Sprocket with function of preventing tooth slipping

A function and sprocket technology, which is applied in the field of sprocket with anti-skipping function, can solve the problems such as non-continuous work, decreased work efficiency, and accidents, so as to avoid tooth skipping, reduce frequency and cost, Guaranteed normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

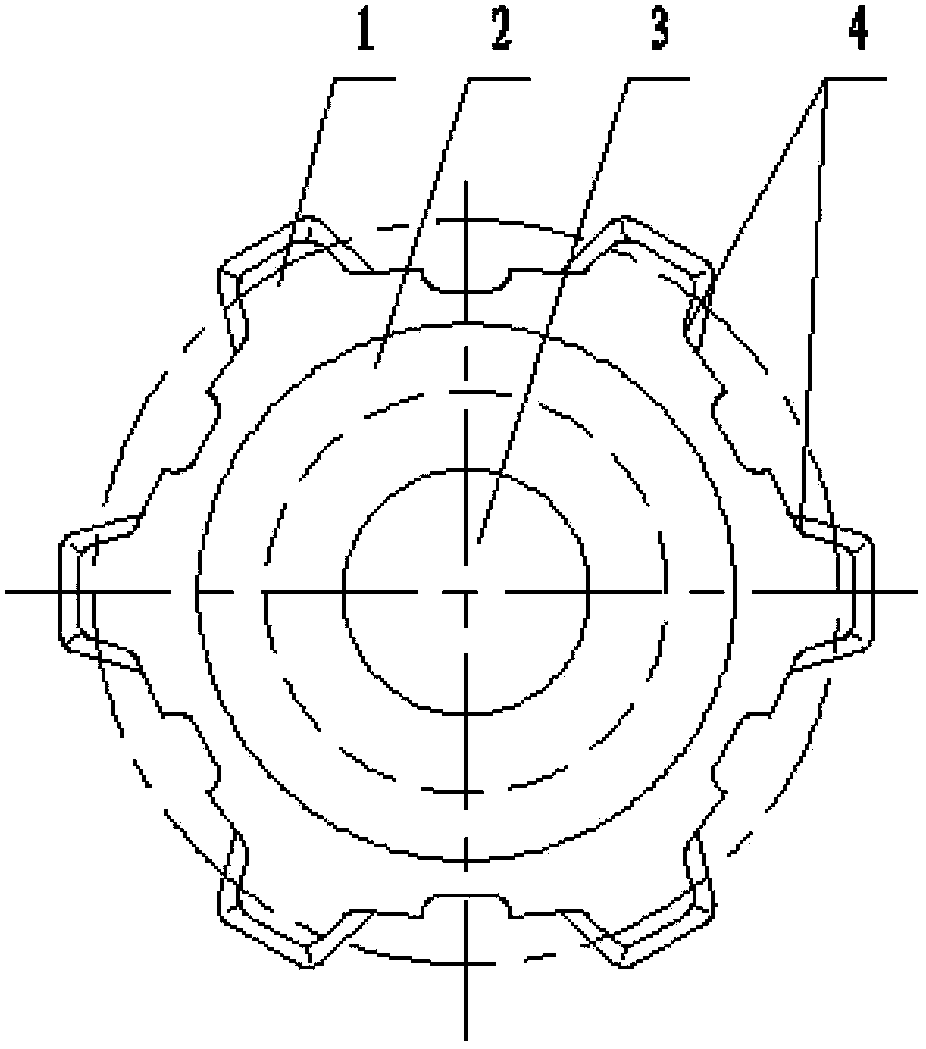

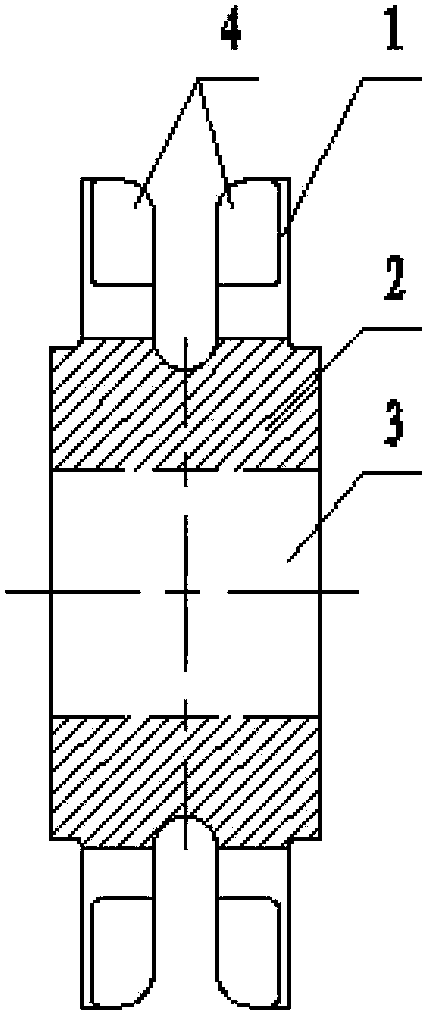

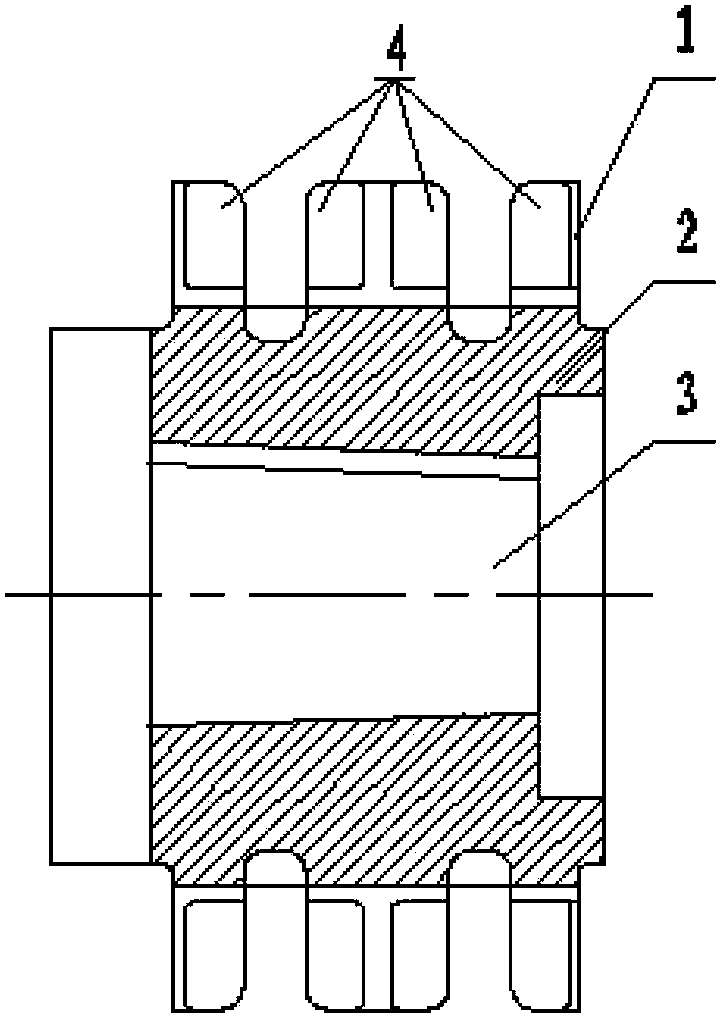

[0017] A sprocket with the function of preventing tooth jumping comprises a wheel disc 2, an axis hole 3 is formed on the axis of the wheel disc, and a keyway can be formed in the axis hole. On the outer surface of the wheel disc, a multi-circle sprocket 1 is made at intervals, and its quantity is not limited.

[0018] The innovation point of the present invention is that: the front end and the rear end of each chain tooth all make an anti-skid groove, and the shape of the anti-skid groove coincides with the shape of the edge of the chain, so as to prevent the chain from slipping off.

[0019] When the sprocket has two turns, an anti-skid groove is formed at the front end and the rear end of the inner surface of each sprocket.

[0020] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com