Method for constructing sludge treatment system based on sludge component

A sludge treatment and sewage treatment technology, applied in water/sludge/sewage treatment, sludge treatment, separation methods, etc., can solve problems such as spending a lot of energy, improve treatment effect, high construction efficiency, and save equipment and space effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]Oil-based mud treatment, oil-based mud is the oil-based mud mixed with a large amount of drill cuttings produced during the oil and gas field production process, accompanied by the use of oil-based drilling fluid during the drilling process. Molecular polymer mixed with rock debris, containing water (<10%), oil (15-40%), and solids (50-70%).

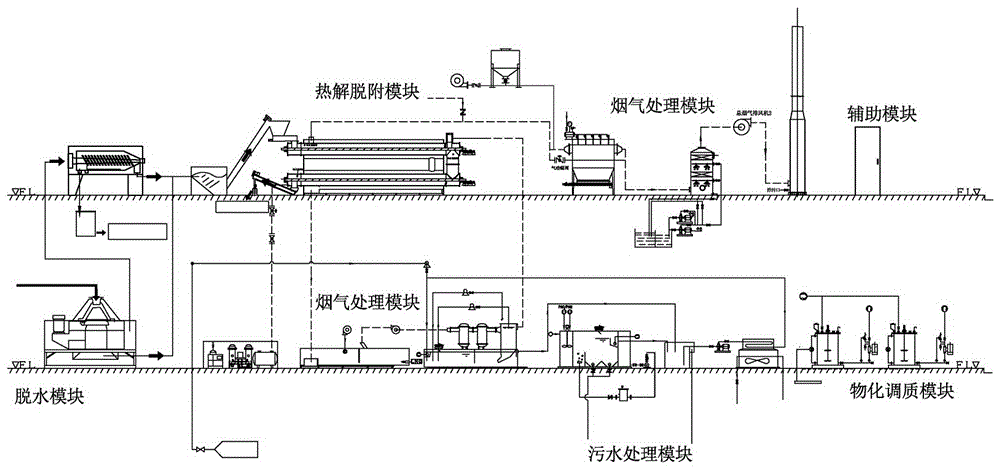

[0055] according to figure 1 As shown, the treatment adopts physicochemical conditioning module, dehydration module, thermal desorption module, flue gas treatment module, sewage treatment module and auxiliary module. The module adopts a drying machine and a centrifuge, first drying and then centrifuging; the thermal desorption module adopts a two-stage inner auger type furnace body; the flue gas treatment module includes a secondary combustion device, a three-phase separation device and a bag dust removal device ; Auxiliary modules are nitrogen generation / storage device and mobile master control room.

[0056] In the thermal deso...

Embodiment 2

[0058] Water-based mud treatment, water-based mud is the waste containing various chemical agents mixed with a large amount of drill cuttings produced during the drilling process of oil and gas fields. A mixture of high molecular polymers such as lubricants, anti-slump agents, flow regulators, and oil-preserving materials and drilling cuttings, containing water (<5%), oil (10-20%), and solids (50-70%) %).

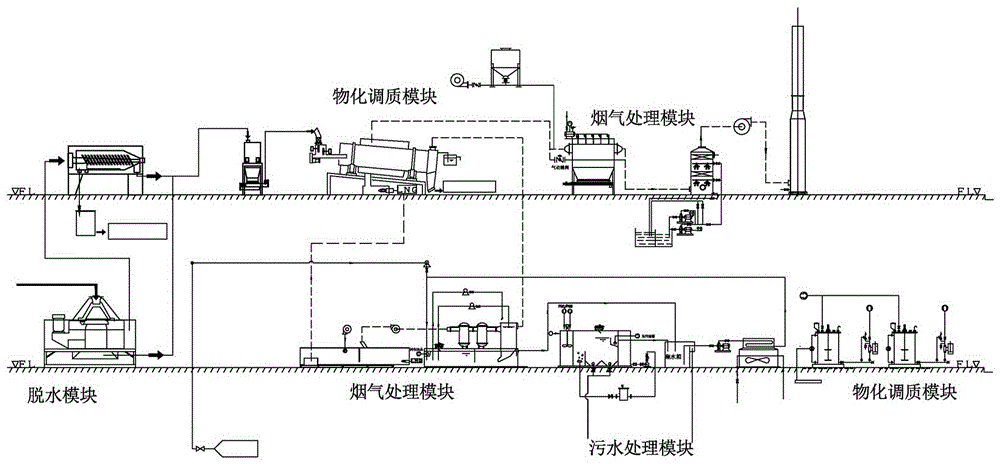

[0059] according to figure 2 As shown, the treatment adopts the physical and chemical conditioning module, dehydration module, drying / drying module, flue gas treatment module, and sewage treatment module. The drying / drying module adopts a drum-type high-efficiency drying device; the flue gas treatment module includes a secondary combustion device, a three-phase separation device and a bag dust removal device.

[0060] The maximum reaction temperature in the drum-type high-efficiency drying device: 150-300°C, the residence time of the material at the maximum reaction temp...

Embodiment 3

[0062] Landed sludge treatment, landed sludge is the oily sludge produced by well site operations and pipeline equipment leakage in the process of oilfield exploitation, including crude oil transportation, equipment maintenance and oil well breaking process, crude oil leakage to the ground, blowout and blowout accidents, etc. The crude oil caused by the leakage of crude oil on the ground and other reasons flows to the ground, thereby forming a landing sludge on the ground. Landed sludge contains a mixture of crude oil, sand and gravel, and weeds. The light components are volatilized, and the heavy oil is mainly black, viscous, coarse, and contains a lot of weeds, woven bags, large pieces of gravel, etc. Foreign matter, containing water (5-10%), oil (5-10%), and solid (80-90%).

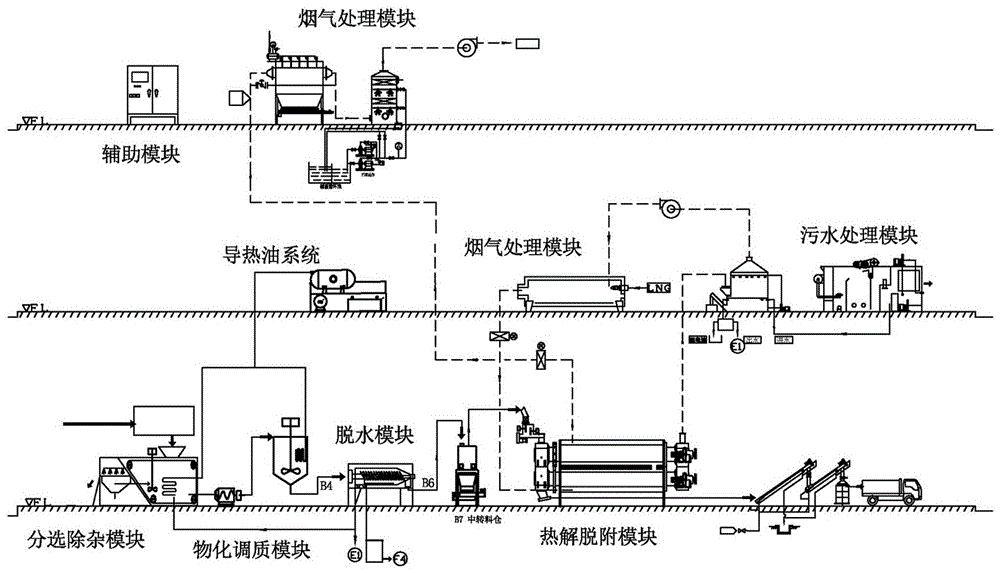

[0063] according to image 3 As shown, the treatment adopts the sorting and impurity removal module, the physical and chemical conditioning module, the dehydration module, the thermal desorption modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com