Net chain conveying system suitable for whole vehicle conveying and corrugated paper logistics conveying

A conveying system and corrugated paper technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems affecting the conveying effect and service life of conveying network chains, and achieve the effects of avoiding tooth skipping, improving conveying effect and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

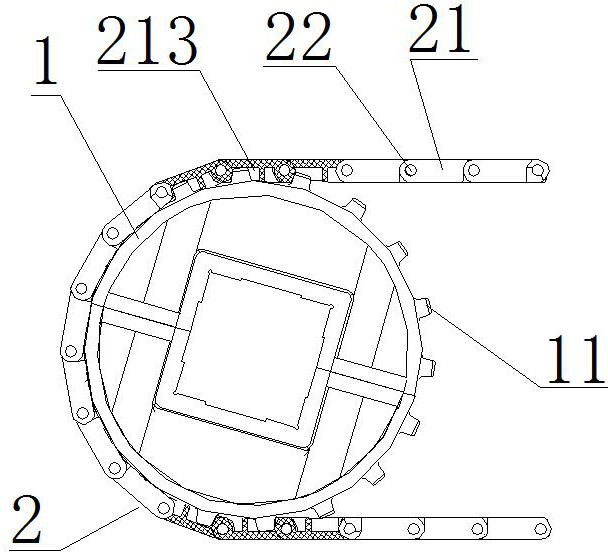

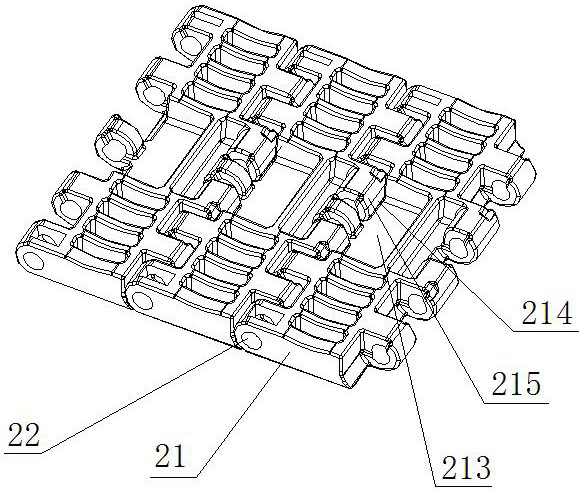

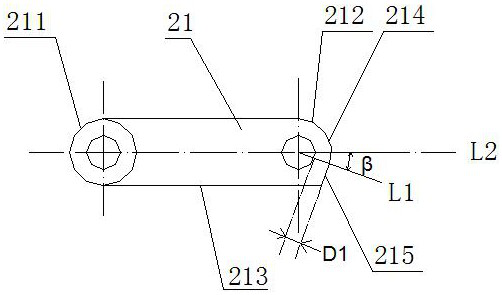

[0024] Such as figure 1 , 2 3, the present invention is composed of at least one transmission sprocket 1 and an endless conveyor network chain 2 fitted on the transmission sprocket 1. Each transmission sprocket 1 is evenly distributed with a plurality of gear teeth 11, and the transmission network chain 2 is composed of a plurality of chain links 21 inserted sequentially along the length direction of the conveyor network chain 2, and each chain link 21 is provided with a front row lug 211 and a rear row lug 212 along the length direction of the conveyor network chain, respectively. The front and rear lugs of the adjacent chain links 21 are arranged in a staggered manner along the width direction of the conveying net chain 2 and are rotatably connected by a pin 22.

[0025] An engagement groove 213 is provided on the back of each link 21, and a continuous arc surface 214 and a flat surface are provided on the surface of the rear lug 212 of the previous link 21 adjacent to the link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com