Tungsten carbide spraying equipment with both grinding and surface defect repair functions

A technology of spraying equipment and defect repair, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine parts, etc., can solve the problems of uneven surface of the roll, repair, and the failure of the grinding sheet to fit, etc., to improve the performance The effect of leveling the effect and improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

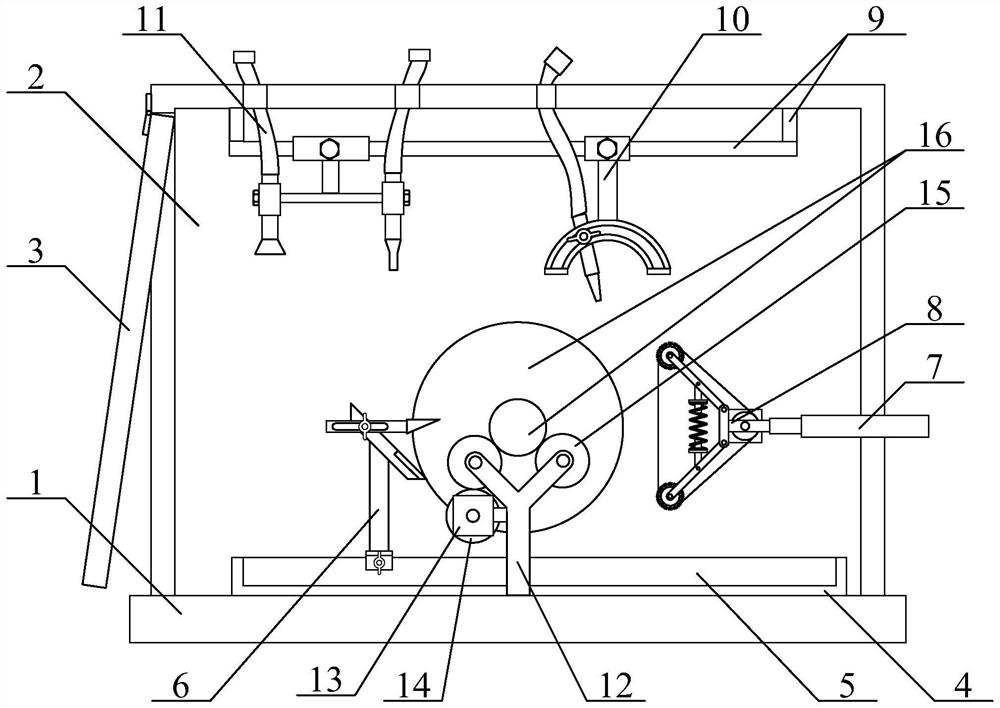

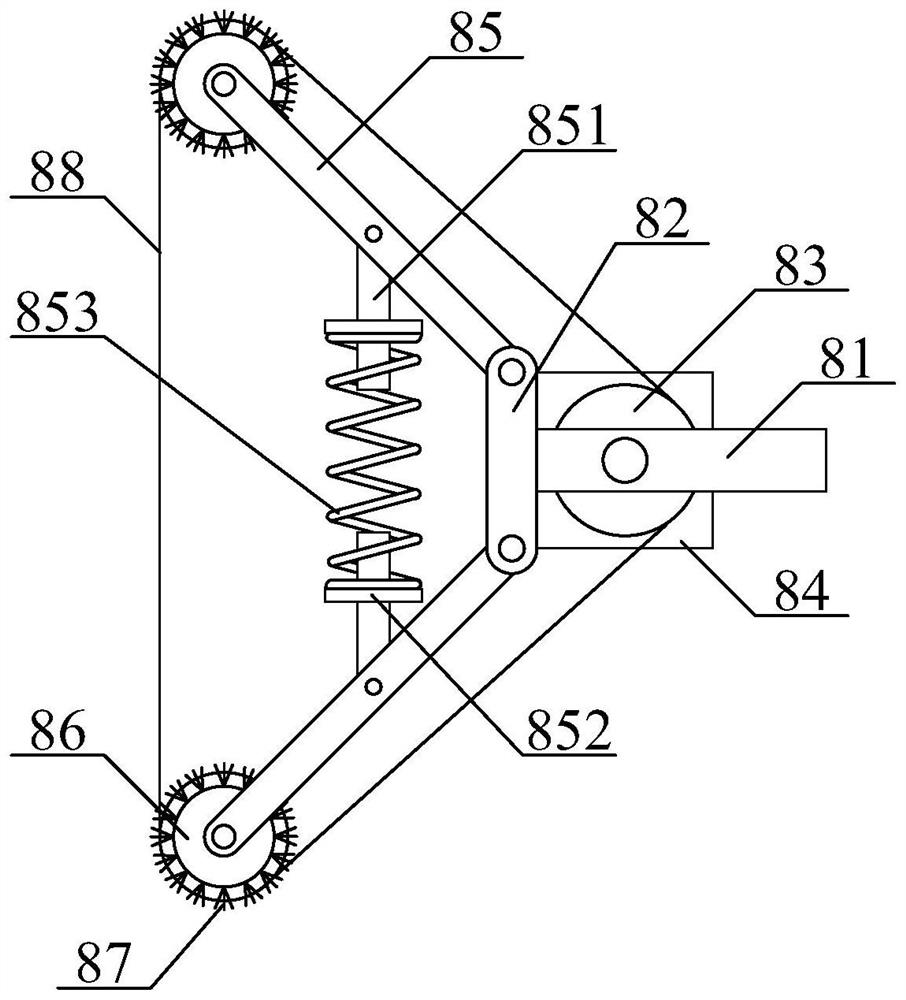

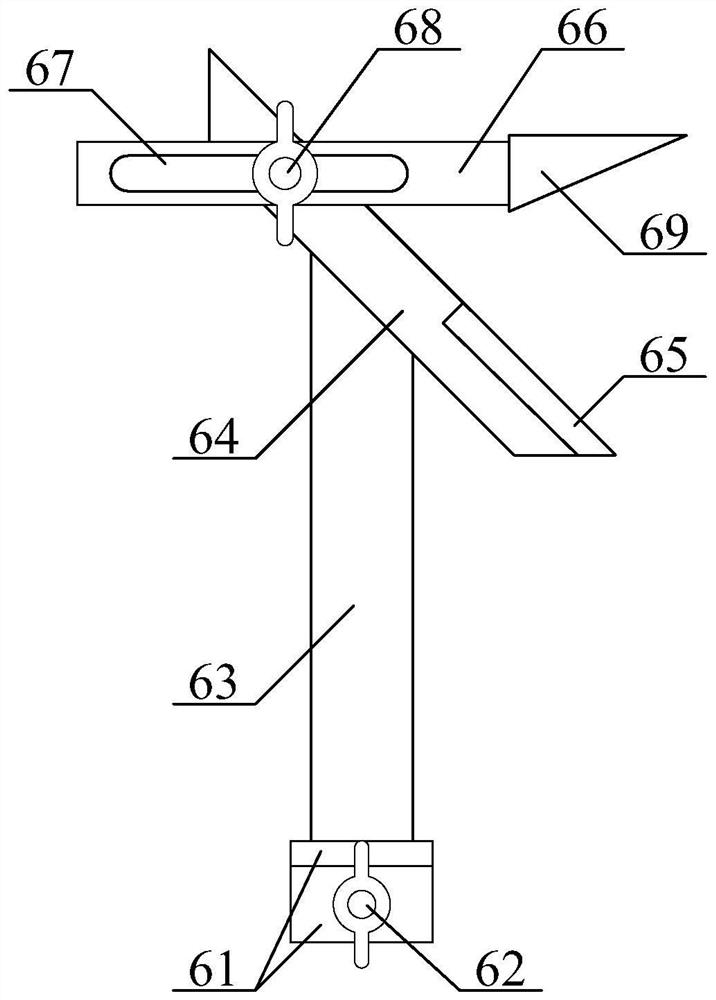

[0039] as attached figure 1 And attached figure 2 As shown, a tungsten carbide spraying equipment with both grinding and surface defect repairing functions includes a base 1, a casing 2, a protective cover 3, a collection frame 4, a collection tank 5, a roll shaping frame structure 6, a cylinder 7, and an arc surface Polishing frame structure 8, guide rail 9, adjustable spray gun fixed frame structure 10, processing and cleaning frame structure 11, Y-shaped frame 12, driving motor 13, driving wheel 14, driven wheel 15 and roll to be processed 16, the shell 2 bolts Connected to the upper part of the base 1; the hinge of the protective cover 3 is connected to the inner left side of the shell 2; the collection frame 4 is bolted to the upper middle position of the base 1; the collection groove 5 is opened on the collection frame 4; the roll shaping frame structure 6 is installed on the upper left side of the collection frame 4; the cylinder 7 bolts are connected to the inner rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com