Multi-wedge-belt cutter

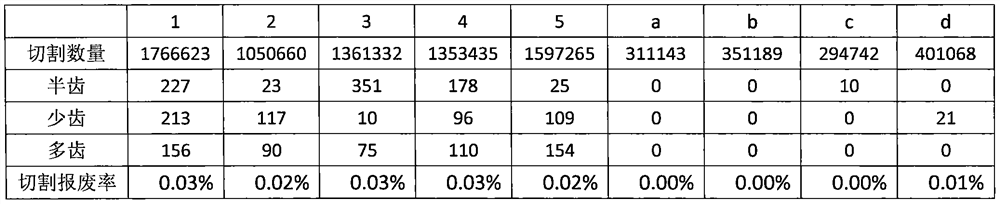

A multi-ribbed belt and cutting machine technology, applied in metal processing and other directions, can solve the problems of less wedge or half wedge, multi-ribbed belt scrap, multi-ribbed and other problems, and achieve the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

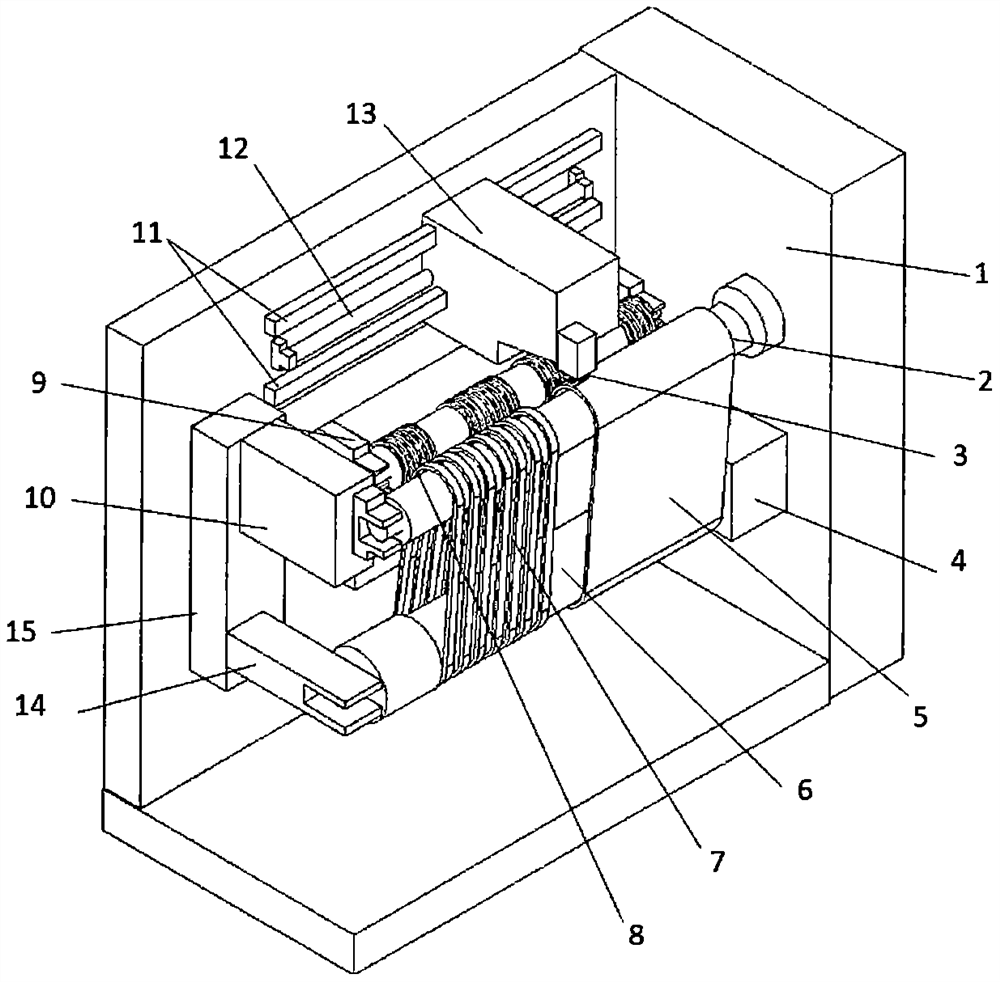

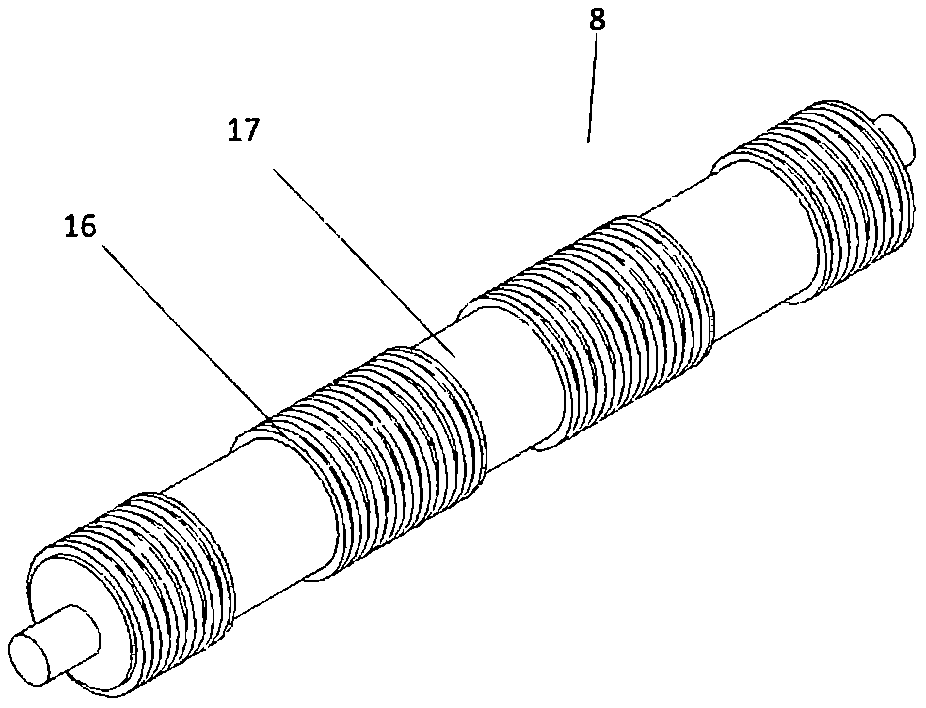

[0023] figure 1 It is a schematic diagram of the structure of the V-ribbed belt cutting machine. The V-ribbed belt cutting machine includes a fixed bracket 1. The fixed bracket 1 has a base and two sides. One end of the supporting roller 2 is installed on one side of the fixed bracket 1, and the other end is suspended. It is convenient to put the rubber sleeve 5 on it, the tension roller 6, the guide roller 8 are arranged parallel to the axis of the support roller 2, the end of the tension roller 6 close to the fixed end of the support roller is connected with the tension device 4, and the other end is the same as the support roller 2 The mode is suspended, and is convenient to adorn rubber sleeve 5. The tensioning device 4 is connected to the fixed bracket 1 in a movable manner, and the movement of the tensioning device 4 can be a rotary motion, and the tensioning ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com