Automatic cage pulling device of cage type operation in fishery production

A cage-type, working technology, applied in the fields of animal husbandry, fishing, application, etc., can solve the problems of high labor intensity, high labor consumption and high skill, and achieve the effect of low production cost, simple structure and use, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

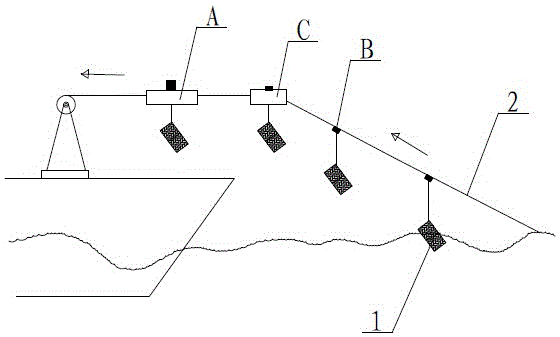

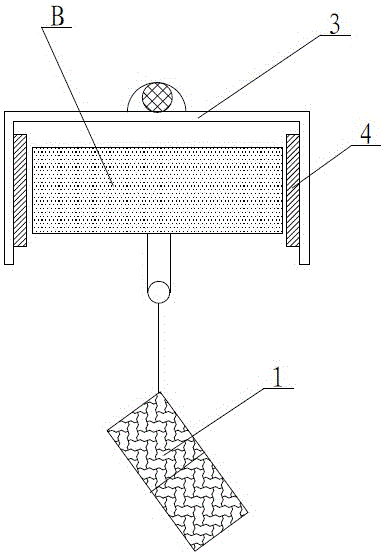

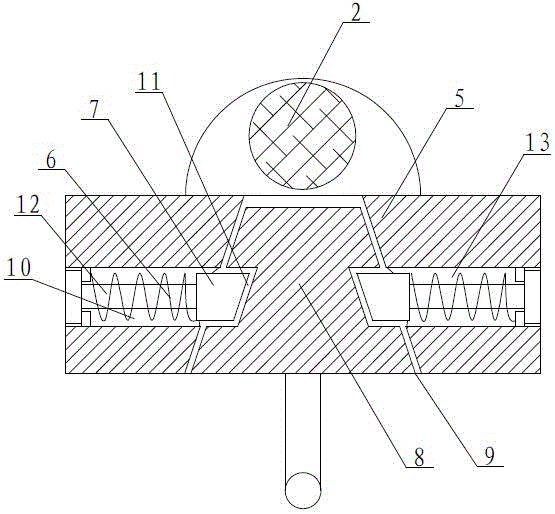

[0018] As shown in the figure, an automatic cage-drawing device for cage-type operations in fishery production includes a power source, a trapping cage 1, and a main rope 2. The power source is used to pull the main rope 2, and the main rope 2 drives the trapping cage 1 and also It includes a decoupling mechanism A, the decoupling mechanism A includes a fixed frame 3, a driver 4, and a connector B, the driver 4 is installed on the fixed frame 3, and the connector B includes a shell 5, an elastic member 6, and a lock tongue 7 and the inner core 8, the outer shell 5 is connected with the main rope 2, the lower end of the outer shell 5 is provided with an inner cavity 9 for the inner core 8 to slide into, and the side of the outer shell 5 is provided with an inner cavity 9 communicating with the inner cavity 9 The chute 10, the lock tongue 7 can slide along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com