A chain belt tray device

A pallet and chain belt technology is applied in the field of chain belt pallet devices to achieve the effect of large conveying capacity and avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

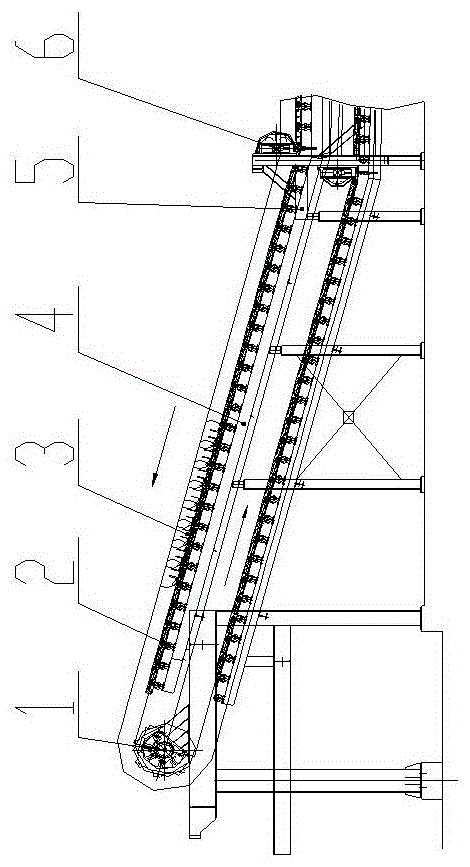

[0033] figure 1 As shown, a chain belt tray device 3 is arranged on the chain belt tray conveyor, supported on the roller 2 of the roller base 4 of the conveyor frame 5, the chain belt tray device 3 is driven by the driving sprocket 1 to run, The corner of the tray device 3 presses the left and right chain plates of the chain belt device through the guide wheel 6 to prevent the chain plate from lifting up with the tray under the action of the driving force when the chain belt tray device 3 moves, causing the chain belt to detach from the rollers The track formed by the device 2 causes the chain belt to deviate, which affects the normal production of the chain belt pallet conveyor.

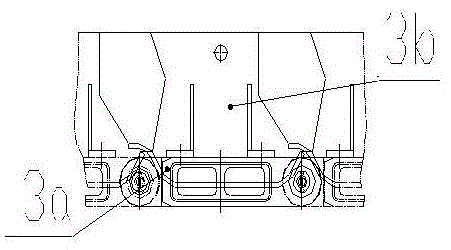

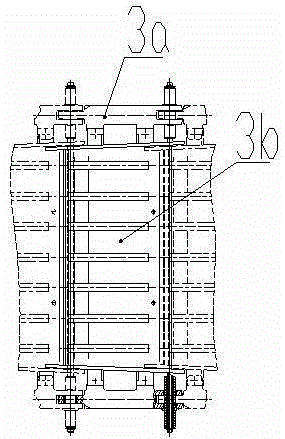

[0034] Such as figure 2 , image 3 and Figure 4 As shown, the chain belt tray device 3 is made up of a chain belt 3a and a duckbill U-shaped tray 3b. The iron block falls on the duckbill U-shaped tray 3b, and the tray 3b is driven to run along with the chain belt 3a. The duckbill U-shaped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com