Form design system for personalized implants

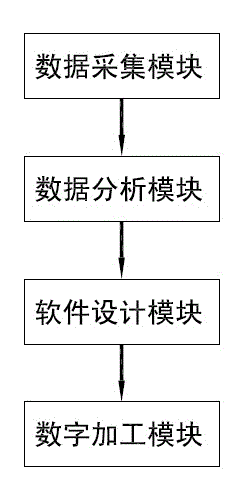

A technology for designing systems and implants, applied in the field of biomedical engineering, can solve problems such as high cost, impact on medical quality, waste of medical resources, etc., and achieve the effects of preventing substandard products, high design accuracy, and saving medical costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

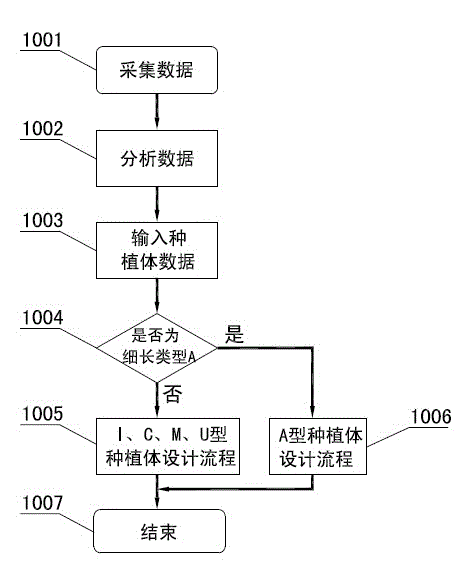

[0073] Figures 1~9 is the best embodiment of the present invention, the following is combined with the appendix Figures 1~9 The present invention will be further described.

[0074] A complete implant denture mainly consists of three parts: crown, abutment, and implant. The implant is the innermost part, which is screwed into the patient's alveolar bone and acts as a fixed support. The implant can be divided into four parts from the inside out: the implant root, the implant part, and the implant neck. , the implant shoulder. The abutment is located between the implant and the crown, connecting the implant and the crown, and is divided into three parts: the bottom of the abutment, the end of the abutment, and the neck of the abutment. The bottom of the abutment is the part where the abutment extends into the implant, the neck of the abutment is the part that passes through the gingiva, and the end of the abutment is the part where the top is connected to the crown. The cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com