Curve tracer in symmetrical process

A technology of process curve and trajectory, applied in the field of efficient automatic marking machine, can solve the problems of high labor cost, affecting process quality, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the drawings and embodiments.

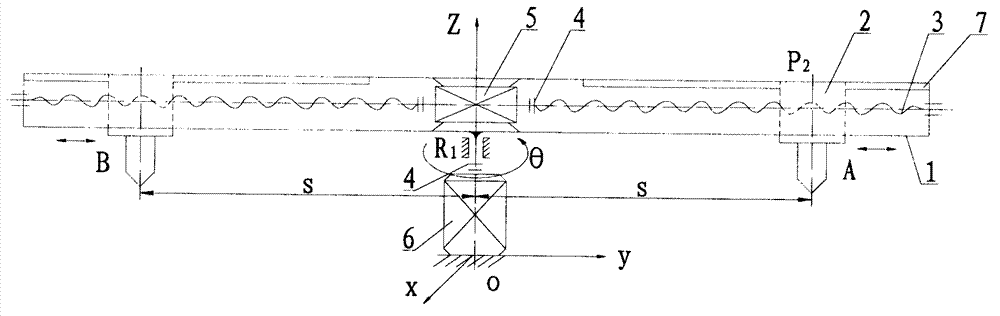

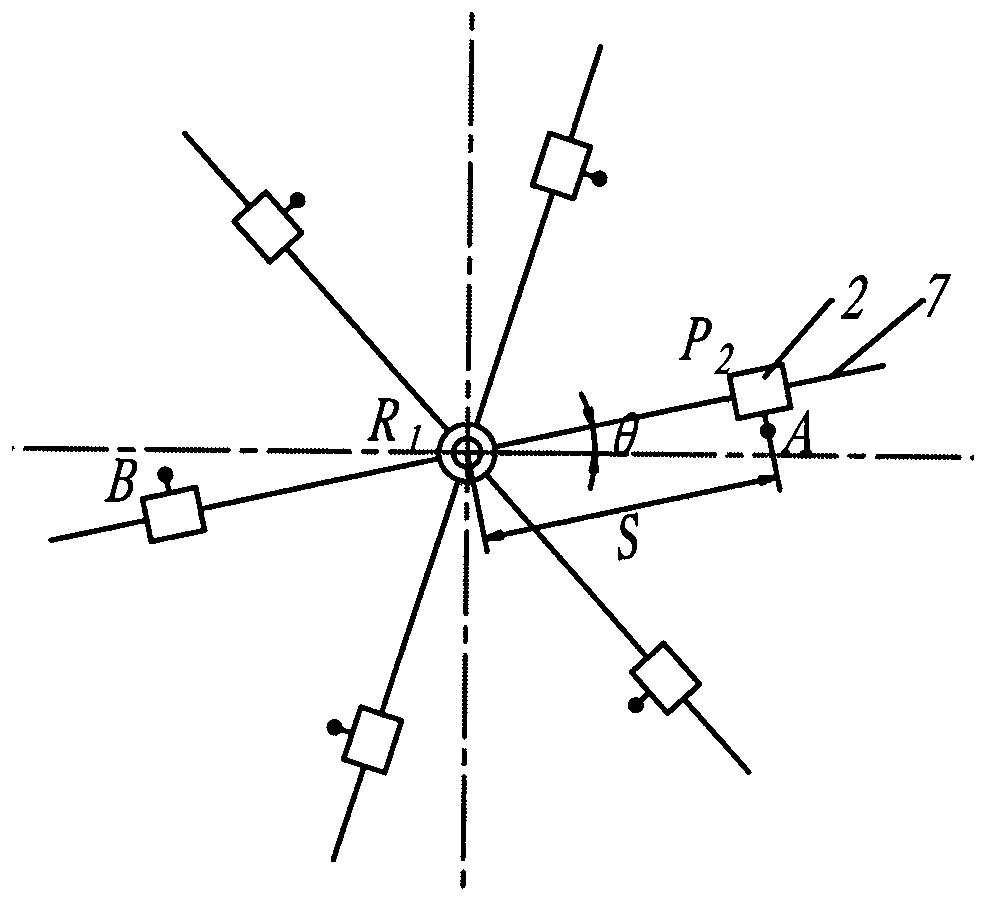

[0009] Attached figure 1 It is a schematic structural diagram of an embodiment of the present invention. The technical solution is: a symmetrical process curve tracker, including frame 0, main arm 1, nut slider 2, screw rod 3, coupling 4, and auxiliary motor 5. , The main motor 6, the guide rail 7, the main arm 1 and the frame 0 form a rotating pair R 1 After that, it is connected with the main motor 6 through the coupling 4, and on the two sides of the main arm 1 centered on the rotation axis Z of the main motor 6 in the length direction of the main arm 1, a pair of screw rods 3 with opposite rotation directions are respectively installed with a nut slider 2 for transmission System, the screw 3 is connected to the auxiliary motor 5 with dual output shafts located in the center of the main arm 1 through the coupling 4, and the nut slider 2 and the guide rail 7 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com