A multifunctional timing sprocket cover

A timing sprocket, multi-functional technology, applied in the direction of engine components, machine/engine, shell, etc., can solve the problems of timing chain system failure, failure to directly observe the working condition of hydraulic tensioner, etc., and achieve the goal of preventing tooth skipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

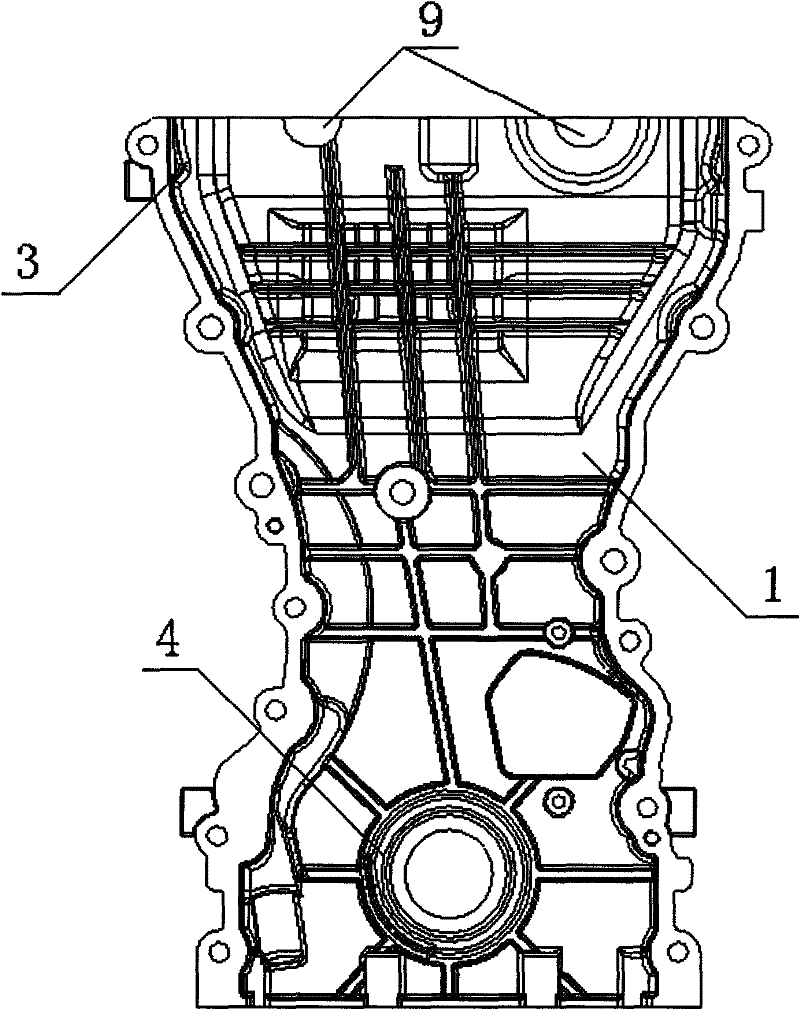

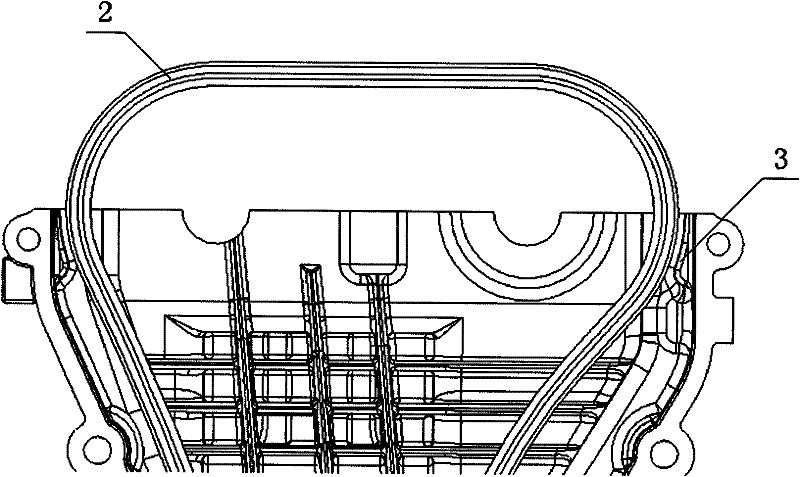

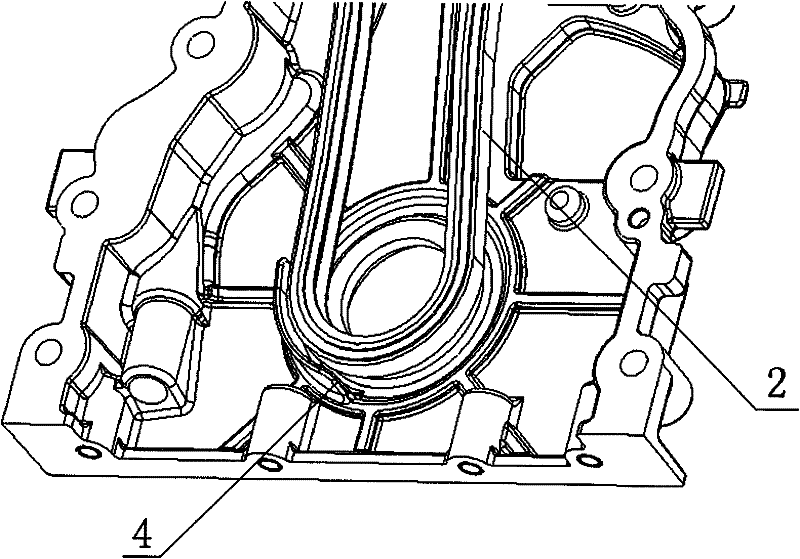

[0028] Depend on Figure 1-Figure 7 Combining the shown structures, it can be seen that the multi-functional timing sprocket cover includes a timing sprocket cover 1, and the inner side of the timing sprocket cover 1 is located at the inner side of the timing chain 2 and the sprocket on the exhaust side of the camshaft. The first chain guide groove 3 is provided at the place where the meshing and the camshaft intake side sprocket are about to separate, and the second chain guide groove 4 is provided at the timing chain 2 and the crankshaft sprocket; The top of the cover 1 is provided with grooves 9 corresponding to the bolts of the intake camshaft and the bolts of the exhaust camshaft, and the semicircular rubber plug 8 is correspondingly installed in the groove 9; the timing sprocket cover 1 includes Two parts, namely the metal part and the transparent visible part 7 corresponding to the hydraulic tensioner 5, the visible part 7 is transparent high-strength plexiglass, the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com