Hot-melt film bonding and compounding equipment and compounding method thereof

A composite equipment and hot-melt film technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of insufficient bonding, easy deviation, affecting the composite speed, etc., and achieve the realization of resources The effect of recycling, reducing deviation adjustment error, and high-efficiency vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

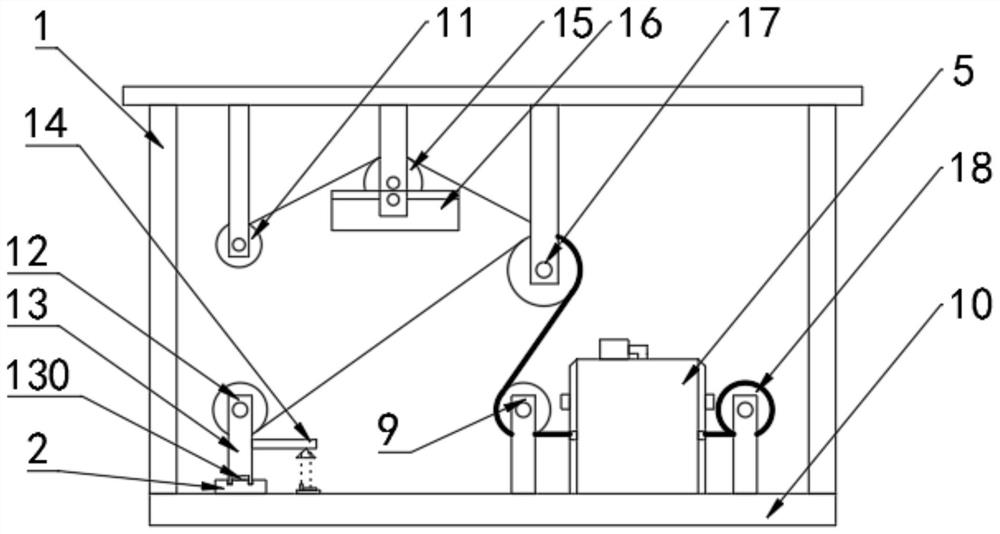

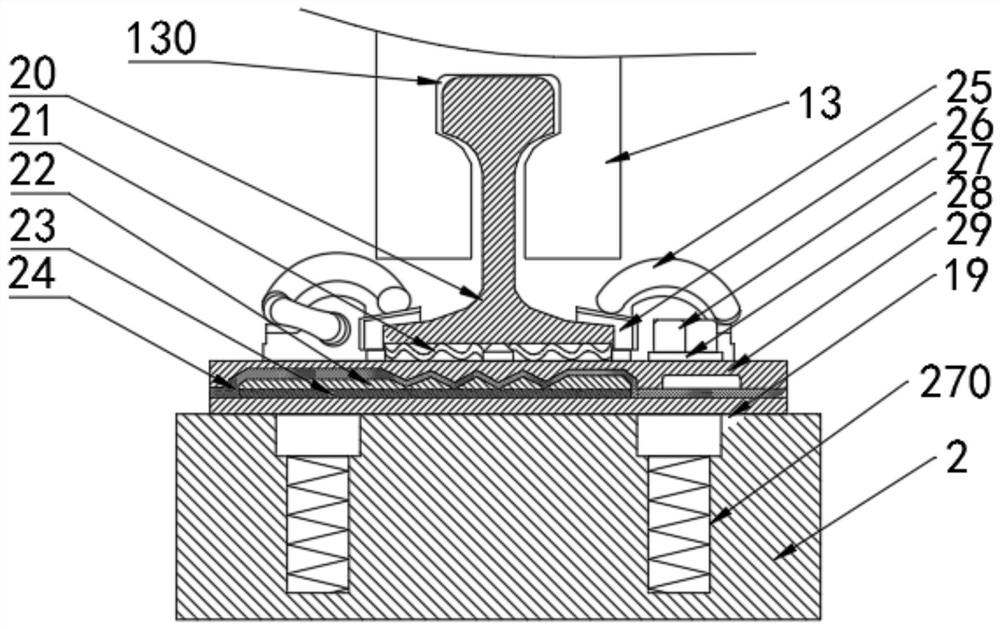

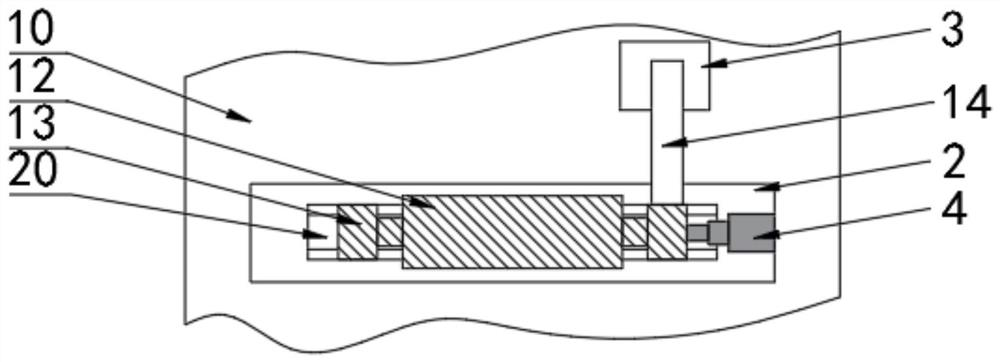

[0055] Such as Figure 1-Figure 6 As shown, the present invention discloses a hot-melt film bonding compound equipment, which includes a base 2 and a frame 1 arranged on the base 2, and is characterized in that, along the unwinding direction, there are also arranged in sequence: an unwinding device; device; a composite drying device; and a winding device; wherein, the unwinding device includes a first unwinding mechanism on the top of the frame 1 and a second unwinding mechanism on the base 2, and the gluing device includes The glue box 16 that is located at the top of the frame 1 and the gluing roller 15 that is located at the top in the glue box 16, the composite drying device includes a composite roller 17 and a drying mechanism, and the winding device is located away from the drying mechanism On the base 2 on one side; the second unwinding mechanism includes a second unwinding roller 12, a detection unit for detecting the offset of the substrate, and a deflection adjustmen...

Embodiment 2

[0076] Embodiment 2, the difference with embodiment 1 is

[0077] Such as Figure 1-Figure 4 As shown, the present invention discloses a hot-melt film bonding compound equipment, which includes a base 2 and a frame 1 arranged on the base 2, and is characterized in that, along the unwinding direction, there are also arranged in sequence: an unwinding device; device; composite roller 17; and winding device; wherein, the unwinding device includes a first unwinding mechanism arranged on the top of the frame 1 and a second unwinding mechanism arranged on the base 2, and the gluing device includes a The glue tank 16 at the top of the frame 1 and the gluing roller 15 that is located at the top in the glue tank 16, the winding device is arranged on the base 2 away from the drying mechanism side; the second unwinding mechanism includes the first Two unwinding rollers 12, a detection unit for detecting the deviation of the substrate and a deviation adjustment unit.

[0078] In the abo...

Embodiment 3

[0093] In addition, the present invention also provides a hot-melt film bonding composite method, which uses the above-mentioned production equipment, including the following steps:

[0094] S1 roll-up: respectively install the first substrate roll and the second substrate roll of the hot-melt film on the first unwinding roller 11 of the first unwinding mechanism and the second unwinding roller 12 of the second unwinding mechanism, Start the second unwinding mechanism and the first unwinding mechanism in turn to start unwinding;

[0095] S2 deviation adjustment: the detection unit dynamically detects the alignment of the first substrate and the second substrate, and drives the adjustment frame 13 to move laterally through the deviation adjustment unit, so that the two sides of the second substrate are always aligned with the two sides of the first substrate alignment;

[0096] S3 gluing: the gluing roller 15 rolls and sticks the glue in the glue box 16, and the first base mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com