Automatic discharging device of aluminum alloy sawing center robot

A technology of automatic unloading device and robot, which is applied in metal processing and other fields, can solve the problems of low production efficiency and high labor force, and achieve the effects of improving production efficiency, reducing labor force, and saving labor production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

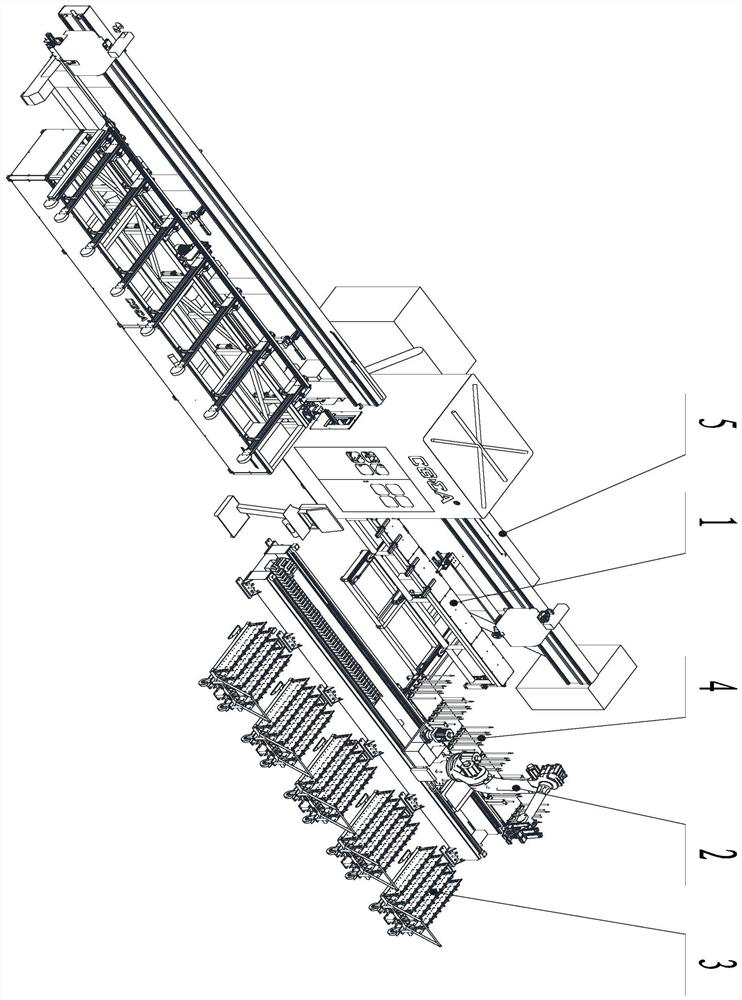

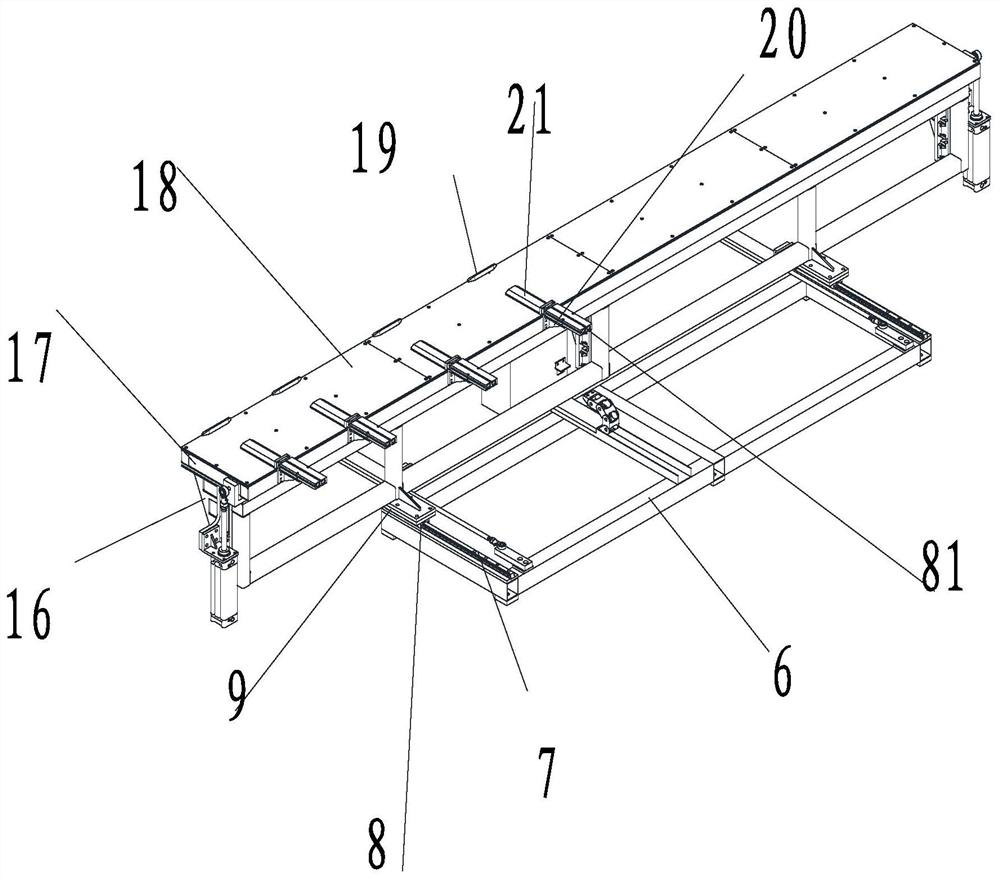

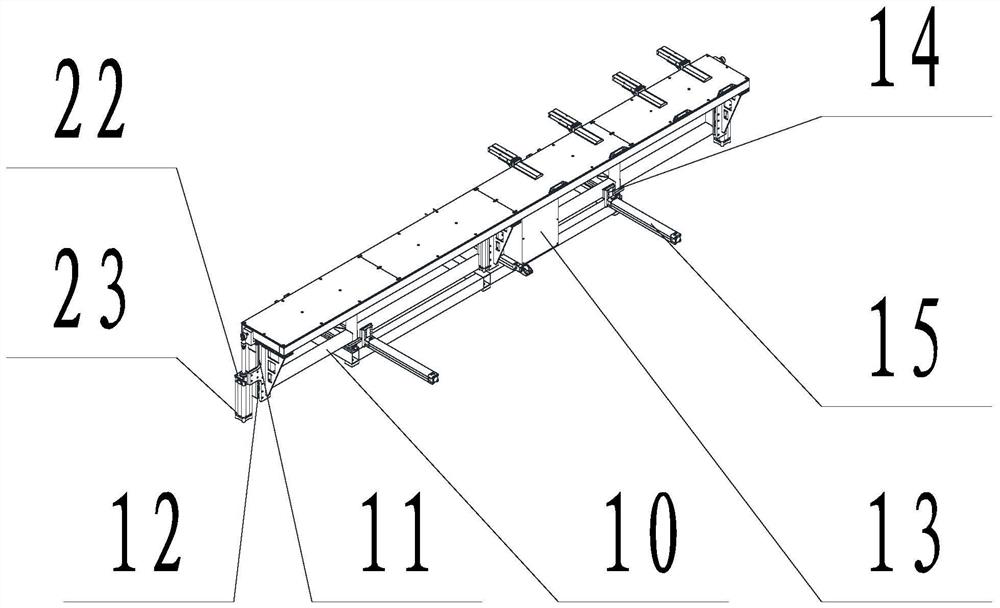

[0033] Such as Figure 1-14 As shown, an automatic unloading device for an aluminum alloy sawing center robot includes a discharge table mechanism 1, a joint robot mechanism 2, a molded material cart 3, a surplus material cart 4, and a control system 5.

[0034] After the pumping mechanism of the CNC sawing center of aluminum profiles pumps the sawed profiles onto the discharge worktable 18, one side of the profiles is positioned by the profile support plate 19, and the profile pressing cylinder 81 drives the profile pressing block 21 to press the profiles The other side of the profile is compressed. After the profile is pressed, the lifting cylinder 23 drives the workbench parts to descend along the guide rail B12 through the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com