Intensive large-scale ion-type rare earth ore leaching mother liquor continuous treatment system and method

A technology of ion-type rare earth ore and processing system, which is applied in the field of intensive large-scale continuous treatment system for leaching mother liquor of ion-type rare earth ore. Clear liquid discharge control varies from person to person, to achieve precise control of impurity removal pH and precipitation pH, saving labor production costs, and improving occupational hygiene conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

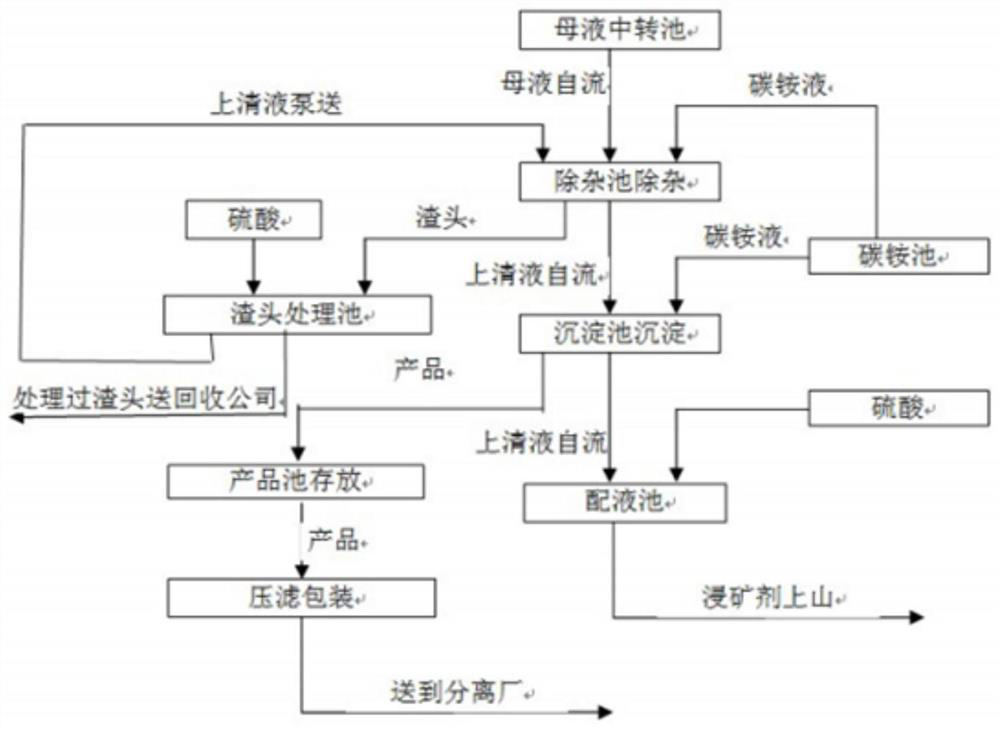

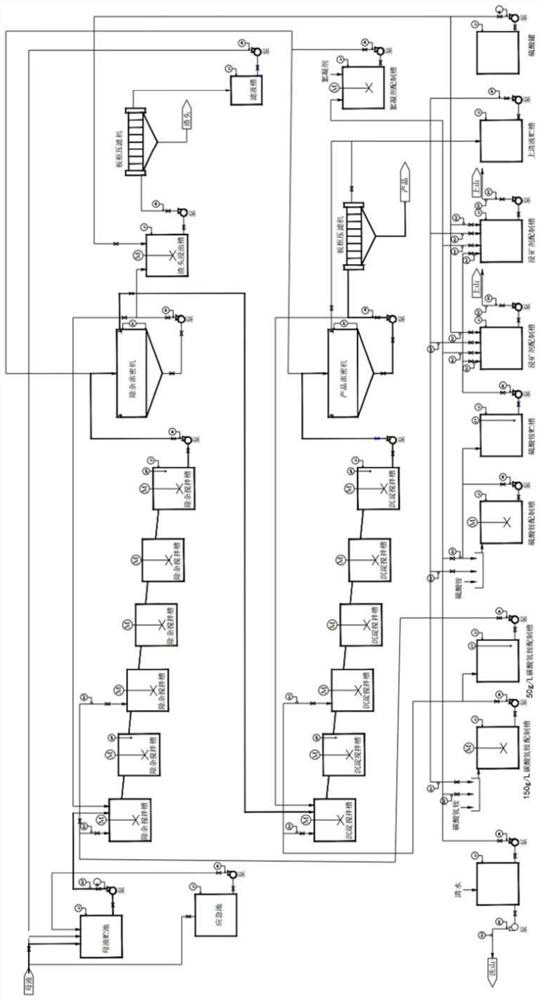

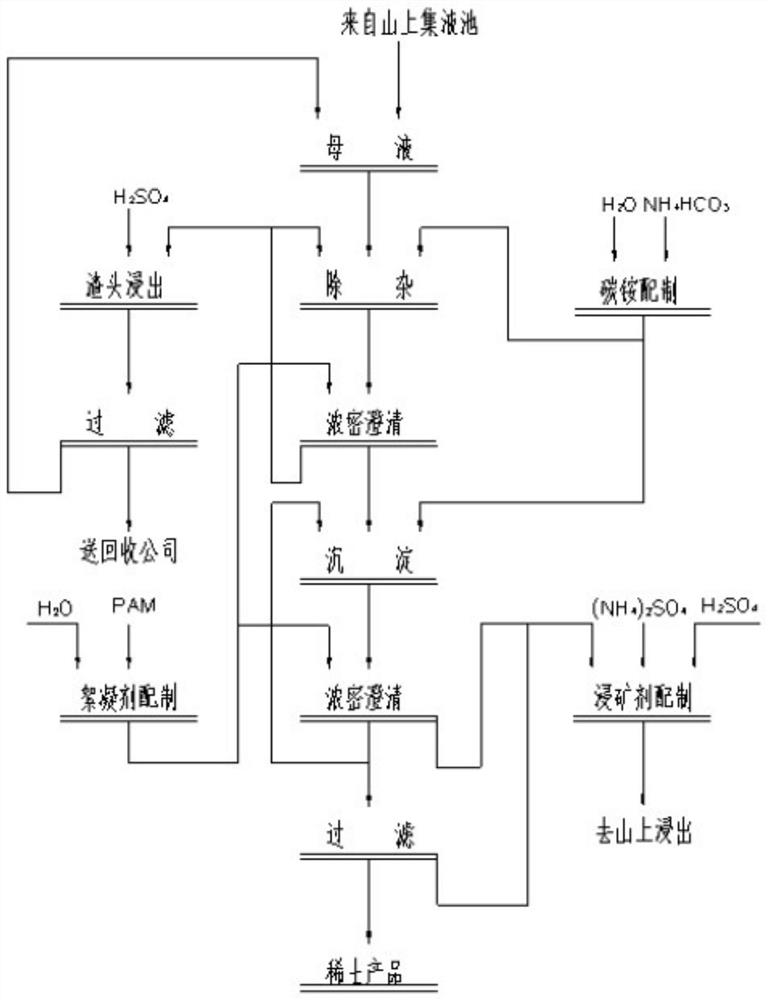

[0114] Using the intensive large-scale ion-type rare earth ore leaching mother liquor continuous treatment system of the present invention, the total stirring time of the multi-stage series impurity removal stirring module stirring is 60min, adding mother liquor and 50g / L ammonium bicarbonate solution, continuous reaction, according to mine collection The amount of mother liquor, set the mother liquor flow rate, control the appropriate ammonium bicarbonate flow rate to achieve the required target pH, add 50g / L ammonium bicarbonate solution, the pH value of the second stage is controlled to 5.2, and the pH value of the sixth stage is controlled to 5.4.

[0115] The time and conditions of thickening and aging are all carried out in the thickening tank, which realizes solid-liquid separation and aging function at the same time, and the aging time is 8 days.

[0116] The total stirring time of the multi-stage series precipitation stirring module is 60min, adding 150g / L ammonium bic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com