A chain-belt pallet conveyor system

A conveyor, pallet technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., to ensure synchronization, ensure high efficiency, and overcome unstable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

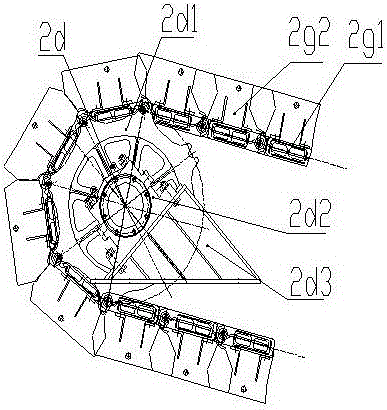

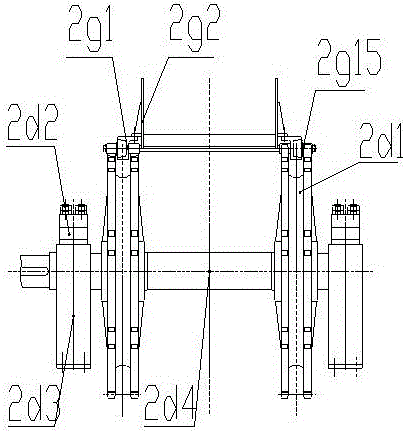

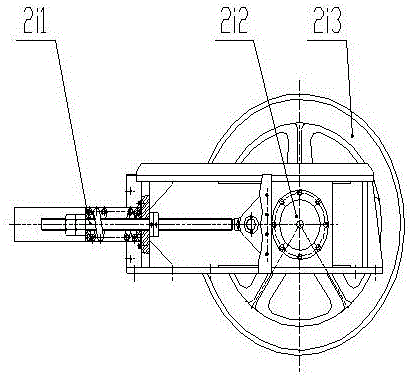

[0064] Such as figure 1 , figure 2 As shown, the chain-belt pallet conveyor 2 of the present invention is installed on the conveyor frame 5 below the cast iron machine 4, and the iron block falls into the chain-belt pallet conveyor 2 through the two-way automatic anti-shock iron shunt trough 1 of the cast iron machine. The iron block is transported by the chain-belt pallet conveyor, and finally falls into the car through the automatic two-way iron block flow chute 3 of the conveyor or falls on the ground accumulation yard.

[0065] Such as image 3 , Figure 4 As shown, the iron blocks dropped by the cast iron machine fall on the chain-belt tray conveyor through the chute 1a and the fixed chute 1c that automatically receive the two-way buffer diverter 1, and the chute liner 1j is fixedly installed at the bottom of the chute 1a, and the chute liner 1j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com