Crankcase plug riveting device

A crankcase and riveting technology, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of difficulty in controlling the riveting depth of the plug, affecting the assembly quality, and high labor intensity, so as to eliminate workpiece damage and Potential safety hazards, reducing labor production costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

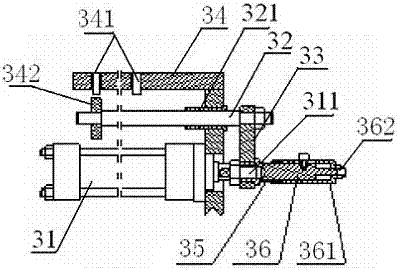

[0030] According to the position of the oil passage plug on the crankcase body that needs to be riveted in, determine that the crankcase body plug should be riveted from several different directions around the side of the case body. Yingquan calculates how much pressure is needed to press the plug into place, and then selects an oil cylinder with a suitable bore diameter according to the calculated pressure.

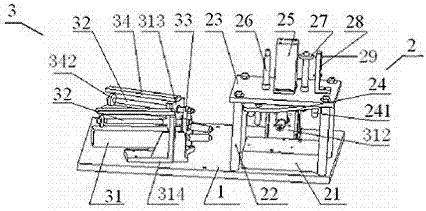

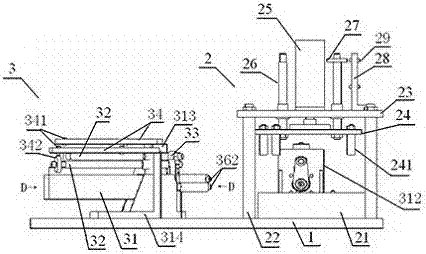

[0031] The invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5-1 , Figure 5-2 As shown, a crankcase plug riveting device includes a base 1 , a workpiece positioning and clamping mechanism 2 and a riveting actuator 3 arranged on the same base 1 .

[0032] The workpiece positioning and clamping mechanism 2 includes a workpiece supporting seat 21 fixedly connected with the base 1, a supporting column 22, a workpiece pressing rod 241, a pressing plate 24, an upper supporting plate 23 and a workpiece clamping oil cylinder 25 arranged sequentially from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com