Ground wire and core wire automatic wire placing and stranding device for cable processing

A land and cable technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high work intensity and low work efficiency, and achieve the effects of reducing labor intensity, improving work efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

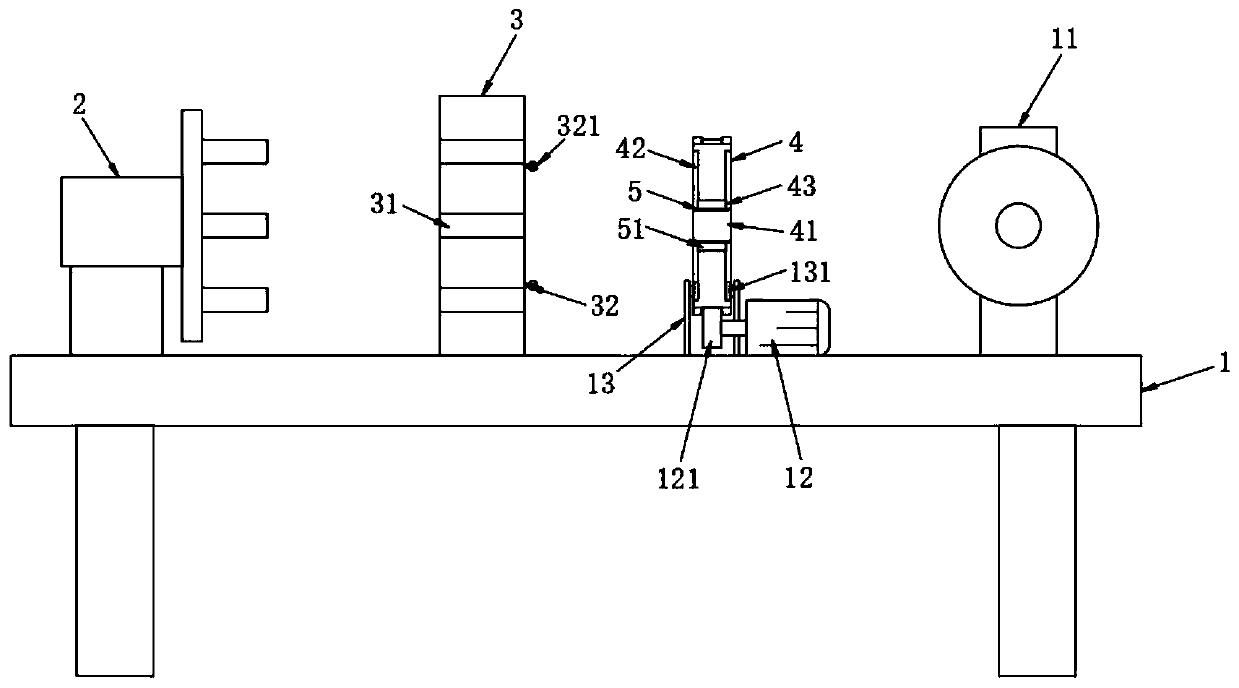

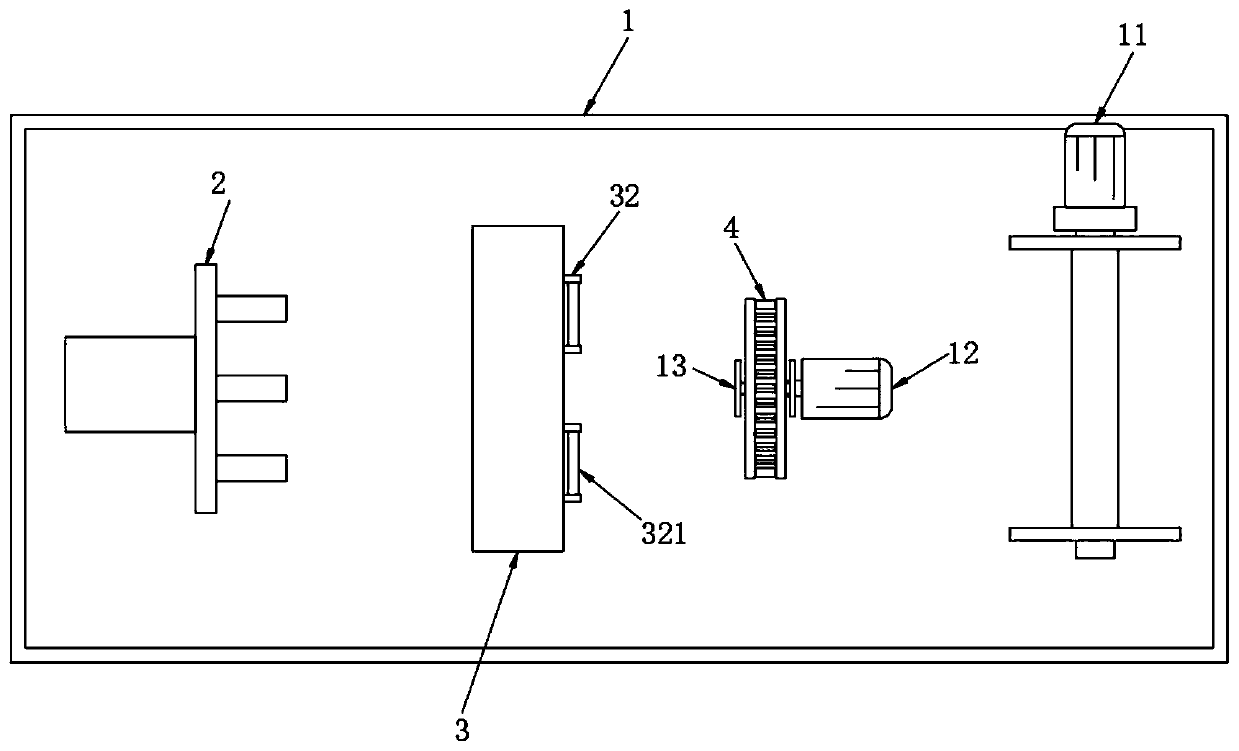

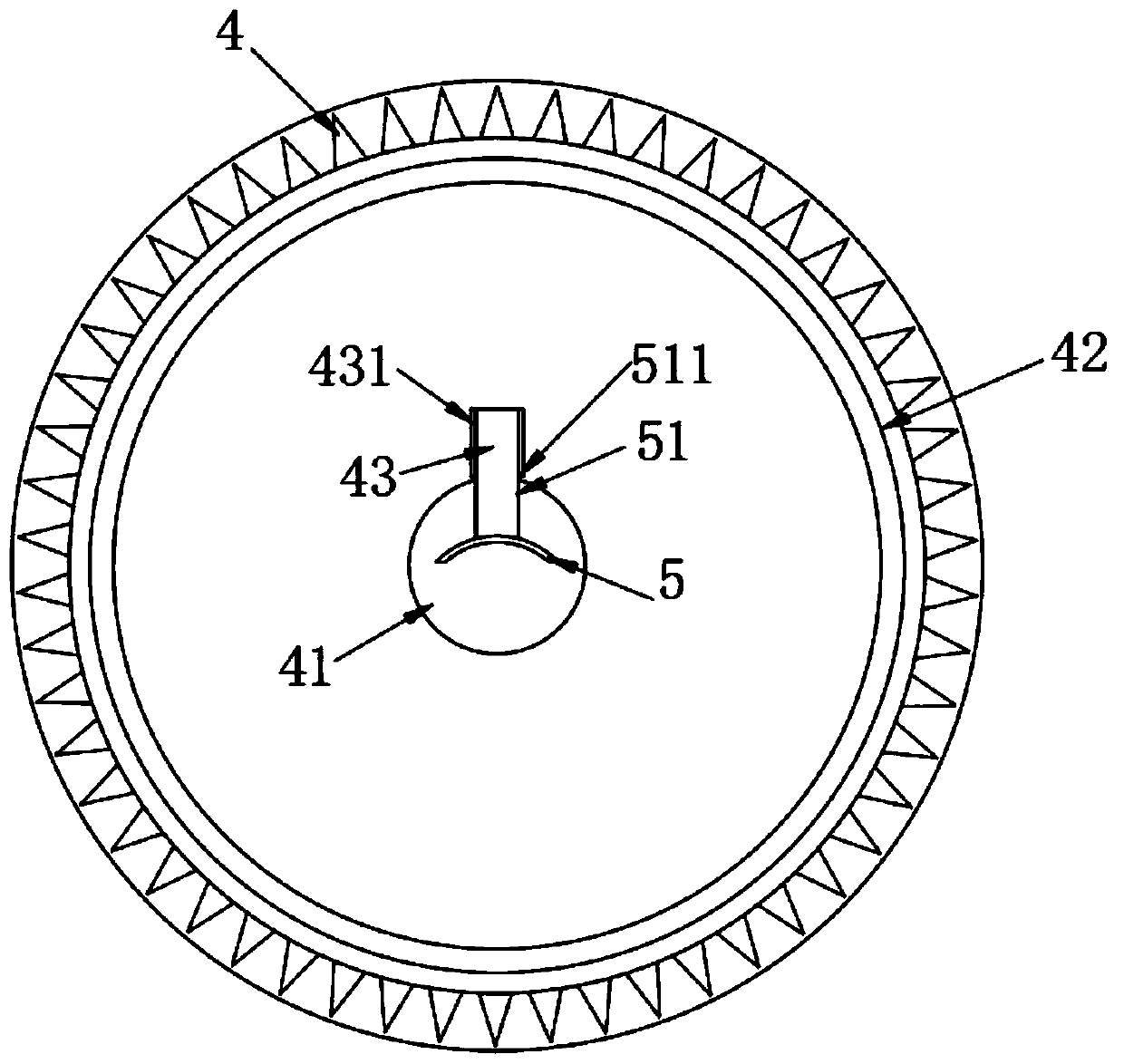

[0027] see Figure 1-5 , the present invention provides a technical solution for the automatic release and plying device of ground wire core wires for cable processing: including a workbench 1, a pay-off plate 2 is fixedly connected to the left side of the top of the workbench 1, and a wire branch block 3 is fixedly connected to the top of the workbench 1, The distribution block 3 is located on the right side of the release plate 2. There are five through holes 31 inside the distribution block 3. The motor 12 is fixedly connected to the top of the workbench 1. The motor 12 is electrically connected to the external power supply. The motor 12 is located in the distribution block. 3. On the right side, the output end of the motor 12 is fixedly connected with a gear 121, the top of the workbench 1 is provided with a ring gear 4, the ring gear 4 is meshed with the gear 121, and the top of the workbench 1 is fixedly connected with two symmetrically distributed mounting plates 13 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com