Diamond circular saw blade with nock-type tool bits

A technology of diamond saw blades and cutter heads, which is applied in the field of circular saw blades, can solve the problems of easy breakage of the cutter head, work-related accidents of the cutter head, waste of resources, etc., reduce the probability of matrix fracture, reduce labor production costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

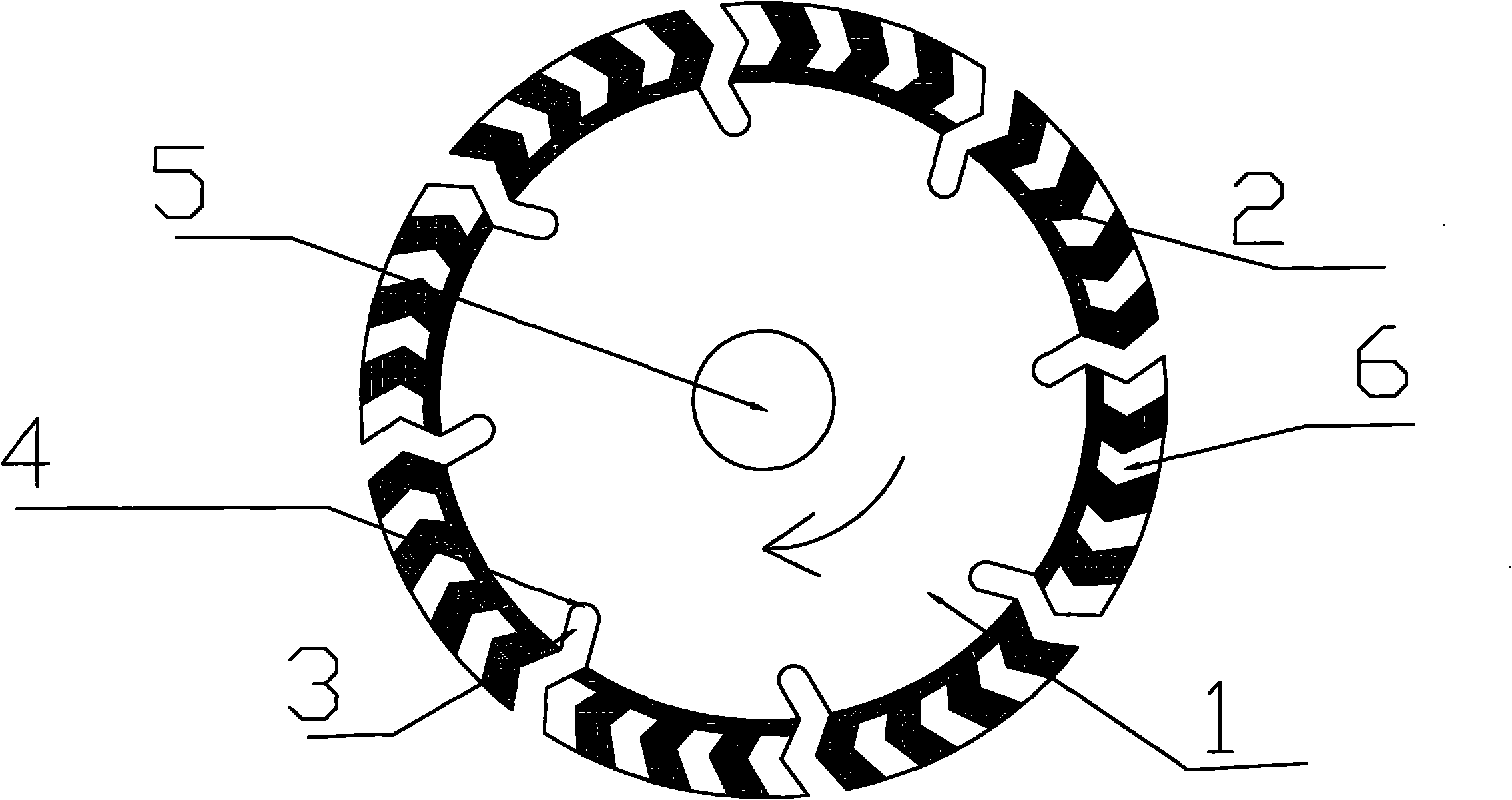

[0016] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0017] As shown in Figure 1, the present invention consists of a base body 1 and a cutter head 2. The inclination angle of the water tank 3 on the base body 1 is 25 degrees, and is evenly distributed on the inner surface of the outer circumference of the base body 1. The bottom of the water tank 3 has a smooth arc 4. The cutter head 2 is designed as an arrow-tail type, and the base body 1 is a flat circular steel plate with a central hole, which rotates in the direction indicated by the> block of the cutter head 2. On the same side of the cutter head 2, one of them is an odd-numbered groove, and the adjacent one is an even-numbered groove, which are arranged alternately to ensure that the weights on both sides of the substrate 1 are the same, so that the diamond saw blade can ensure stability during rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com