Chain tensioning device

A technology for tensioning devices and chains, applied in the field of chain tensioning devices, can solve the problems of increasing production costs and high manufacturing and processing costs of tensioning sprockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

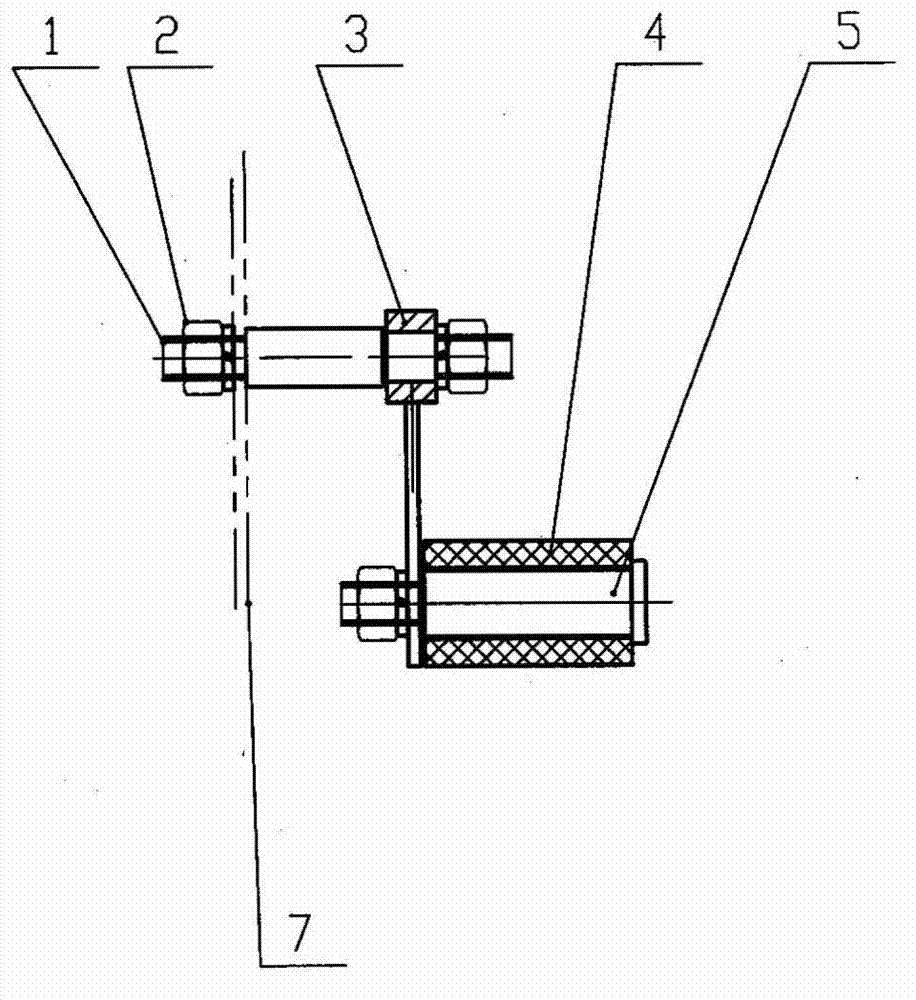

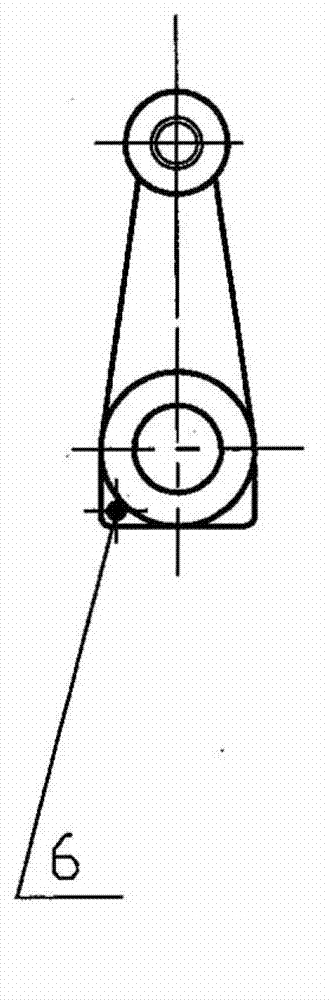

[0010] Such as figure 1 , 2 As shown, one end of the fixed shaft 1 of the present invention is fixed on the bottom cover 7 of the transmission box through the locknut 2, and the other end is installed with the locknut 2 to the rotating sleeve 3, and the threaded end of the pin shaft 5 passes through the tensioning nylon wheel 4 Finally, use the anti-loosening nut 2 to install on the swivel sleeve 3, and one side of the end of the swivel sleeve 3 is drilled with a tension spring hole 6, and the tension spring hook is in the tension spring hole 6, and the tensioning device is tightened to make the tensioning nylon The wheel 4 is close to the transmission chain, and rotates around the fixed shaft 1 with the movement of the chain, so as to play a role of continuous tension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com