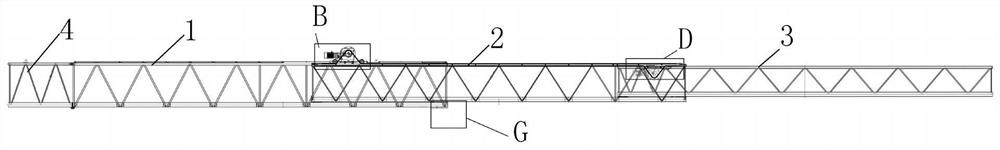

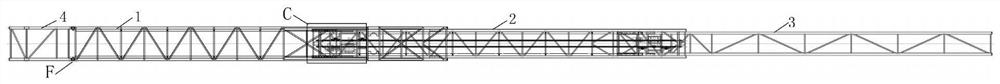

Crossing frame telescopic main arm and double-arm telescopic push type crossing frame

A technology of telescopic arms and spanning frames, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long completion time, long network sealing time, and inability to meet the construction time requirements, and achieve the effect of preventing tooth jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

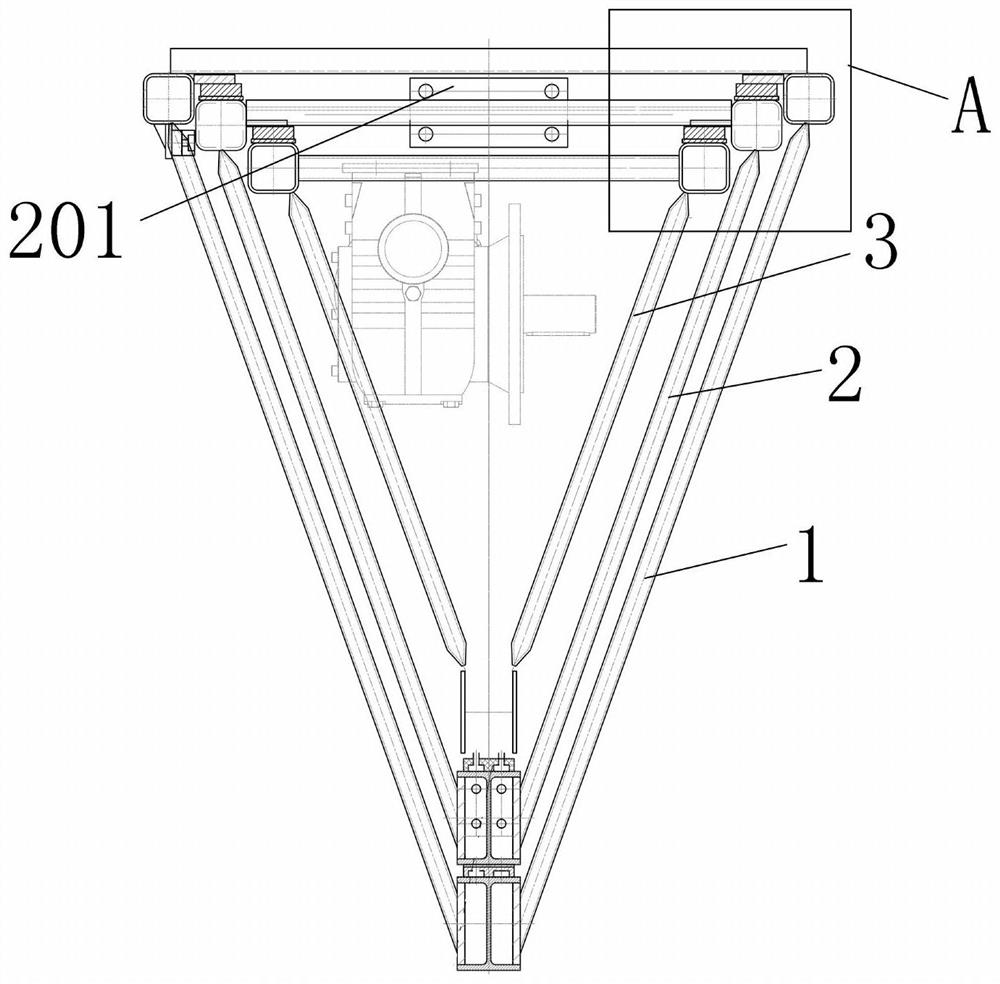

[0059] The difference between embodiment 2 and embodiment 1 is that the cross sections of the four telescopic arms are rectangular. The two lower chords are made of thickened H-shaped steel, the two upper chords are made of square steel pipes, and the diagonal and straight webs are welded between them. The number of sliders 5 positioned at the rear part of the lower surface of the lower chord of the second telescopic arm 2 and the third telescopic arm 3 is also two respectively, directly sliding on the thickened surface of the I-beam. The number of the front sliders 5 arranged on the upper surface of the lower chord of the first telescopic arm 1 and the second telescopic arm 2 is also two respectively, which play a role of supporting the second telescopic arm 2 and the third telescopic arm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com