Ingot-suspended automatic spinning machine

A suspended spindle-type, automatic technology, which is applied in the bundles of newly ejected filaments, textiles and papermaking, etc., can solve the problems of poor quality promotion, corrosion, high power consumption, etc., and achieve the effect of expanding the use area.

Inactive Publication Date: 2011-09-21

张钦桂

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Viscose filament is a wet-spinning process, and doffing must be done manually. Carbon disulfide gas in the spinning workshop is unavoidable for workers, and workers must be replaced every 3 to 5 years. / l Corrosion is serious, and it has become a problem in the world that the general doffing mechanism cannot enter

The fully continuous spinning machine has been introduced abroad, but it is difficult to popularize because of large equipment, high power consumption and poor quality.

In addition, due to the limitations of workers doffing, the spinning speed R531 91m / min, R53580m / mm can not be increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0023] 1. It is difficult to press the upper cover of the centrifugal cylinder at high speed, and the manual test has been simulated successfully.

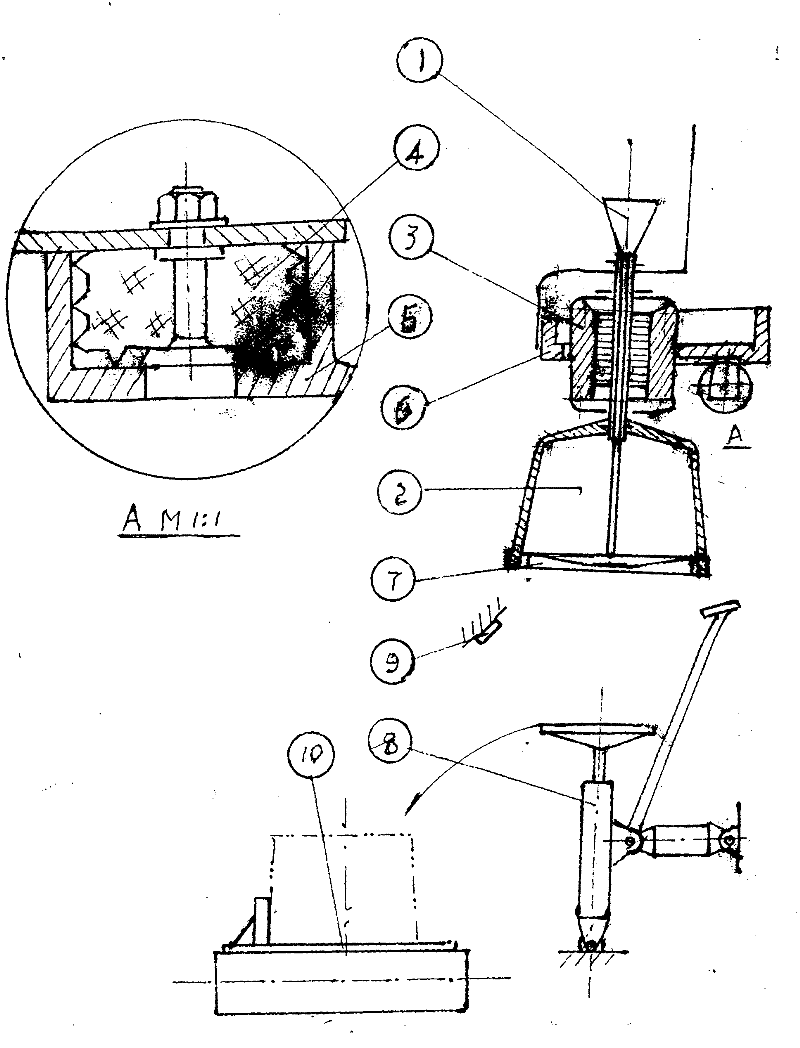

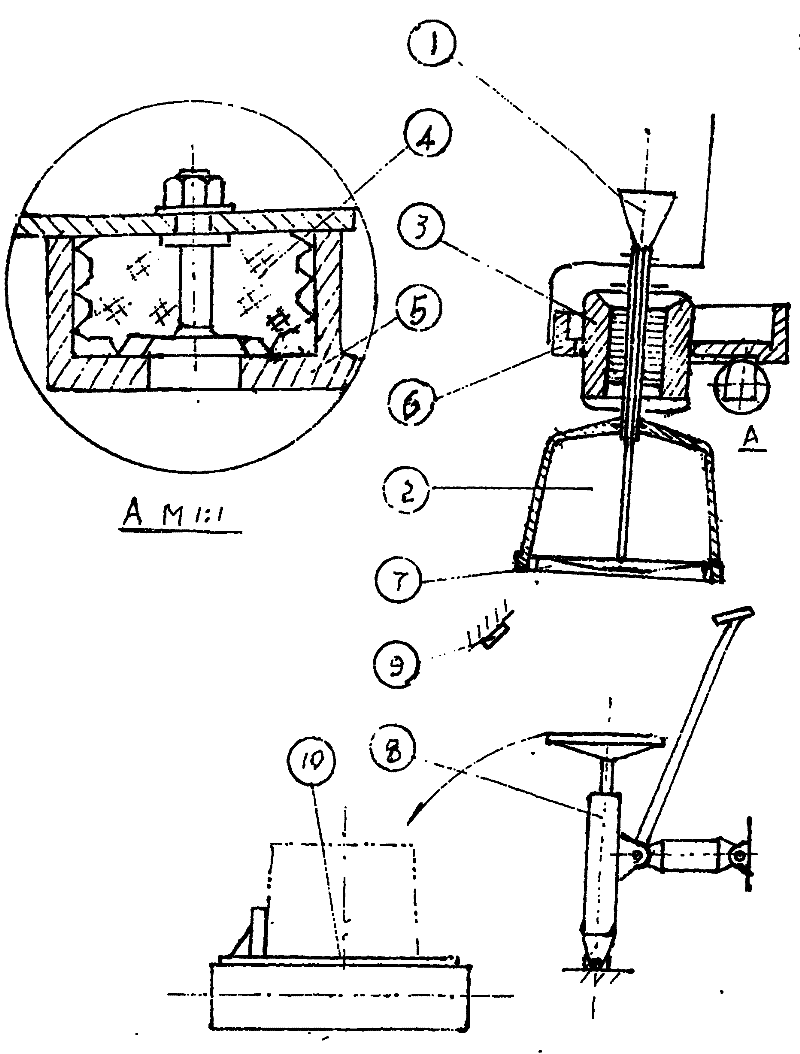

[0024] 2. Suspension spindle is an important part and CN200710071331, 4 patented energy-saving centrifugal cylinder should be used

[0025] 3. The suspended spindle automatic doffing machine can increase the spinning speed and must adopt the ZL88104569.1 patented technology.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Forty thousand viscose filament yarn spinning workers exist in China at present, but have to change jobs every 3-5 years as suffering from carbon bisulfide gas; and since the acid bath for the wet spinning technique of viscose filament yarn uses 240 g / l sulfuric acid which is seriously corrosive, a common spinning mechanism can not be easily available, and the spinning can only be carried out manually, which is a problem in the world. A full continuous spinning machine has appeared abroad; however, by using the full continuous spinning machine, the after-treatment technique of the spinning cake must be moved onto the spinning machine for monofilament treatment, and thus, the full continuous spinning machine has the defects of huge equipment, high power consumption and poor quality of rayon filament, and is hard to popularize. The ingot-suspended automatic spinning machine disclosed by the invention uses an energy-saving centrifugal cylinder CN200710071331,4 as the main body, can operate instead of human labor, and thus, relieves the workers of the damage from carbon bisulfide gas, thereby lowering the labor and production cost. By the aid of Patent ZL88104569 technology, the invention can increase the spinning speed by 20% as compared with the prior art, and can also save powder of electric ingot consumption by 30% on the basis of the energy-saving centrifugal cylinder. The spinning cake can be directly released from the factory, thereby widening the application range and benefiting the social production.

Description

Technical field: [0001] The invention relates to a suspension-type automatic doffing machine for viscose filament centrifugal spinning machines, which can transform all centrifugal spinning machines, and can also design and manufacture new suspension-type automatic doffing spinning machines. technical background: [0002] Viscose filament is a wet-spinning process, and doffing must be done manually. Carbon disulfide gas in the spinning workshop is unavoidable for workers, and workers must be replaced every 3 to 5 years. / l Corrosion is serious, and it has become a worldwide problem that the general doffing mechanism cannot enter. Foreign countries have introduced full continuous spinning machines, but they are also difficult to popularize because of large equipment, high power consumption, and poor quality. In addition, due to the limitations of workers doffing, the spinning speed R531 91m / min, R53580m / mm can not be increased. Invention content: [0003] A suspension-ty...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D7/02

Inventor 张钦桂

Owner 张钦桂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com