Fuel-injector high-precision automatic wire winding device and method thereof

An automatic winding, high-precision technology, used in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as inability to meet, poor consistency, low efficiency, etc., to avoid loose or broken windings , Appropriate degree of tightness, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

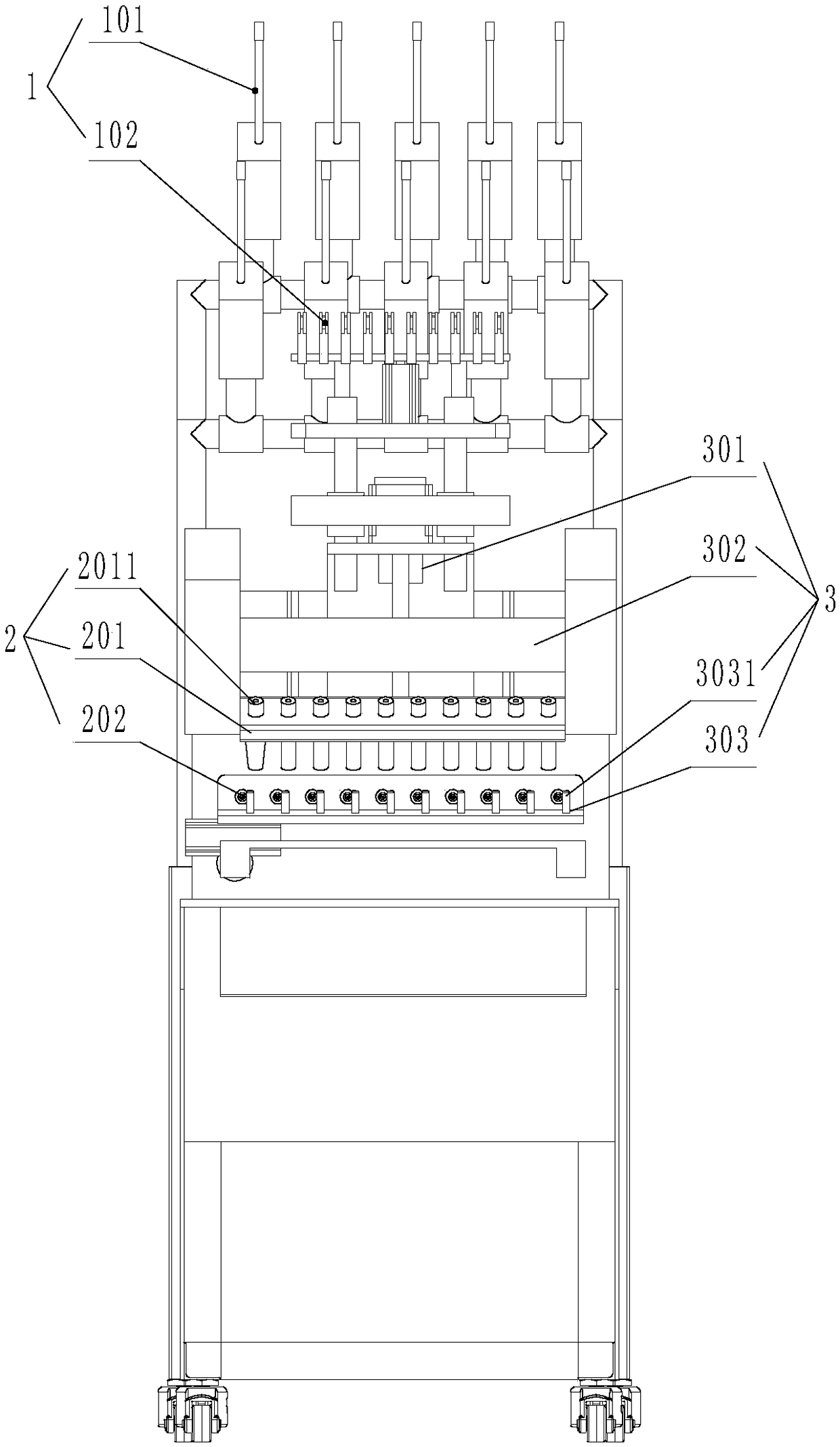

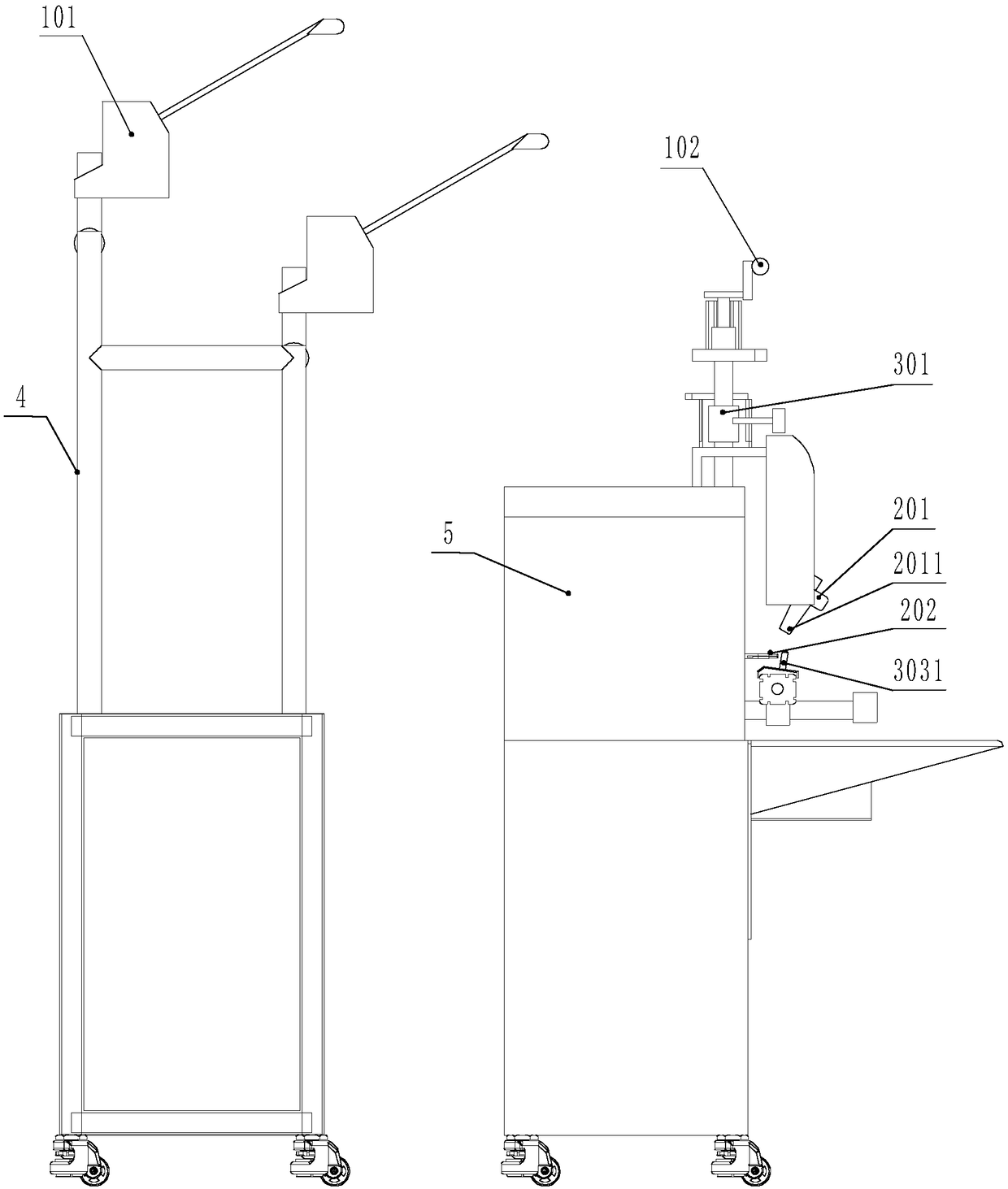

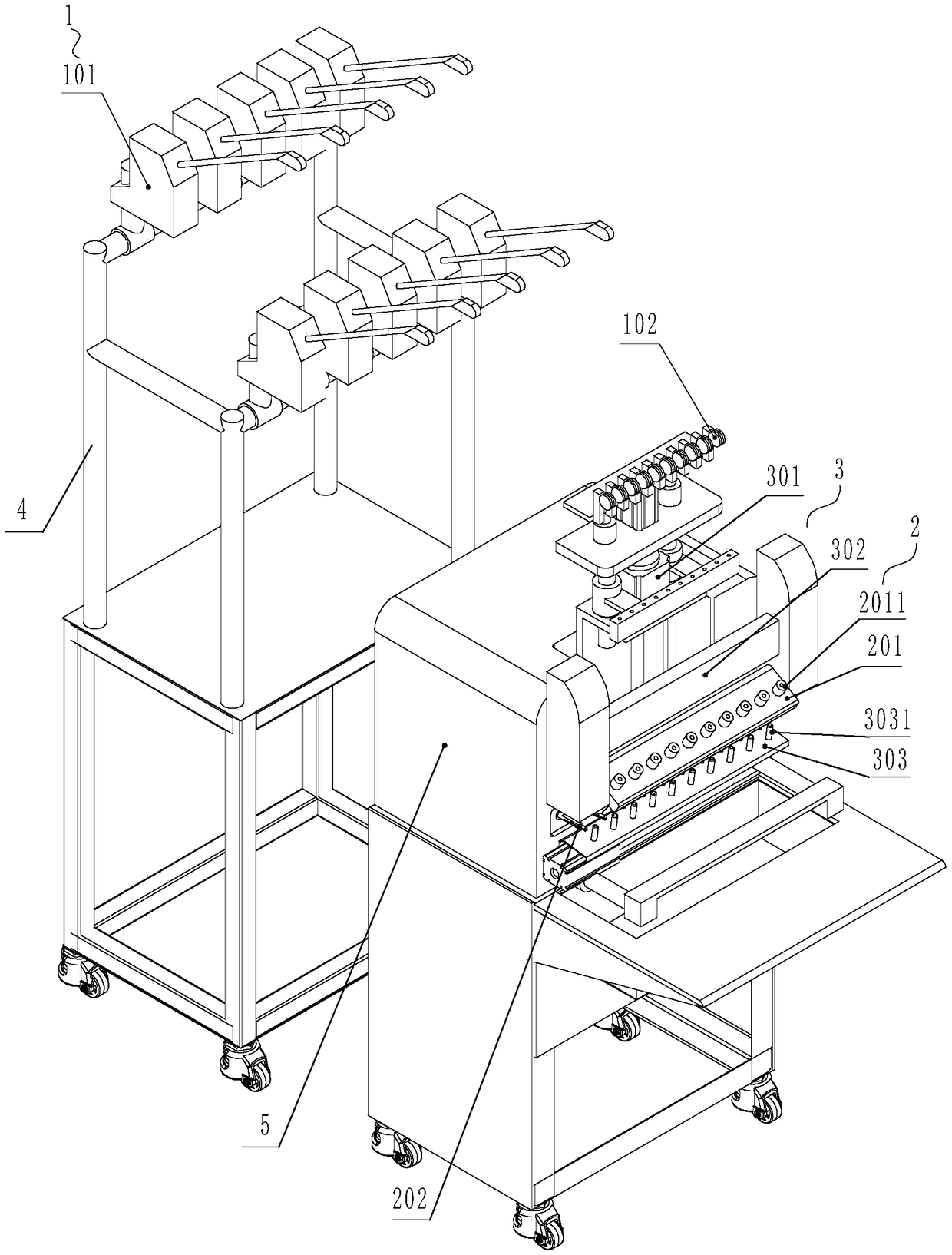

[0060] A high-precision automatic winding device for a fuel injector, comprising a tension control mechanism 1, a main winding mechanism 2, a coil tap winding mechanism 3; a control system; the control system is connected with the tension control mechanism 1 and the main winding mechanism respectively 2. The coil tap winding mechanism 3 is connected. in:

[0061] The tension control mechanism 1 is used to keep the tension of the wire stable during the winding process, so that the coil can be wound neatly while avoiding loosening or breaking of the winding. This tension control mechanism 1 comprises electronic tension device 101, guide wheel 102, and electronic tension device 101 is installed on the pay-off frame 4, and the tension control precision of this electronic tension device 101 is ± 0.5g, and electronic tension device 101 and control system The input and output ends are connected; the guide wheel 102 is installed on the top of the coil tap winding mechanism 3 for guid...

Embodiment 2

[0066] A method for high-precision automatic winding of a fuel injector, the method comprising the following steps:

[0067] S1. Waiting to start

[0068] After the wire is stably adjusted by the electronic tensioner 101 of the tension control mechanism 1 (the tension control accuracy is ±0.5g), it passes through the guide wheel 102 and the wire arranging needle 2011 of the wire arranging mechanism 201 in sequence, and then winds up to the thread breaking mechanism 303 On the pin 3031 of the fuel injector, the high-precision automatic winding device of the fuel injector is waiting to start production;

[0069] S2. The first tap of the wound coil

[0070] When the bobbin is sent to the station and the control system receives the start command, the control system controls the lifting mechanism 301 of the coil tap winding mechanism 3 to move up and down and the left and right moving mechanism 302 of the thread end to move left and right, and wind the terminal at one end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com