Air tightness detection system and workpiece clamping abnormity early warning method

A technology of air tightness detection and workpiece, which is applied in the direction of using liquid/vacuum to measure liquid tightness, and by measuring the increase and deceleration rate of fluid, etc., can solve the problem that the machine cannot be started, and achieve the effect of avoiding defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

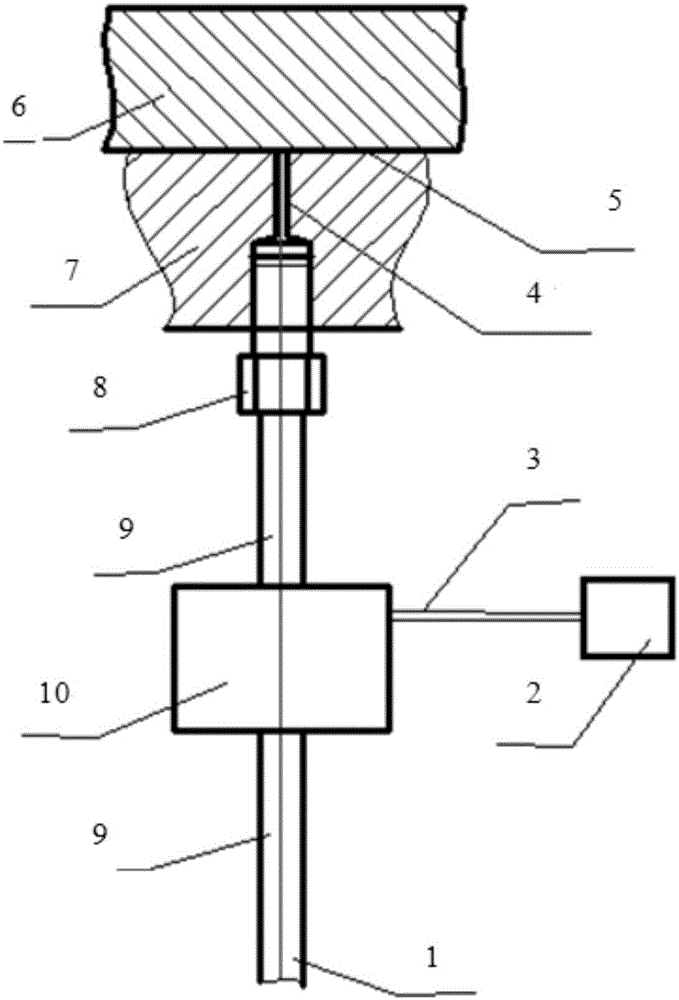

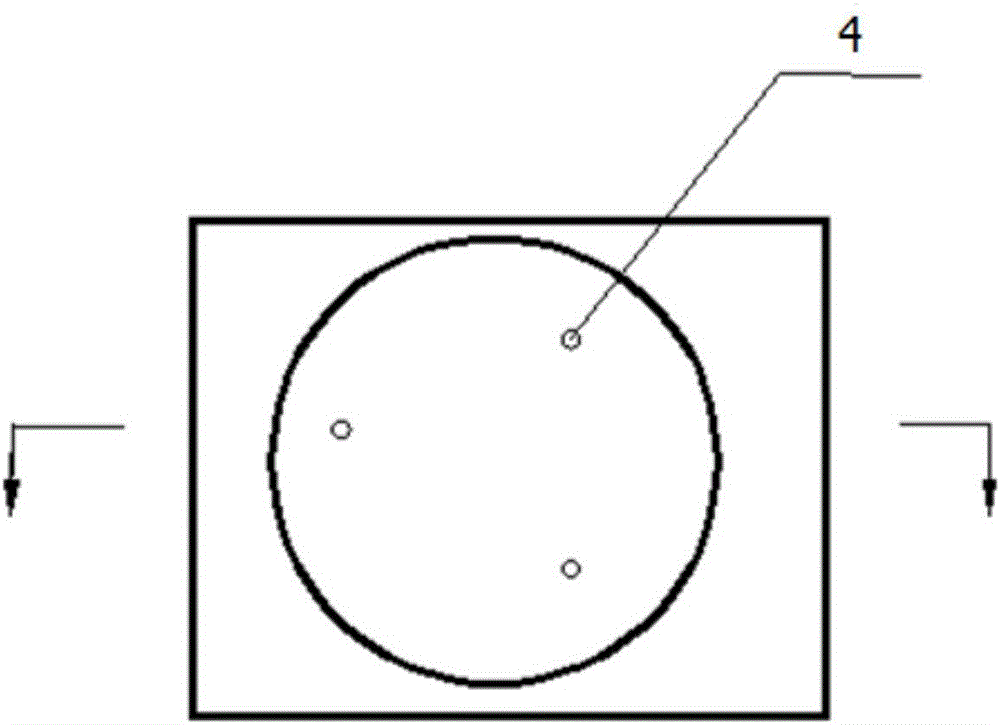

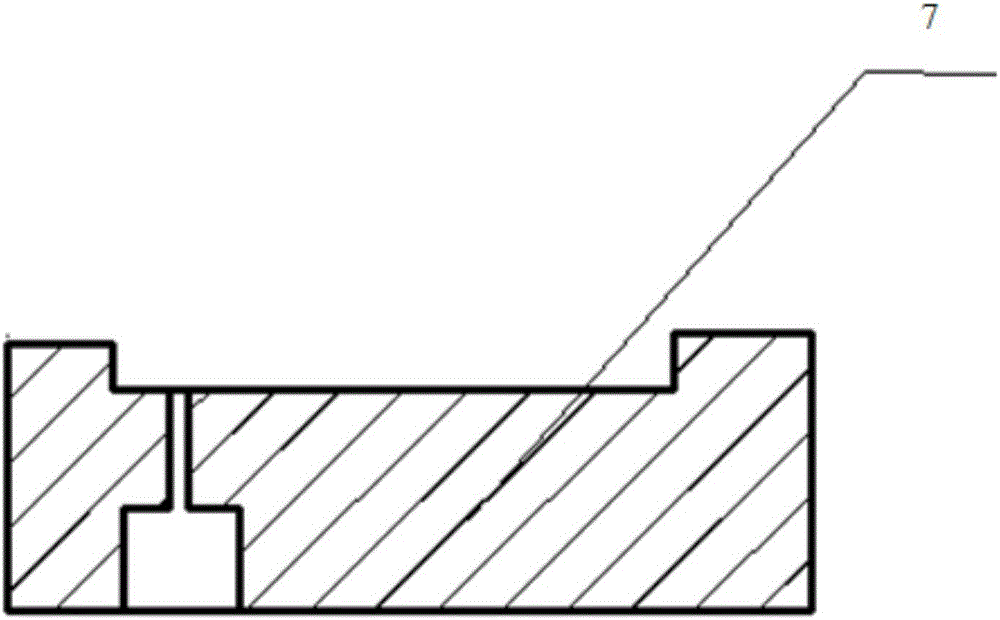

[0028] figure 1 is the overall diagram of the air tightness detection system, figure 2 is the top view of the fixture, image 3 is a sectional view of the fixture.

[0029] Air tightness detection system, including air inlet 1, CNC machine 2, air pressure change signal output line 3, vent hole 4, contact surface between fixture and workpiece 5, workpiece to be processed 6, fixture 7, air pipe joint 8, air pipe 9, Air pressure detector 10.

[0030] Before the workpiece to be processed is loaded into the fixture, blow off the waste aluminum chips on the contact surface between the fixture and the workpiece. After the workpiece 6 to be processed is loaded into the fixture 7, the gas with a certain pressure is input from the air inlet 1, and the gas passes through the air pipe 9. Air pressure detector 10, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com