Method for assembling touch screen foam of smart phone

A smart phone and assembly method technology, applied to the structure of telephones, etc., can solve the problems of production and punching environment, high product defect rate, TP foreign matter dust spots, etc., to reduce defect rate and production cost , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

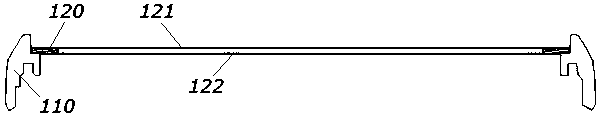

Image

Examples

Embodiment Construction

[0018] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

[0019] When the existing touch screen foam is pasted on the front case of the smart phone alone, the width of the suspended part of the touch screen foam is much larger than the width pasted on the front case, which may be caused by collapse, extrusion or Therefore, those skilled in the art usually stick the touch screen foam to the touch screen of the smart phone first, and then assemble it on the front shell in the form of components. The method of affixing the touch screen foam to the front case will not adopt the method of supplying the touch screen foam and the front case in the form of components to the production line of the smart phone for assembly.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com