Internal connection structure of button cell and manufacturing method of internal connection structure

An internal connection structure and button battery technology, which is applied in secondary battery manufacturing, battery pack components, primary batteries, etc., can solve the problems of limited space between welding tabs and the inner surface of the battery case, occupying a certain amount of space, and high equipment costs , to achieve the effect of saving production cost, avoiding missing welding and reducing welding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

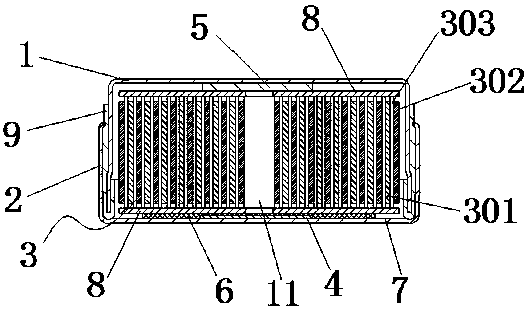

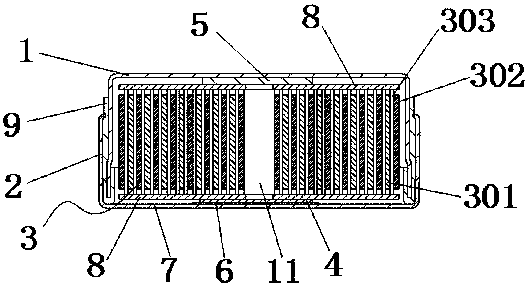

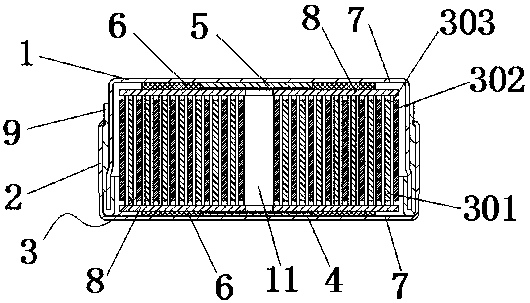

[0027] The internal connection structure of the button battery of the present invention includes an upper casing 1 and a lower casing 2 formed by covering, a winding body 3 is provided between the lower casing 2 and the upper casing 1, and the winding body 3 is formed In a cylindrical shape, the wound body 3 includes a positive electrode sheet 301, a negative electrode sheet 302, and a separator 303 located between the positive electrode sheet 301 and the negative electrode sheet 302 for separating the positive and negative electrode sheets. The body 3 has a positive electrode tab 4 and a negative electrode tab 5 respectively extending to the upper and lower parts of the winding body; the positive electrode tab 4 is connected to the positive electrode sheet 301, and the negative electrode tab 5 is connected to the negative electrode sheet 302 At least ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com