Structure for preventing gear slippage in optical disk drive

A technology of optical disc drive and tooth jumping, which is applied in the configuration/installation of the head, tracking search/alignment, driving/moving the recording head, etc., which can solve the problems of difficult installation of plates, increase of parts and assembly costs, small size, etc., and achieve simplification The effect of structure and number of parts, complexity simplification, and man-hour saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to achieve the above-mentioned purpose of the present invention, the technical means adopted and other effects are given a preferred embodiment, and are described as follows in conjunction with the accompanying drawings.

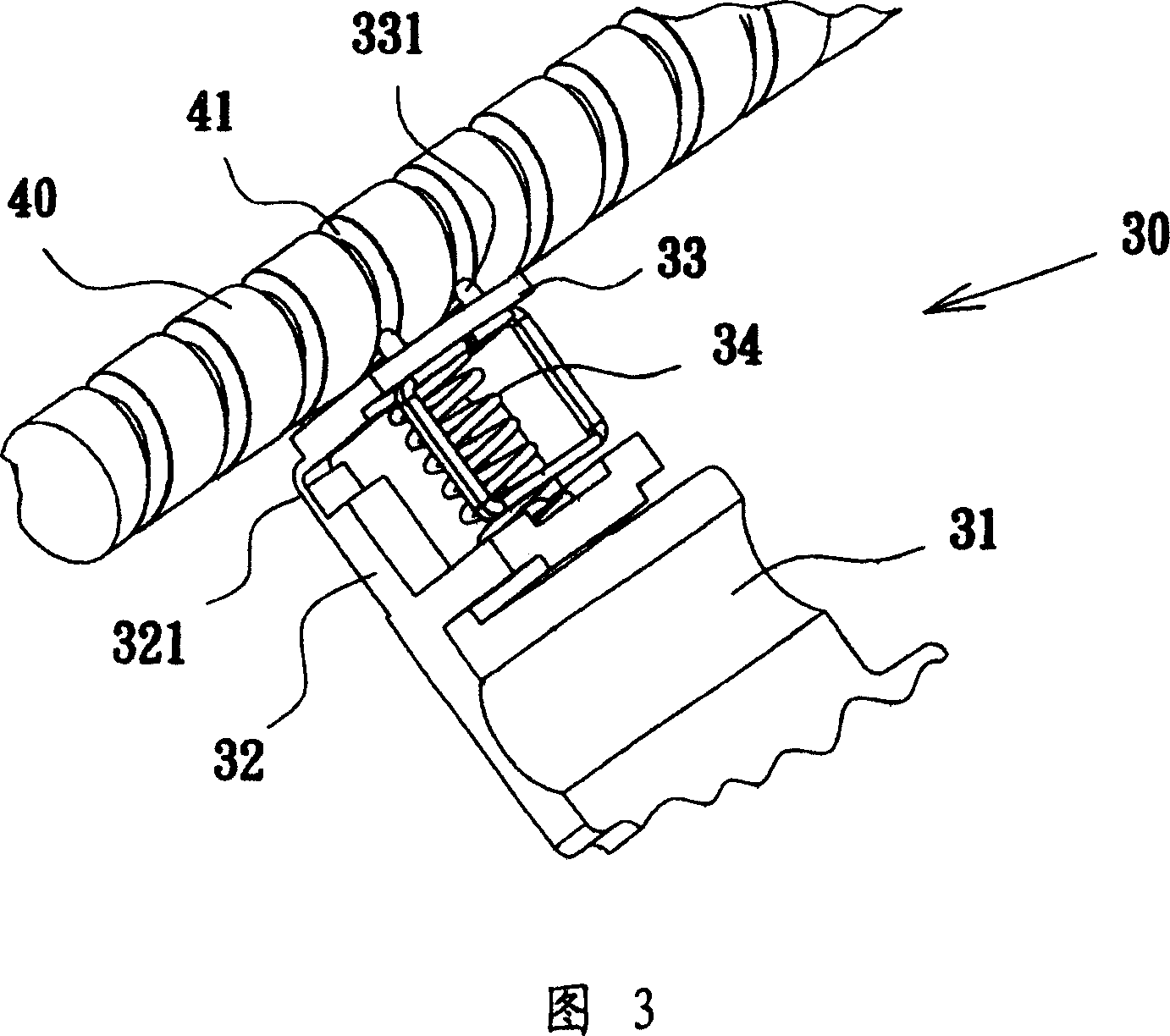

[0017] Referring to FIG. 3 , the tooth jump prevention structure 30 of the optical disc player of the present invention mainly includes a connecting seat 31 , a supporting frame 32 , a tooth seat 33 and a limiting spring 34 . One end of the support frame 32 is connected to the connection seat 31, and a reading head (not shown) is arranged on the connection seat 31, and the other end of the support frame 32 is connected to the tooth seat 33, and the tooth seat 33 is provided with a rack 331, and the tooth seat The rear end of 33 is provided with a limit spring 34, the limit spring 34 pushes the rack 331 of the gear holder 33 to engage in the thread groove 41 of the screw 40, and the screw 40 is rotated by a motor 50 (referring to Fig. 5 ), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com