specified machining procedure; the feeding device comprises a mechanical arm and a CCD detection device installed on the mechanical arm; the at least two machining devices include a silk-screen printing device and a servo position adjustment device; the servo position adjustment device is installed on the silk-screen printing device, the silk-screen printing device is adjusted through the touch screen position fed back by the CCD detection device, and therefore it is guaranteed that the silk-screen printing device directly faces the machining position. The full-automatic printing machine has the advantages that the full-automatic production procedure is achieved; meanwhile, as the multiple silk-screen printing-drying machining devices are arranged, multicolor chromatography can be achieved through one production line, the production efficiency can be greatly improved, and the production cost can be greatly reduced.

Owner:广州泰行智能科技有限公司

Method and device for fault classification of micro vibration motor defects based on convolutional neural network

ActiveCN109946606BImprove detection efficiencyReduce labor production costsImage enhancementCharacter and pattern recognitionGeneration processElectrical resistance and conductance

The invention discloses a defect classification method and device of a micro-vibration motor based on a convolutional neural network. The collected voltage signal images connected in series to both ends of the collection resistance of the micro-vibration motor energization circuit are input to the trained convolutional neural network. The model can realize the accurate identification of the defect types of the micro vibration motor. The whole process is an automatic identification operation, which does not require too many staff to participate in the entire generation process, which greatly improves the detection efficiency and reduces labor production costs.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com