Patents

Literature

158results about How to "Improve joint performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

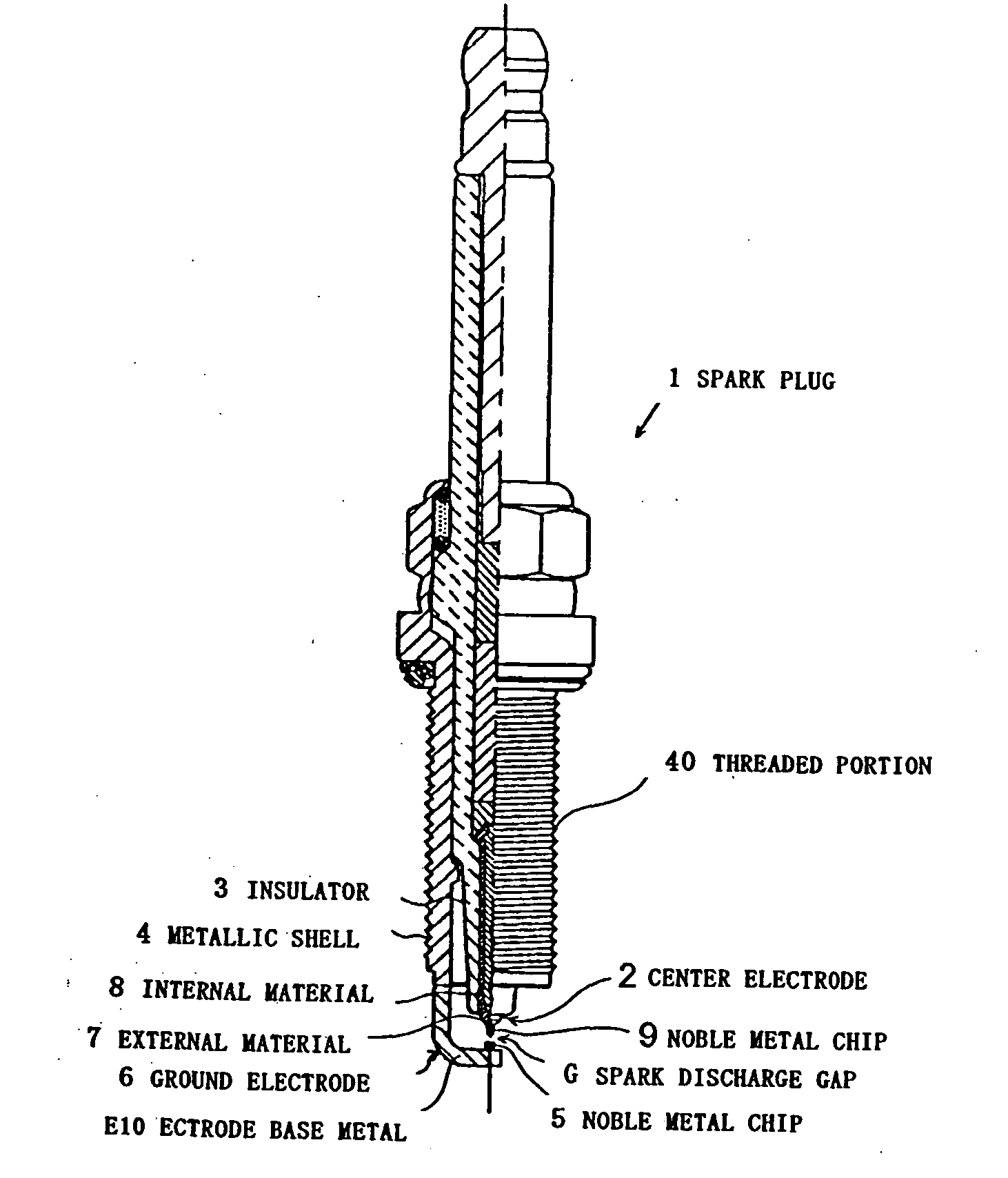

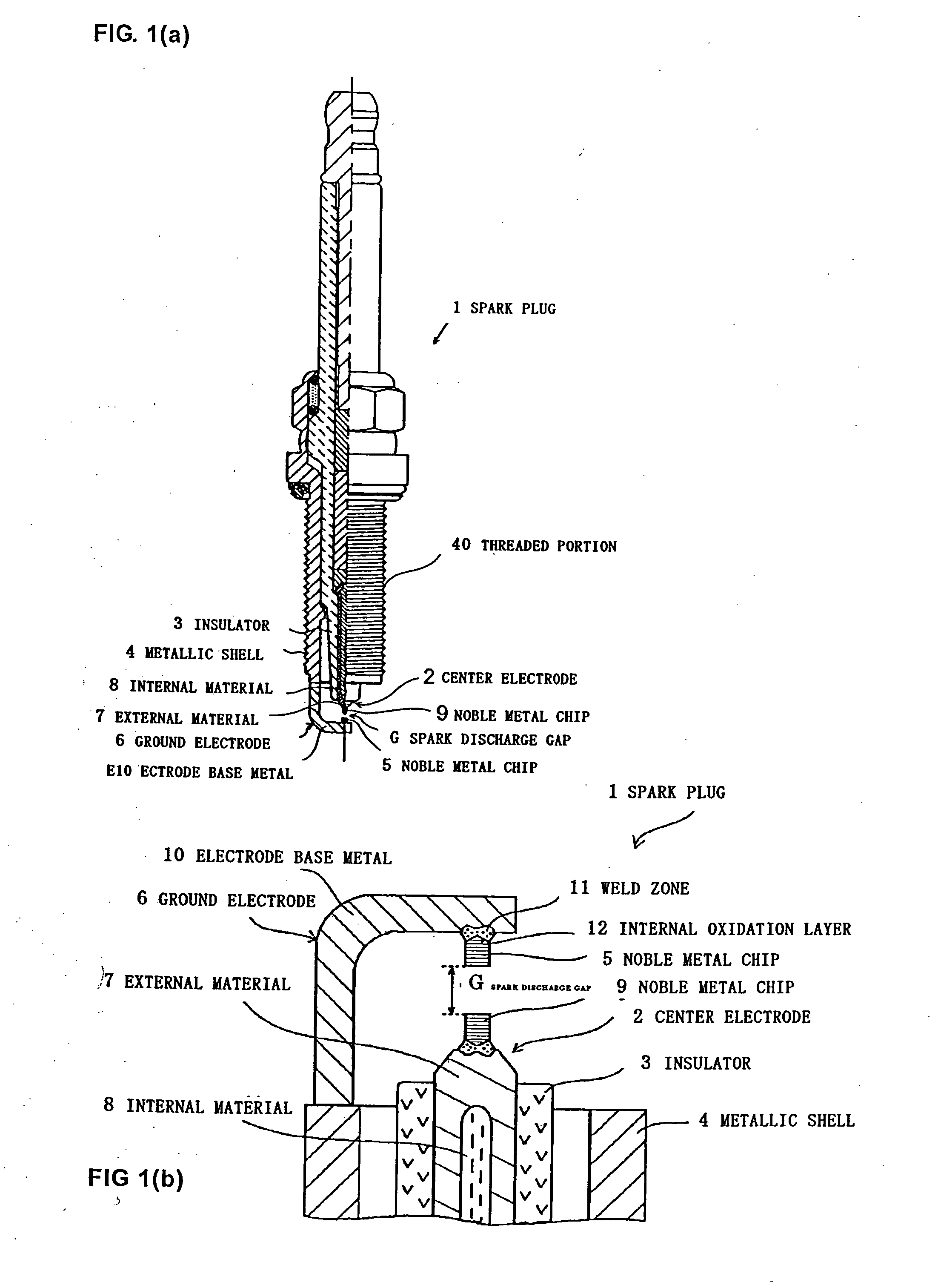

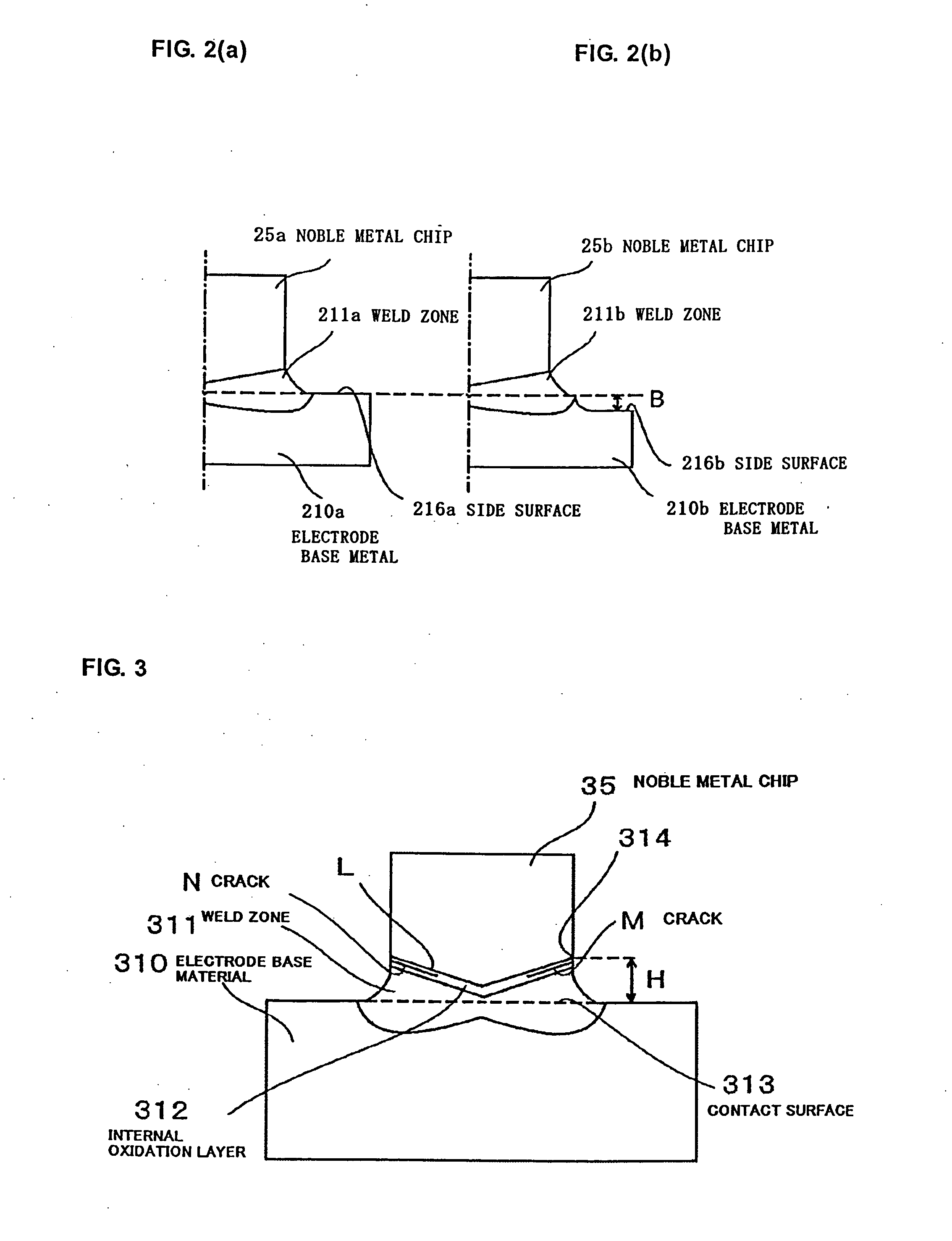

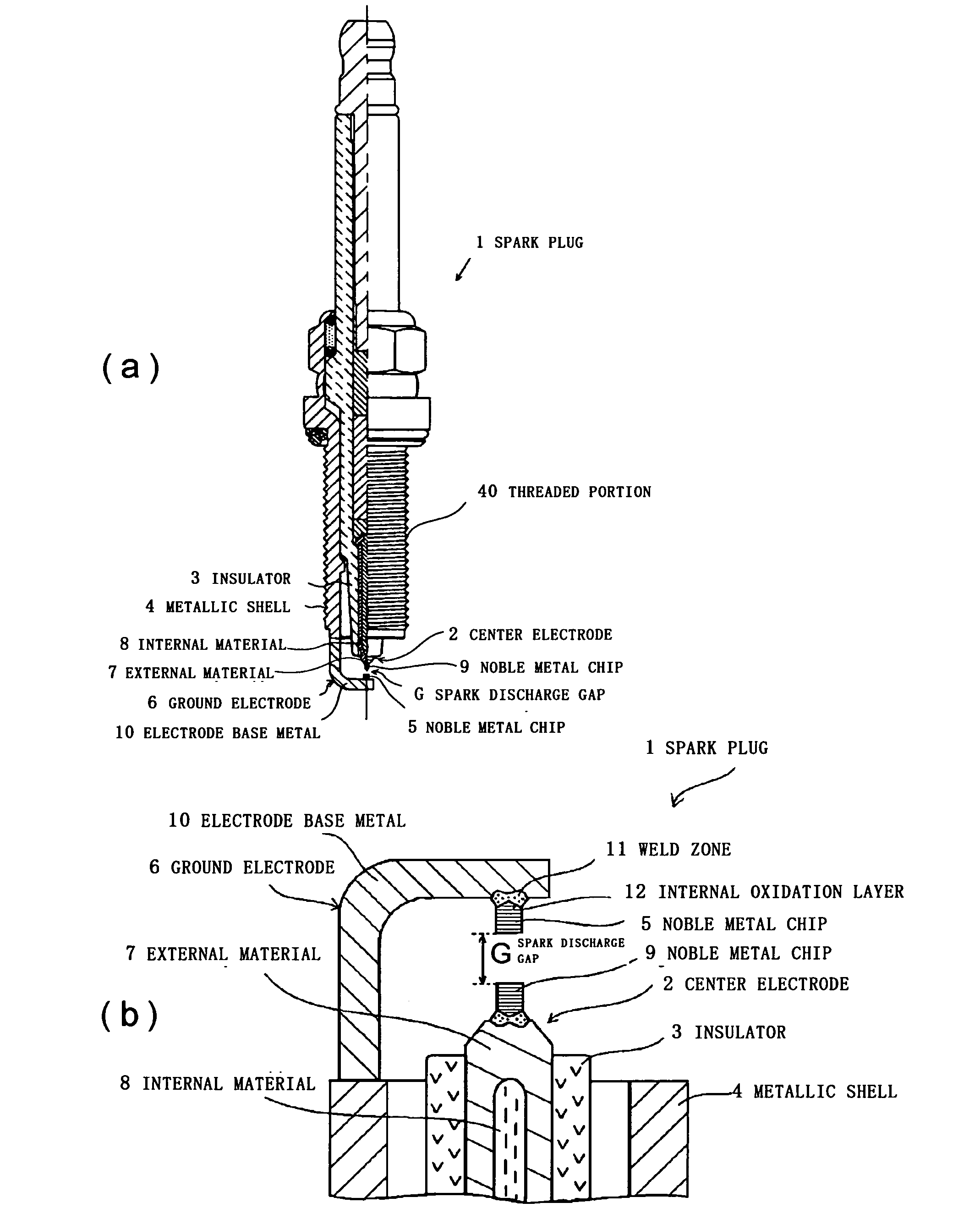

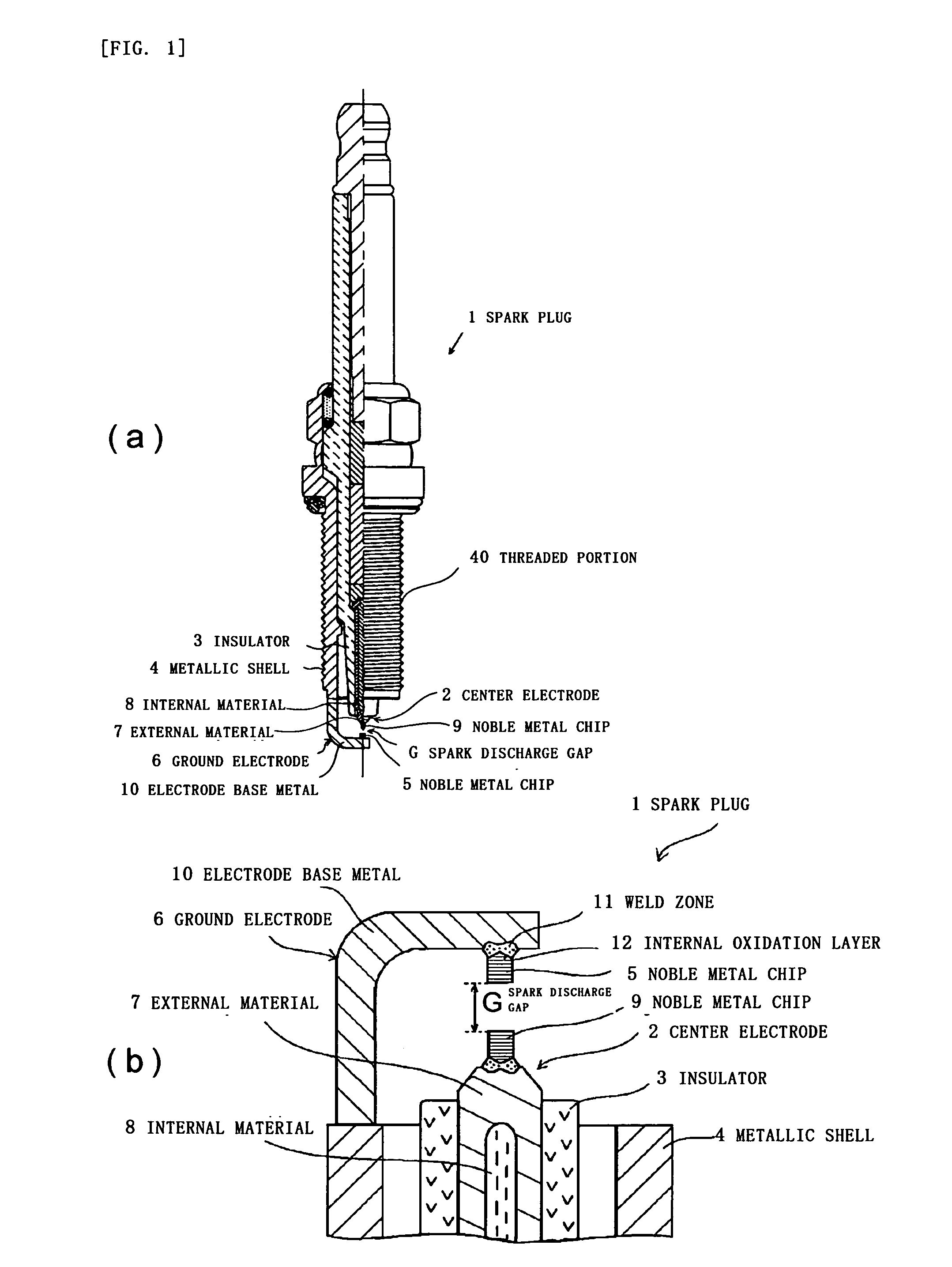

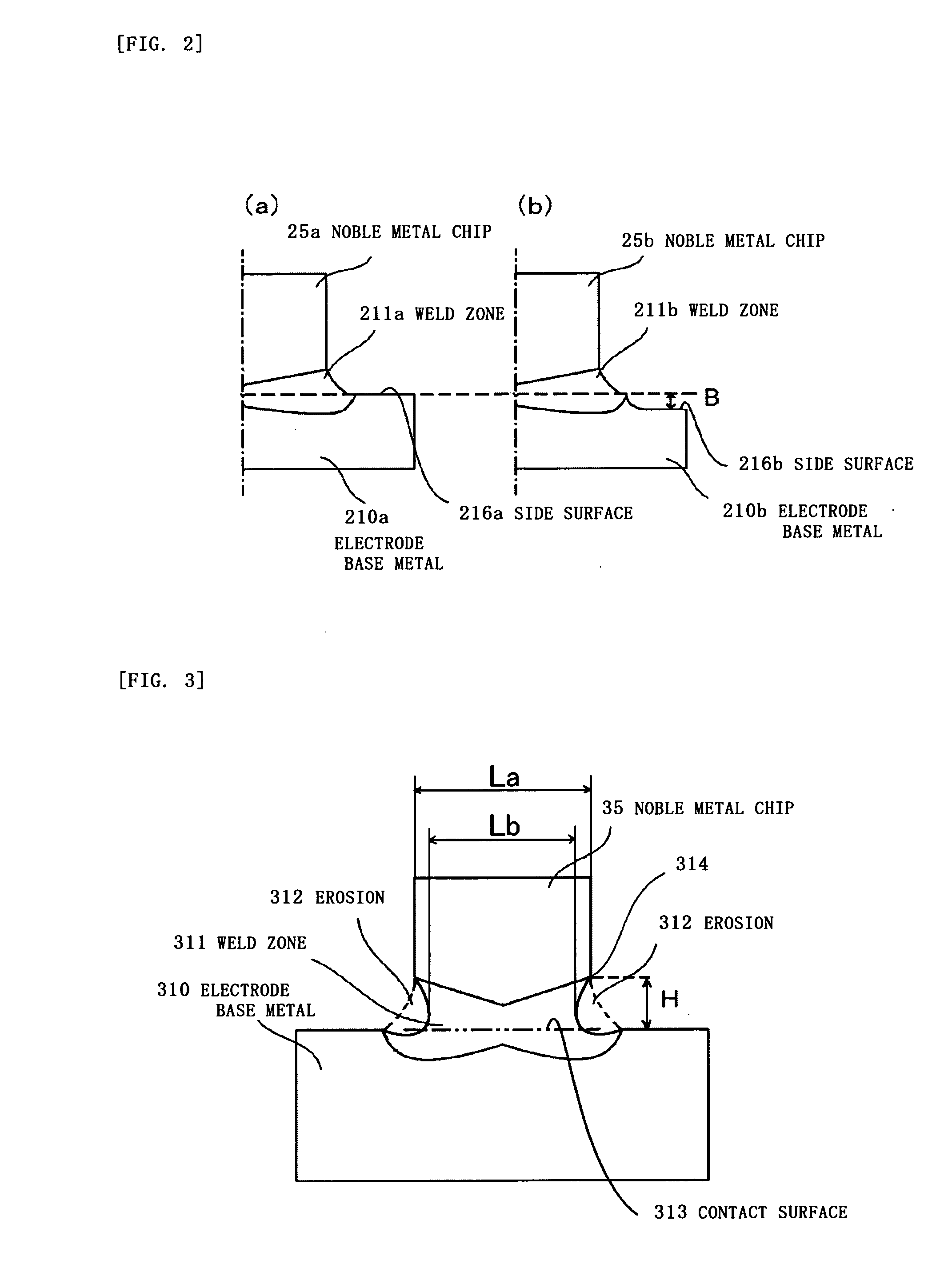

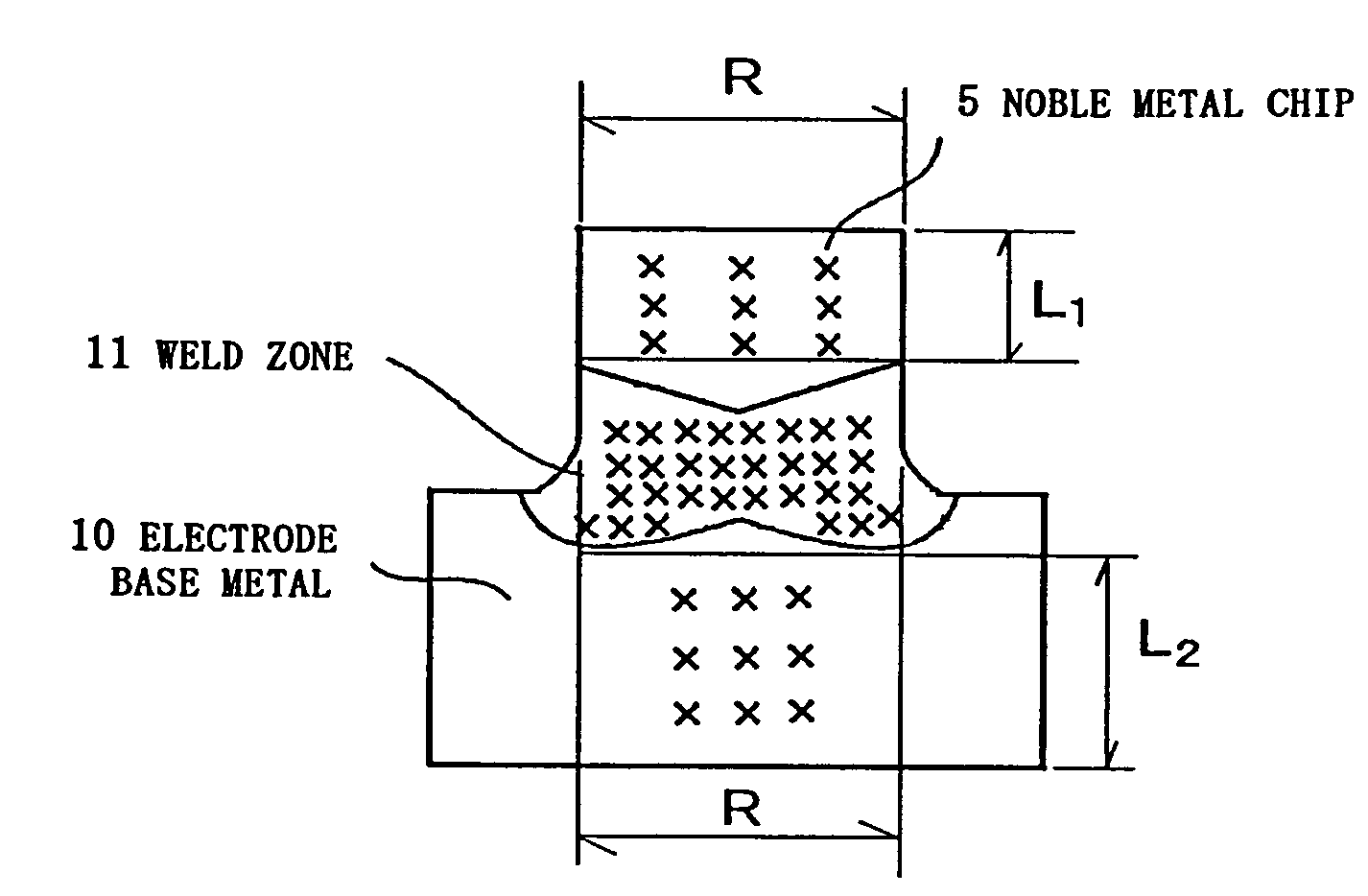

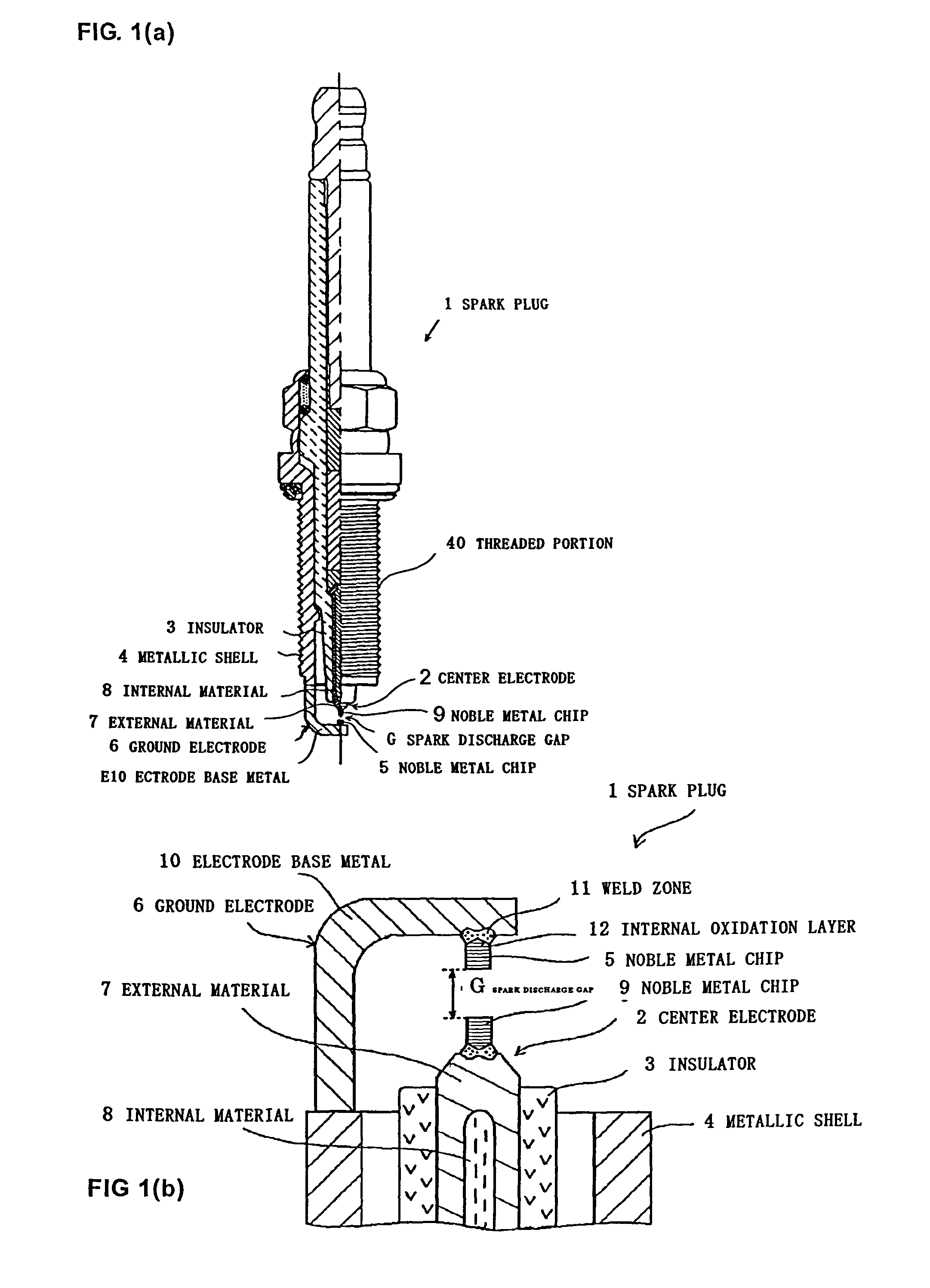

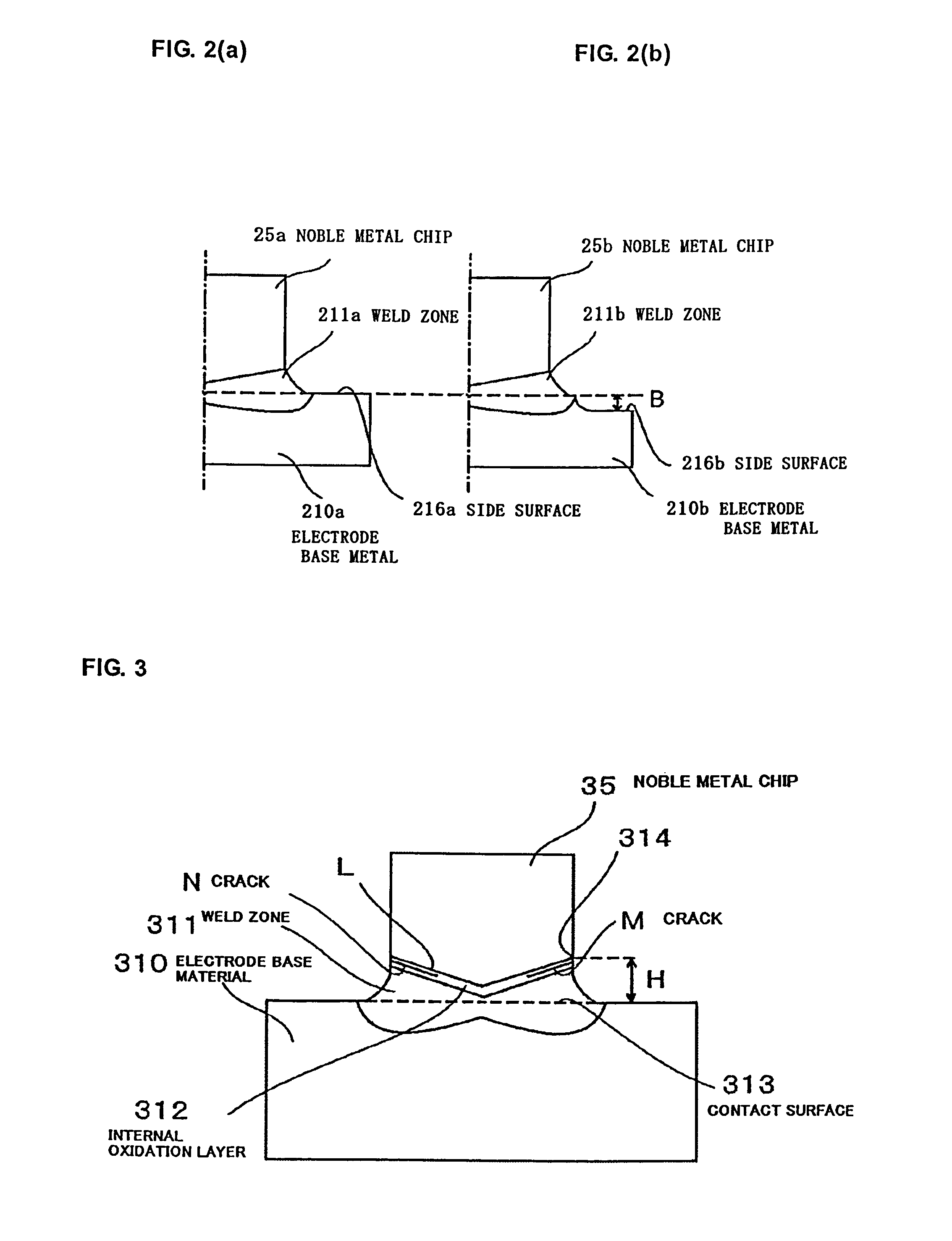

Spark plug and process for producing the spark plug

ActiveUS20100264802A1Prevent oxidationPrevent separation and detachmentSpark gapsSparking plugs manufactureEngineeringSpark plug

A spark plug in which an ignition portion of a ground electrode formed through joining of a noble metal chip to the ground electrode has high durability, and a method of manufacturing the spark plug.

Owner:NGK SPARK PLUG CO LTD

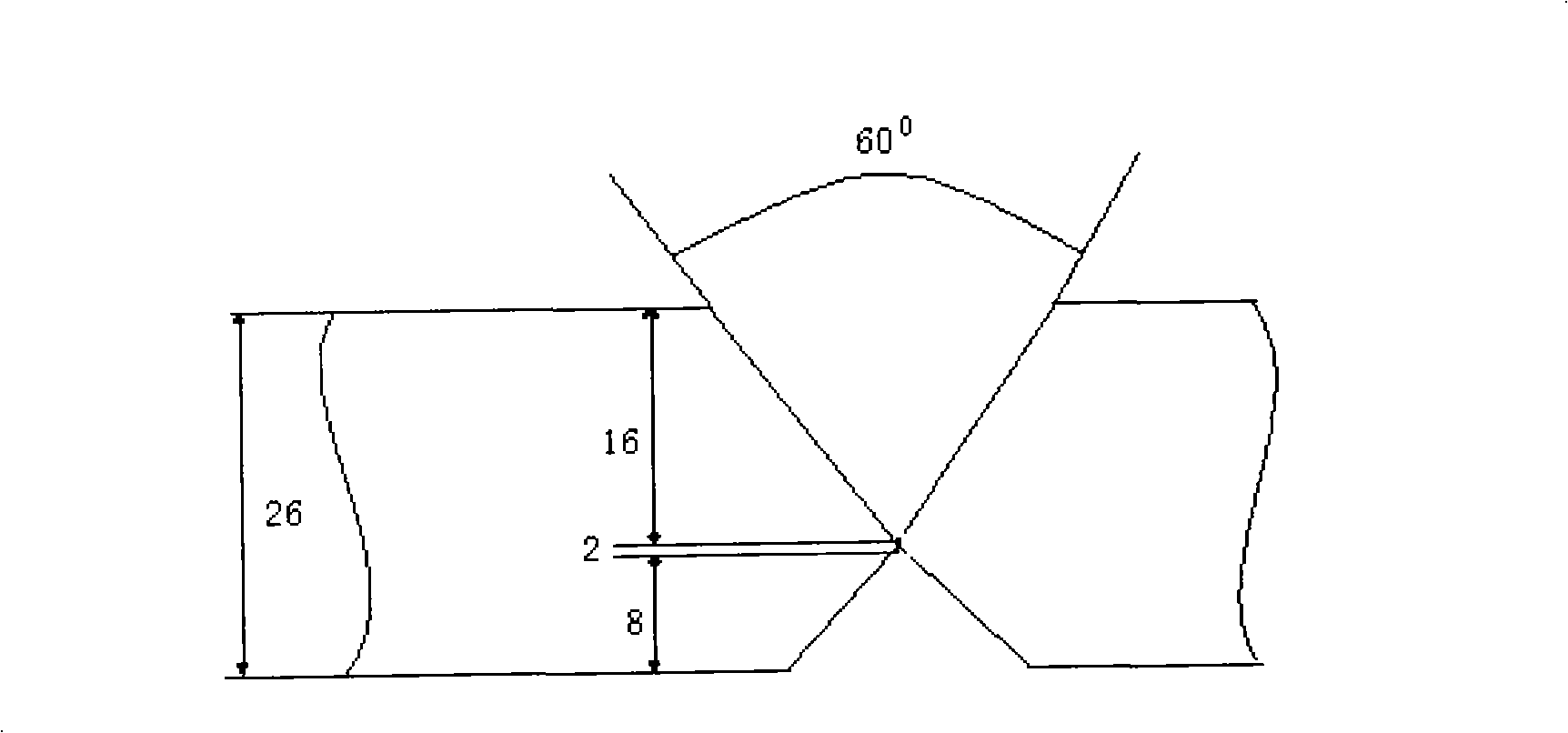

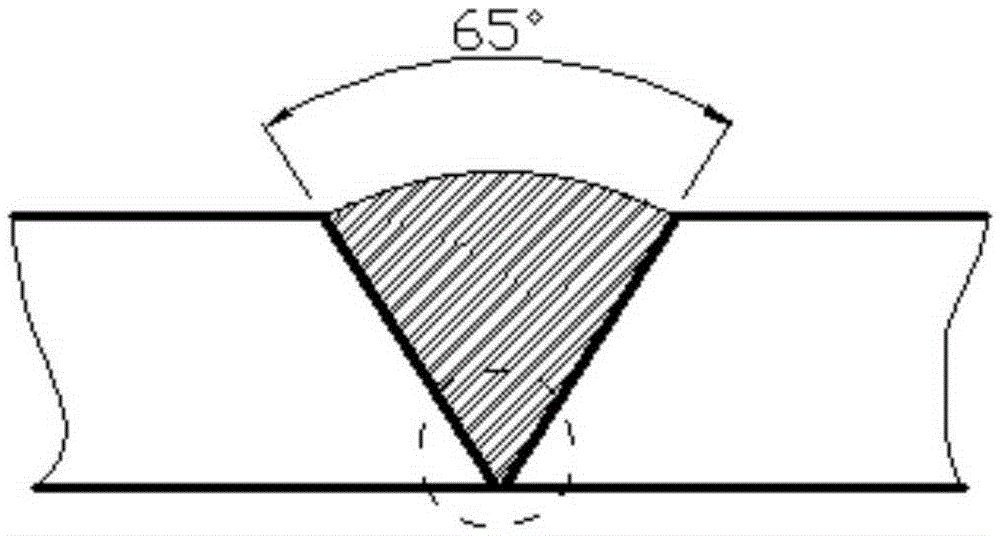

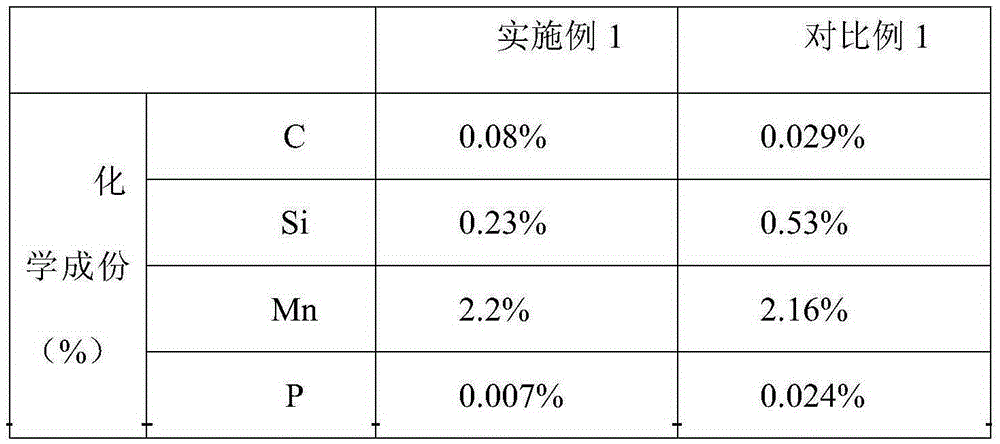

High intensity steel gas shielded welding technique method

InactiveCN101310908AHigh Impact Toughness ReserveImprove crack resistanceArc welding apparatusChemical compositionEngineering

The invention relates to a gas shielded welding technological method of high strength steel, which comprises the following technological steps: (1) a gas shielded welding joint is cut with a dual-V dissymmetrical divided edge at the angle of 60 degrees and the blunted edge of 2mm; (2) welding wires with the nominal strength of 700MPa are adopted for welding and have the tensile strength of a deposited metal of Rm more than or equal to 700MPa; (3) the mixed gas-shielded welding with 20 percent of CO2 plus 80 percent of Ar and argon-rich gas is adopted and no preheating is required before the welding and no heat treatment is carried out after welding; (4) the chemical composition of the welding wires adopted by weight percentage is that: C is 0.04 to 0.12, Si is 0.40 to 0.80, Mn is 1.40 to 2.0, P is less than or equal to 0.020, S is less than or equal to 0.015, Ni is 0.40 to 1.0, Cr is 0.20 to 0.50, Ti is 0.06 to 0.20, Cu is 0.30 to 0.50, B is 0.002 to 0.0079, Als is less than or equal to 0.02. The method of the invention has good welding technological performance, simple operation, convenient application and high efficiency and energy saving, and is quite applicable to the welding of steel used in a high-strength structure in the ocean engineering.

Owner:武钢集团有限公司

Aluminum alloy intermediate temperature solder for braze welding

ActiveCN1970213ASolving Brazing ProblemsSimple processWelding/cutting media/materialsSoldering mediaSolderingUltimate tensile strength

It relates to an aluminum alloy solder with its components' mass percentage 16-20%Cu,5-8%Si,0.2-2.0%Mn,0-2%Mg, and the rest being Al. Small portion of Ti and B fine grains can be added to the solder to improve processing performance. The molten temperature of solder ranges 500-540DEG C, solder welding temperature 540-570DEG C, suitable for aluminum alloy soldering with the solids line temperature below 540DEG C. The solder can be made into different types like blocks, quick condensed strips or bars, suitable for vacuum soldering, protective solder and flame solder. The solder 6A02,2A5 alloy joint has tensile strength bigger than 100MPa, joint shearing force bigger than 80Mpa, without significant reduction of the joint strength after 200h salt fog corrosion.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

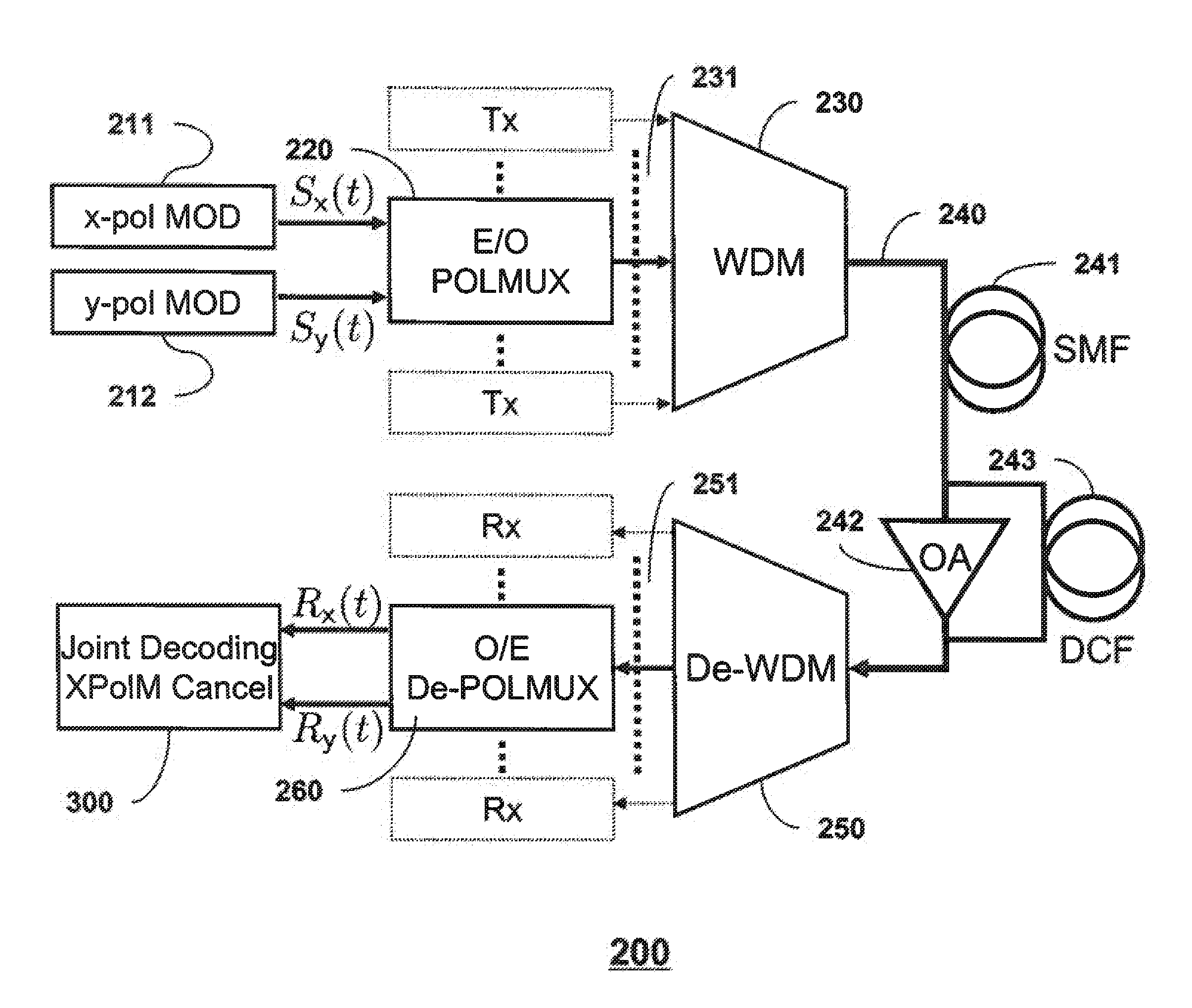

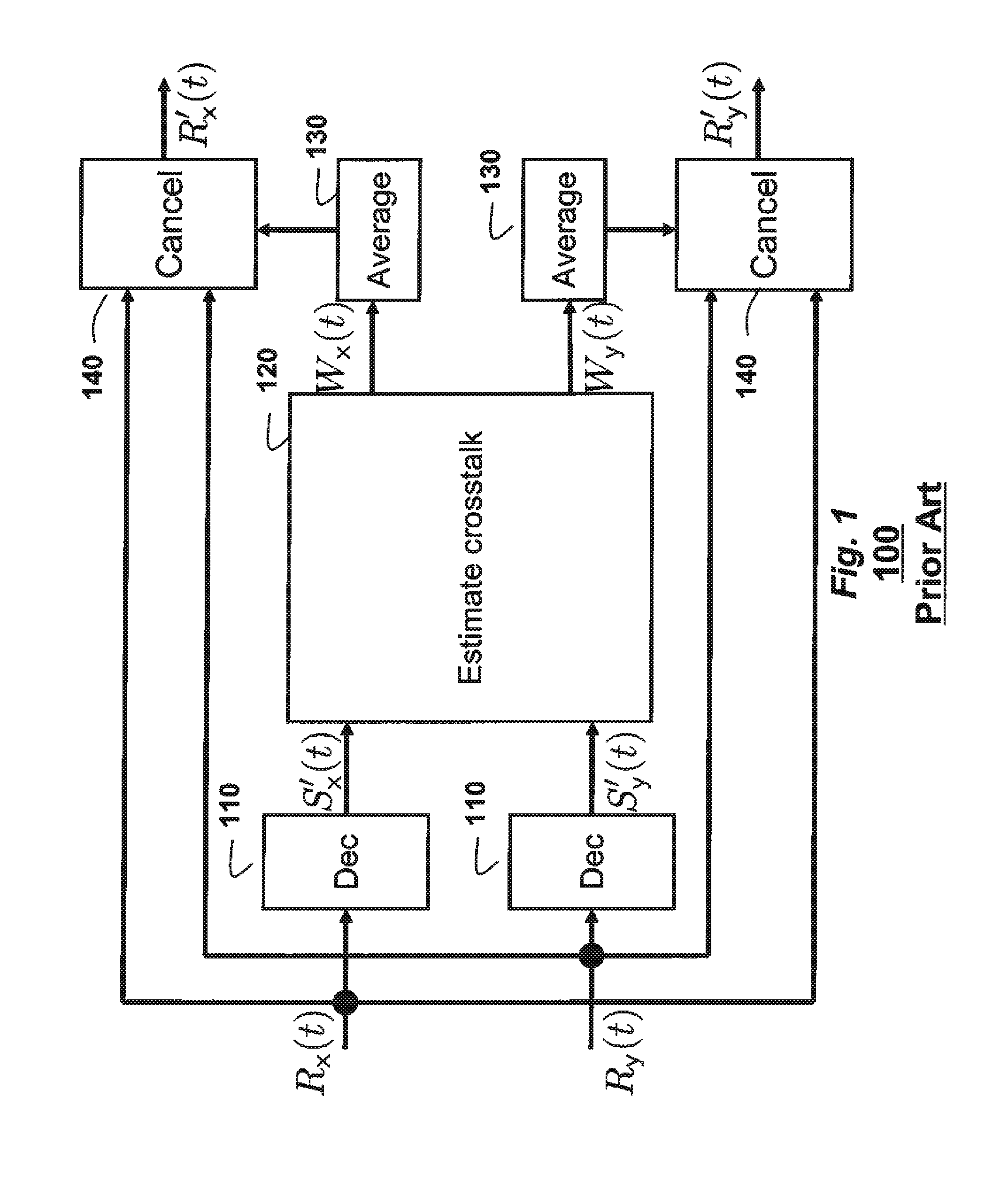

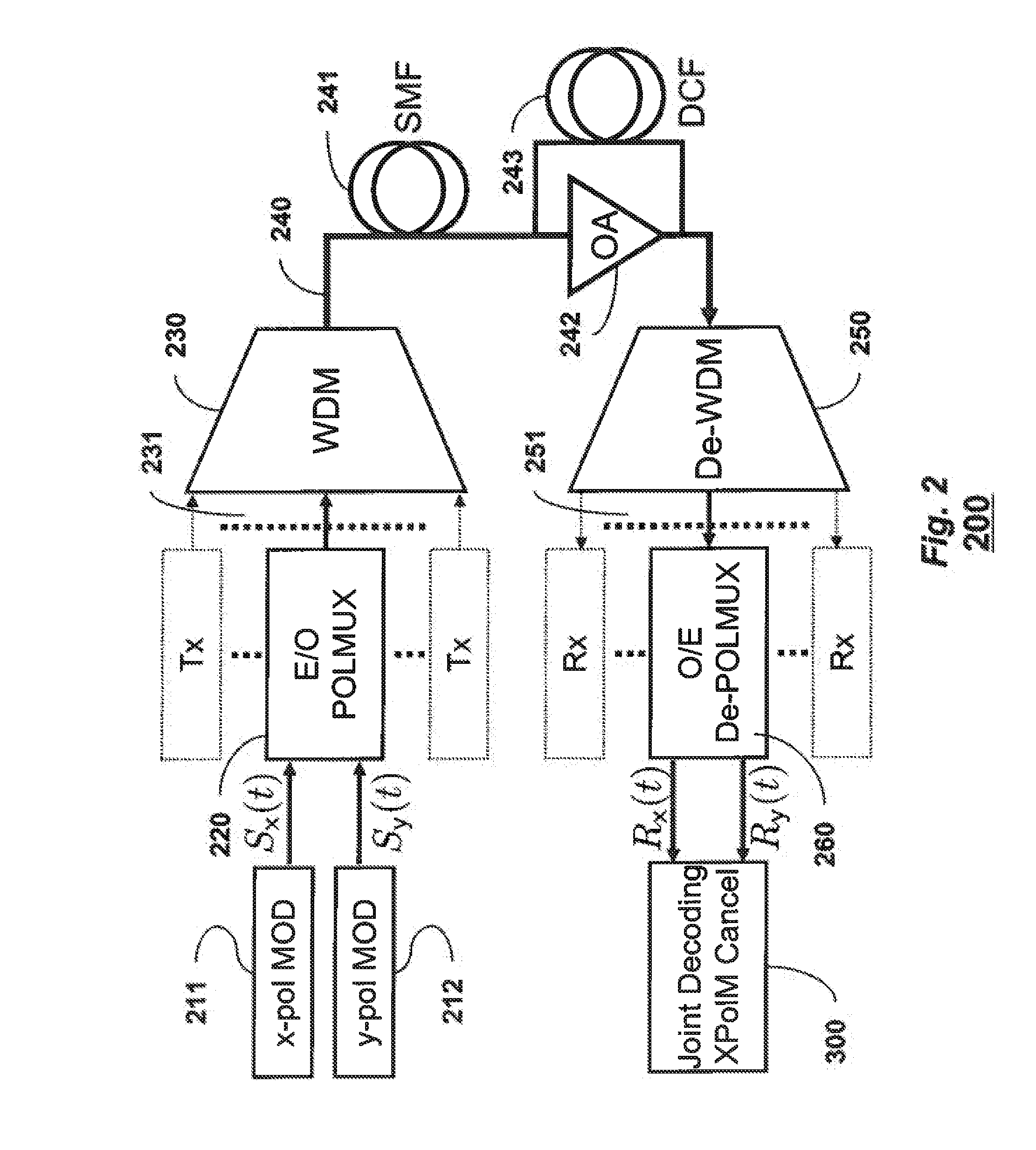

Adaptive Cross-Polarization Modulation Cancellers for Coherent Optical Communication Systems

InactiveUS20120263464A1Improve joint performanceEfficiently signaledPolarisation multiplex systemsChannel estimationFiberFourier transform on finite groups

For coherent fiber optic communications, the nonlinear XPolM impairment is the most important issue to realize over-100 Gbps high-speed transmissions. A method provides a way to cancel time-varying XPolM crosstalk by introducing multi-stage adaptive mechanism. In the method, a low-complexity adaptive filtering based on recursive least-squares (RLS) first tracks the time-varying crosstalk along with the per-survivor trellis-state decoding. The estimated channel and the decoded data are then used to calculate the empirical covariance, which is in turn exploited to obtain more accurate channel estimates by means of optimal-weighted least-squares. This is performed with a low-complexity processing over frequency domain with fast Fourier transform. The performance is significantly improved with turbo principle decoding, more specifically, iterative decoding and iterative estimation over a block.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Spark plug and process for producing the spark plug

InactiveUS20100264801A1Prevent oxidationElectrode thickness can be decreasedSpark gapsSparking plugs manufactureEngineeringGrounding electrodes

A spark plug in which an ignition portion of a ground electrode formed through joining of a noble metal chip to the ground electrode has high durability, and a method of manufacturing the spark plug.

Owner:NGK SPARK PLUG CO LTD

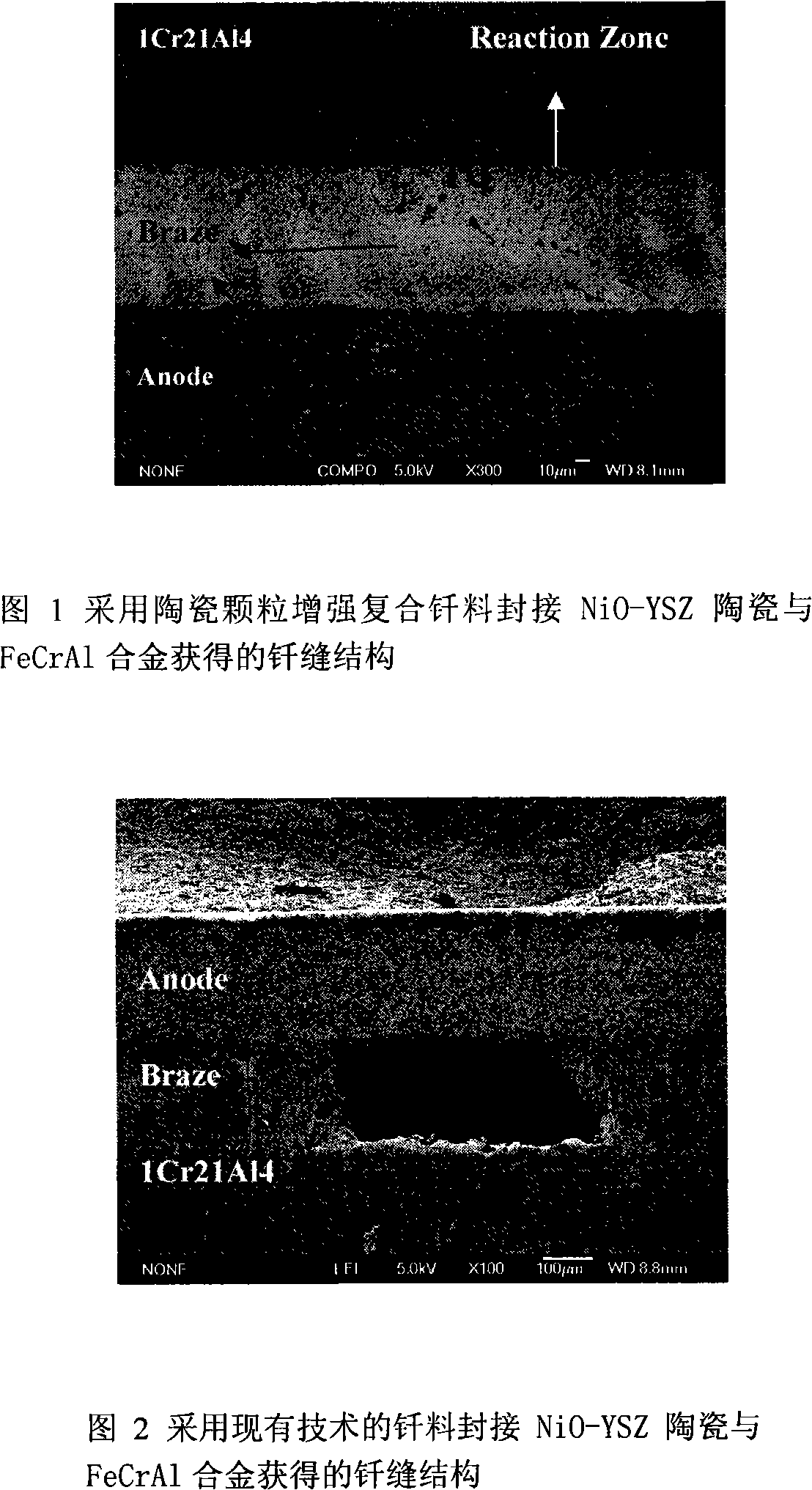

Ceramic granule reinforced composite material

InactiveCN101288928ACoefficient of thermal expansion matchingHigh Prepositioned Functional ViscosityWelding/cutting media/materialsSoldering mediaReducing atmosphereComposite solder

The present invention relates to a ceramic particle strengthening composite solder used for ceramic / ceramic or ceramic / metal solder. The ceramic particle strengthening composite solder consists of 90 to 99.8 percent of metal powder A and 0.2 to 10 percent of ceramic particle B according to the weight percentage; the metal powder A is formed by mixing Ag powder and Cu powder; relatively to the metal powder A, the mol rate of the Ag powder is 80 to 99.5 percent and the mol rate of the Cu powder is 0.5 to 20 percent. The ceramic particle strengthening composite solder provided by the present invention can reduce the generation of air holes in welding line, work at the high temperature of around 800 DEG C, and prolong the service life of the welding line at the high temperature and in the oxidizing atmosphere and the reducing atmosphere, thus obtaining the welding with high joint performance.

Owner:UNIV OF SCI & TECH OF CHINA +1

High-strength and high-toughness automatic submerged arc welding wire with weathering resistance

InactiveCN101537549AGood atmospheric corrosion resistanceGood joint performanceWelding/cutting media/materialsSoldering mediaWeather resistanceChemical composition

The invention relates to a high-strength and high-toughness automatic submerged arc welding wire with weathering resistance and mainly aims at overcoming disadvantages of poor atmospheric corrosion resistance, high production cost and the like of the existing submerged arc welding materials. In term of technical measures, the welding wire is made from the following chemical components by weight percent: C: 0.05-0.12, Si: 0.01-0.10, Mn: 1.50-2.1. S: not more than 0.015, P: not more than 0.020, Ni: 0.20-0.60, Cr: 0.20-0.50, Cu: 0.25-0.50, Ti: 0.05-0.16, B: 0.002-0.010, Als: 0.001-0.015, Fe and other unavoidable impurities. The welding wire is matched with a basic sintered flux for welding, a weld joint has excellent atmospheric corrosion resistance and comprehensive mechanical properties, and a deposited metal at a weld seam has tensile strength up to 560MPa and ballistic work up to 107J at -40 DEG C and up to 87J at -50 DEG C.

Owner:武钢集团有限公司

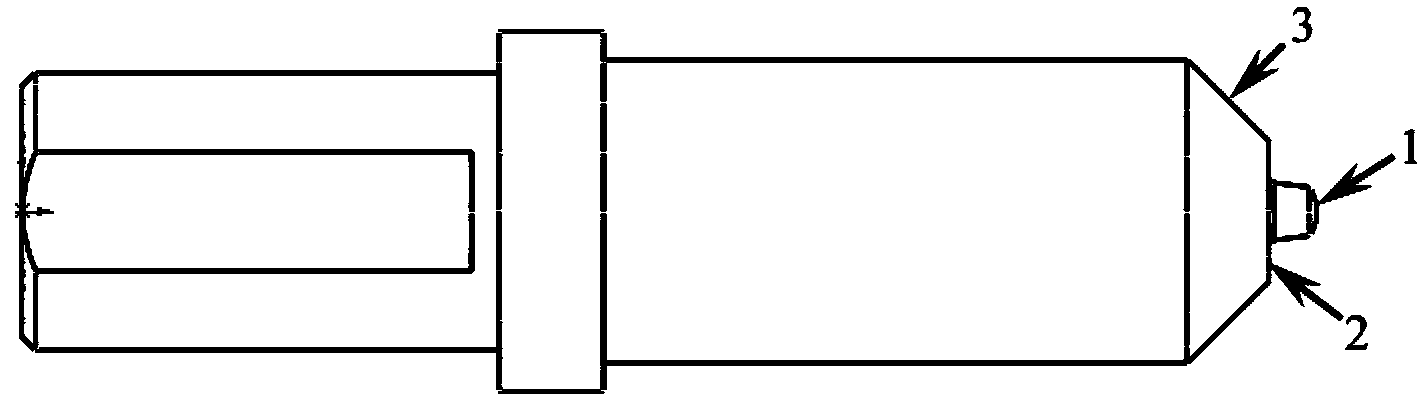

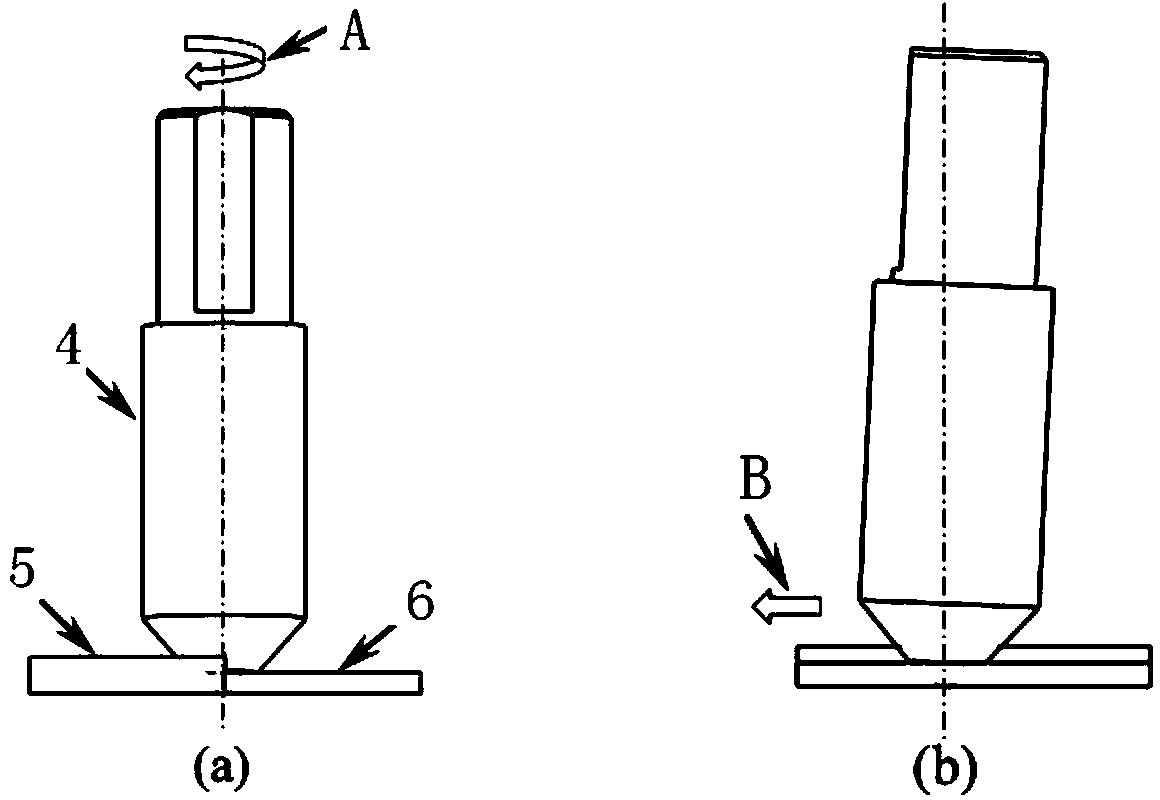

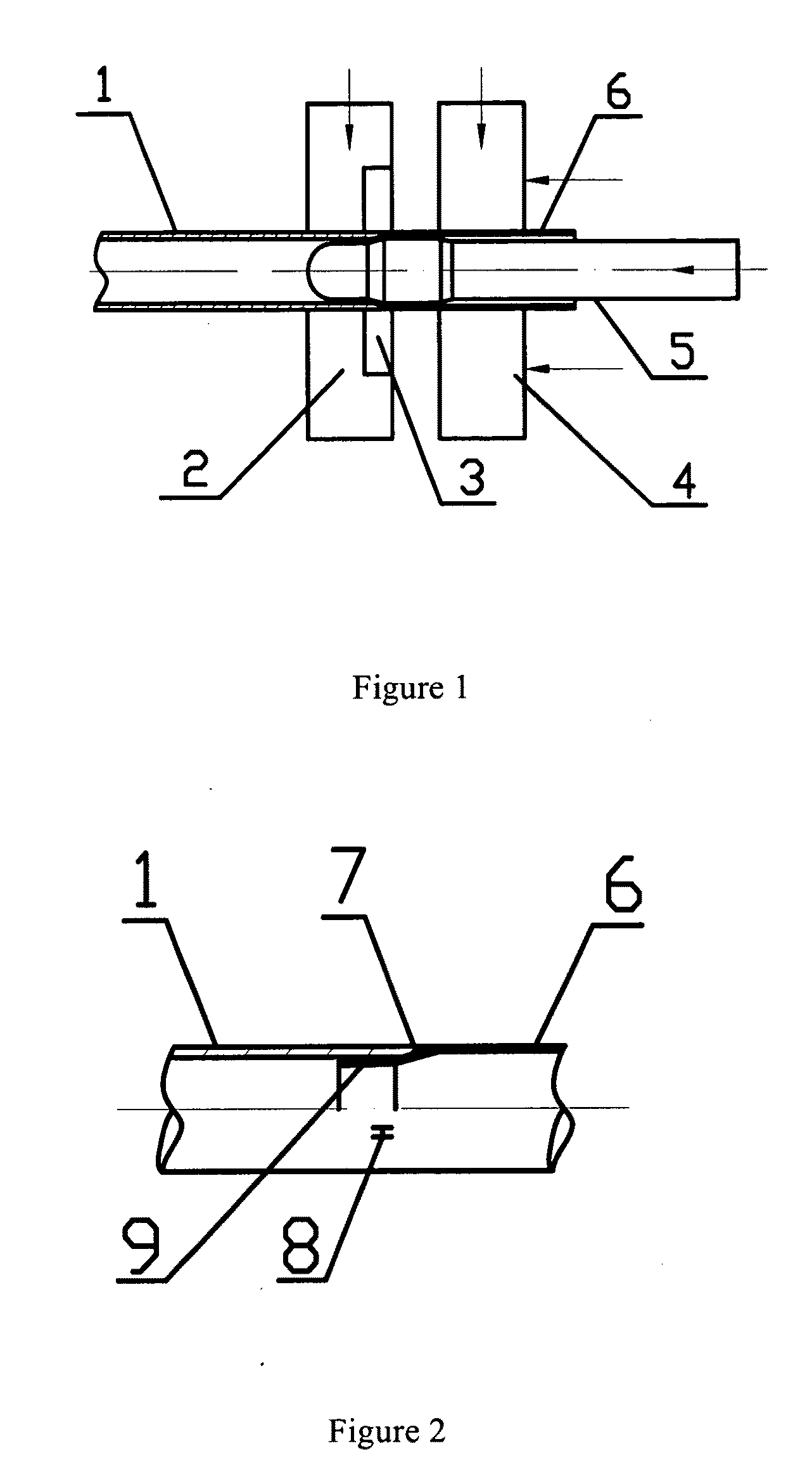

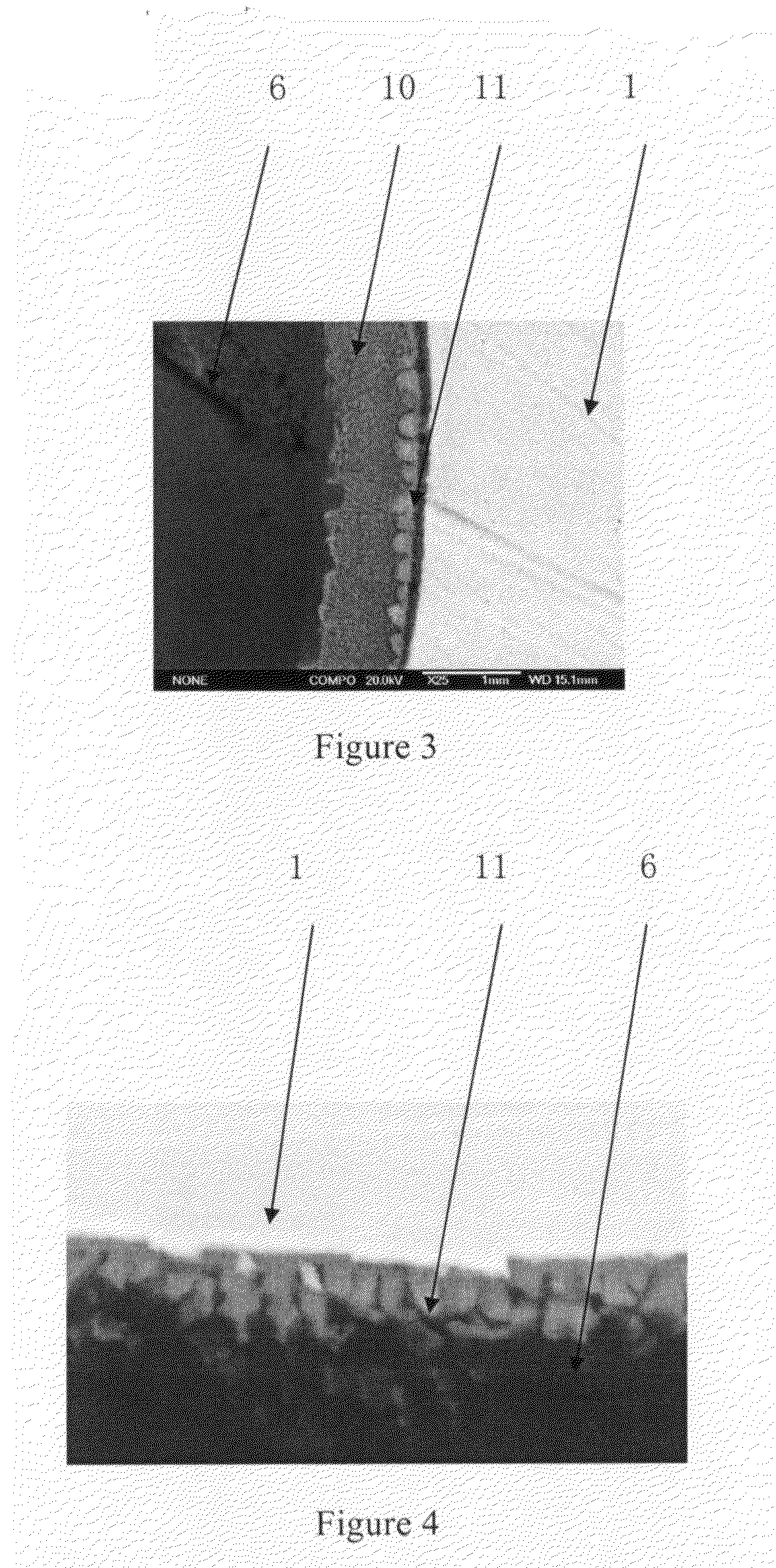

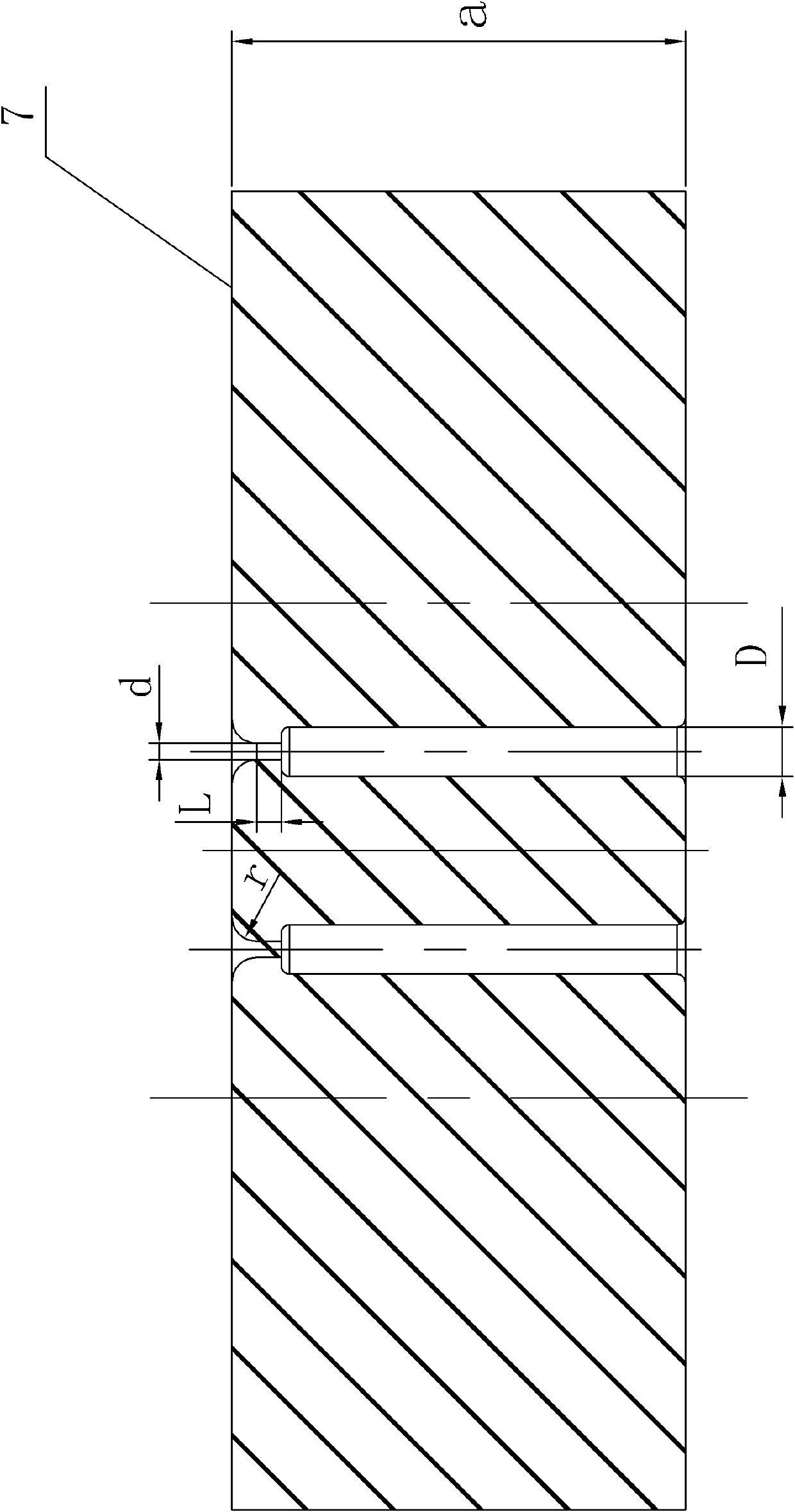

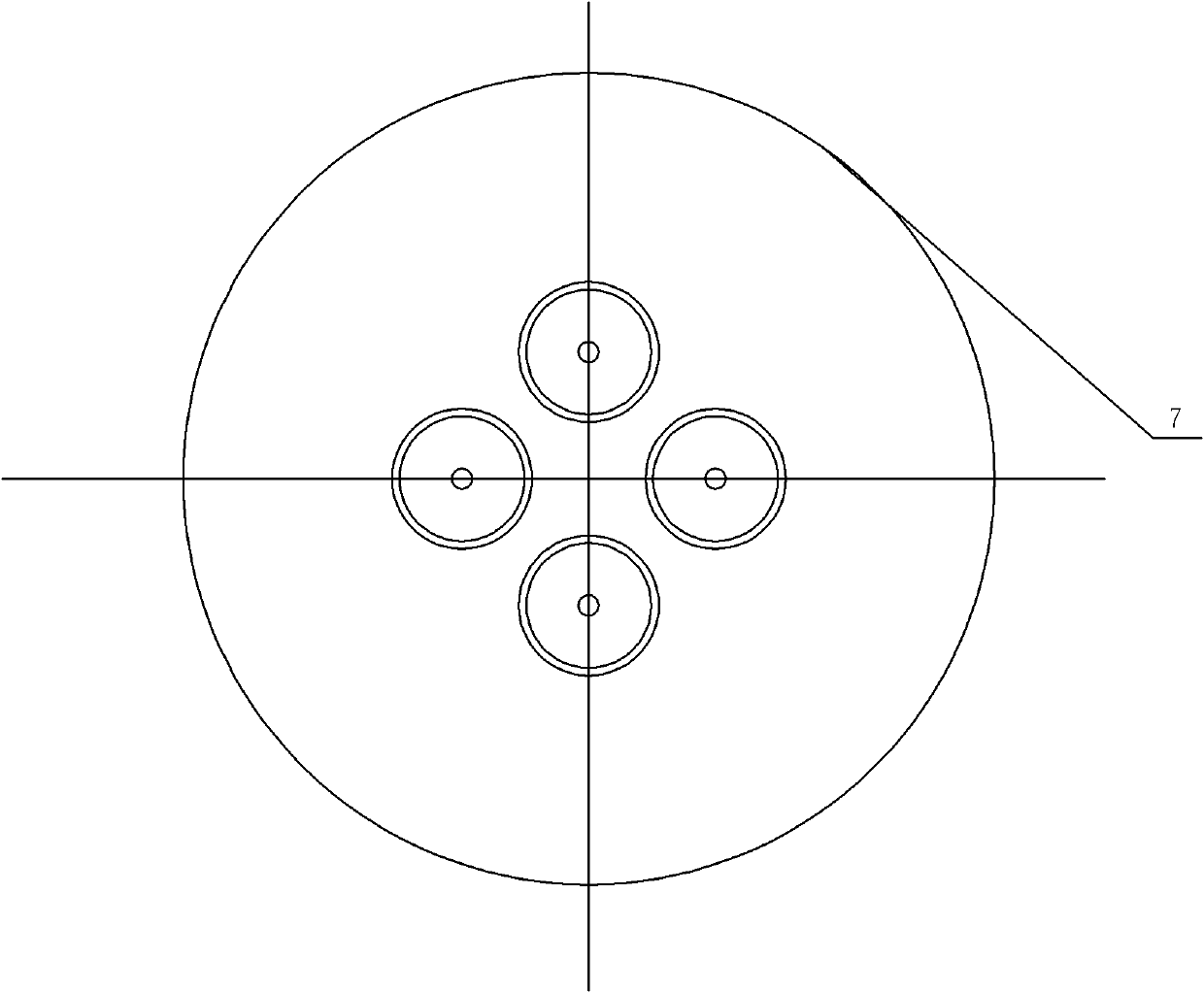

Stirring head for friction stir welding used for welding parts with different thicknesses and welding method

InactiveCN103949769AIntegrity guaranteedGuaranteed reliabilityWelding/soldering/cutting articlesMetal working apparatusEngineeringFriction stud welding

The invention relates to a stirring head for friction stir welding used for welding parts with different thicknesses and a welding method. A cutting accessory shaft shoulder is added on the basis of the existing stirring head, and the accessory shaft shoulder plays a role in cutting and removing the redundant material on the thicker side of connectors having different thicknesses to acquire a flat friction stir welding joint. The method is carried out on common friction stir welding equipment, a nose or tool of the equipment is not transformed at all, then the requirements on the equipment and the welding method are greatly simplified; in addition, in the welding process, a shaft shoulder of the stirring head and the two side surfaces of the part are parallel, so that the phenomena that metal of the connector is insufficiently extruded or damaged by shearing are not caused, the integrity and the reliability of the part are guaranteed; moreover, the accessory cutting shaft shoulder of the stirring head also plays an important role as for the part whose thickness suddenly changes, and the smooth welding process of the part is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

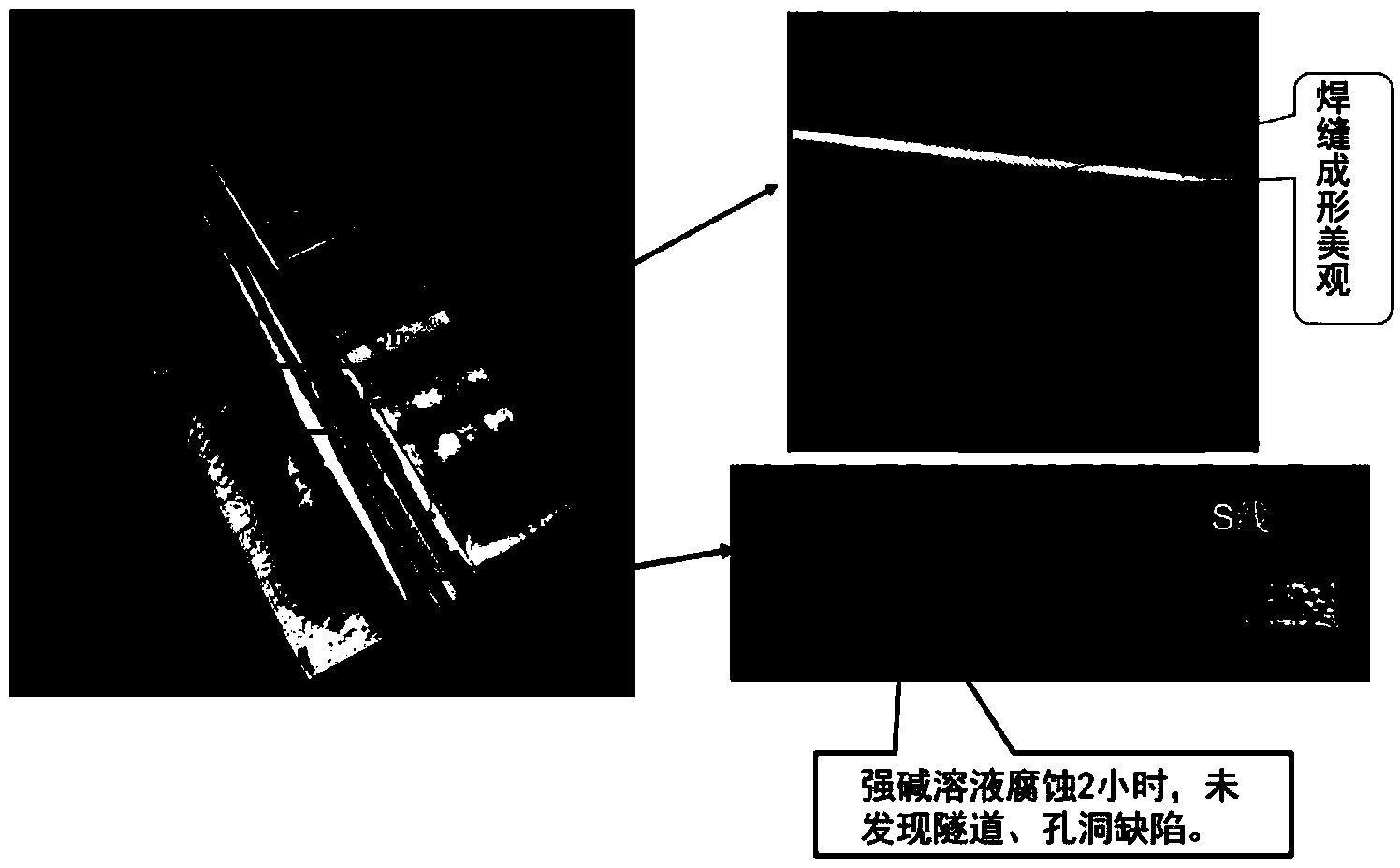

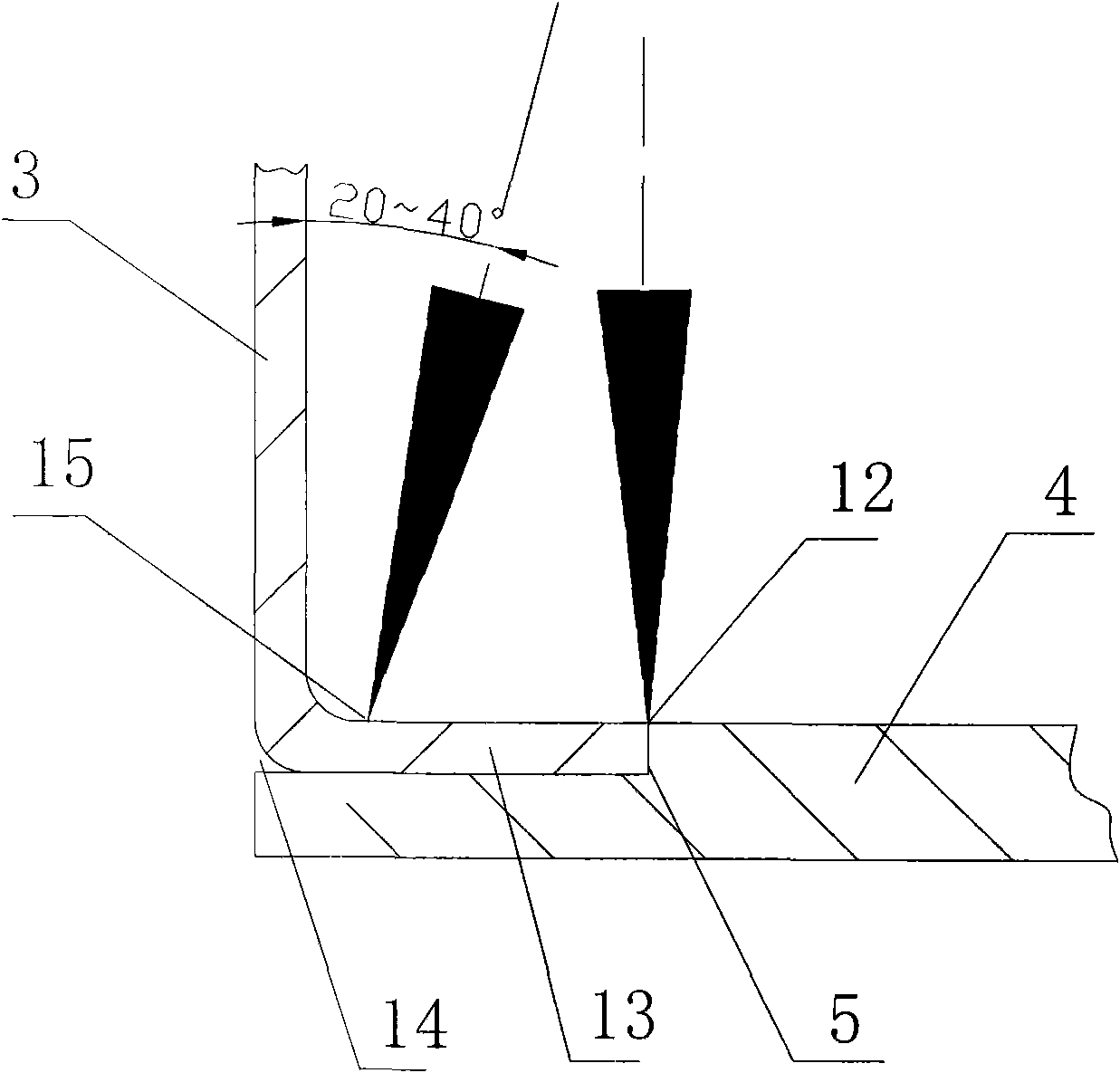

High strong weather resistance cold rolling container coating plate laser welding process

InactiveCN101905379ASafe and reliable clampingAvoid connectivityLaser beam welding apparatusWeather resistanceEngineering

The invention relates to a strong weather resistance cold rolling container coating plate laser welding process, solving the problems that the existing strong weather resistance cold rolling container coating plate welding precision is low, welding line moulding is poor, joint performance is poor, process is complex and production efficiency is low. The technical scheme adopts the laser welding technology, and joint structure for halving joint and angle joint is designed, a gap for escaping steam when welding coating is reserved, and the gap is convenient for realizing accurate assembly positioning, and the technological conditions of welding line protection gas and laser welding control are adopted, so as to ensure that the welded construction member has no deformation, appearance of welding line is beautiful, coating burning loss is less, welding joint performance is not lower than base metal, thus completely meeting the precision and quality requirements of container erection welding, and the process is simple and production efficiency is high.

Owner:武汉钢铁有限公司

Tungsten-transition layer/stainless steel hot isostatic pressing diffusion bonding method

ActiveCN109396631AReduce residual stressSpread evenlyNon-electric welding apparatusStress reliefDivertor

The invention discloses a tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method. Through the tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method, the problems that tungsten-steel connecting parts for first-wall plasma divertors of fusion reactors are likely to form large thermal stress at interfaces and microdefects in the prior art are solved. According to the tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method provided by the invention, pure tungsten, a transition layer and stainless steel serve as raw materials, are subjected to enveloping treatment and then are subjected to hot isostatic pressing treatment, stress relief annealing and envelop removing, and hot isostatic pressing diffusion connecting pieces can be obtained. The tungsten-transition layer / stainless steel hot isostatic pressing diffusion bonding method is simple in operation, non-defective metallurgical bonding can be realized, and the joint performance is excellent and stable.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

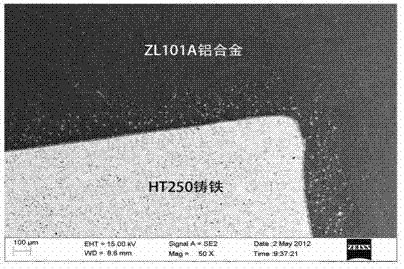

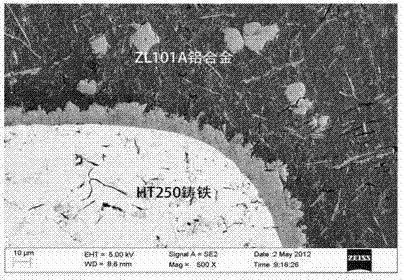

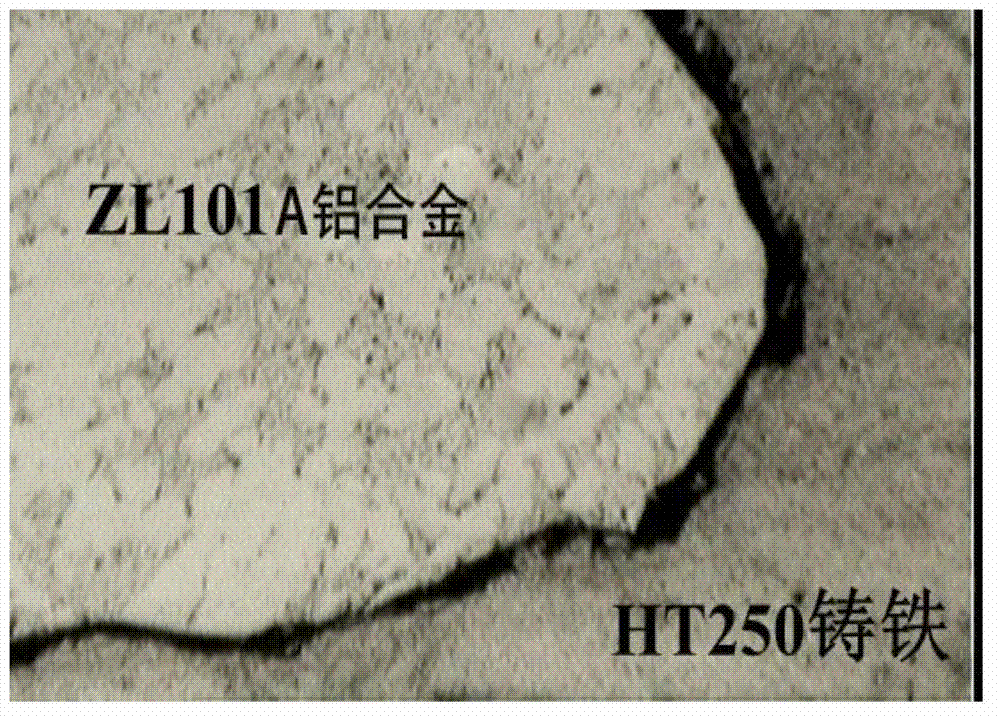

Preparation process of dual-metal engine cylinder composite material

InactiveCN102773463AGuaranteed physical propertiesEnhanced interface bindingPotassium fluorideMetallic materials

The invention relates to a preparation process of a dual-metal engine cylinder composite material, the preparation process comprises the following steps of: firstly, acid-washing a HT250 cast iron cylinder liner and carrying out surface degreasing and derusting treatment on the HT250 cast iron cylinder liner; then dipping the HT250 cast iron cylinder liner into a prepared proportional saline solution, so that the surface of the HT250 cast iron cylinder liner is soaked in the saline solution; then drying the HT250 cast iron cylinder liner, and putting the HT250 cast iron cylinder liner in a ZL101A aluminum alloy melt body for hot immersion plating; fixing the immersion-plated HT250 cast iron cylinder liner in a mold cavity of a metal mold casting mold, casting, melting and cooling a ZL101A aluminum alloy, wherein concentration of the saline solution is 100-200g / L, the saline solution is prepared by mixing water together with potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF2, and calcium chloride CaC12 according to a mass ratio of 39-46:16-26:15-21:6-15:5-10. According to the preparation process, the engine cylinder composite material is obtained through treating the ZL101A aluminum alloy and HT250 cast iron by a self-prepared surfactant and implementing a dual-metal composite casting process on the ZL101A aluminum alloy and the HT250 cast iron, wherein two metal materials of the ZL101A aluminum alloy and the HT250 cast iron are not mixed and kept with original physical properties; but the ZL101A aluminum alloy and the HT250 cast iron obtain an extremely perfect combination interface, so that casting metallurgical bonding of 99.5 percent and above is achieved.

Owner:烟台路通精密科技股份有限公司 +1

Spark plug and process for producing the spark plug

ActiveUS8106572B2Prevented separation and detachmentPrevent oxidationSpark gapsSparking plugs manufactureGrounding electrodesSpark plug

A spark plug in which an ignition portion of a ground electrode formed through joining of a noble metal chip to the ground electrode has high durability, and a method of manufacturing the spark plug.

Owner:NGK SPARK PLUG CO LTD

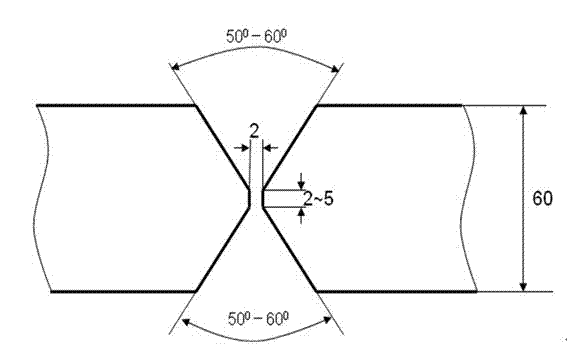

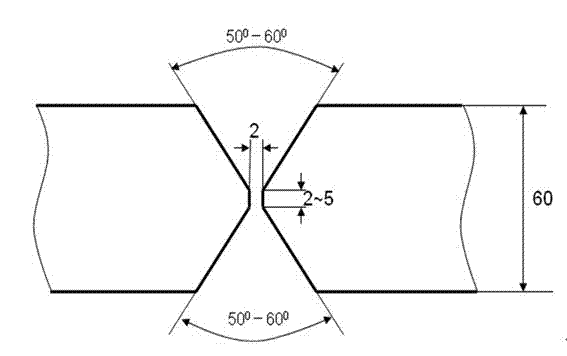

Thick plate submerged arc welding technology for low-temperature maritime engineering

ActiveCN102363238AImprove toughnessImprove securityArc welding apparatusEngineeringMechanical property

The invention discloses a thick plate submerged arc welding technology for low-temperature maritime engineering, which comprises the steps of: adopting a thick plate F550 which meets chemical compositions and weight percentage as well as classification society rules, wherein the steel carbon equivalent Ceq is less than or equal to 0.60%; selecting solder wires which meet chemical compositions andweight percentage; adopting a symmetrical double-faced X-shaped groove as a submerged arc welding groove, wherein the groove angle is 50-60 degrees, and the groove gap is 2-5mm; when the thickness ofa steel plate is less than or equal to 60mm, and the temperature is not lower than 10 DEG C, preheating to 100 DEG C for welding; and selecting the welding parameter, wherein the weld heat input quantity is less than or equal to 50kJ / cm. When the multilayer and multi-channel continuous welding technology is adopted by the invention, a welding joint is excellent in comprehensive mechanical property, and a welding line and a welding heat affected zone are good in impact toughness.

Owner:NANJING IRON & STEEL CO LTD +1

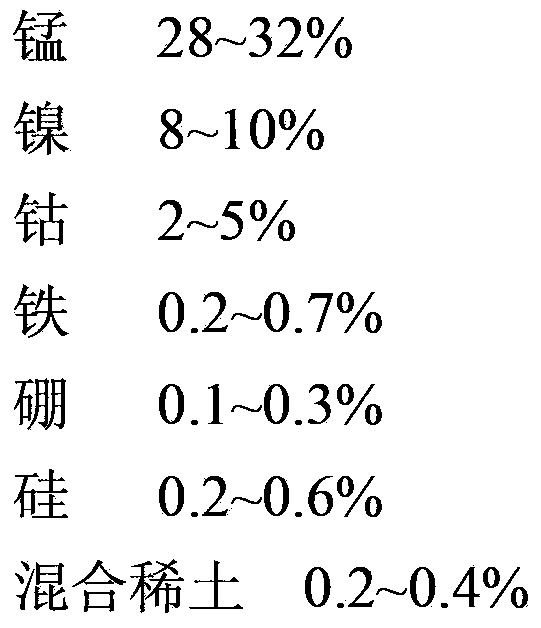

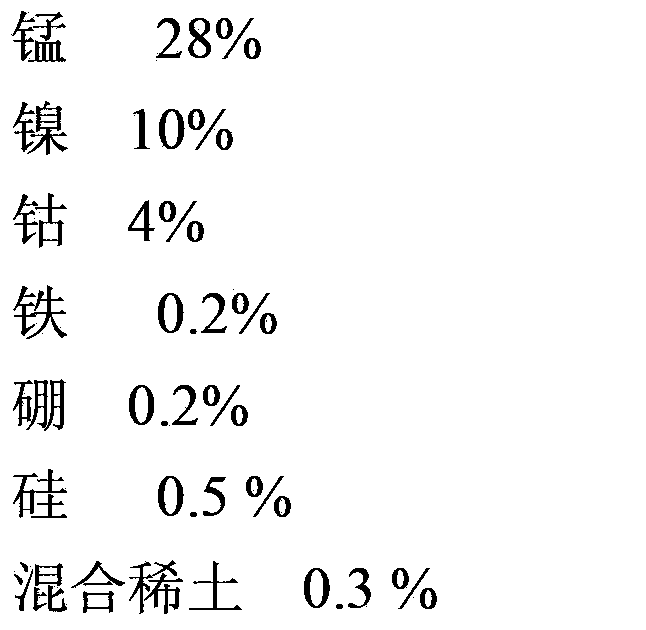

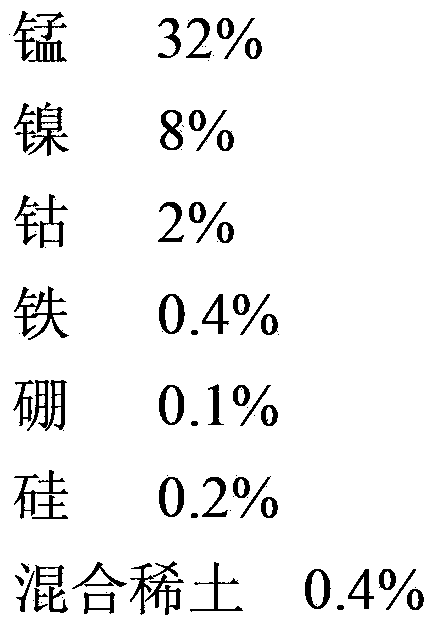

Copper-based solder and preparation method thereof

ActiveCN103358051ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCorrosionSmelting process

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

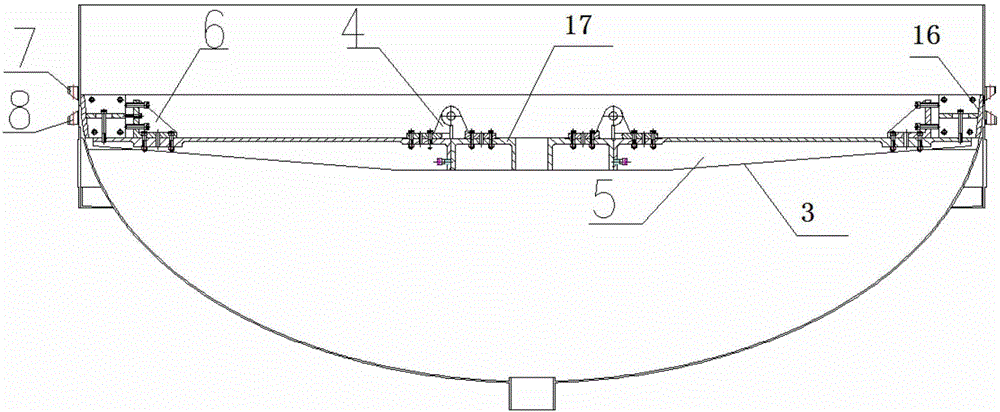

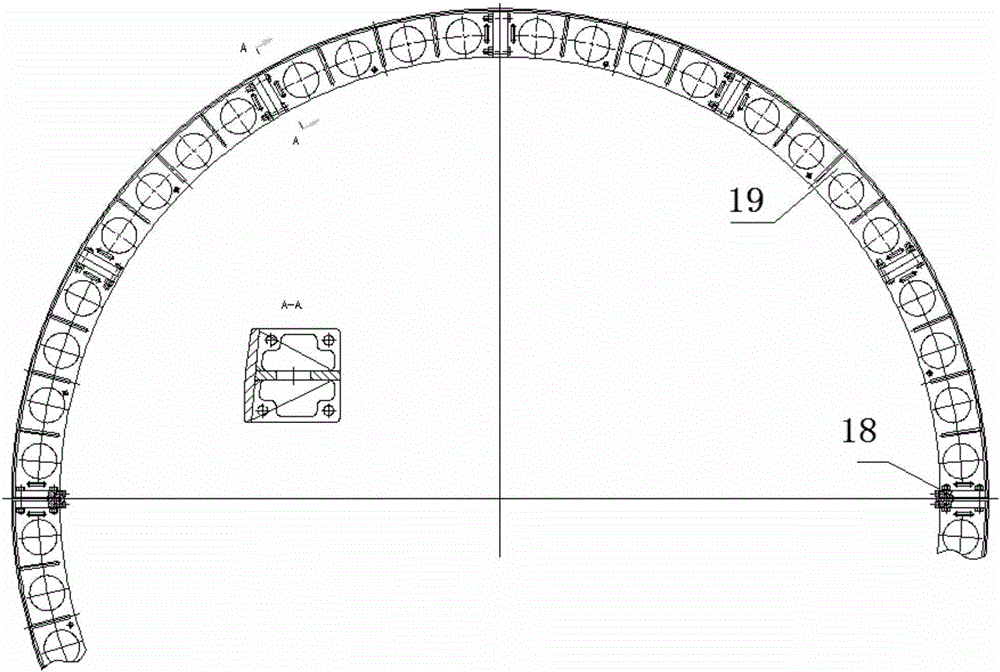

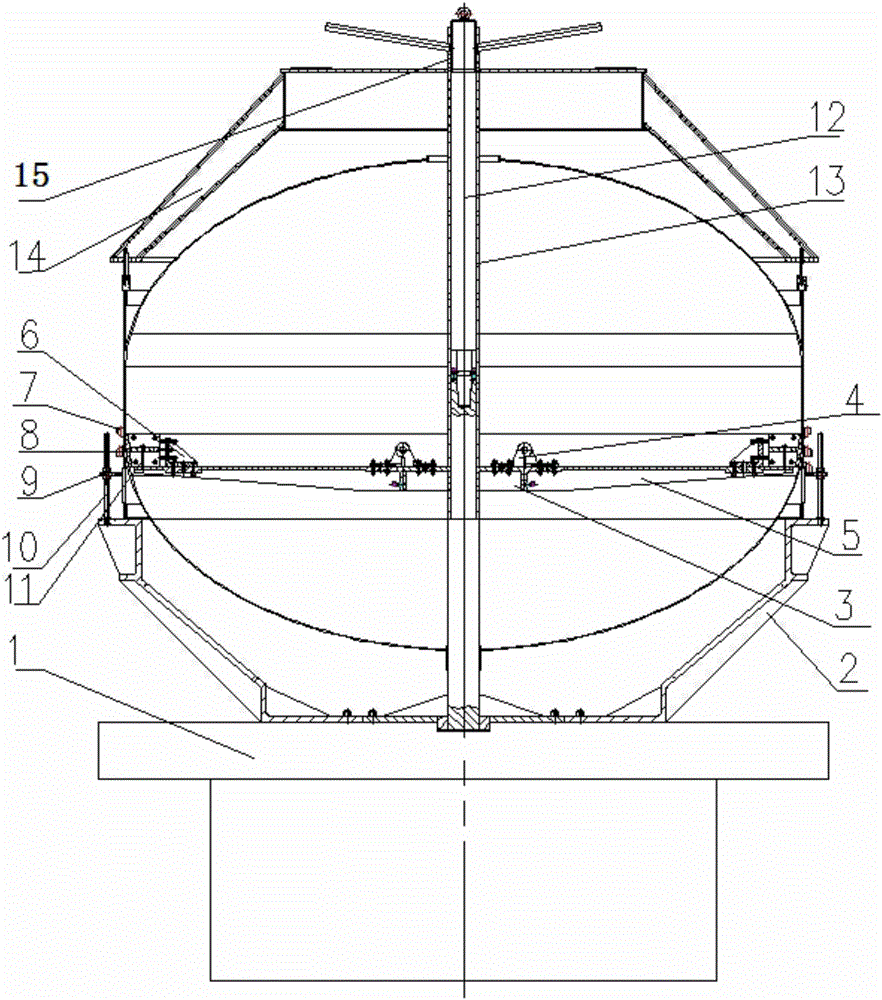

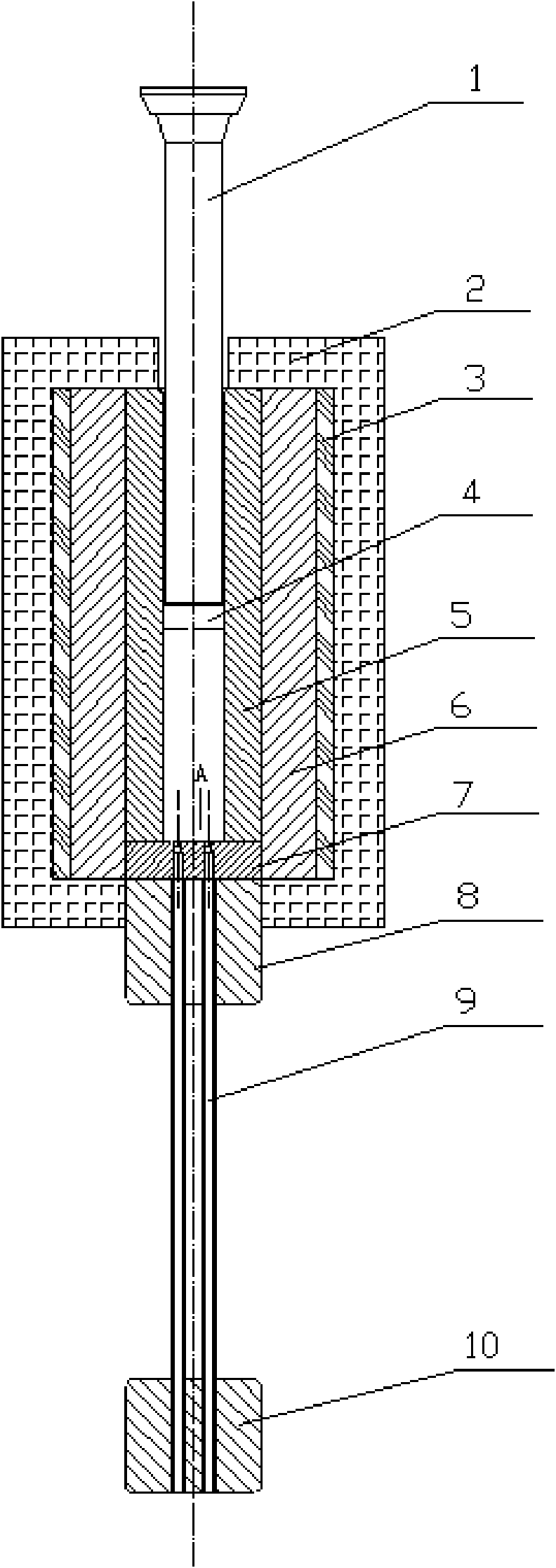

Centering butt joint positioning supporting device for vertical type stirring friction welding storage box assembly annular seam

ActiveCN106624335AHigh assembly precision requirementsReduce stressWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingButt joint

The invention provides a centering butt joint positioning supporting device for a vertical type stirring friction welding storage box assembly annular seam and relates to the field of aerospace product processing technology equipment. The centering butt joint positioning supporting device comprises a positioner seat, a base, an annular seat, an inner support tensioning structure, a barrel section outer hoop assembly, a fork-shaped outer hoop assembly, supporting plates, adjusting threaded rods, a mandrel, a supporting sleeve, a pressing cover and a pressing wheel. The base is fixedly installed on the upper surface of the positioner seat. The adjusting threaded rods are arranged in the circumferential direction of the upper surface of the top end of the base. The annular seat is horizontally and fixedly installed in an outer box body structure. The inner support tensioning structure is fixedly installed on the annular seat. The barrel section outer hoop assembly and the fork-shaped outer hoop assembly are installed on the outer wall of the outer box body structure. The mandrel is circumferentially, vertically and fixedly installed in the center of the positioner seat, and the top of the mandrel penetrates through the pressing cover. The supporting sleeve wraps the outer wall of the mandrel. The pressing wheel is fixedly installed at the top end of the mandrel. Overall box welding is achieved; the welding efficiency is improved; the high assembling precision is ensured; the production manufacturing cost is reduced; and the aerospace product quality is improved.

Owner:CAPITAL AEROSPACE MACHINERY +1

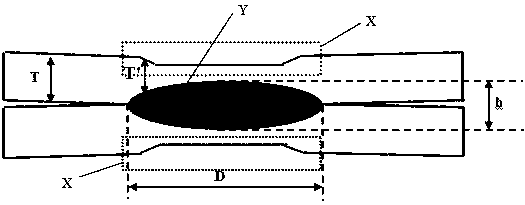

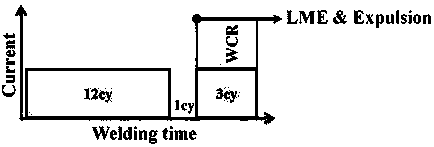

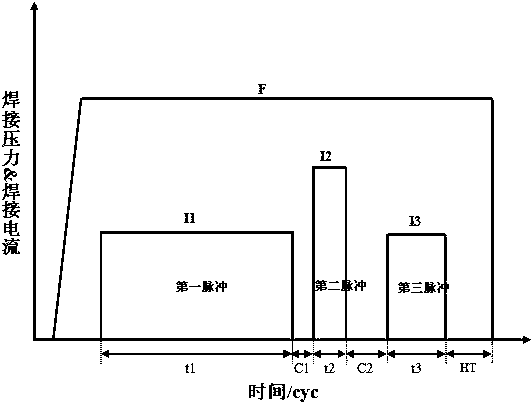

Galvanized high-strength steel resistance spot welding method with good joint performance

ActiveCN108015401AImprove plasticityImprove the fracture modeWelding electric suppliesElectrical resistance and conductanceCrazing

The invention relates to a resistance spot welding method of a galvanized steel plate with tensile strength larger than or equal to 590 Mpa. According to the galvanized high-strength steel resistancespot welding method with the good joint performance, three welding pulses are used in a spot welding period; the first welding pulse and the second welding pulse are used for generating a nugget and restraining the generation of the liquid metal embrittlement (LME) crack, wherein the first welding pulse generates the nugget with the diameter of 3.75 T<1 / 2>-4.25 T<1 / 2>, and the T in the formula isthe plate thickness; the second welding pulse makes the nugget grow slowly; the third welding pulse is a slow-cooling pulse and is used for improving the plasticity of the welding spot. According to the first welding pulse, by setting the time t1 of the first welding pulse and carrying out a test, the welding current I1 of the first welding pulse is obtained, wherein the welding current I1 of thefirst welding pulse is the welding current corresponding to when the nugget with the diameter of 3.75 T<1 / 2>-4.25 T<1 / 2> is generated; and the welding current I2 and the time t2 of the second weldingpulse and the welding current I3 and the time t3 of the third welding pulse are obtained by calculating the welding current I1 and the time t1 of the first welding pulse.

Owner:BAOSHAN IRON & STEEL CO LTD

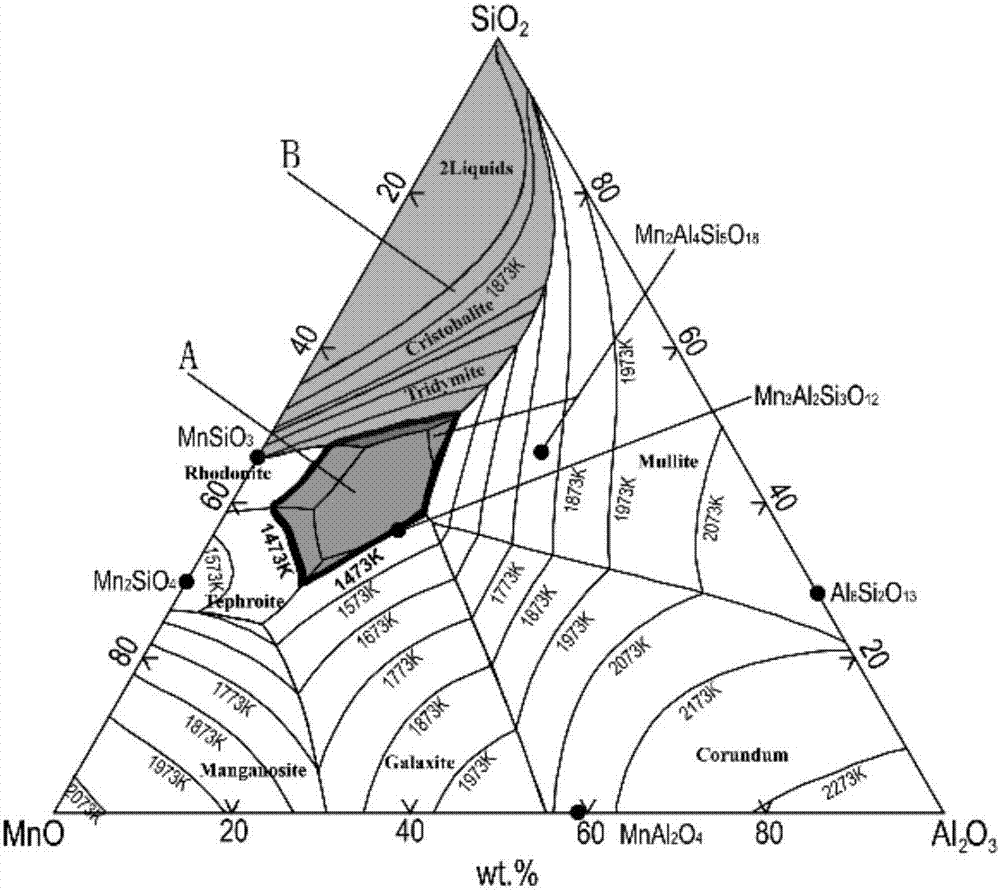

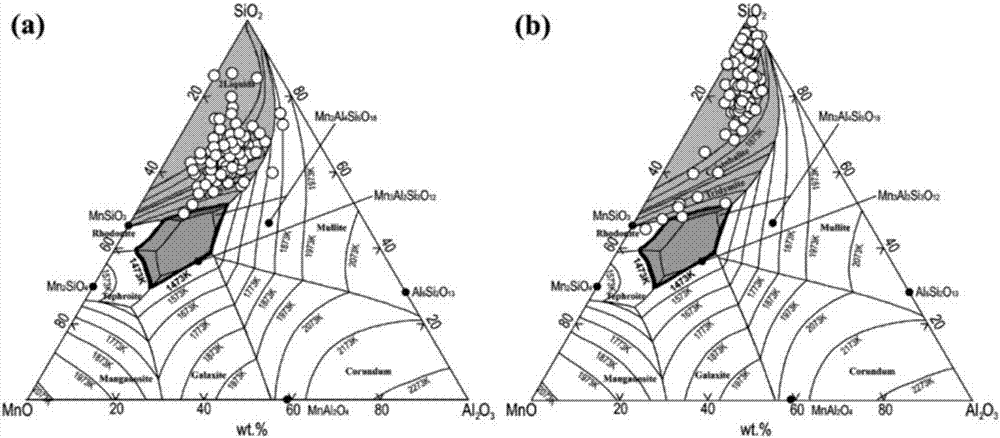

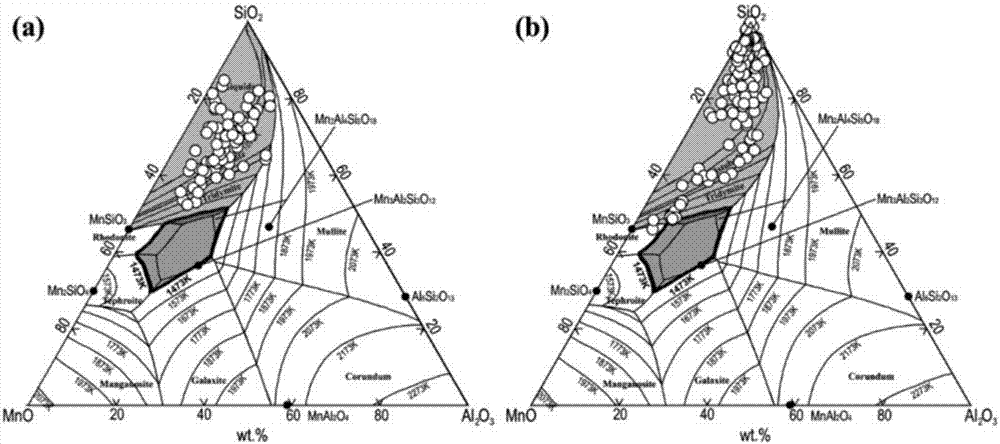

Method for realizing low Young's modulus of oxide inclusion in tire cord steel

InactiveCN108004374AEasily brokenReduce wire breakageManufacturing convertersProcess efficiency improvementWire rodSteelmaking

The invention discloses a method for realizing low Young's modulus of oxide inclusion in tire cord steel. The method comprises a converter steelmaking process, an LF refining process, a soft blowing process and a continuous casting process; the converter steelmaking process comprises the step that refining premelting slag of 6-8kg / t of steel is added in the steel after tapping is finished, whereinthe premelting slag comprises, by weight, 40-50% of CaO, 40-45% of SiO2, 5-10% of Al2O3 and 5-10% of MgO, and CaO / SiO2 is controlled to be less than or equal to 1.0. By designing special smelting operation, the oxide inclusion in steel has lower Young's modulus, the inclusion can better adapt to the following drawing process characteristics of a cord steel wire rod, the inclusion can be broken and separated by the huge pressure stress and compression ratio of steel in the drawing process, and fine control of the oxide inclusion can be realized. The method for realizing low Young's modulus ofthe oxide inclusion in the tire cord steel solves the problem of wire breaking caused by large-size non-deformation inclusions in the tire cord steel, and significantly improves the drawing and stranding performance of the cord steel wire rod.

Owner:XINGTAI IRON & STEEL

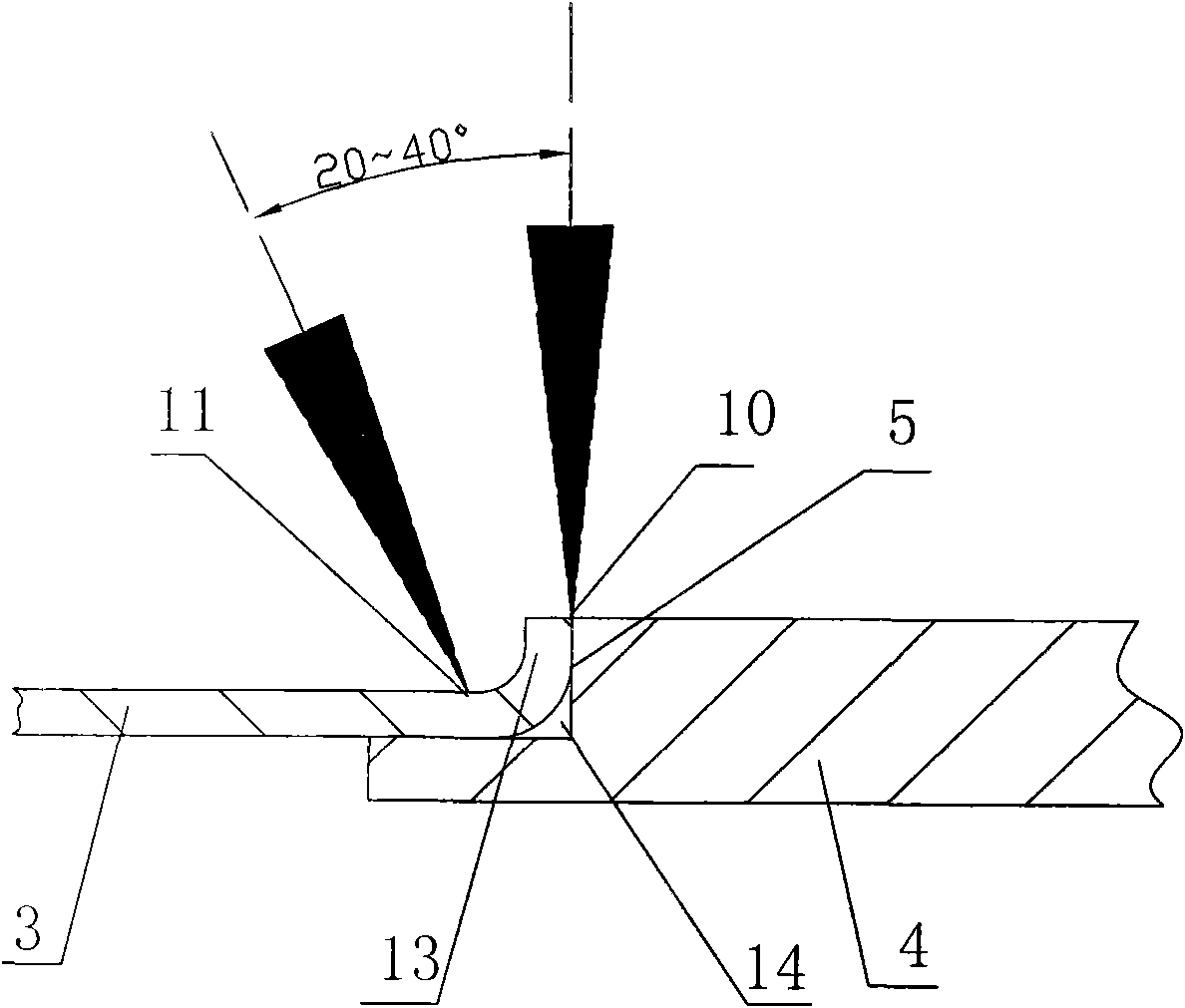

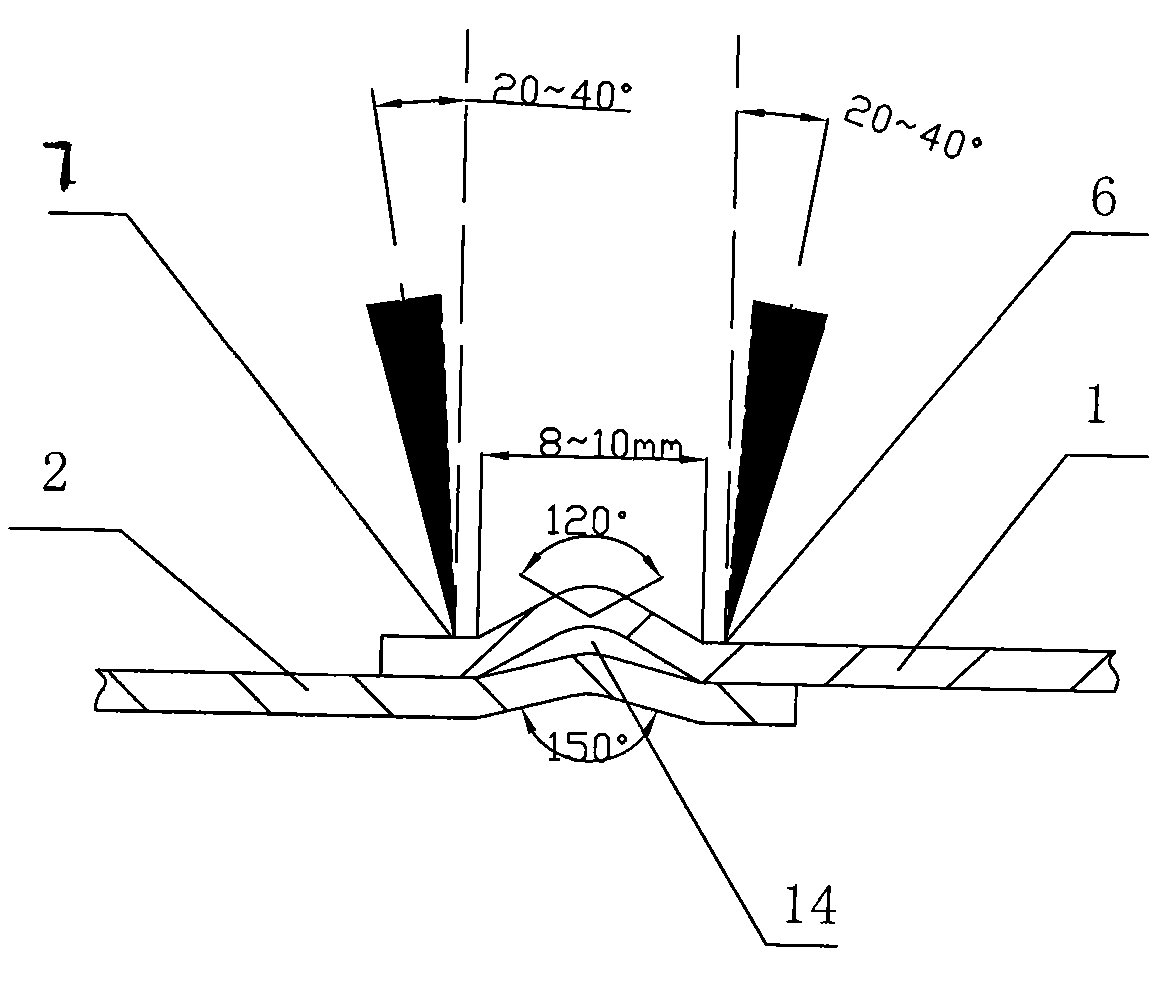

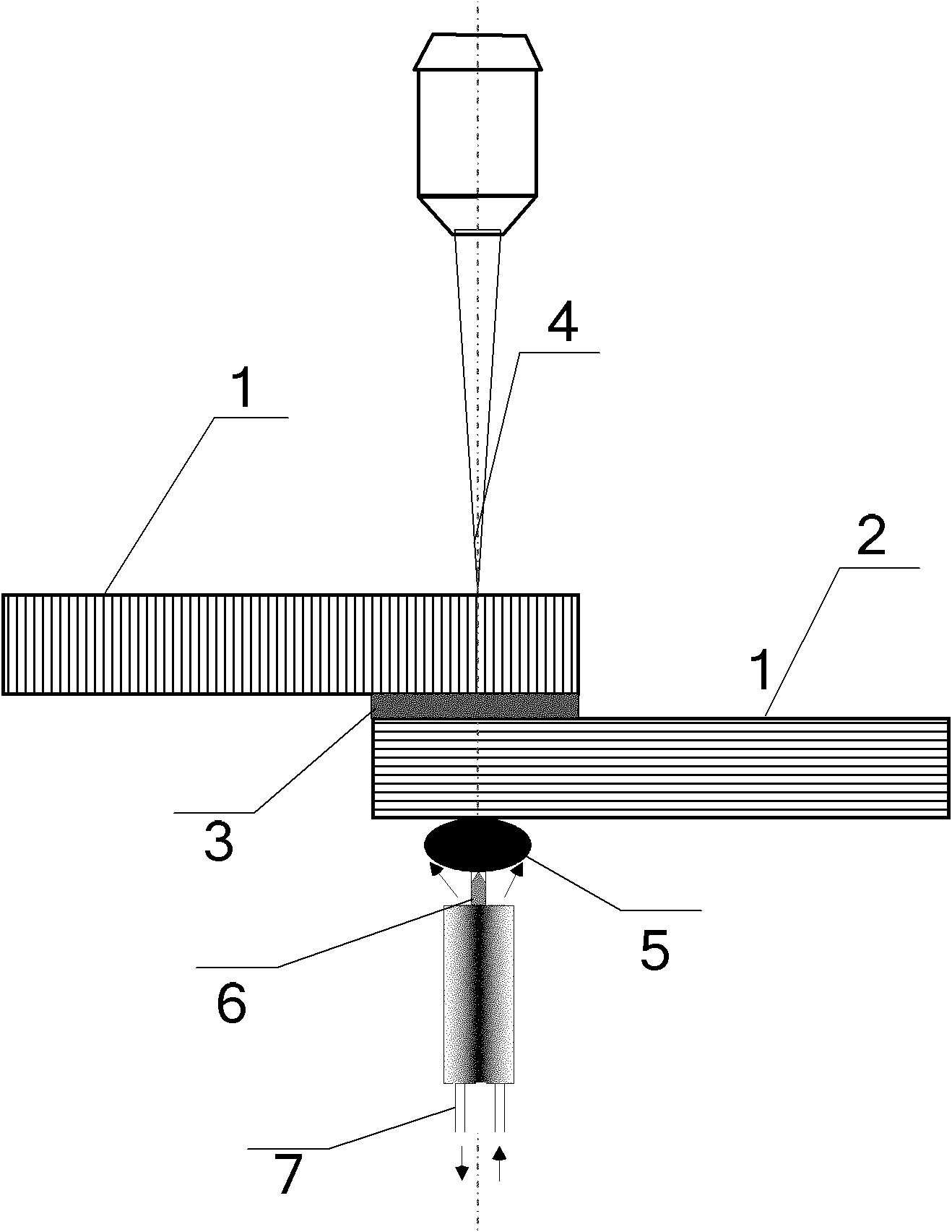

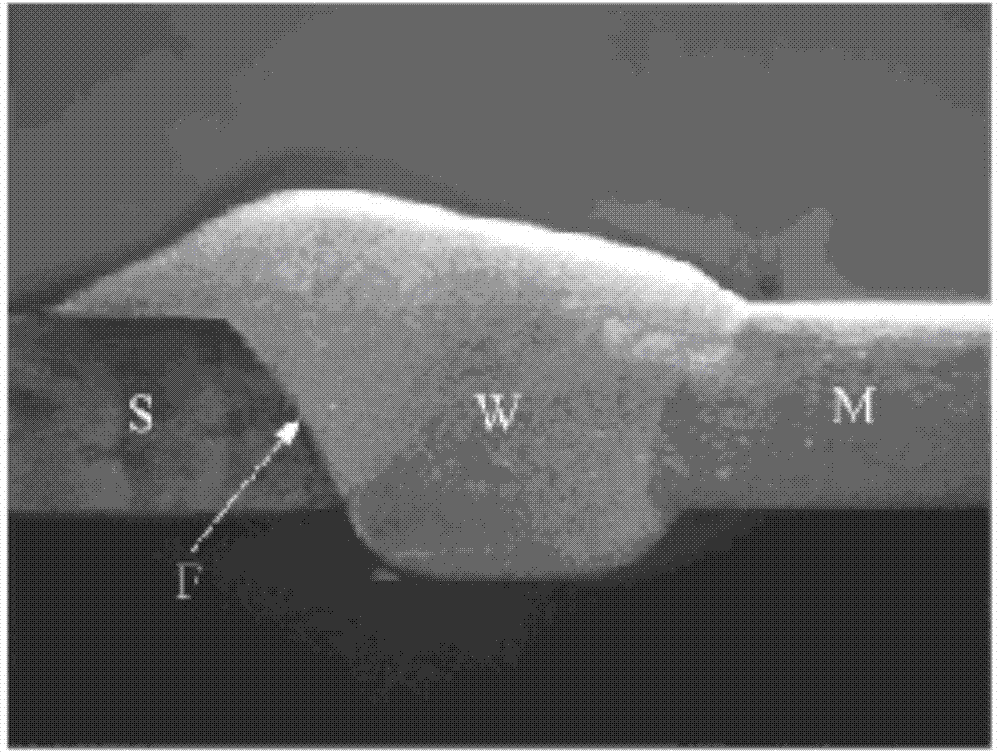

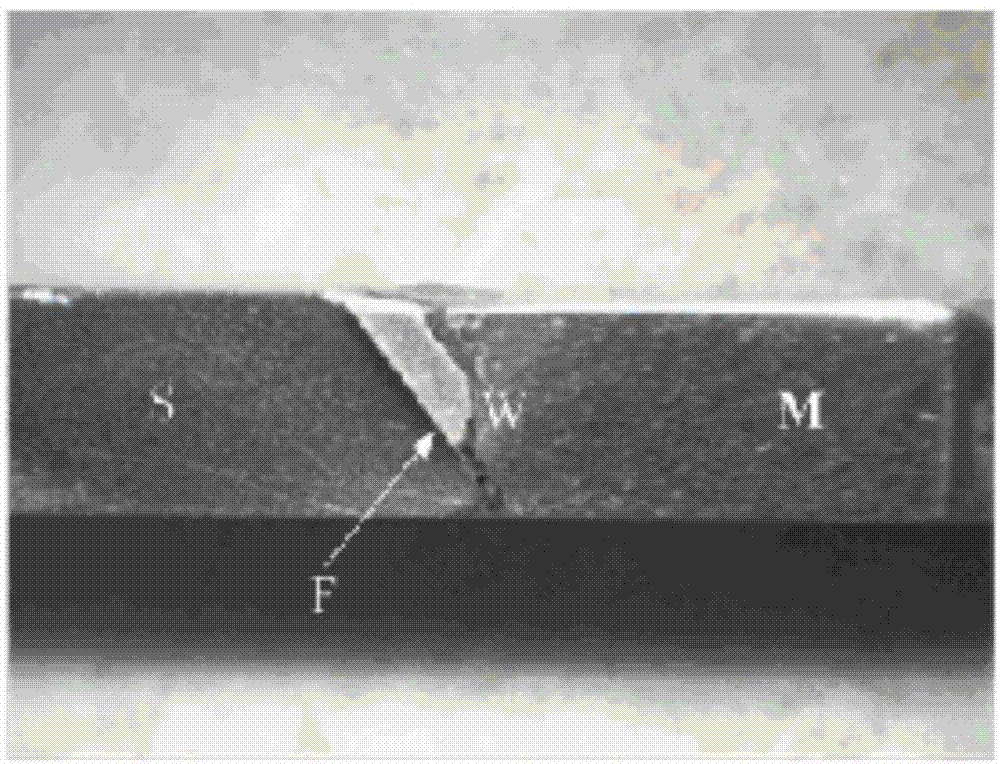

Method for regulating intermetallic compound for dissimilar material overlap joint through laser-arc double-sided welding

InactiveCN102029476AOptimal Response ThicknessGood joint performanceWelding apparatusSeam weldingFusion welding

The invention discloses a method for regulating an intermetallic compound for a dissimilar material overlap joint through laser-arc double-sided welding, relates to a method for overlapping and welding dissimilar materials, and aims to solve the technical problems that the produced intermetallic compound has hardly controlled thickness and a joint has poor mechanical property in the process of overlapping and welding the dissimilar materials. The method comprises the following steps of: prearranging brazing filler metals between overlap joints of the dissimilar materials, respectively arranging laser beams and arcs on two sides of the overlap joints and symmetrically heating and welding simultaneously, wherein the laser beams on the side of low-melting point materials are subjected to deep penetration welding, and the arcs on the side of high-melting point materials are brazed with the brazing filler metals. In the method, the laser beams are arranged on the side of the low-melting point materials to be subjected to deep penetration welding so as to be subjected to fusion welding with the brazing filler metals, and the arcs are arranged on the side of the high-melting point materials to be subjected to heat conduction welding so as to be brazed with the brazing filler metals; and the optimized interlayer reaction thickness is realized and excellent joint performance is achieved by controlling energy matching under the coaction of the laser and the arcs. The method is applied to the field of dissimilar material welding.

Owner:HARBIN INST OF TECH

Preparation method for flux-cored electrode

InactiveCN104384744AAdd lessThe amount of addition is difficult to controlWelding/cutting media/materialsSoldering mediaConveyor belt% diameter reduction

The invention relates to a preparation method for a flux-cored electrode. The method comprises the following steps of preparing a strip with a thickness of 0.1 to 0.5mm from silver solder containing 20 to 45 percent of silver, annealing and cleaning the strip, bending and deforming the strip to form a U-shaped strip with an upward opening by virtue of a roller, vibrating the silver solder to a conveyor belt from a funnel, conveying the silver solder to the U-shaped strip by virtue of the conveyor belt, rolling the U-shaped strip to form a flux-cored wire of an overlapped tubular structure by virtue of the roller, cleaning the surface of the flux-cored wire by virtue of a brush wheel and a brush, performing diameter reduction treatment, straightening the flux-cored wire in a low-temperature resistance heating or cold machining way, and cutting and forming the flux-cored wire, wherein the silver solder is placed in the transparent funnel, and is sufficient; the overlapped part of the flux-cored wire is 0.1 to 2mm wide. The method is simple and reasonable; a conventional soldering process is simplified, the quality of a soldered joint is improved, and the using cost of the solder is effectively lowered by over 30 percent.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

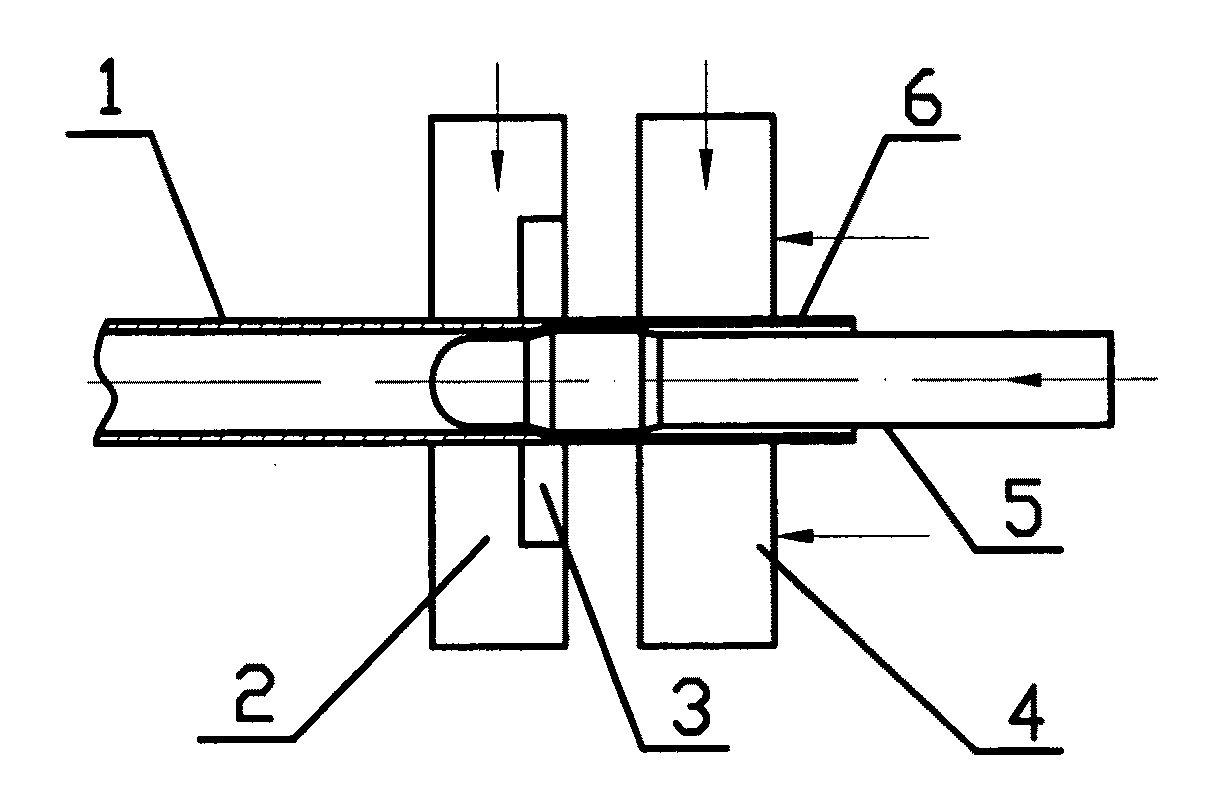

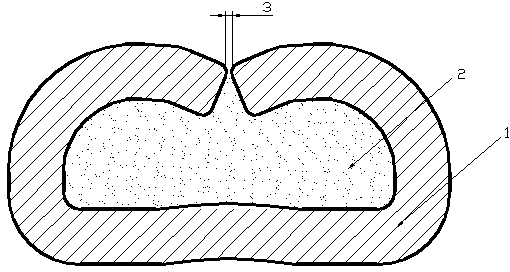

Non-eutectic structure weld joint of copper-aluminum thin wall pipe and its manufacturing method

InactiveUS20090212025A1Thick structureReduce contentPipe elementsRigid pipesElectrical resistance and conductanceUltimate tensile strength

This invention involves a non-eutectic structure welded joint of copper-aluminum thin wall pipe and its manufacturing method. This welded joint includes a chemical bond directly formed between the cone welding section of the copper pipe and the inner wall of the aluminum pipe, to form a columnar grain crystal with a toothed profile. The method includes providing a metal rod in a nosing end of copper pipe welded part, and installing a felder at the corresponding position of fixed electrode group. During welding, a pushing cylinder pushes the travelling electrode group with copper pipe to the aluminum pipe. At the same time a circuit is connected / powered, so the copper-aluminum combined zone is heated by electric resistance heating. The copper pipe moves to the interior of aluminum pipe continuously at the role of the pushing cylinder. The cooled metal rod is drawn out after power-down. The chemical bond directly forms in copper-aluminum joint. The weld does not have eutectic structure. The weld of copper-aluminum joint has characters of high strength and good sealability, thus this joint is appropriate for large-scale use in refrigerating industry.

Owner:ZUO TIEJUN +1

Steel-magnesium dissimilar metal connection method

InactiveCN103495796AThickness limitImprove performance qualityArc welding apparatusWelding/cutting media/materialsIntermetallicMechanical property

The invention relates to a steel-magnesium dissimilar metal connection method in the technical fields of metallurgy, materials, machines and walking machines such as cars and railway vehicles, and belongs to the technical field of dissimilar material connection. According to the steel-magnesium dissimilar metal connection method, for the purpose of realizing steel-magnesium dissimilar metal welding, based on the reaction mechanism of Fe and Al on a fusion-soldered steel / magnesium interface, the influence rule of the interface temperature on reaction kinetics, and the properties of interface reaction products (Fe-Al intermetallic compounds), magnesium alloy welding wire components and welding parameters are optimized to promote a metallurgical reaction of the Fe and Al on the steel / magnesium interface, limit the thickness of a Fe-Al intermetallic compound layer and improve the mechanical properties and welding quality of an MIG fusion-soldered joint of steel-magnesium dissimilar metal. The process of the steel-magnesium dissimilar metal connection method comprises the steps of steel-magnesium weldment edge preparation, adoption of optimized magnesium alloy welding wires, adoption of an optimized welding technology and steel-magnesium dissimilar metal MIG fusion-soldered connection.

Owner:JILIN UNIV

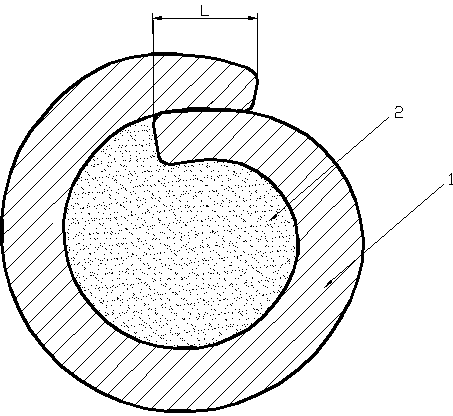

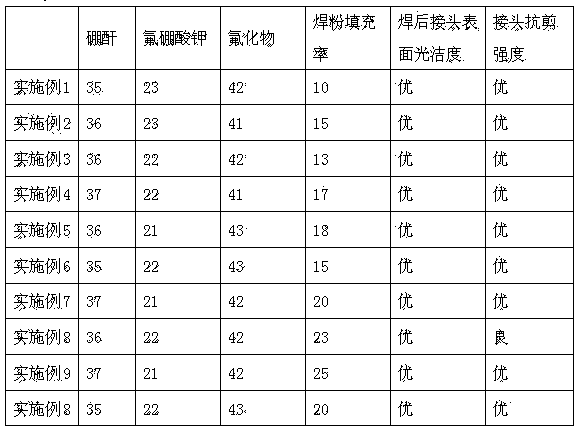

Preparation method of fluxed core welding ring

ActiveCN104227268AAdd lessThe amount of addition is difficult to controlWelding/cutting media/materialsSoldering mediaBrazingResistor

The invention relates to a preparation method of a fluxed core welding ring. The preparation method comprises the following steps: preparing a thin strip 0.1-0.5mm think from a silver brazing material containing 20-45% of silver, carrying out annealing treatment on the thin strip, washing the thin strip subjected to annealing treatment, curling the thin strip by using a roller so as to deform to form a U-shaped strip with an upward opening, vibrating a silver brazing agent to a conveying belt from a hopper, then conveying the silver brazing agent to the U-shaped strip through the conveying belt, rolling the U-shaped strip by the roller so as to deform to form a butted tubular structure, flattening the tubular structure by rolling to form a flat welding wire with a butted seam, cleaning the flat welding wire with a brush wheel and a hairbrush, and heating the flat welding wire through a low temperature resistor and then carrying out looping forming. The active temperature of the silver brazing agent is 550-850 DEG C; the sliver brazing agent is formed by mixing the following components in percentage by weight of the total weight of the silver brazing agent: 35-37% of boric anhydride, 21-23% of potassium fluoborate and 41-43% of fluoride; the silver brazing agent accounts for 10-25% of the total weight of the fluxed core welding ring. The preparation method disclosed by the invention is concise and reasonable, the brazing process is simplified, the quality of a brazed joint is improved and the use cost of the brazing agent can be effectively reduced.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

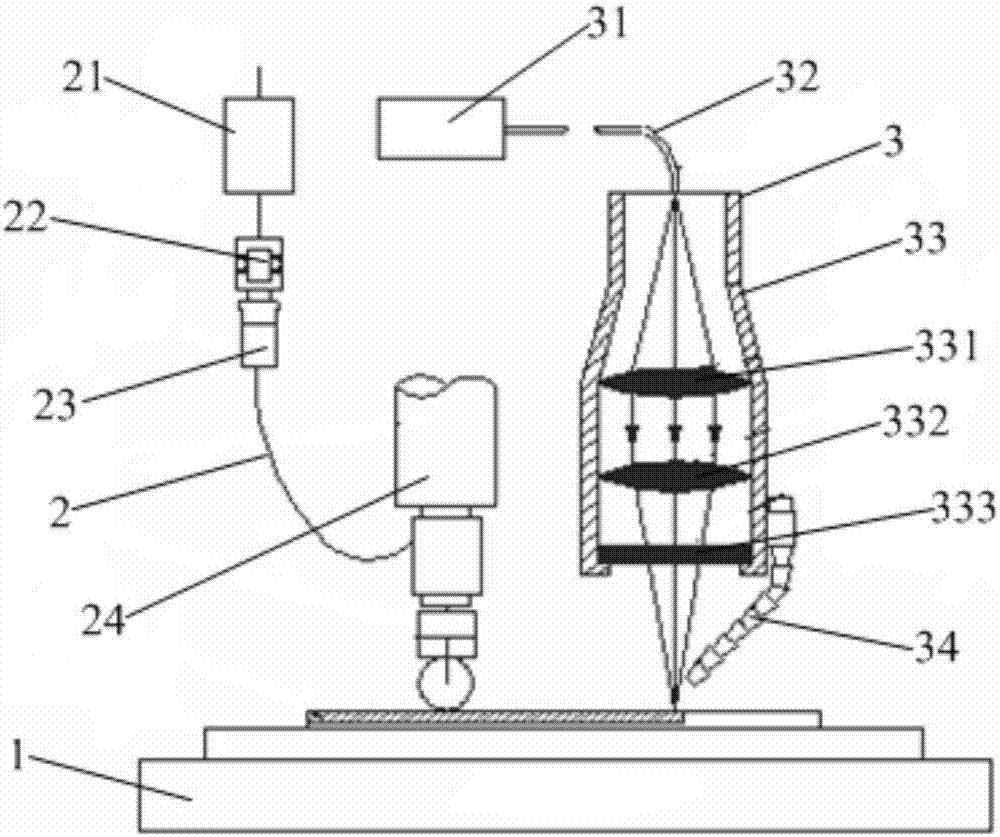

Heterogeneous metal laser-ultrasonic compound welding method and device

ActiveCN107984085ANarrow phase change rangeInhibition of mass productionLaser beam welding apparatusUltrasonic weldingLap joint

The invention provides a heterogeneous metal laser-ultrasonic compound welding method and device. The two advanced technologies of laser welding and ultrasonic consolidation are combined, that is, heterogeneous materials to be welded are connected in an overlap mode to form a lap joint, the position to be welded is welded in a laser welding mode, and the connecting purpose is realized. Under the condition that the temperature of the joint to be welded is below 10-30% of the melting point of an upper layer base material, ultrasonic welding is conducted, and efficient connection of the joint isrealized. According to the heterogeneous metal laser-ultrasonic compound welding method and device, the problem that a brittle joint is formed during welding of heterogeneous materials through a traditional welding method is solved, the problem that only a high energy beam welding method is adopted, though massive formation of intermetallic compound can be partially restrained, the strength of thejoint is still not high is also solved, and the problem difficult to solve that ultrasonic consolidation is only adaptive to low-melting-point thin plate welding is solved.

Owner:NANCHANG UNIV

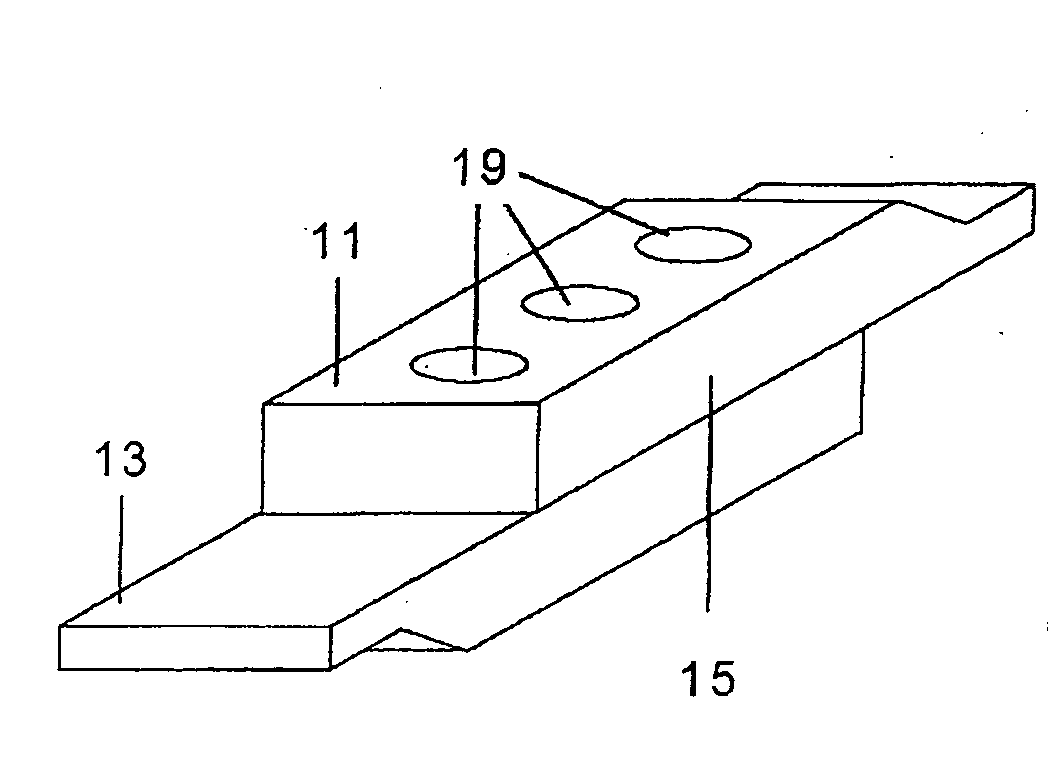

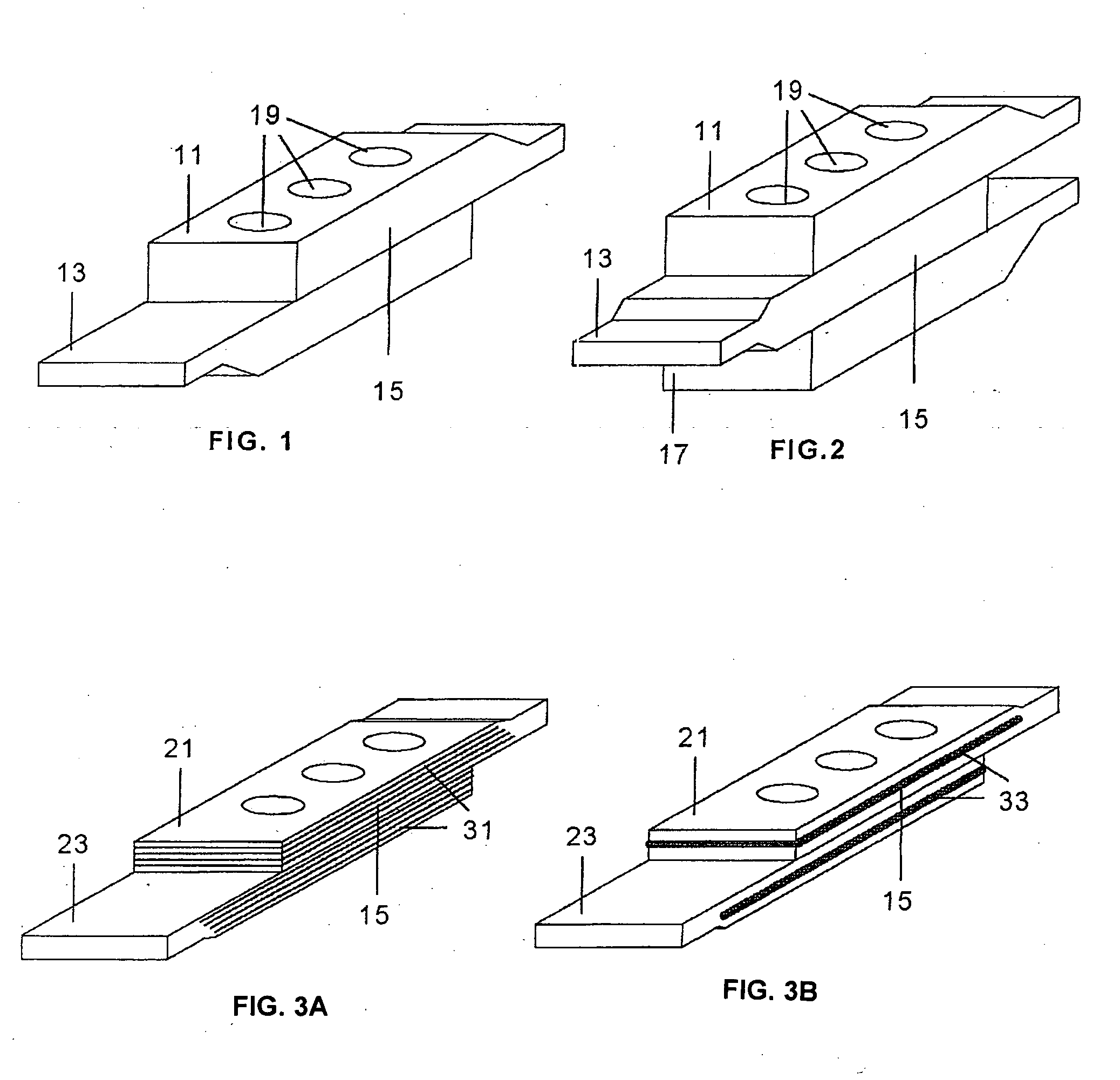

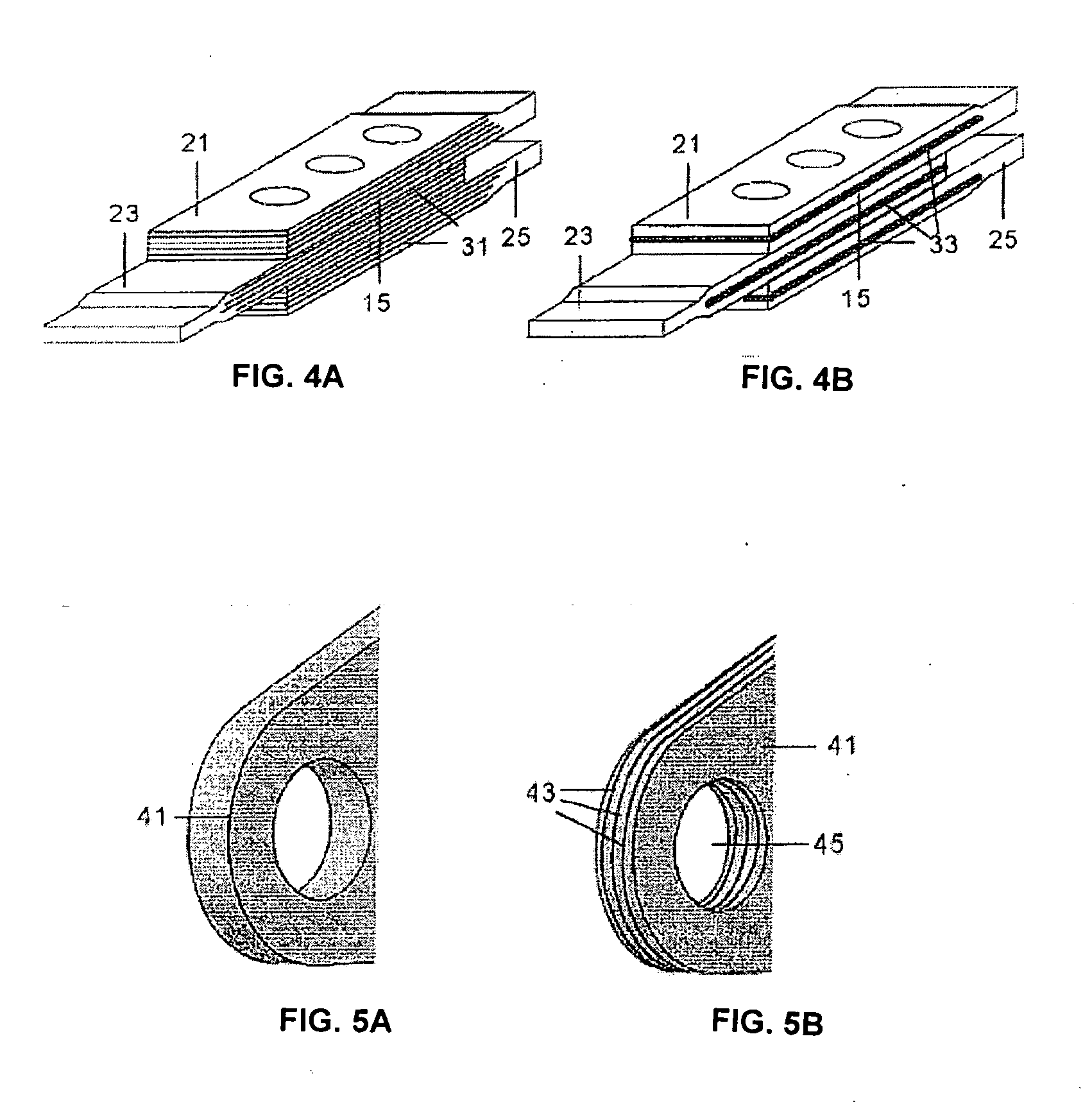

Metallic local reinforcement for heavy loaded joints of composite components

InactiveUS20070154680A1Reduce decreaseReduce weightFuselage framesSheet joiningCarbon fibersMetal foil

A mechanically fastened permanent or detachable joint between two or more parts (21, 23, 25, 41), at least one of them made of a composite material, preferably carbon fibres impregnated with thermoset resin, with continuous plies from the full-composite area along the joint area (15) and including a metal reinforcement, preferably made of titanium, in the joint area (15), the joint area (15) thickness being increased in the thickness of said reinforcement plus the eventual additional composite plies laid only on the reinforced area. The metal reinforcement may consist of one or more metal foils or sheets (31) interleaved between the composite plies or one or more metal plates (33) embedded between two of the composite plies.

Owner:AIRBUS OPERATIONS SL

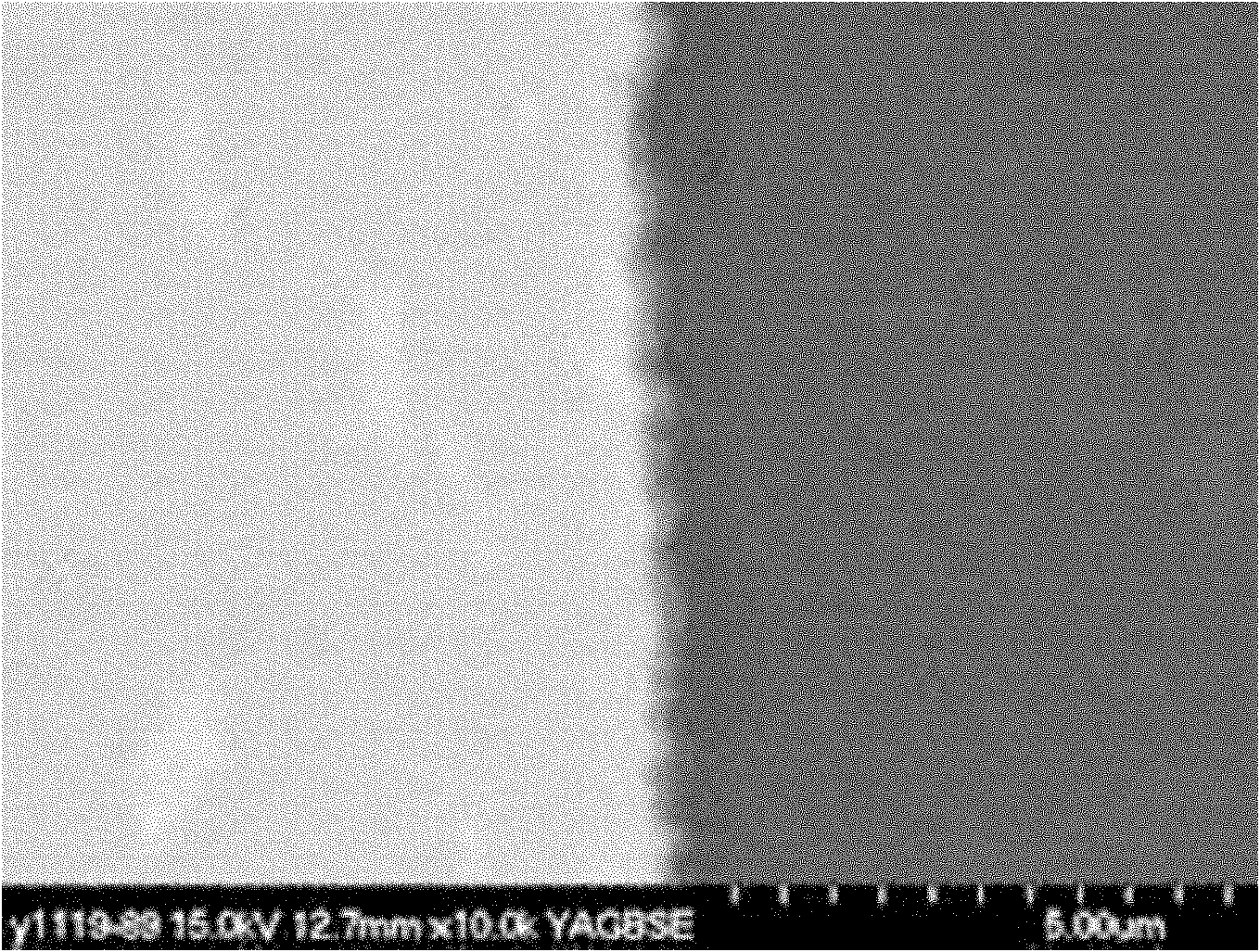

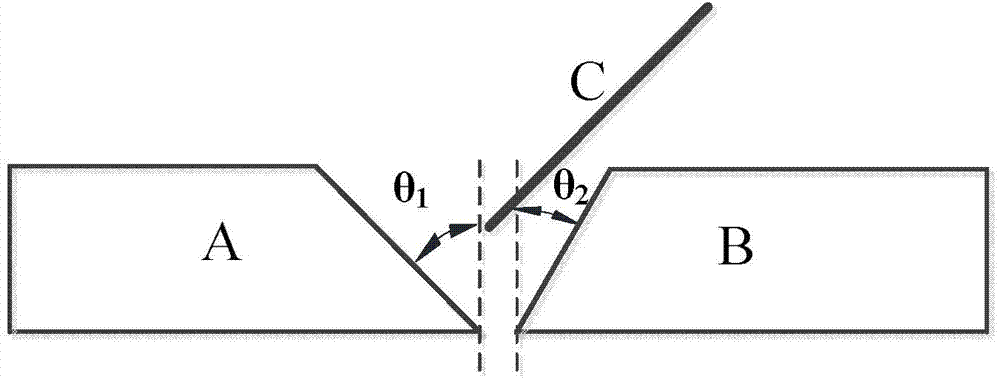

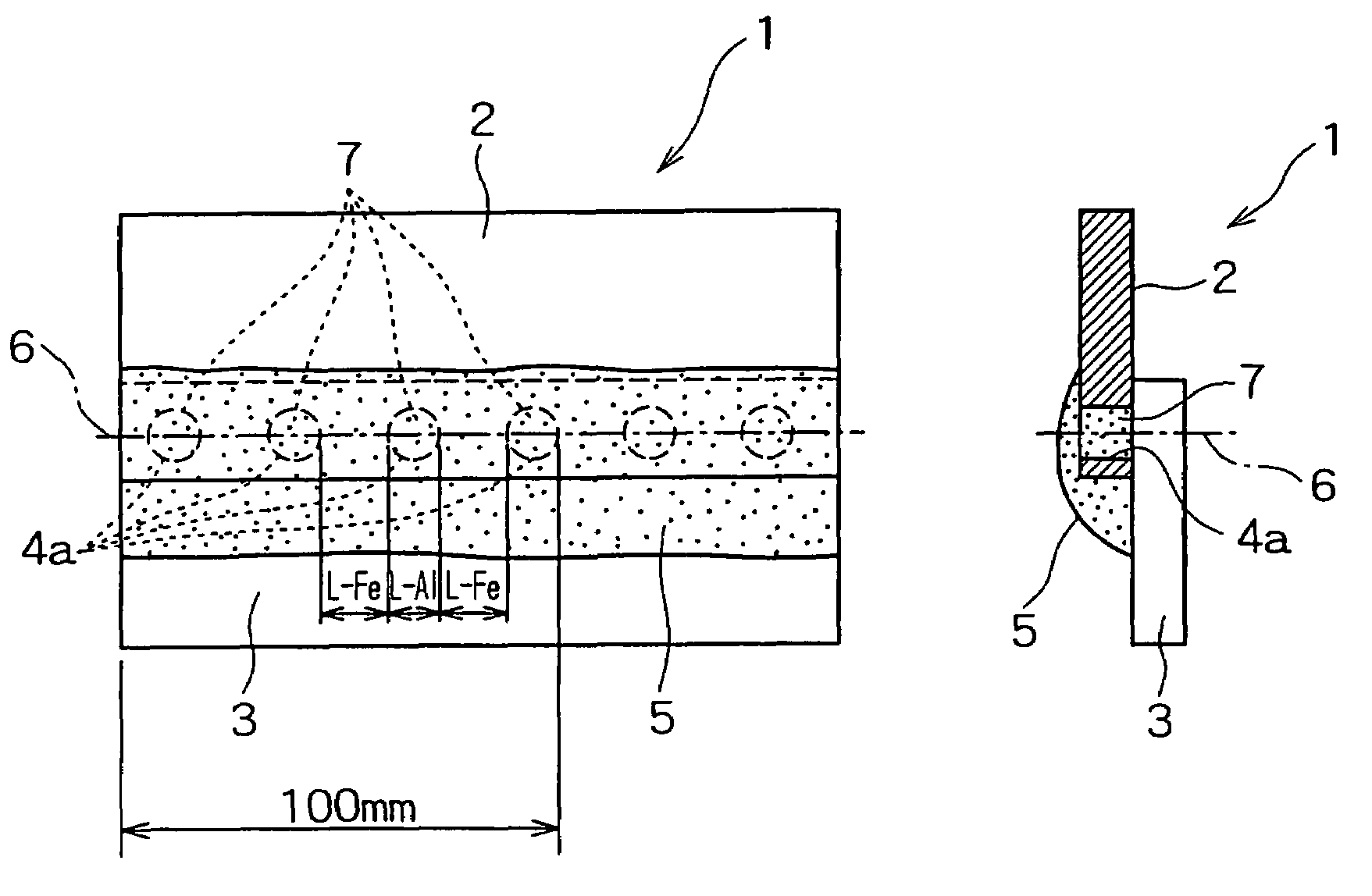

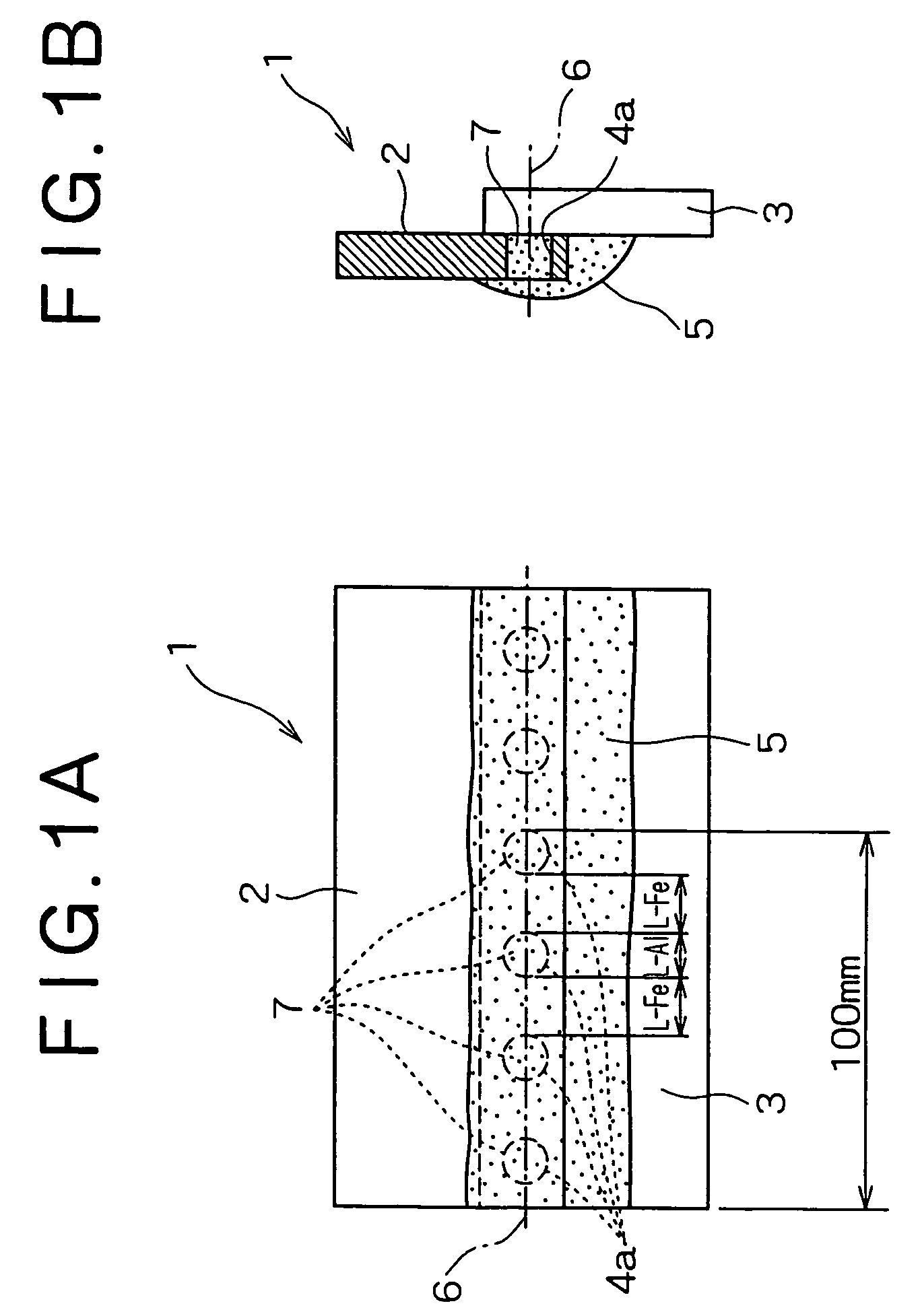

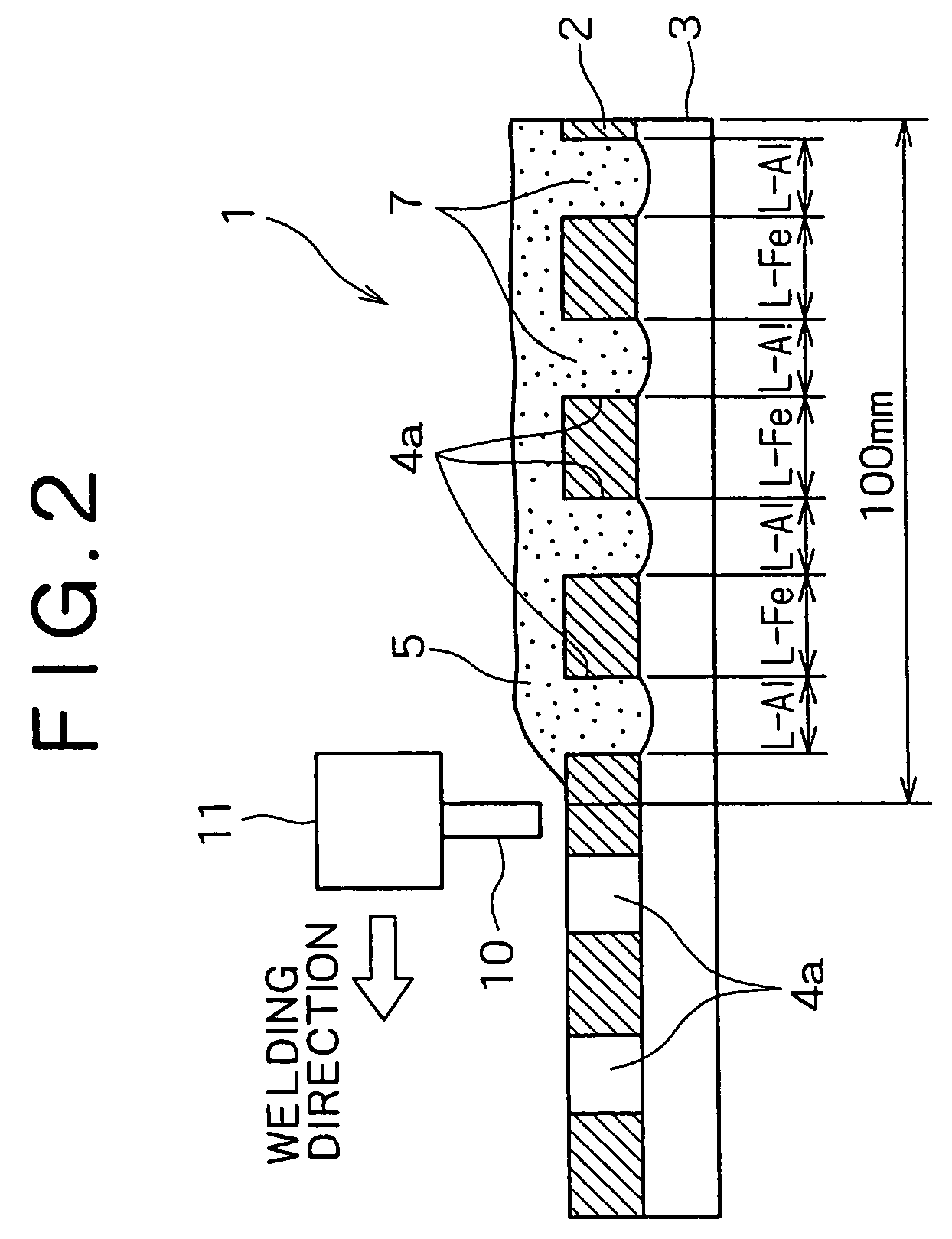

Dissimilar material weld joint formed by joining iron type material and aluminum type material, and weld joining method

InactiveUS7700198B2Improve joint performanceImprove ductilityHot-dipping/immersion processesArc welding apparatusHigh intensityWeld line

Disclosed are: a dissimilar material weld joint being formed by joining an iron type material and an aluminum type material and having not only a high strength but also an excellent ductility; and a weld joining method allowing such a joint to be stably produced. A dissimilar material weld joint 1 formed by joining an iron type material 2 and an aluminum type material 3, wherein: voids 4a are formed beforehand on the side of said iron type material 2 at a predetermined interval along a weld line 6; both said iron type and aluminum type materials are weld joined so that said voids 4a are filled with molten aluminum 7; and the minimum value of the ratio (L-Al) / (L-Fe) of the length (L-Al) of an aluminum type welding material 10 with which said voids 4a are filled to the length (L-Fe) of said iron type material 2 adjacent to said voids 4a filled with said aluminum type welding material 10 along said weld line 6 on the section containing said weld line 6 is in the range from 0.5 to 7, both the lengths (L-Al) and (L-Fe) being the lengths per 100 mm in length of the weld line 6 formed after welding.

Owner:KOBE STEEL LTD

Methods for producing magnesium alloy welding wires by adopting magnesium alloy foundry scraps

ActiveCN101947705ASolve the loop problemNo pollution in the processWelding/cutting media/materialsSoldering mediaFoundryCarbon Dioxide / Helium

The invention discloses methods for producing magnesium alloy welding wires by adopting magnesium alloy foundry scraps, relating to methods for producing the magnesium alloy welding wires and aiming at solving the problems that the traditional process for producing the magnesium alloy welding wires at present has high production cost, complex process, low safety coefficient and certain pollution to the environment in a melting process due to requirement of shielding gas and addition of a covering agent. One method comprises the following steps of: (1) cleaning scraps; (2) packing; (3) heating and preserving the heat; (4) extruding to form wires, and (5) shearing; and compared with the first method, the difference in the second method is that in the step 3, the cleaned scraps are placed into an iron barrel which is placed into a heating furnace for heating, one end of the iron barrel is rapidly placed into a liner of an extrusion barrel, and the scraps are pushed to the bottom of the liner of the extrusion barrel, and in the step 4, an extruder is started so that an extrusion shaft enters the liner of the extrusion barrel to extrude a heated pressing disk and the scraps. The invention is used for producing the magnesium alloy welding wires.

Owner:HARBIN UNIV OF SCI & TECH

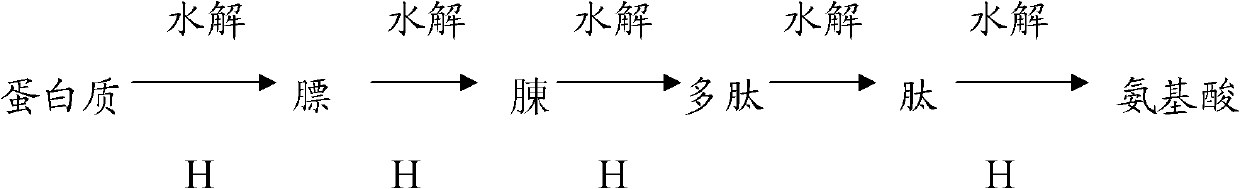

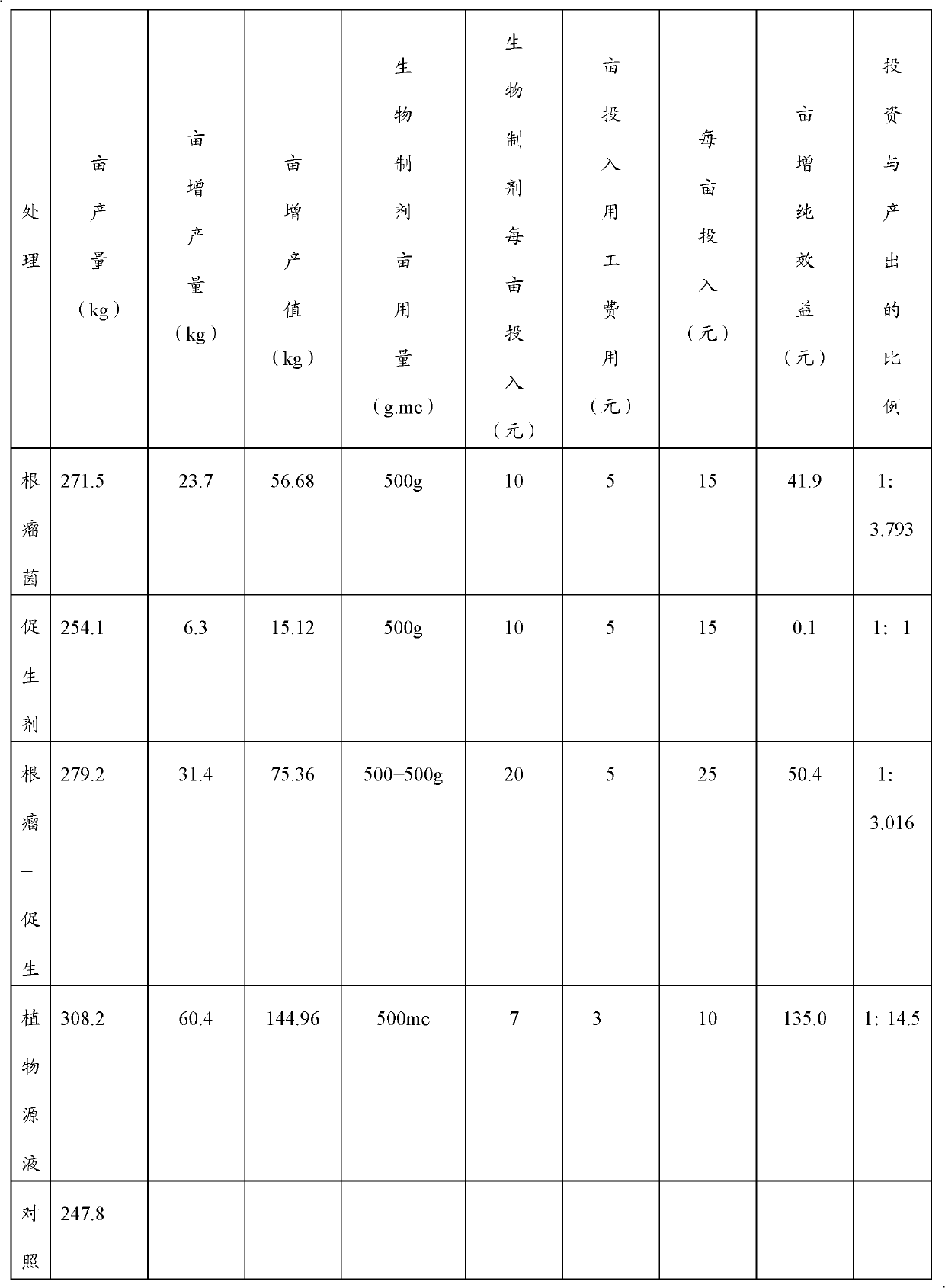

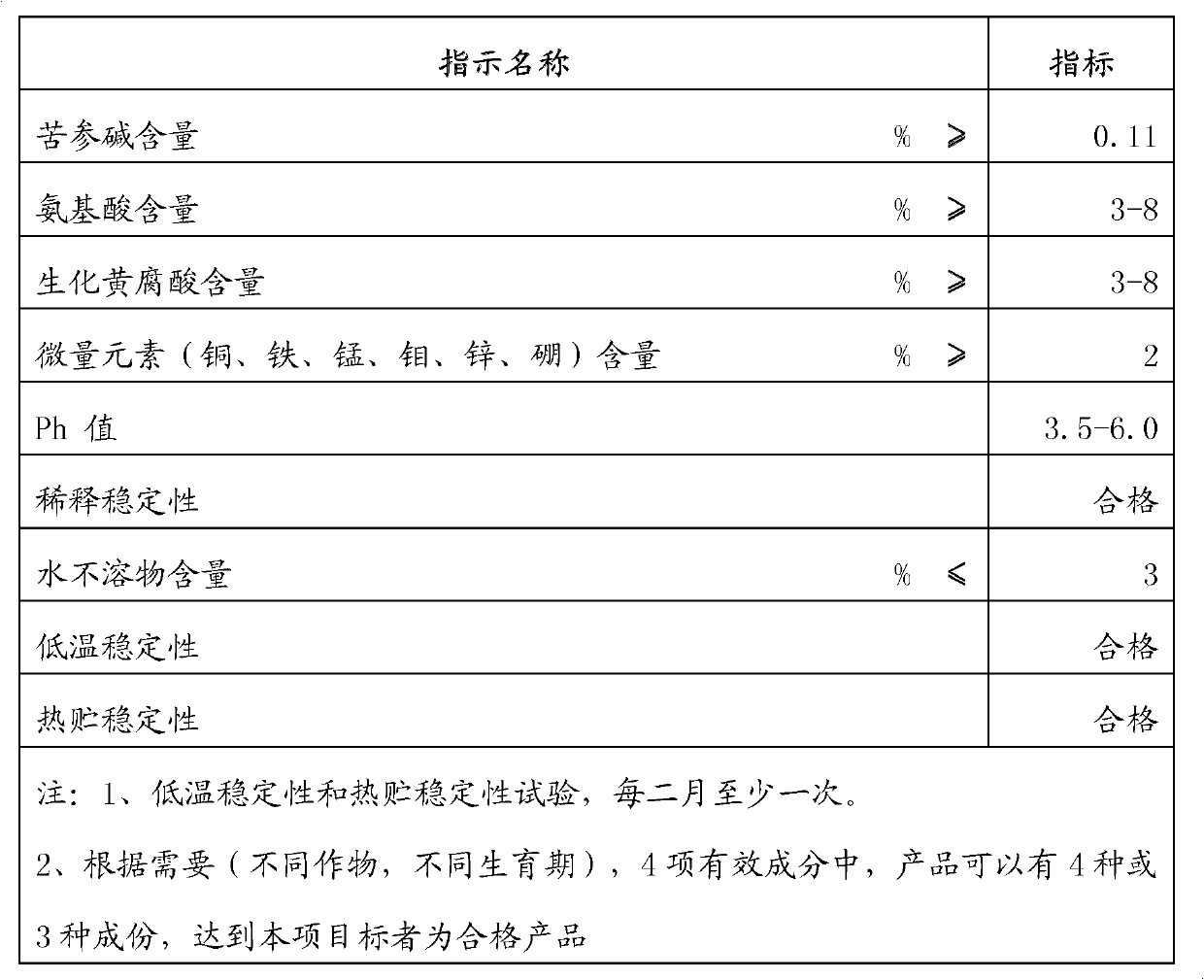

Multifunctional plant-derived growth improvement solution and preparation method thereof

InactiveCN101948360AImprove qualityPromote production increaseBiocidePlant growth regulatorsTrace elementSophora alopecuroides

The invention relates to a multifunctional plant-derived growth improvement solution. The growth improvement solution is characterized by mainly consisting of the following components in percentage by weight: 60-70 percent of active substance extracted from natural plants and 30-40 percent of protein hydrolyzed amino acid in the active substance, wherein the natural plants comprise the following components in percentage by weight: 30-40 percent of sophora alopecuroide, 15-20 percent of Chinese honeylocust fruit, 5-10 percent of sesbania cannabina pers, 15-25 percent of rangoon creeper fruit and 5-10 percent of chinaberry bark. The preparation method comprises the following steps of: selecting the materials, processing and extracting the active substance; hydrolyzing protein into amino acid; and packaging complex trace elements. The invention has the advantages that multiple natural plants are utilized, xtracted, converted and subjected to complexing with trace elements into an aqueous agent product, thus the solution has the effects of insecticide, acaricide and sterilization; if the solution is mixed with chemical pesticide, about 50 percent of the dosage of the chemical pesticide can be reduced, and the toxicity is reduced by 4.05-11.76 times, thus the solution is beneficial to the comprehensive treatment and the ecological balance of pests in the agriculture; if being singly used, the solution can be used for promoting crops to balancedly grow and develop, improving the resilience function and the immunity of the crops and improving the quality, so that the mouthfeel of fruit and vegetables is good, and the production increase is obvious.

Owner:天津市绿源环境景观工程有限公司

Shielded metal arc welding method used for phase welding of X7Ni9 steel and S30408 steel

ActiveCN105269175AAvoid poor resultsAvoid the problem of excessive concentration of internal stressArc welding apparatusWelding/cutting media/materialsStress reliefAlternating current

The invention provides a shielded metal arc welding method used for phase welding of X7Ni9 steel and S30408 steel. The shielded metal arc welding method comprises the following steps that (1) a V-shaped groove or an asymmetric X-shaped groove is adopted as a shielded metal arc welding groove; (2) the two sides of a weld joint of an X7Ni9 steel plate and an S30408 steel plate is kept in a dry state before welding; (3) an alternating current power source is adopted, and suitable welding process parameters are selected; (4) the interpass temperature is kept to be smaller than 90 DEG C, after first layer of base is welded, the weld joint is polished and cleaned, then fine cracks are detected through permeation and eliminated through a polishing method, and afterwards, filling welding is conducted; and (5) after one side is welded, the reverse side needs to be subjected to back gouging and be polished, and similarly, fine cracks are detected through permeation and eliminated through polishing. According to the shielded metal arc welding method, the properties of the two steel are both taken into account fully, so that the quality of a high-strength dissimilar steel welded joint is effectively ensured. Above all, no stress relief treatment is needed after welding, and the high toughness of the welded joint at the temperature of -196 DEG C can be still ensured.

Owner:WUHAN YIYE STEEL STRUCTURE

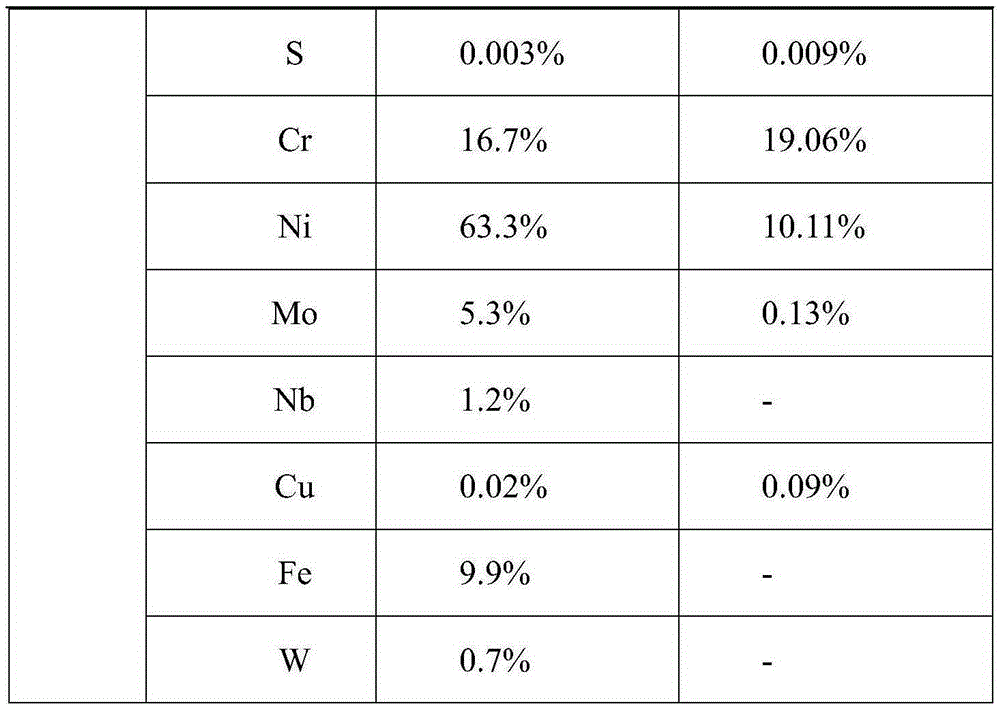

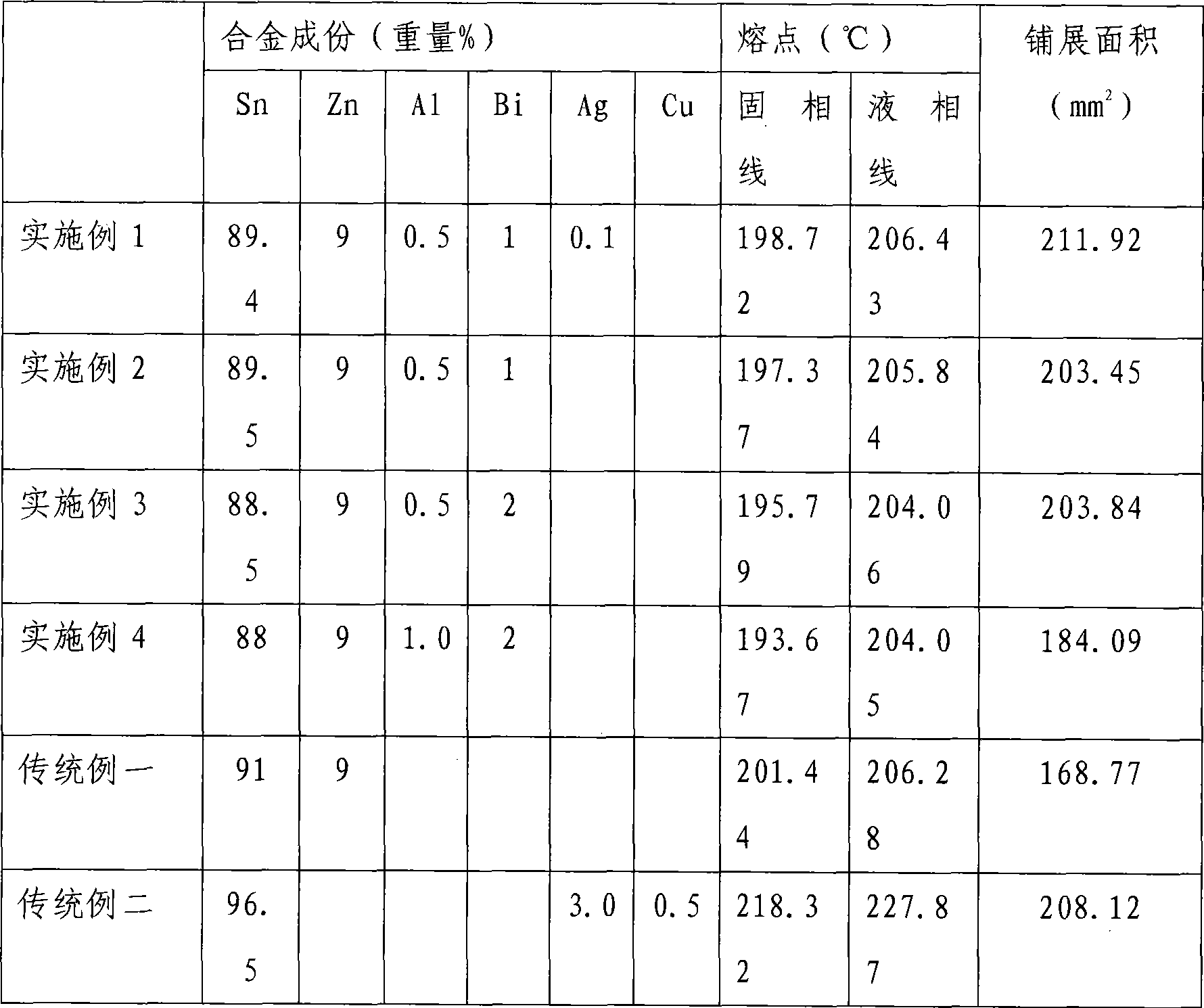

Lead-free solder for aluminum soft soldering

InactiveCN101486133AStrong antioxidantGood wetting propertiesWelding/cutting media/materialsSoldering mediaZincChemical composition

The invention discloses low-temperature brazing solder for aluminum substrate materials. The solder is leadless solder; and not only the solidified structure is improved compared with needle zinc-phase tin-zinc eutectic alloy and the wettability is improved but also the solder can form joints with higher strength with aluminum substrates. The low-temperature brazing solder for the aluminum substrate materials comprises the following chemical compositions in percentage by weight: 9 to 15 percent of zinc, 0.01 to 2 percent of aluminum, 0.01 to 2 percent of silver, 1 to 3 percent of bismuth, and the balance being tin. The leadless solder alloy obtained by the proposal does not use toxic lead, has stronger antioxidation and better wettability compared with the prior Sn-Zn alloy, and is more suitable for aluminum soft soldering compared with the prior Sn-Ag-Cu solder alloy; and the joints have better performance and lower cost.

Owner:YIK SHING TAT INDUSTRIALCO LTD +2

Chinese medicinal compound preparation for treating fracture and preparation method thereof

InactiveCN102379941AIncrease blood flowReduce aggregationAnthropod material medical ingredientsAntipyreticSalvia miltiorrhizaDrynaria

The invention relates to a Chinese medicinal compound preparation for treating fracture, which comprises the following Chinese medicine raw materials in part by weight: 8 to 12 parts of peach seed, 13 to 17 parts of safflower, 8 to 12 parts of Szechuan lovage rhizome, 8 to 12 parts of red paeony root, 8 to 12 parts of Chinese angelica, 8 to 12 parts of root of red-rooted salvia, 13 to 17 parts of fortune drynaria rhizome, 13 to 17 parts of Himalayan teasel root and 2 to 4 parts of notoginseng root (electuary). A preparation method comprises the following steps of: cleaning the nine medicinal materials, mixing in a ratio, adding water in an amount which is 4 to 7 times the total weight of the medicinal materials or 70 volume percent ethanol, decocting for two times, 80 minutes each time, mixing two-time decoction, filtering, and concentrating to obtain liquid extract of which the specific gravity is 1.18 at the temperature of 60 DEG C. The conventional preparation process is adopted. The preparation can be prepared into any one pharmaceutical formulation such as tablets, capsules, granules, oral liquid, pills and syrup. By the Chinese medicinal compound preparation prepared by the method, fracture healing time is obviously shortened, calluses grow more quickly, firmly and reliably, and the curative effect is far superior to that of the conventional Chinese medicine for treating the fracture.

Owner:INST OF BASIC RES & CLINICAL MEDICINE CHINA ACAD OF CHINESE MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com