Full-automatic multifunctional complete set of stone processing equipment and processing method

A stone processing, multi-functional technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of uneven surface of the bottom plate, low degree of automation, low production efficiency, etc., to achieve a small number of workers and a high degree of automation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and practical implementations.

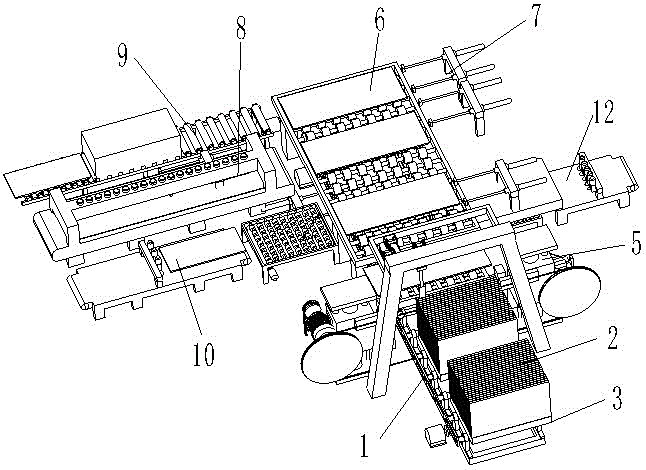

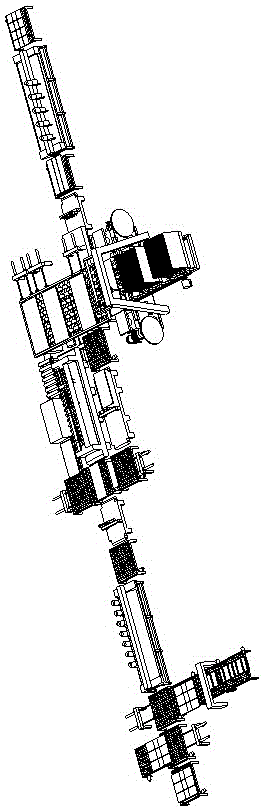

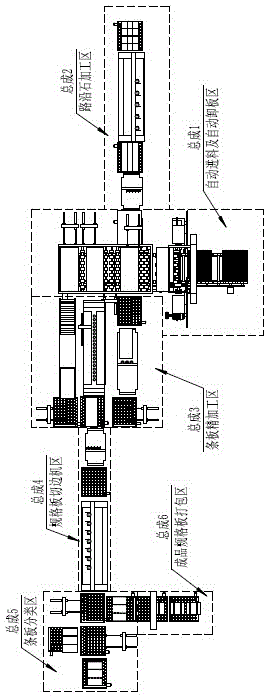

[0033] The full-automatic multi-functional stone processing equipment of the present invention comprises a machine body 1 and a feeding conveyor belt 3 arranged on the machine body 1 for transporting blocks 2, and the feeding conveyor belt 3 is provided with cutting strips 4 and blocks. 2 The cutter 5 connected to the bottom, the feed conveyor belt 3 is also provided with a discharge conveyor belt 6 located on its upper layer, and several groups of cylinder push rods 7 are arranged on the side of the discharge conveyor belt 6, One side of the conveyor belt 6 relative to the cylinder push rod is provided with a stone polishing machine 8, a fire board machine 9 or a stone lychee noodle processing machine 10, and an oil cylinder push rod 11 is also provided on the described feed conveyor belt 3. The side with the relative oil cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com