Film combining machine

A film laminating machine and film machine technology, applied in the direction of external support, transport packaging, multiple packages, etc., can solve the problems of high preparation and operation costs, easy failure, and low working efficiency of the glue pressing device, so as to save production Production cost, stable and noiseless operation, and the effect of improving product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

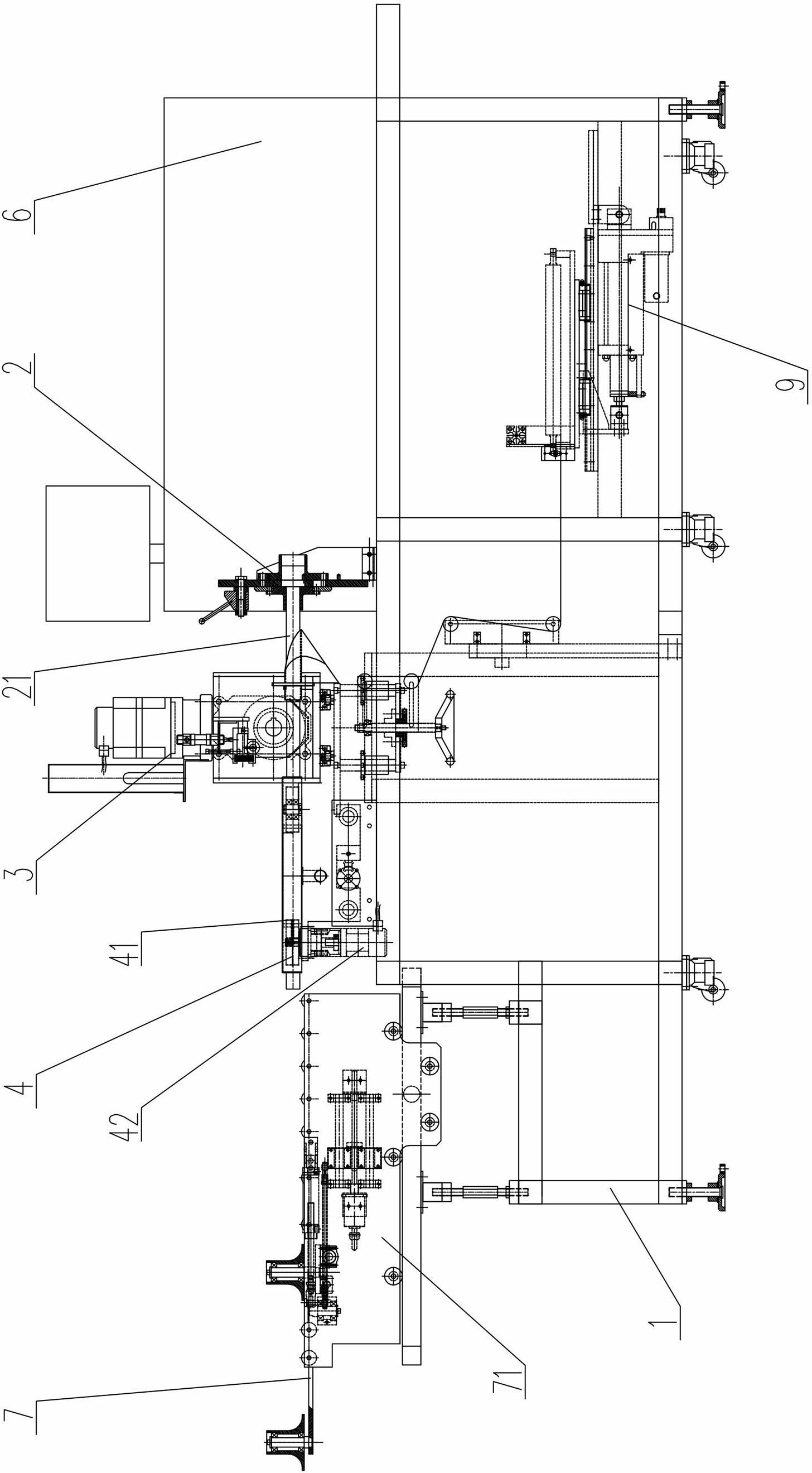

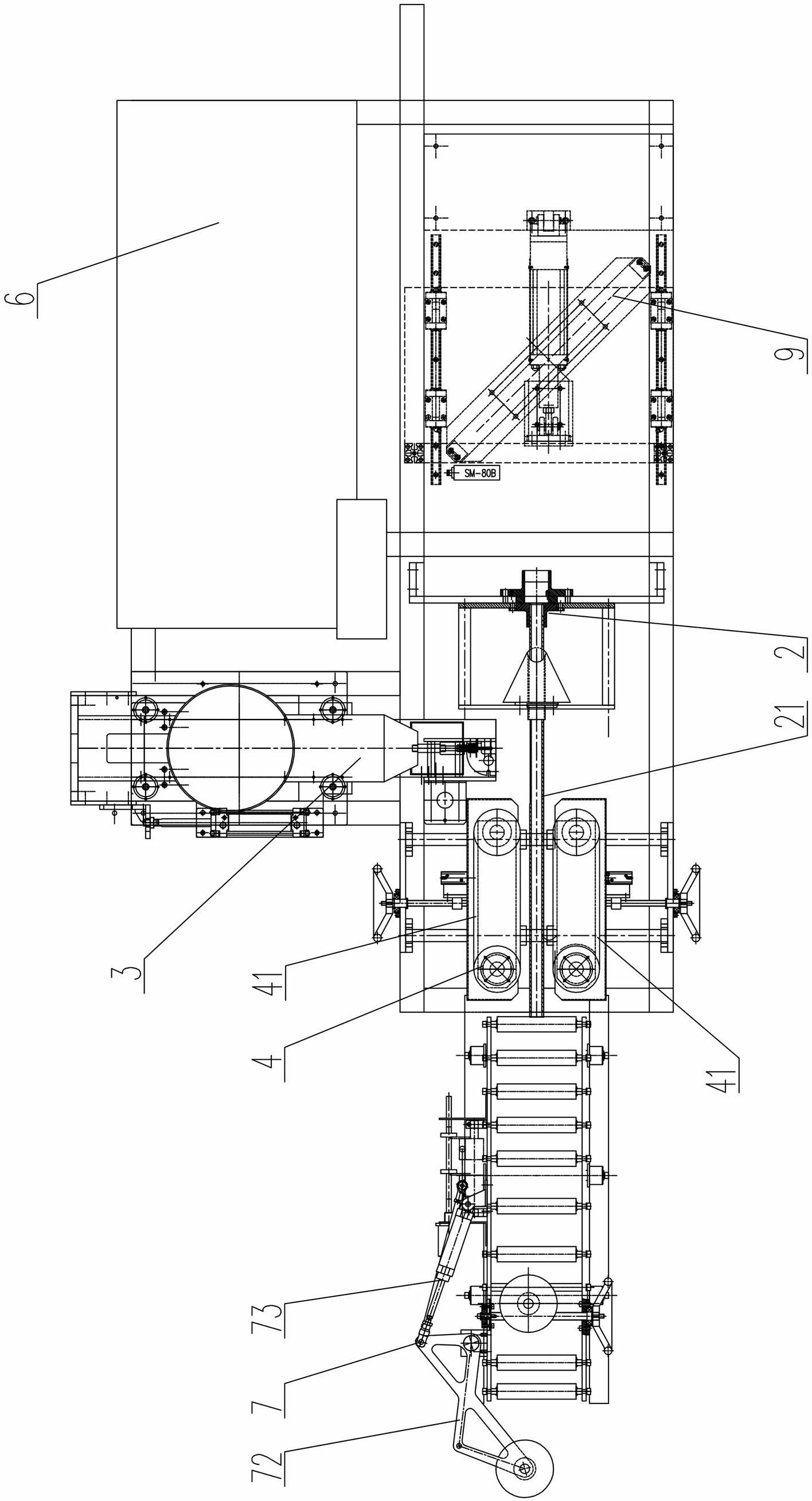

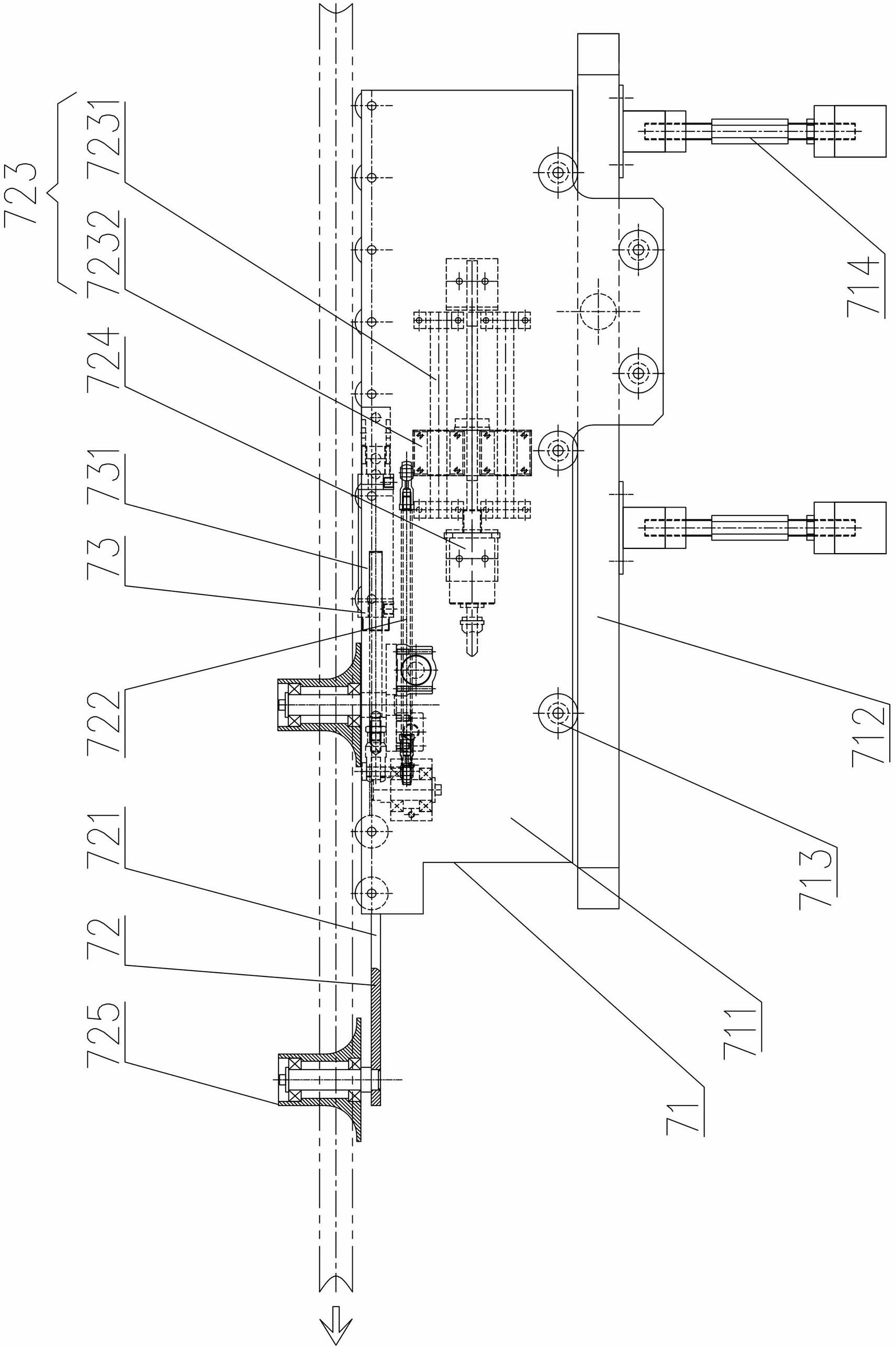

[0040] Figure 1 to Figure 11 Shown is an embodiment of the film laminating machine of the present invention, including forming device 2, gluing device 3, material driving device 4, electric control device 6 and speed synchronization device 7 arranged on frame 1, gluing device 3 It includes a glue-discharging mechanism 35 and a glue-squeezing mechanism 36 that supplies glue to the glue-discharging mechanism 35. The glue-discharging mechanism 35 is directly connected to the glue outlet of the glue-discharging mechanism 36. The glue-discharging mechanism 36 is installed on a horizontal driving mechanism 31 so that The glue-discharging mechanism 35 only moves along the horizontal direction to apply glue, and the glue-extruding mechanism 36 is directly set at the glue outlet of the glue-discharging mechanism 35, and is driven by the horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com