Screw structure for automobile rectifier current output

An automotive rectifier and current technology, applied in the direction of output power conversion devices, electrical components, clamping/spring connections, etc., can solve the problems of rectifier scrapping, M5 threaded hole slipping, etc., and achieve the effect of meeting the output requirements of large currents

Inactive Publication Date: 2011-05-18

王满知

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

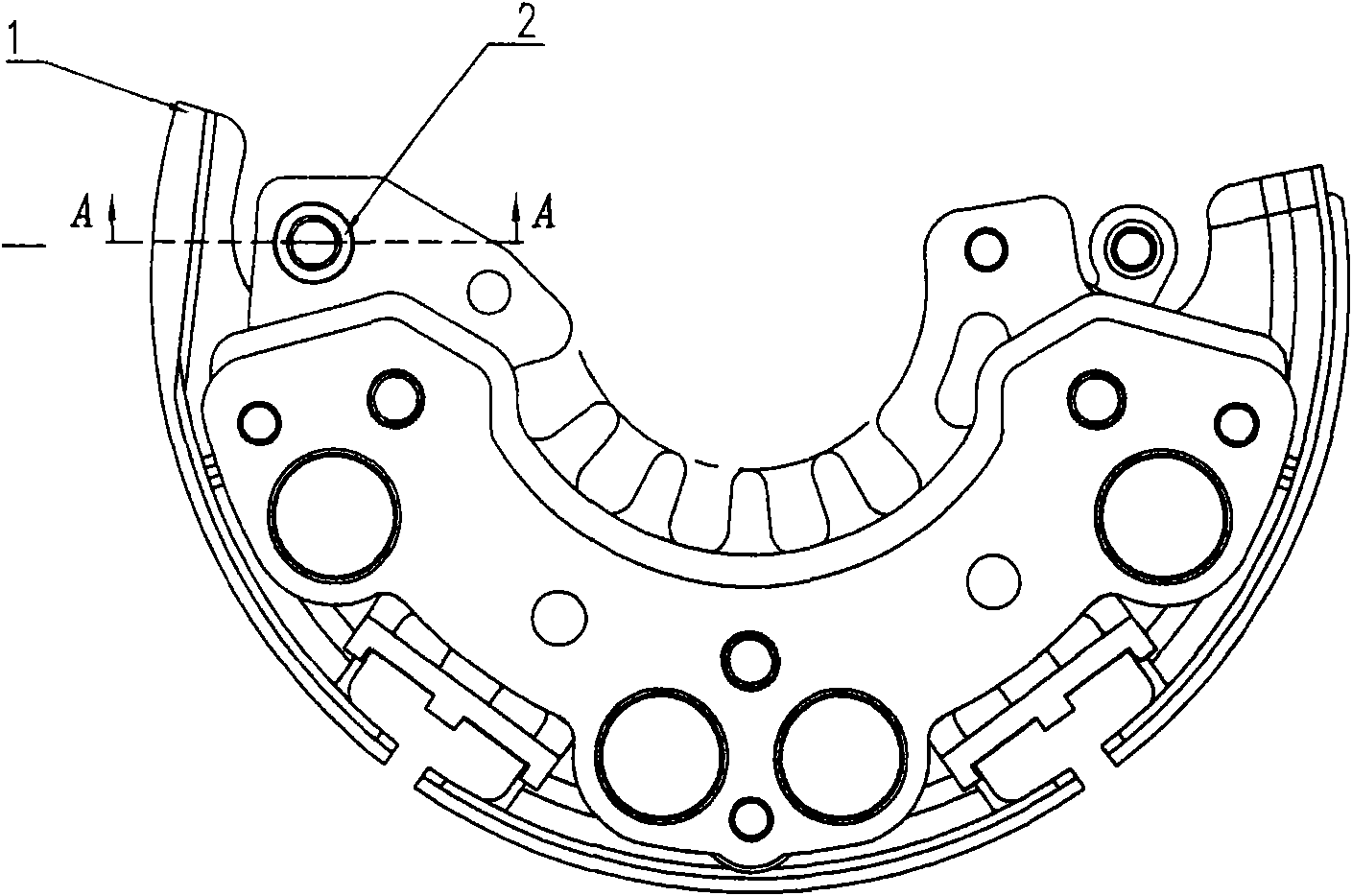

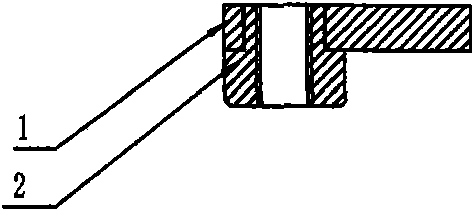

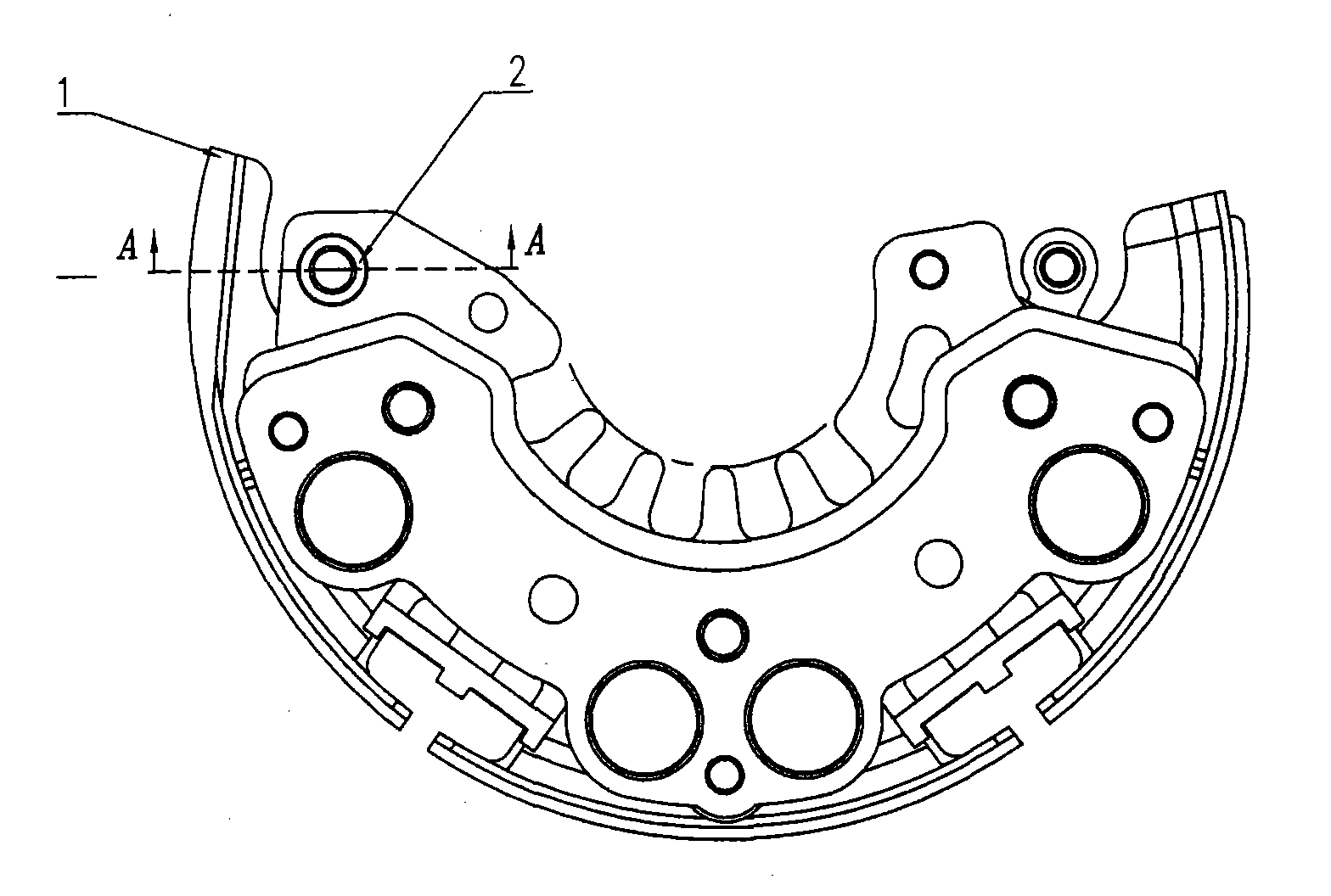

[0010] refer to figure 1 , figure 2 Among them, the present invention includes a positive plate 1 and an M5 metal nut 2 . Fix the M5 metal nut (2) on the positive plate (1) by straight-grain extrusion, so that the M5 metal nut (2) and the positive plate (1) form a whole, and then assemble other parts on the together form a rectifier.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a screw structure for automobile rectifier current output, comprising a positive plate and an M5 metal nut. The screw structure is characterized in that the M5 metal nut is fixed on the positive plate in the mode of straight line extrusion, and the M5 metal nut and the positive plate form a whole. The invention has the advantages that the torsional strength of the metal nut can completely satisfy the requirement on screw tightening torque and also guarantees the stability and the reliability of generator current output.

Description

technical field [0001] The invention relates to an automobile accessory, in particular to a screw structure for current output of an automobile rectifier. Background technique [0002] At present, the existing automotive rectifiers all use Japanese Hitachi series rectifiers. The input end of the electrical equipment is mainly fixed on the positive plate through a screw, and the positive plate fixes the screw with an M5 threaded hole. Since the assembly torque of the M5 screw is too large, and the material of the positive plate is aluminum alloy with a thickness of only 4mm, it is easy to cause the M5 threaded hole to slip when the screw is tightened, resulting in scrapping of the rectifier. Contents of the invention [0003] The purpose of the present invention is to overcome the deficiencies of the prior art and provide a threaded structure for the current output of an automobile rectifier. This structure can increase the torsional strength of the M5 thread and ensure th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02M1/00H01R4/28

Inventor 王满知

Owner 王满知

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com