Power Steel Rod Flange Bolt Fastening Tool

A flange bolt and fastening tool technology, which is applied in the field of power steel rod flange bolt fastening tools, can solve the problems of limited fastening torque, spreading out, and difficulty in fastening large-diameter bolts in place, etc., to meet the fastening torque Requirements, the effect of ease of transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

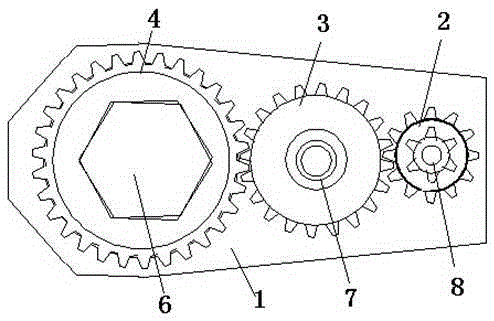

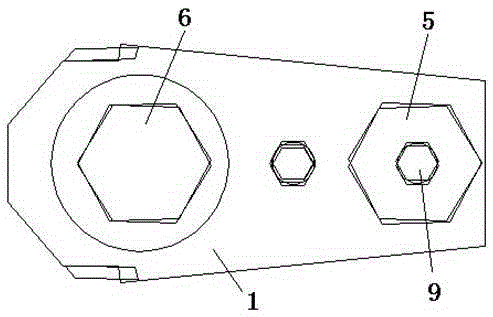

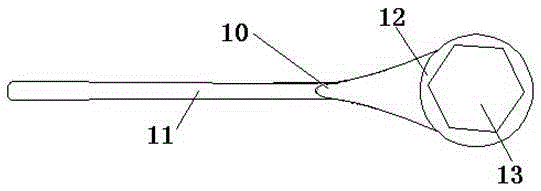

[0022] Such as Figure 1 to Figure 4 Shown is a power steel rod flange bolt tightening tool, including operating wrench and connecting parts;

[0023] Such as figure 1 and figure 2 shown. The connecting part includes a plate-shaped body 1, and the back of the plate-shaped body is sequentially arranged with a power gear 2, a transmission gear 3, and a bolt gear 4; the power gear 2 meshes with the transmission gear 3, and the transmission gear 3 and the bolt Gear 4 is meshed;

[0024] The central axis of the power gear 2 passes through the plate-shaped body 1 to reach the front of the plate-shaped body, and the corresponding position on the front of the plate-shaped body 1 is provided with a wrench bolt 5 connected with the central axis of the power gear;

[0025] The central position of the bolt gear 4 is a hollow structure, and there are flange bolt holes 6 for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com