Shuttlecock

A badminton and hair planting technology, applied in the field of badminton, can solve the problems of high labor cost, many production processes, unqualified badminton, etc., and achieve the effects of reducing production cost, avoiding unqualified products, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

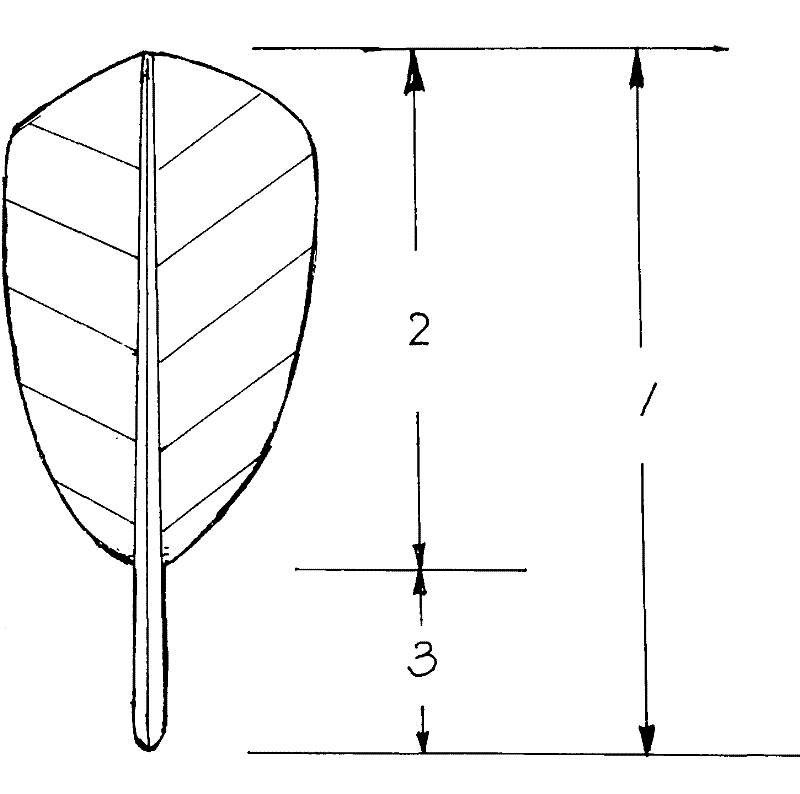

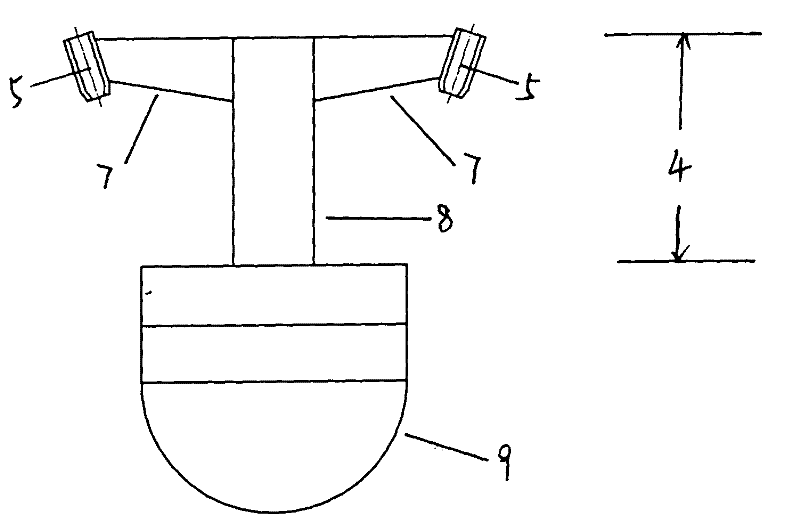

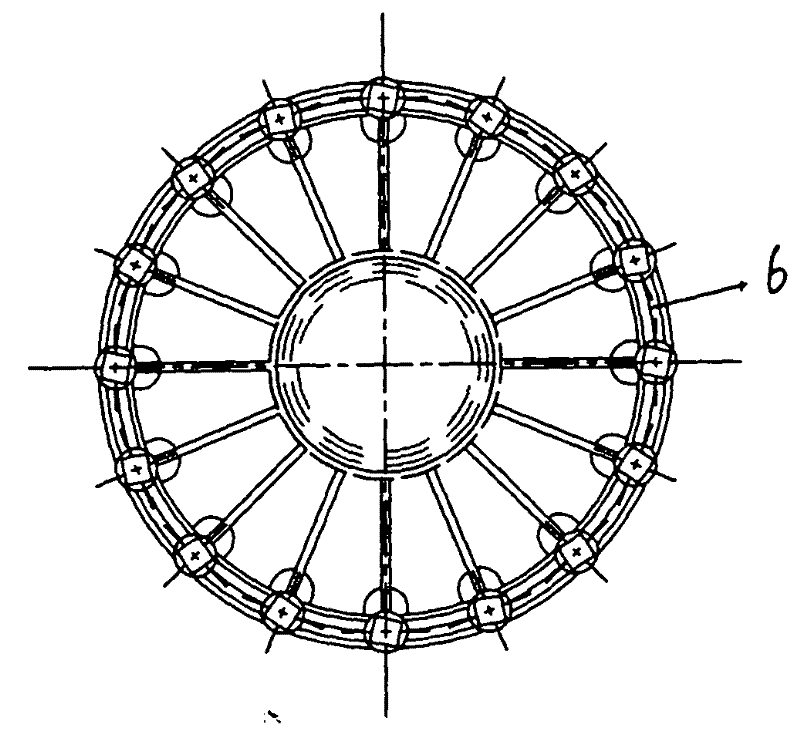

[0016] figure 1 It is to make the blade 1 of the badminton of the present invention, the blade 1 is made up of the wing 2 at the upper end and the root 3 at the lower end; figure 2 The hair-planting bracket 4 in the hair-planting tube 5 is composed of a connecting rib 6, a support rod 7 and a connecting rod 8. Such as image 3 As shown, the ball head 9 and the hair-planting bracket 4 can be molded at one time or molded separately and then connected together. Such as Figure 4 Shown, after the blade 1 of making is implanted into the hair-planting tube 5, it has just become the shuttlecock of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com