Technique for roasting and dressing laterite nickel ore

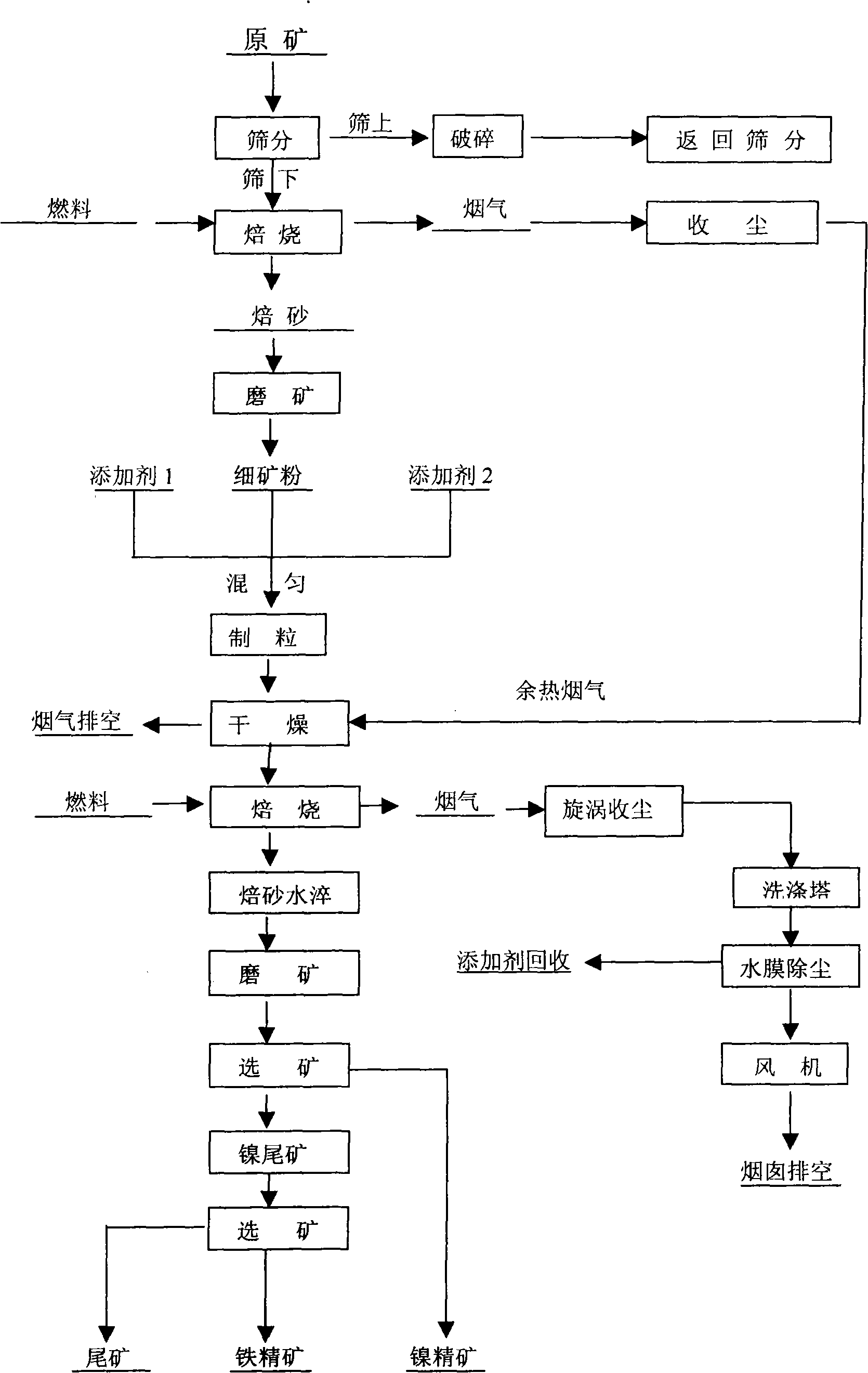

A technology of laterite nickel ore and process method, which is applied in the field of laterite nickel ore treatment and beneficiation, double kiln roasting-mineralization treatment of laterite nickel ore, which can solve the problems of difficult post-processing, large amount of chlorinating agent, and high roasting temperature. Achieve the effects of strong equipment reliability, strong raw material adaptability, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The lateritic nickel ore contains 0.94% nickel, 0.06% cobalt, and 50.14% iron. The ore is roasted at 750°C for 30 minutes in the first rotary kiln, and the calcine is cooled and then ground. The ground calcine is mixed with 4 % coke powder and 6% calcium chloride are mixed into pellets, the diameter of the pellets is 6-12mm, the pellets are dried at 150°C for 1 hour, and the dry pellets are roasted in the second rotary kiln at a roasting temperature of 900°C to control the low oxygen content in the tail gas 2%, roasting time 50 minutes, water quenching and grinding after calcined sand is released, and the pulp is separated by a magnetic separator with medium magnetic field strength. The nickel concentrate contains 11.2% nickel, 0.65% cobalt, and the nickel recovery rate is 80%. The concentrate is flotation, and the nickel content of the concentrate after flotation is 18.0%; the tailings are separated by strong magnetic separator, shaker and flotation machine, and the iro...

Embodiment 2

[0027] The lateritic nickel ore contains 1.42% nickel and 22.50% iron. The ore is roasted at 600°C for 20 minutes in the first rotary kiln, and the calcine is cooled and then ground. The ground calcine is mixed with 6% charcoal powder, 10 % Calcium chloride dihydrate mixed pellets, pellet diameter 10-12mm, pellets were dried at 150°C for 1 hour, dry pellets were put into the same rotary kiln for roasting, roasting temperature was 1000°C, and the oxygen content in the tail gas was controlled to be less than 2% , the roasting time is 120 minutes, water quenching and grinding after the calcined sand is released from the furnace, the pulp is separated by a magnetic separator with a medium magnetic field strength, the nickel concentrate contains 16.7% nickel, and the nickel recovery rate is 85%; the concentrate is flotation, floatation The nickel content of the concentrated ore after beneficiation is 24.3%.

Embodiment 3

[0029] The lateritic nickel ore contains 1.85% nickel and 12.83% iron. The ore is roasted in the first rotary kiln at 900°C for 90 minutes. After the calcine is cooled, it is ground. % Sodium chloride mixed pellets, pellet diameter 10-20mm, pellets dried at 150°C for 1 hour, dry pellets into the second rotary kiln for roasting, roasting temperature 1100°C, control the oxygen content in the tail gas to less than 2%, roasting The time is 180 minutes. After the calcined sand is released from the furnace, it is water quenched and ground, and the pulp is separated by a magnetic separator with a medium magnetic field strength. The nickel content of the nickel concentrate is 22.9%, and the nickel recovery rate is 86%. The concentrate is flotation, and after flotation The concentrate contains 31.2% nickel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com