Battery pack upper cover full automatic glue coating installing system

An installation system, fully automatic technology, applied in the direction of battery cover/end cover, battery pack components, battery box/jacket, etc., can solve the problem of glue type and dosage cannot be guaranteed, affecting the overall performance of the battery pack, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

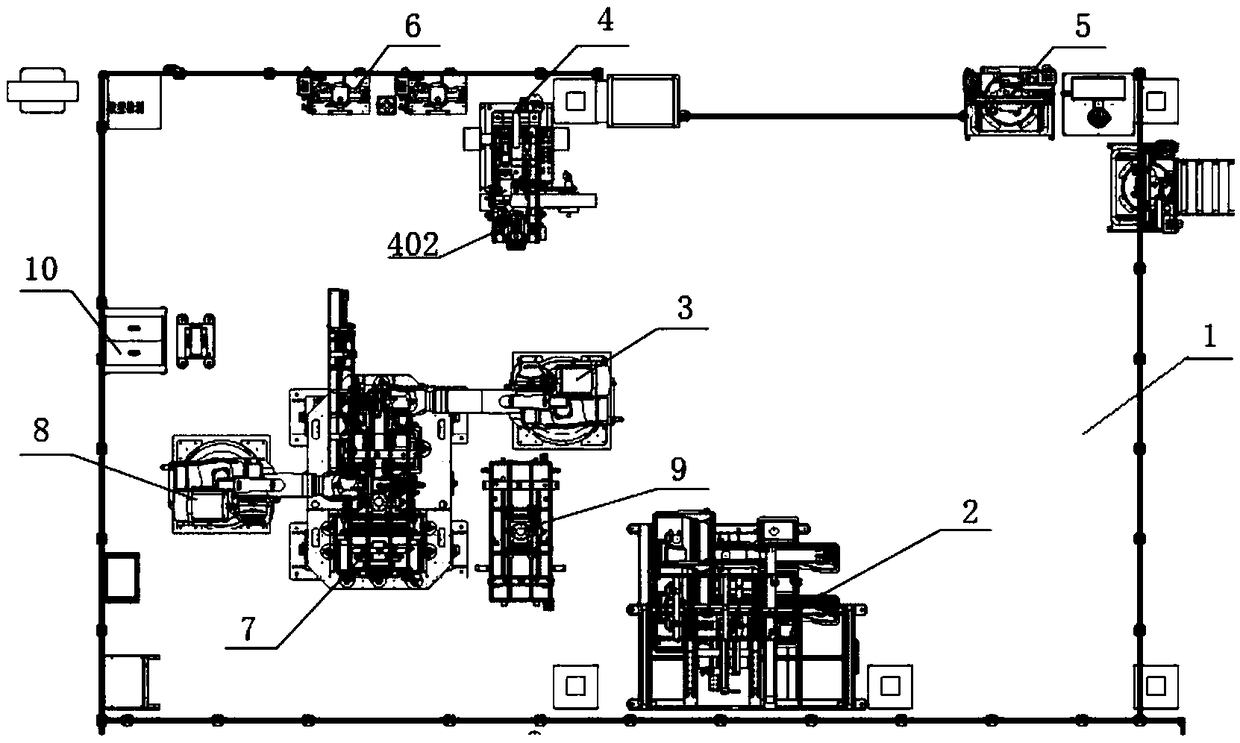

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , a fully automatic gluing installation system for the upper cover of the battery pack provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the system includes a workbench 1, and the workbench 1 is used to carry various components;

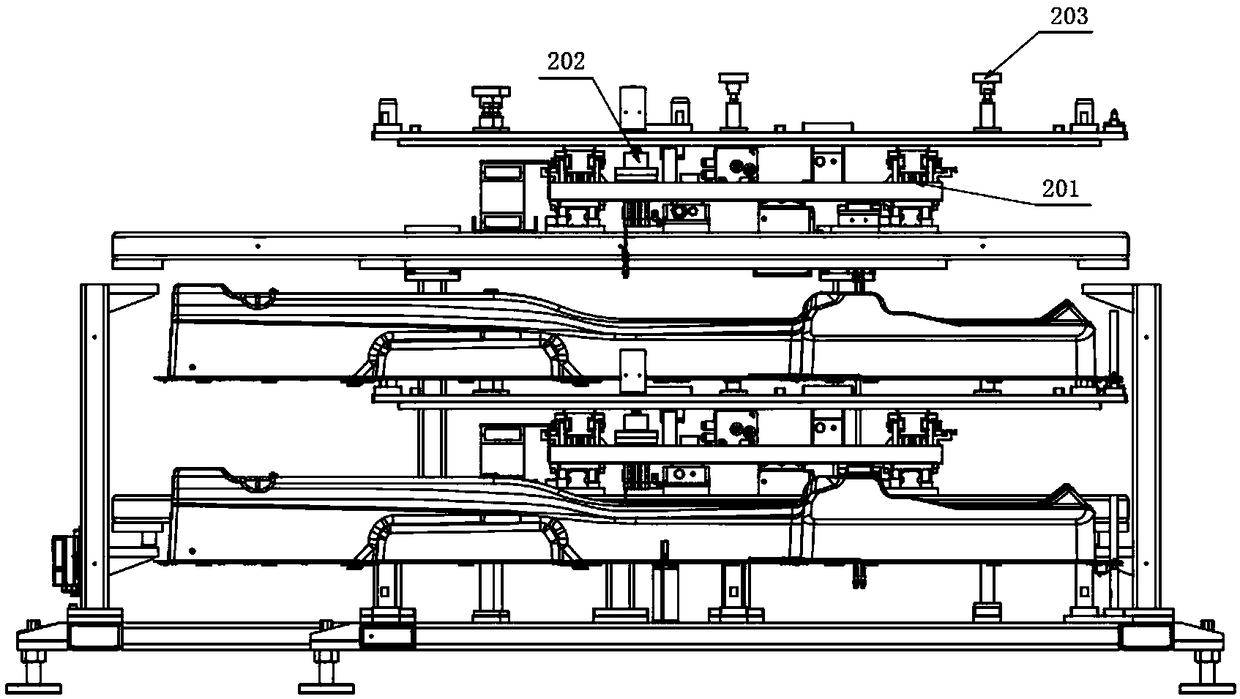

[0033] The static material rack 2 is used to provide the upper cover of the battery pack to be glued; the static material rack includes a translation assembly 201 , a positioning assembly 202 and a workpiece support assembly 203 .

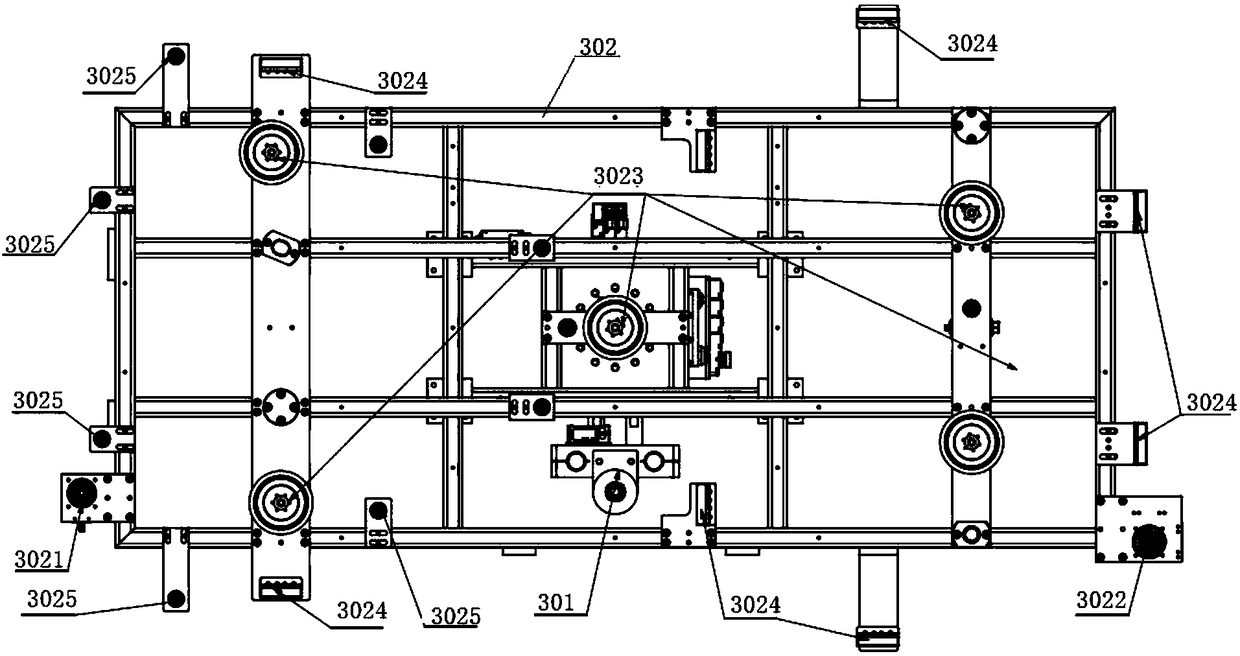

[0034] Glue-applying robot 3, described gluing-applying robot 3 comprises photographing assembly 301, carrying clamp 302 and is used for realizing described photographing assembly 301 and the quick-change plate of described carrying clamp 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com