Slat automatic feeding and unloading mechanism and working method

An automatic feeding and unloading machine technology, applied in the direction of working accessories, conveyors, manufacturing tools, etc., can solve the problems of low degree of automation, uneven floor surface, and inability to improve production efficiency, so as to achieve less workers and higher degree of automation High, saving labor production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and actual implementations.

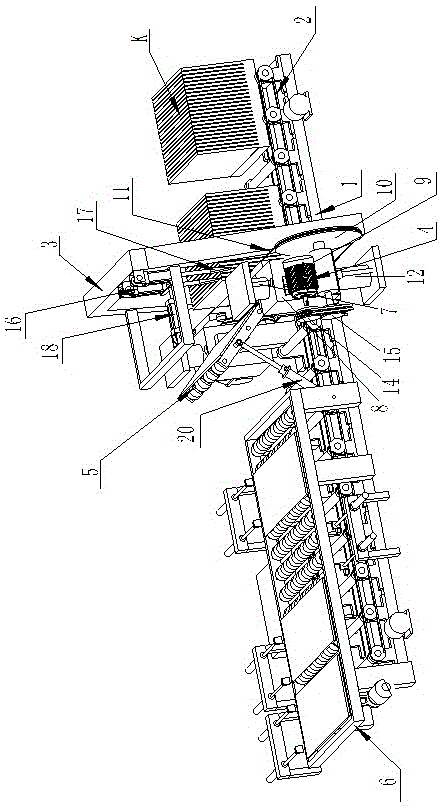

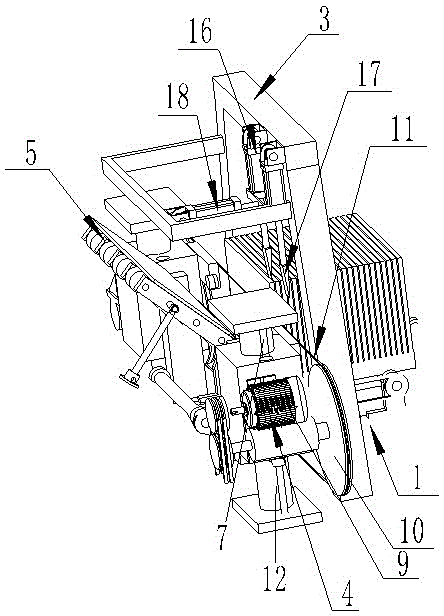

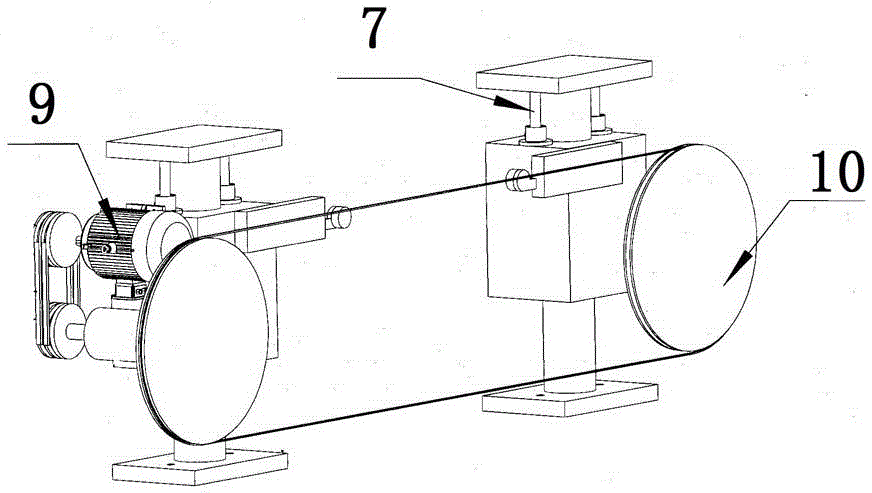

[0026] The automatic slat feeding and unloading machine of the present invention includes a body 1 and a feeding conveyor belt 2 arranged on the body 1 for conveying blocks K. The conveyor belt is provided with a discharge rack 3, and the body 1 There is a cutter 4 for cutting off the connection between the slats and the bottom of the block. The unloading rack 3 is provided with a reversible slat support plate 5 for receiving the slats. There is a slat discharge conveyor belt 6, the cutter 4 can be a circular saw, a band saw, etc., the reversible slat support plate 5 has two stations, one station is close to the surface of the slat to be cut, and the other One station is docked with the discharge conveyor belt 6, so that the slats on the reversible slat support plate 5 are conveyed to the discharge conveyor 6, and the plates on the reversible slat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com