Micro-vibration motor defect failure classification method and device based on convolutional neural network

A technology of convolutional neural network and vibration motor, applied in the direction of biological neural network model, neural learning method, neural architecture, etc., can solve the problems of difficulty in ensuring accuracy and low efficiency, and achieve high-precision detection, high detection accuracy, and improved The effect of poor generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

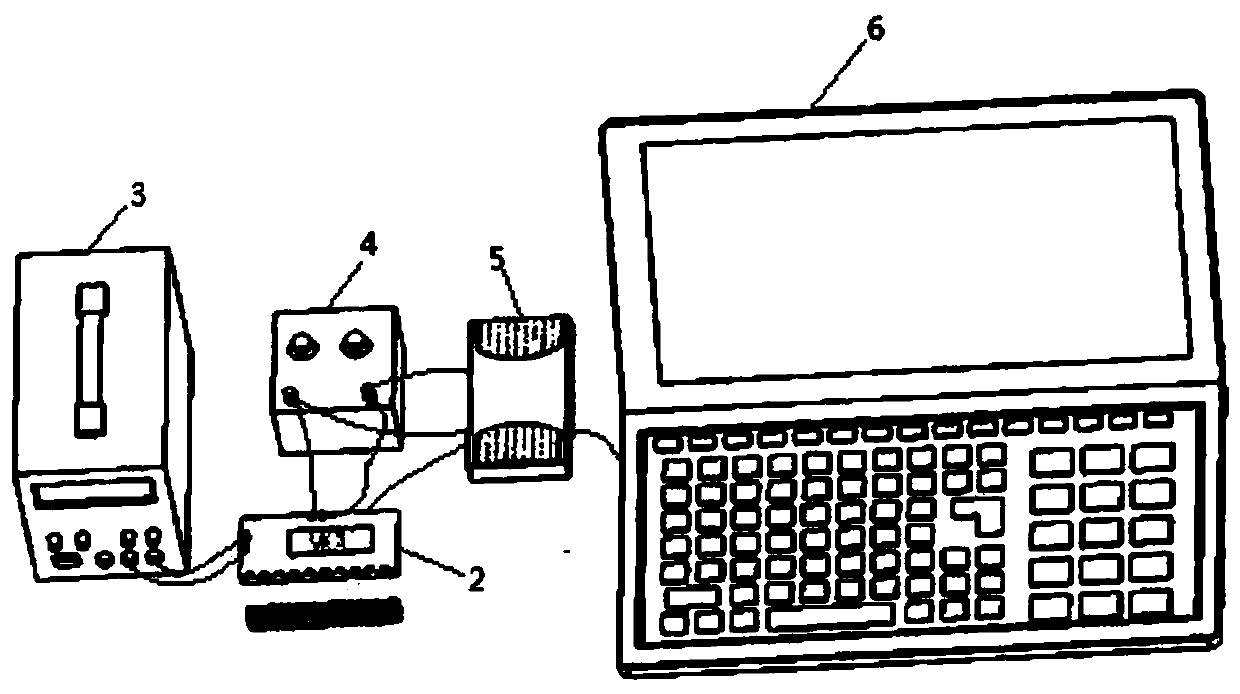

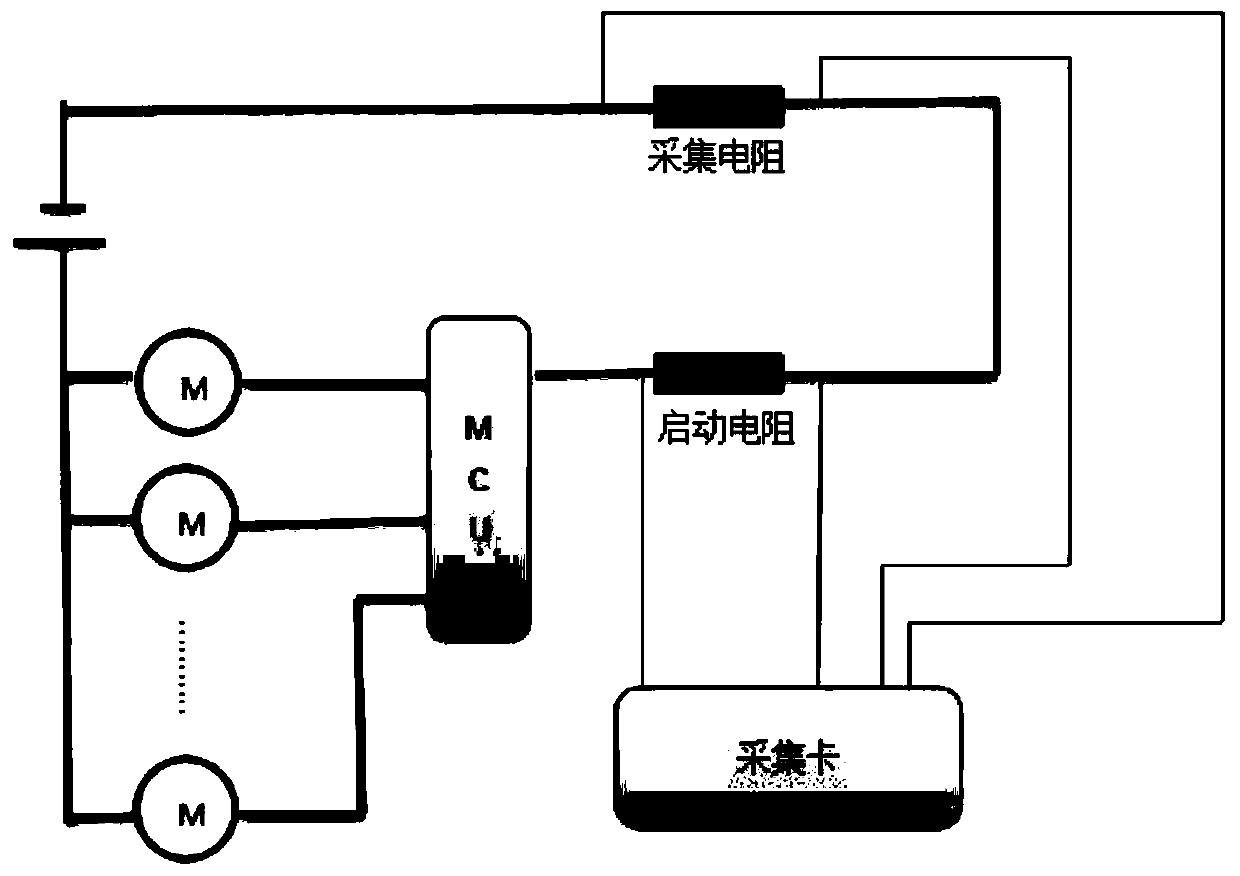

[0044] The micro-vibration motor defect classification device provided in this embodiment, such as Figure 1 to Figure 3 As shown, it includes a micro-vibration motor fixture 1 , a micro-control unit 2 , a power supply 3 , a collection resistor 4 , a start-up resistor, a data collection card 5 and a computer 6 .

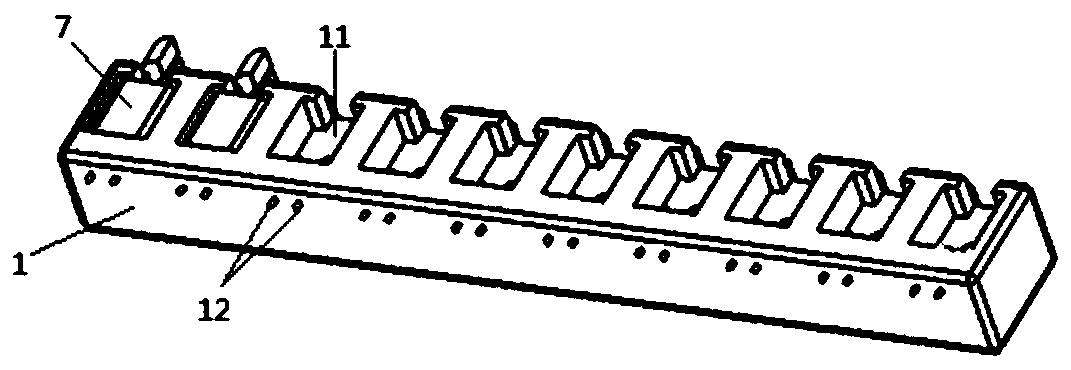

[0045] like image 3 As shown, the micro vibration motor fixture 1 is provided with a number of card slots 11 for installing the micro vibration motor 7, and two electrodes 12 corresponding to the electrical connection ports of the micro vibration motor are designed on one side of the slot wall of the card slot. It matches the appearance of the micro vibration motor; the eccentric block of the micro vibration motor extends from the groove wall on the other side of the slot, and the slot wall of the slot is designed with a limit structure to prevent the axial movement of the micro vibration motor. It is a limit piece fixed on the inner side wall of the card slot, and...

Embodiment 2

[0048] In this embodiment, the labview software is used to collect the voltage signal, and the OpenCV support package of python is used to process the collected voltage signal image. The computers all use serial communication, the host uses its own serial port, the labview software uses the visa serial communication support package, and the python uses the pyseries serial communication support package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com