Method for adjusting tensioning wheel indicator of timing system of engine

A technology of timing system and adjustment method, which is applied in the direction of engine components, machines/engines, transmissions, etc., and can solve problems such as loosening of the tension wheel pointer, unaccounted for, and tooth jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

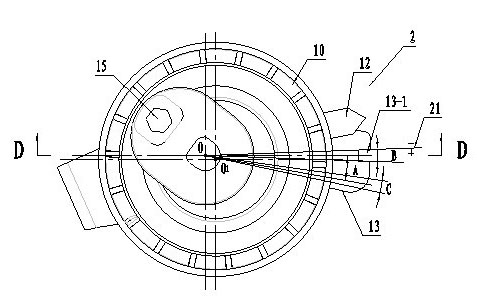

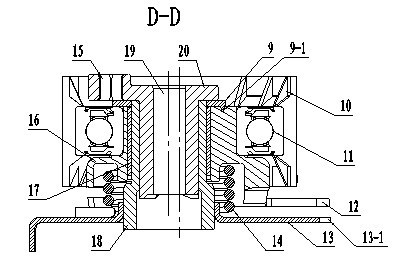

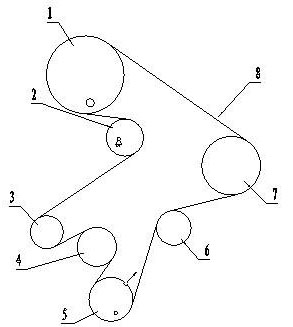

[0017] see image 3 , the engine timing system includes camshaft timing pulley 1, tension pulley 2, oil pump timing pulley 3, idler pulley 4, crankshaft timing pulley 5, water pump pulley 6 and Fuel pump timing pulley 7. The camshaft timing pulley, the fuel pump timing pulley, the crankshaft timing pulley, and the oil pump timing pulley mesh with the timing belt respectively. The function of the timing system is to ensure that the crankshaft and camshaft rotate synchronously at all times. The synchronous rotation requirement is: the crankshaft rotates twice, the camshaft rotates once, that is, the piston walks a full stroke, and the intake and exhaust valves are opened and closed once. When installing, turn the crankshaft timing pulley to the first and fourth cylinder pistons at the top dead center, that is, the groove mark on the crankshaft pulley 5 is aligned with an arrow mark on the engine casing. Both the crankshaft timing pulley and the camshaft timing pulley are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com