Printing and dyeing device for textiles

A technology for textiles and printing and dyeing rollers, which is applied in textiles and papermaking, textile material processing, liquid/gas/steam textile material processing, etc. It can solve the problems of reducing the continuity of printing and dyeing, poor uniformity of nozzle spraying, and inability to achieve continuous operations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

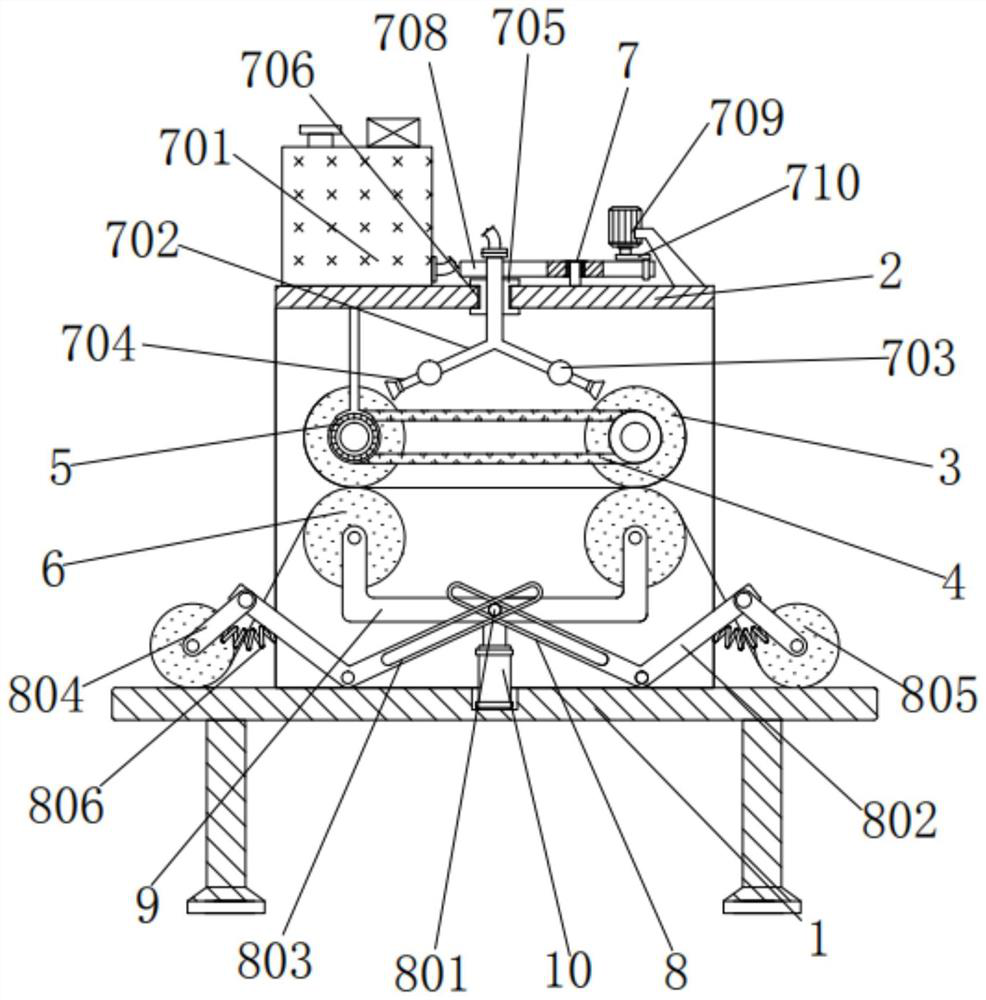

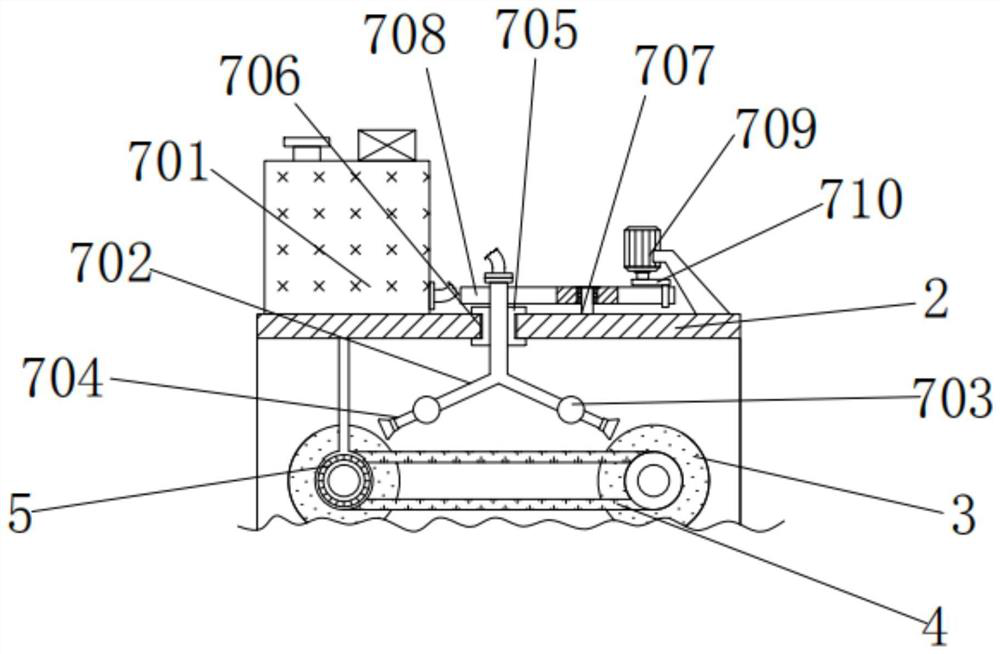

[0030] A printing and dyeing device for textiles, comprising a bottom frame 1, a square frame 2 is fixedly connected to the top of the bottom frame 1, two printing and dyeing rollers 3 are arranged inside the square frame 2, and the rear of the two printing and dyeing rollers 3 and the square frame 2 The end faces are rotationally connected, and the front shaft of the printing and dyeing roller 3 is connected by rotation through the belt 4. The belt 4 makes the printing and dyeing roller 3 rotate at the same time, and the rotating shaft of the left printing and dyeing roller 3 is fixedly connected with the output shaft of the first motor 5. The model of the first motor 5 It is ECMA-E11320RS, the top bracket of the first motor 5 is rotatably connected to the top of the inner wall of the square frame 2, there is a round roller 6 under the two printing rollers 3, and the positions of the printing rollers 3 on both sides are the same as those of the round roller 6 on the correspondi...

Embodiment 2

[0032] As an option, see figure 1 , 3 And 6, for the printing and dyeing device of textiles, the top of the square frame 2 is provided with a spray assembly 7, and the spray assembly 7 includes a barrel 701, a tee pipe 702, a round pipe 703, a nozzle 704, a slide block 705, and a chute 706 , vertical rod 707, fork plate 708, second motor 709 and curved rod 710, material cylinder 701 is fixedly connected to the top left side of square frame 2, and the right end of material cylinder 701 is communicated with three-way pipe 702 through flexible pipe, and three-way pipe 702 The outer wall of the slider 705 is provided with a slider 705, the outer wall of the tee pipe 702 runs through the inside of the slider 705 and extends into the square frame 2, the outer wall of the slider 705 is equipped with a chute 706, and the slider 705 and the chute 706 form a sliding structure , and the shape of the slider 705 is an I-shaped slider. This design can guide the slider 705. The chute 706 is...

Embodiment 3

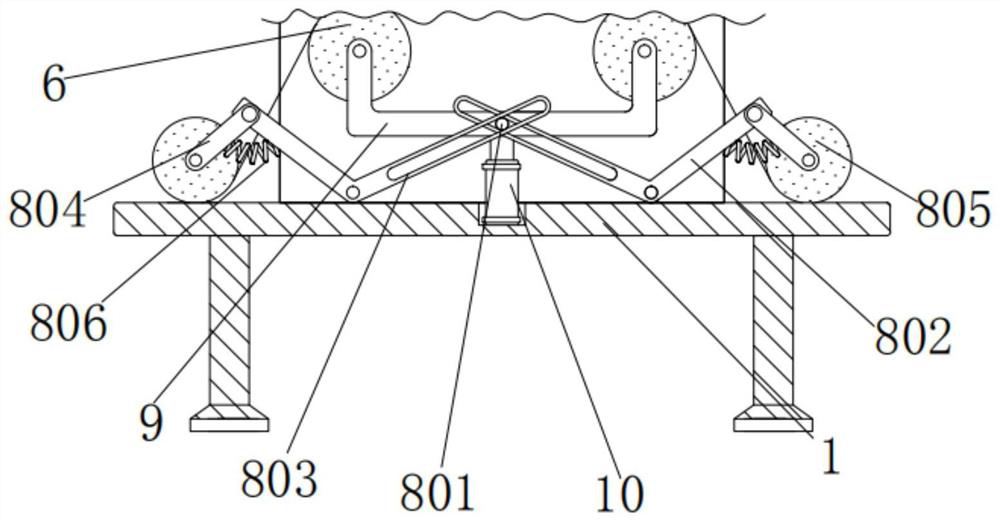

[0035] As an option, see figure 1 , 2 , 4 and 5, used for printing and dyeing devices for textiles, the inner bottom of the square frame 2 is provided with a pressing assembly 8, and the pressing assembly 8 includes a round rod 801, a curved frame 802, a through groove 803, a pole 804, a pressure roller 805 and The spring 806, the rear end of the round rod 801 is fixedly connected with the front of the bracket 9, the outer wall of the round rod 801 is fitted with a through groove 803, the through groove 803 is processed on the front inner side of the curved frame 802, and the corner of the curved frame 802 passes through the pin It is rotatably connected with the rear end face of the inner wall of the square frame 2. The square frame 2 makes the curved frame 802 rotatable when it is stressed. The outer side is rotationally connected, and the end of the support rod 804 is rotationally connected with a pressing roller 805, which is used to compress the cloth. The design makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com