Coating process of carbon fiber fishing rod

A coating process and carbon fiber technology, which is applied to devices for coating liquid on surfaces, coatings, surface pretreatment, etc., can solve the problems of unstable quality, difficult management, long production cycle, etc., and save the conductive treatment process. , the effect of reducing environmental pollution and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific implementation.

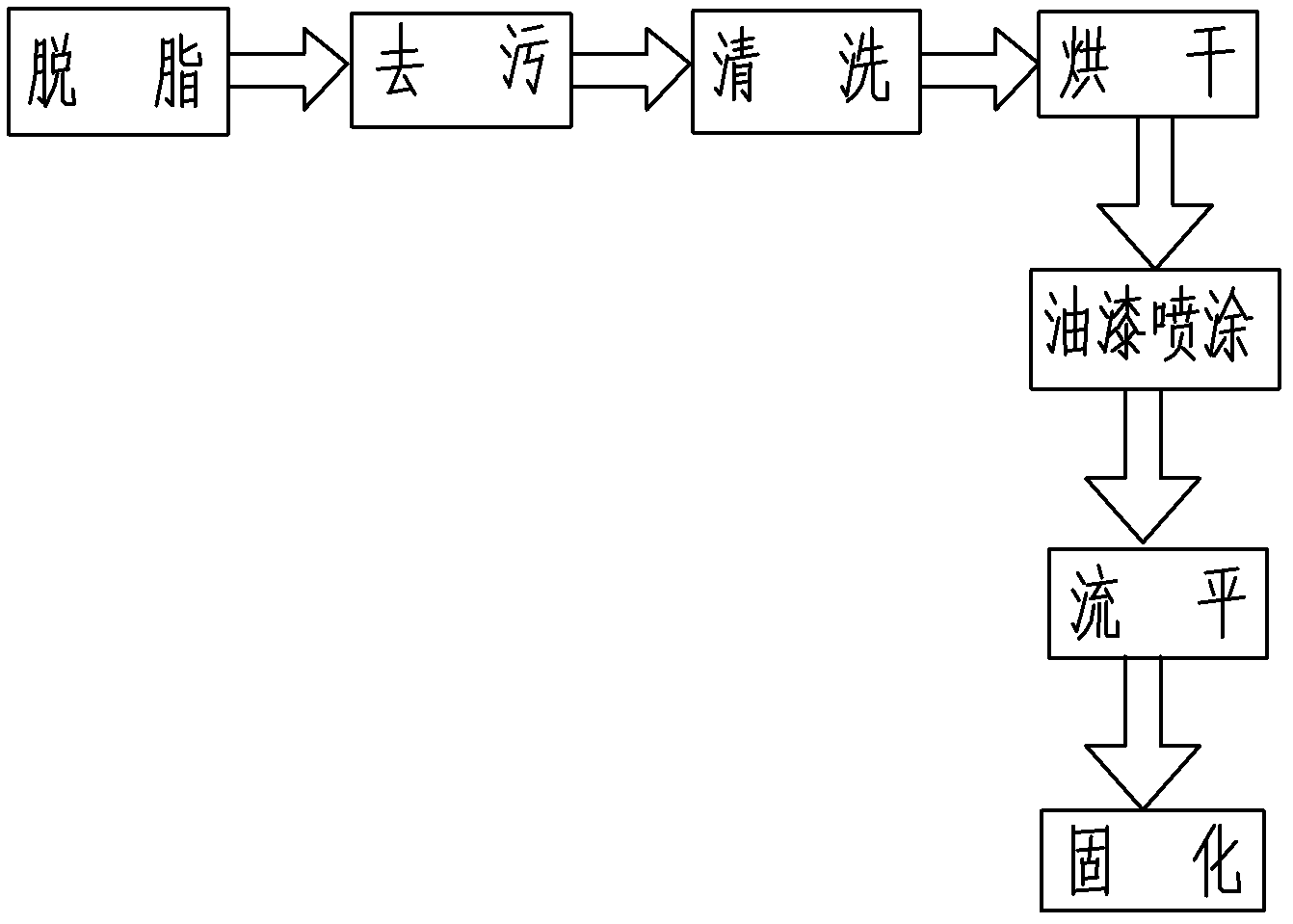

[0029] A carbon fiber fishing rod coating process is characterized in that: the specific steps are as follows:

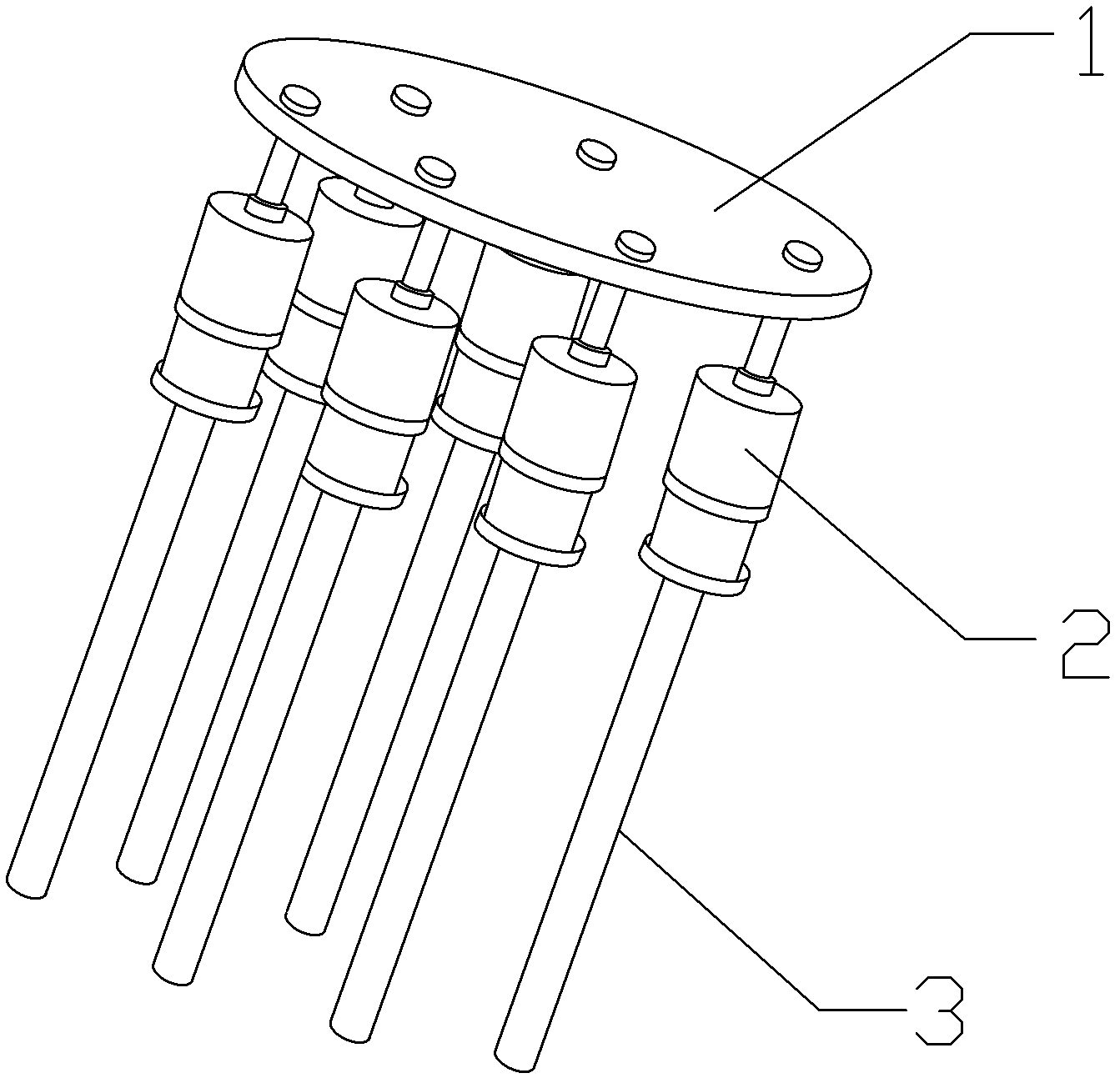

[0030] (1) Degreasing, decontamination, cleaning and drying of fishing rods: First, tie the formed fishing rods packed with carbon fiber composite materials into bundles of 40-60 pieces according to the thickness, and then use an automatically controlled boom to lift the bundled fishing rods Hang it into the degreasing tank of the cleaning tank, put the diluted degreasing liquid in the degreasing tank, generally use the surface degreasing and degreasing agent sprayed (such as Lvsen brand industrial cleaning agent E3), the degreasing can be determined according to the number of poles In order to ensure normal degreasing, the general concentration is 1:10-20 times diluted with water, (that is, 5%-10% tank volume); after degreasing, it enters the decontamination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com