Comb-type multidirectional displacement bridge telescoping apparatus

A multi-directional displacement and telescopic device technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of broken fasteners, unsound cleaning system, failure of bolts fixing sliding tooth plates, etc., to prevent tooth skipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

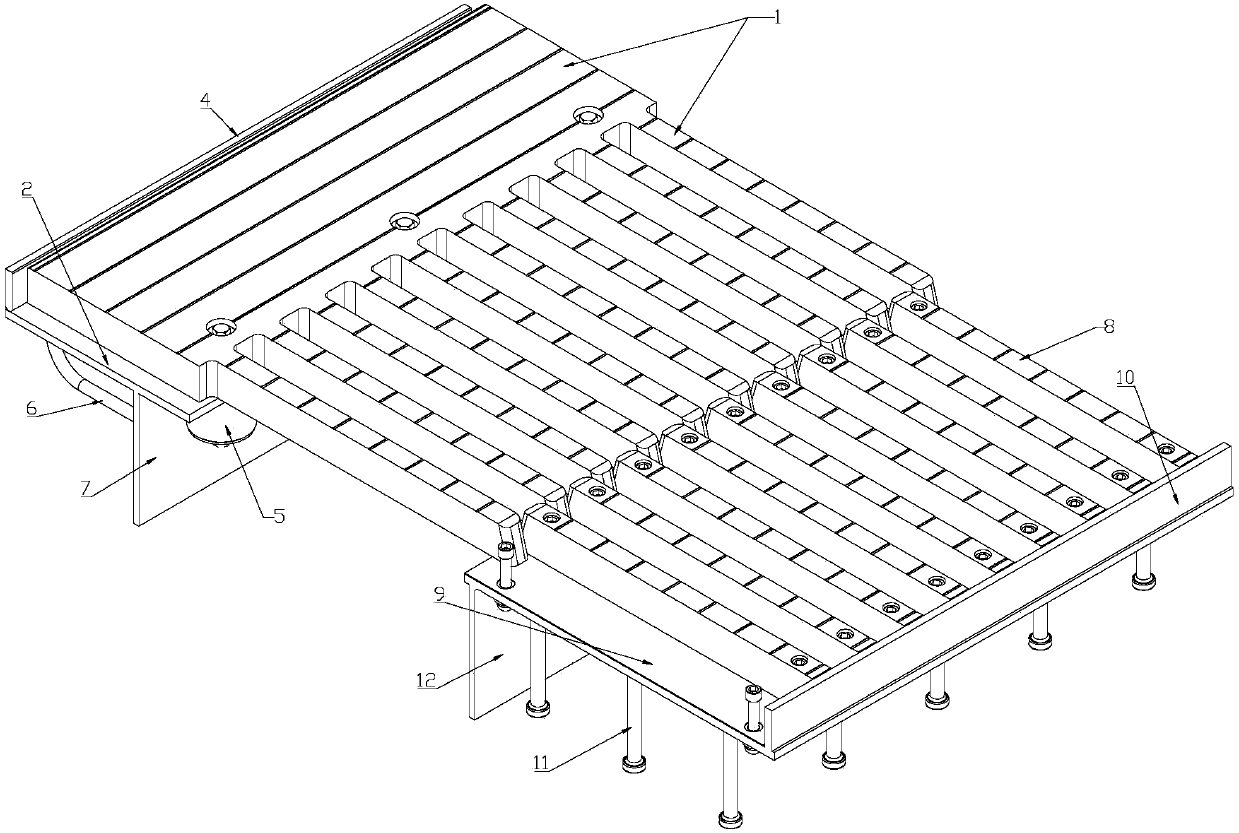

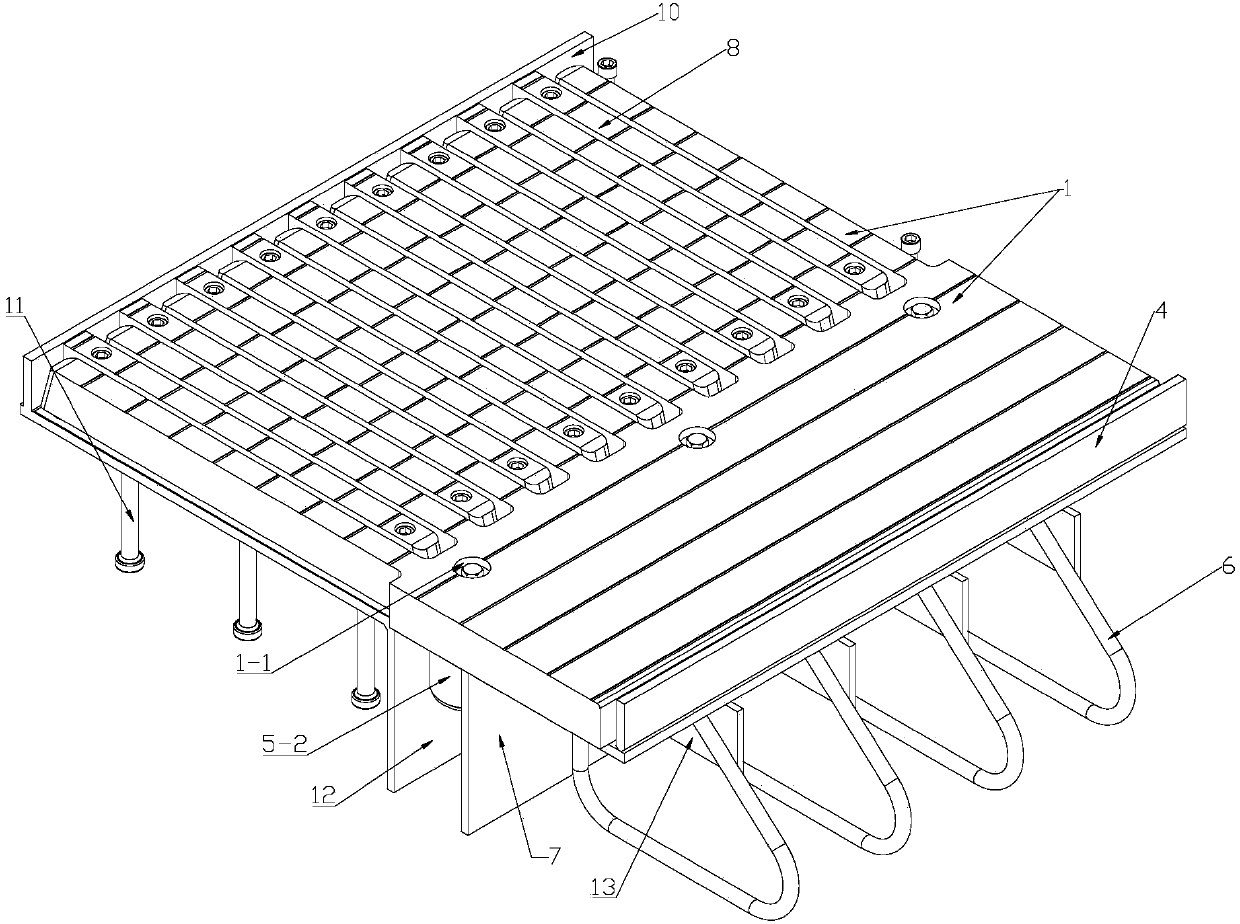

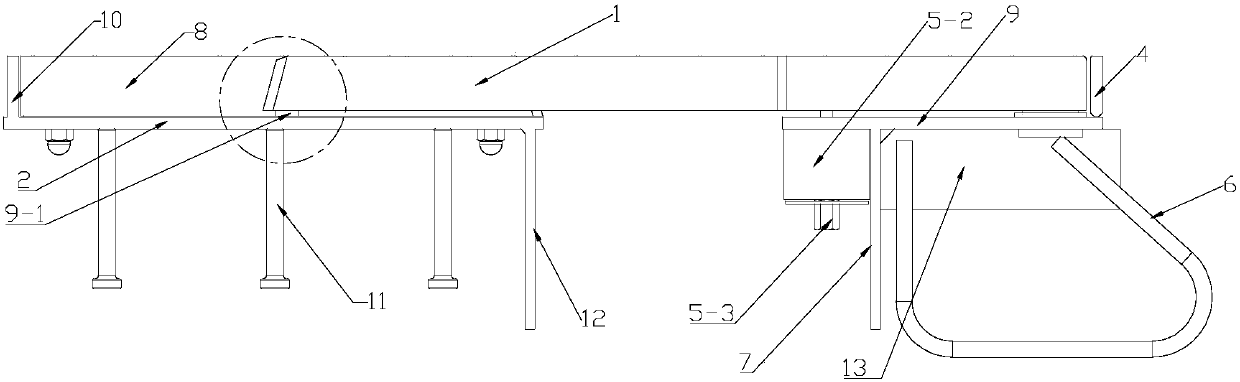

[0036] see Figure 1 to Figure 10 , a comb-tooth type multi-directional displacement bridge telescopic device, comprising a fixed tooth plate, a sliding tooth plate, a fixed beam body, and a sliding beam body. The teeth of the fixed tooth plate 8 are arranged on the fixed beam body 2, so the The comb back of the sliding tooth plate 1 is arranged on the sliding beam body 9. When the sliding tooth plate 1 moves relative to the fixed tooth plate 8, the teeth of the sliding tooth plate 1 and the teeth of the fixed tooth plate 8 are interlaced with each other. :

[0037] The teeth of the fixed tooth plate 8 are bolted on the fixed beam body 2, and the outer end of the fixed beam body 2-1 is provided with a fixed end edge beam 10; 70.

[0038] The sliding tooth plate 1 is connected with the sliding beam body 9 by a rotating shaft device at the comb back away from the tooth portion; and the outer end surface of the sliding beam body 1 is provided with a vertical sliding end edge be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com