Method for exploiting coal bed gas

A technology of coalbed methane and coal seam, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., and can solve the problems of stable and high production of coalbed methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A method for mining coalbed methane includes the following steps:

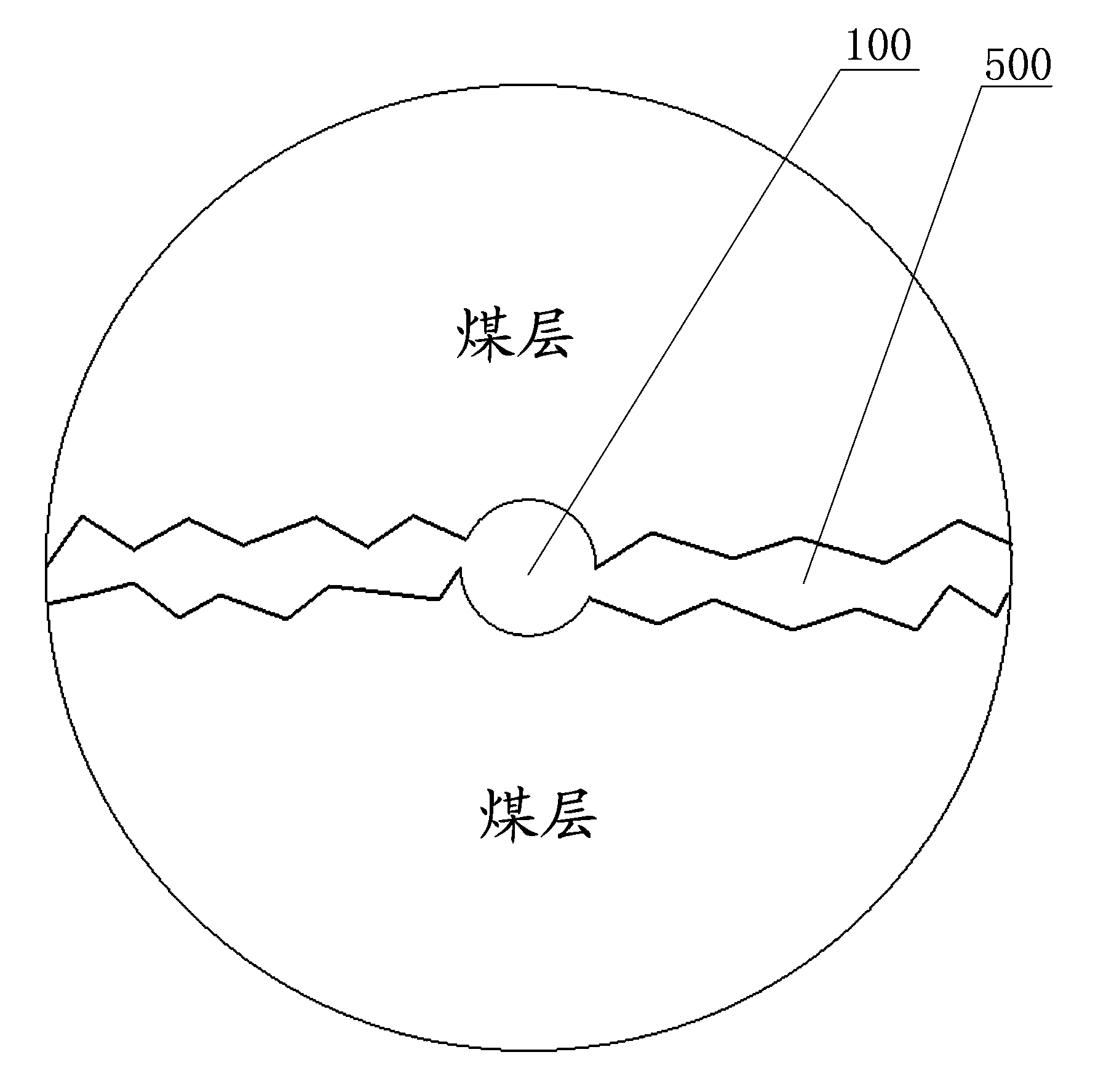

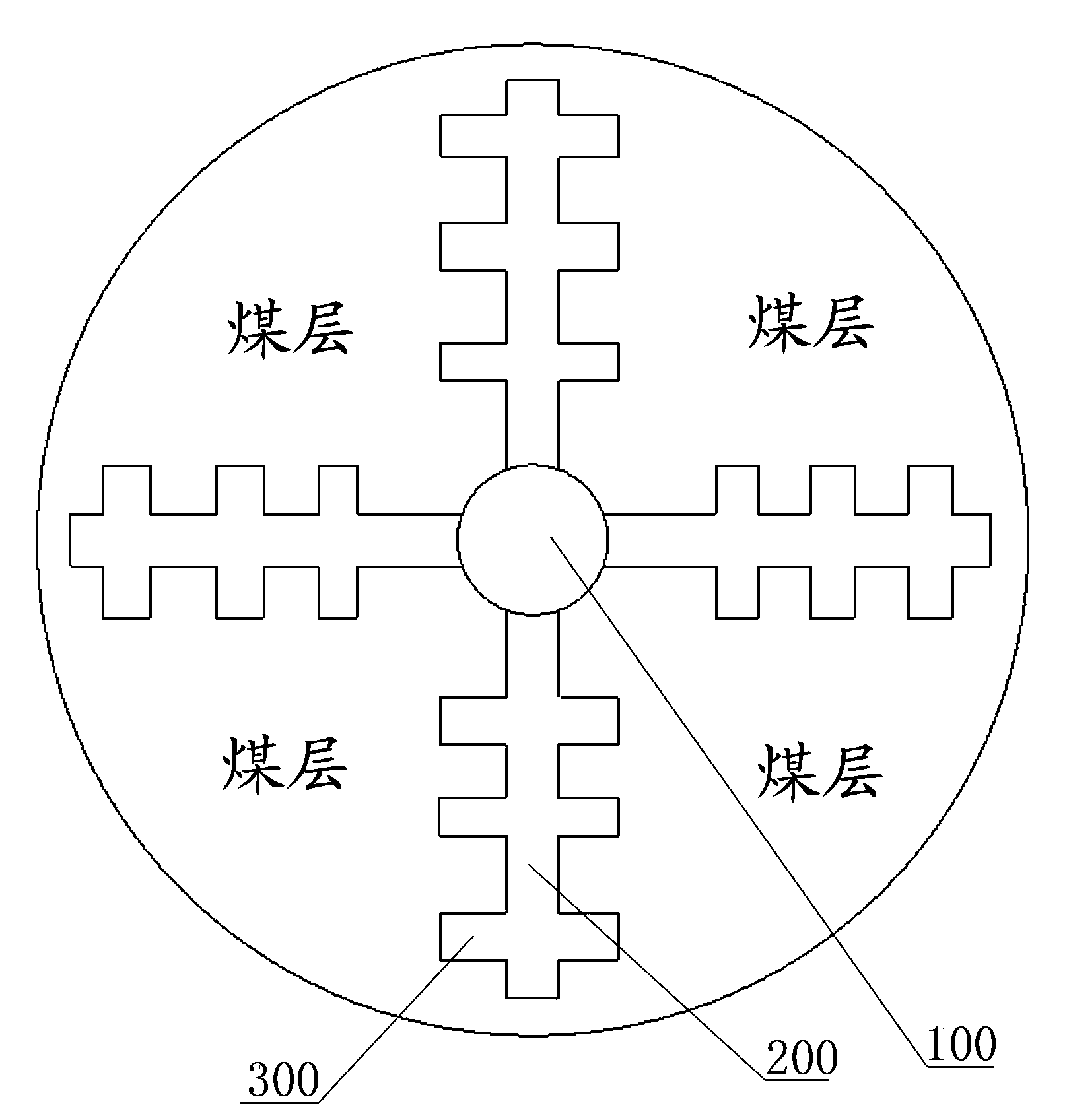

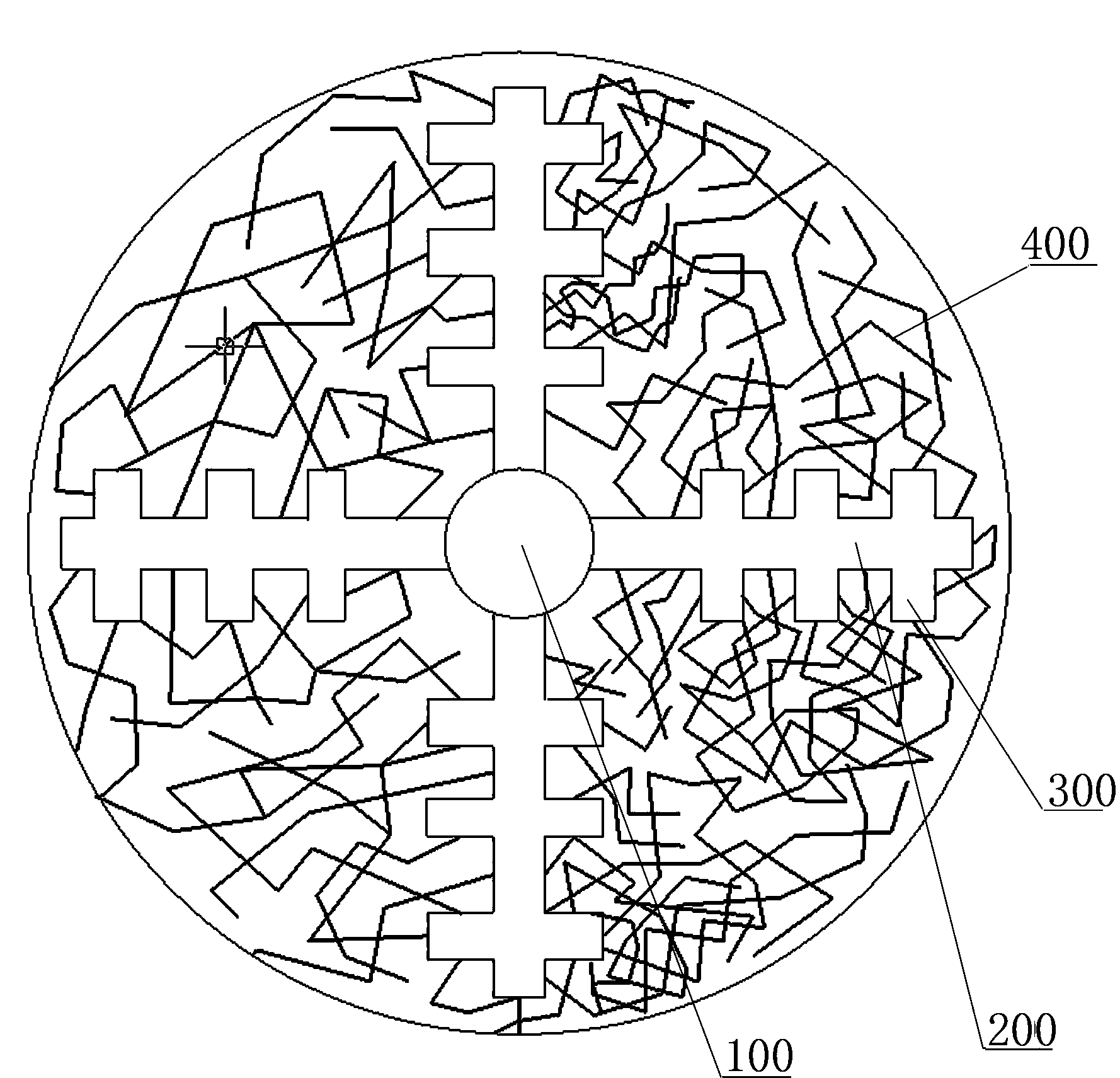

[0083] a. Design the construction plan, drill a vertical well 100 from the ground to the bottom of the coal seam, and then drill several horizontal holes 200 in multiple layers from the inner wall of the vertical well within the thickness of the coal seam. All the horizontal holes 200 distributed in multiple layers are in the axial space After interlacing, a radial shape with the vertical well 100 as the center is formed; the vertical well 100 and the horizontal hole 200 are filled with active water; figure 2 Shown.

[0084] In specific implementation, the WITSUN model of fully enclosed radial well equipment uses high-pressure jet radial horizontal drilling, magnetic positioning + natural gamma logging to determine the casing window depth, and a gyro inclinometer to determine the casing window position. Then, a milling drill bit is used to make a hole on the casing of the target layer, and then a high-press...

Embodiment 2

[0090] The difference between this embodiment and Embodiment 1 is that step c is omitted.

Embodiment 3

[0092] The difference between this embodiment and Embodiment 1 lies in that step b is omitted.

[0093] The design of multi-pulse seam making parameters is as follows:

[0094] 1. Design basis: The peak pressure is between the fracture pressure of the coal seam and the compressive strength of the casing. The design peak pressure of multi-pulse composite joint making is 30MPa.

[0095] 2. Assumptions: The propellant is burned in a confined space; all the generated gas enters the formation through the perforation; the mixed gas conforms to the ideal gas state equation;

[0096] 3. According to the gas state correction equation:

[0097] (A) M1=(μπPHR 2 Set) / (KRT);

[0098] M1: The amount of propellant used to establish the pressure of the initial fractured coal seam, that is, the internal type I and II agent (kg);

[0099] P: Design peak pressure;

[0100] H: Design pressure relief section in the casing;

[0101] R sleeve: inner radius of sleeve;

[0102] K: Gas production volume of the medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com