Methods for producing magnesium alloy welding wires by adopting magnesium alloy foundry scraps

A casting scrap and magnesium alloy technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of low safety factor, complex process, adding covering agent, etc., and achieve good joint performance, high safety factor and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

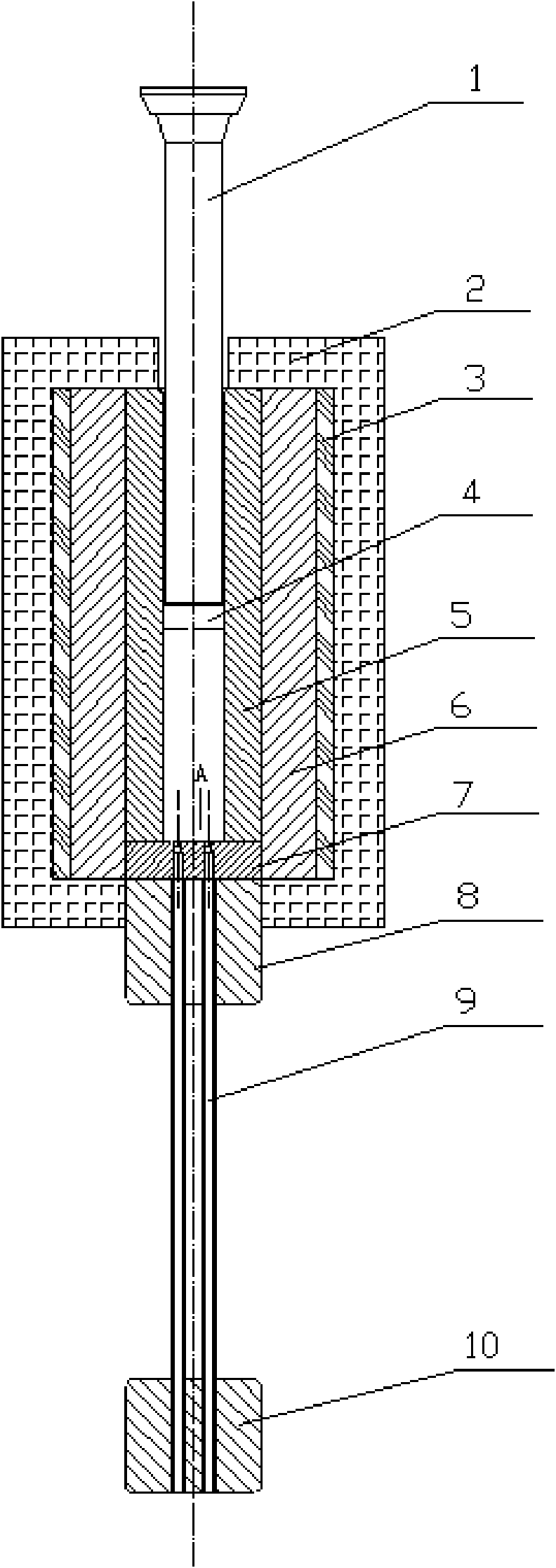

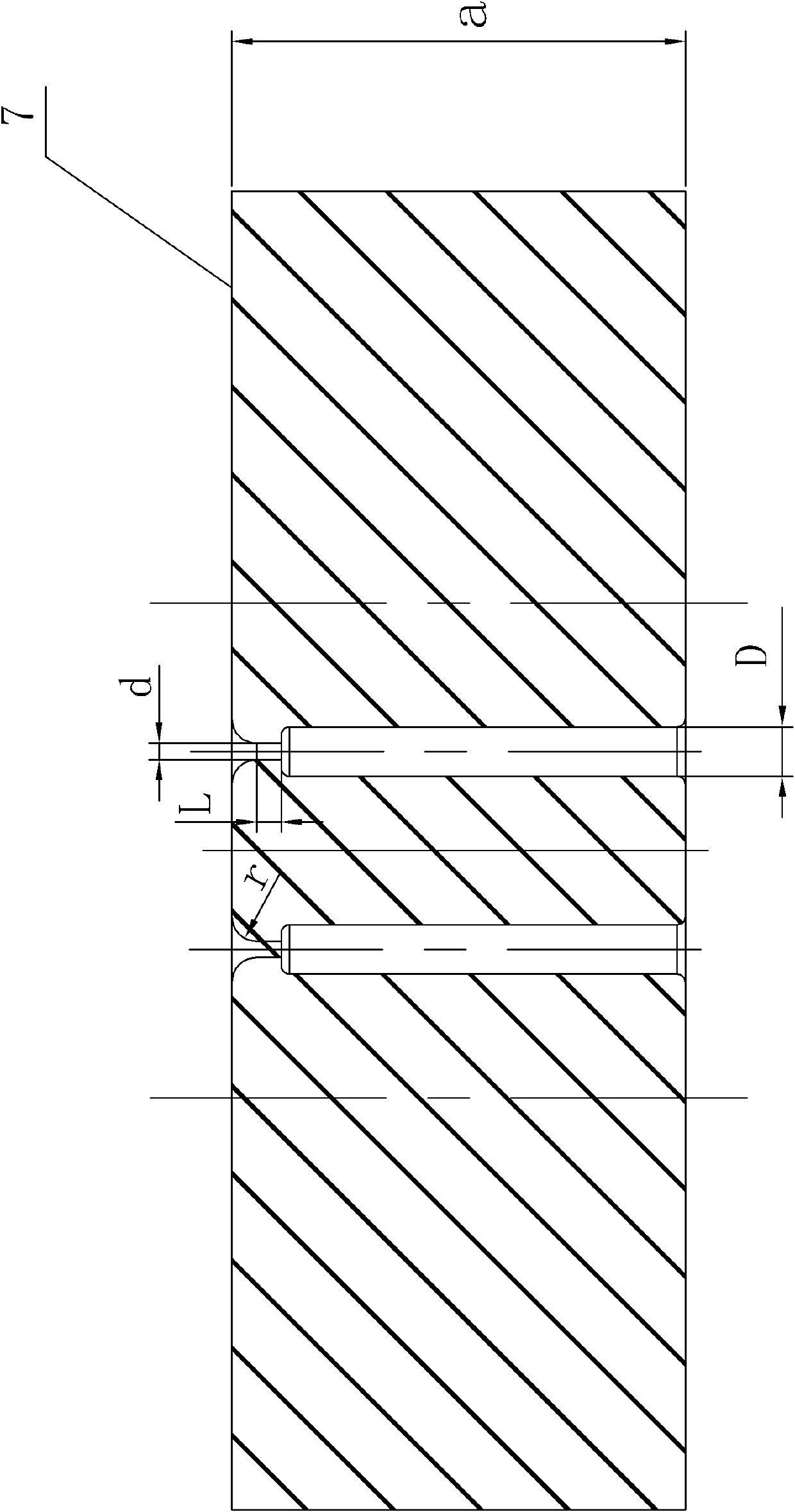

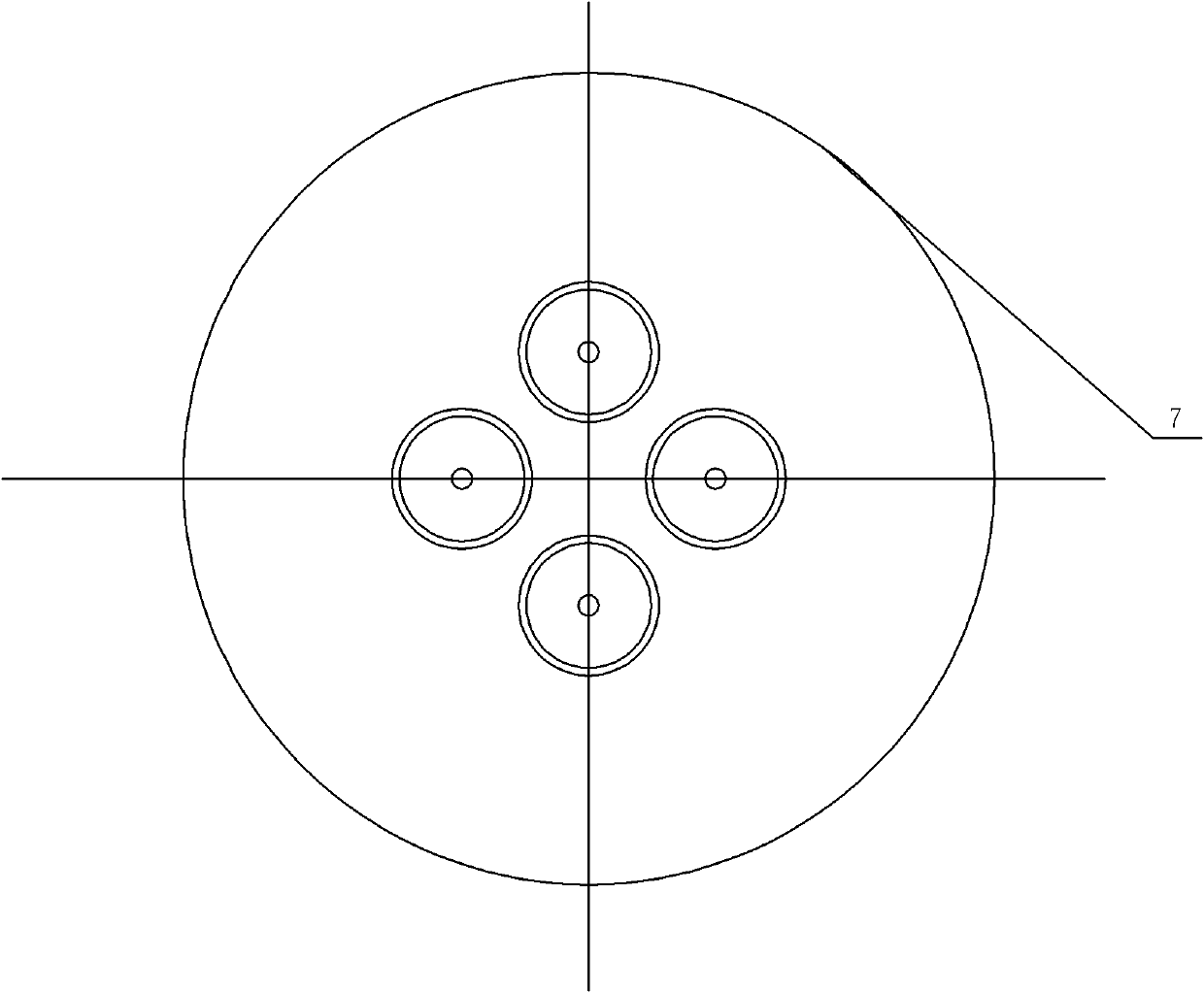

[0008] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the method of this embodiment includes the following steps: Step 1, waste material cleaning: immerse the magnesium alloy casting waste and leftover material with oil stains in the mixed solution for degreasing, the mixed solution has a mass concentration of 45% by volume ratio of 6:1 %-55% nitric acid and sulfuric acid solution with a mass concentration of 95%-98% are mixed, the invasion time is 1-2 minutes, then the oil stain is washed with water, and then immersed in nitric acid with a mass concentration of 15%-25% for etching , the invasion time is 2-3 minutes, and finally the residual acid is washed with water, and then air-dried until there is no water on the surface; Step 2: Filling: Put the template 7 that meets the size requirements of the welding wire into the bottom of the extrusion cylinder liner 5, Put the cleaned magnesium alloy casting waste and leftovers into the inner ...

specific Embodiment approach 2

[0011] Embodiment 2: The method of this embodiment also includes step 5. Step 5 is cutting and packaging, cutting the welding wire that meets the size requirements or directly reeling and packaging. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: In this embodiment, after step five is completed, the following steps are added: rounding one end of the extruded welding wire; putting the welding wire into a tubular heating furnace and passing the rounded end through the wire drawing die Connect with the fixture of the wire drawing machine; the mold is lubricated with high-temperature grease, the heating temperature is 240°C, and the heating speed is 4m / min for wire drawing; Step 4: Select the mold according to the deformation rate of less than 20%, and repeat Step 1 and Step 2 until it meets The diameter requirement of welding wire, this embodiment is suitable for producing the welding wire whose diameter requirement is 2-0.4mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com