High intensity steel gas shielded welding technique method

A welding process and gas shielded technology, which is applied in the field of high-strength steel gas shielded welding technology, to achieve the effects of excellent welding process performance, excellent joint comprehensive performance, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

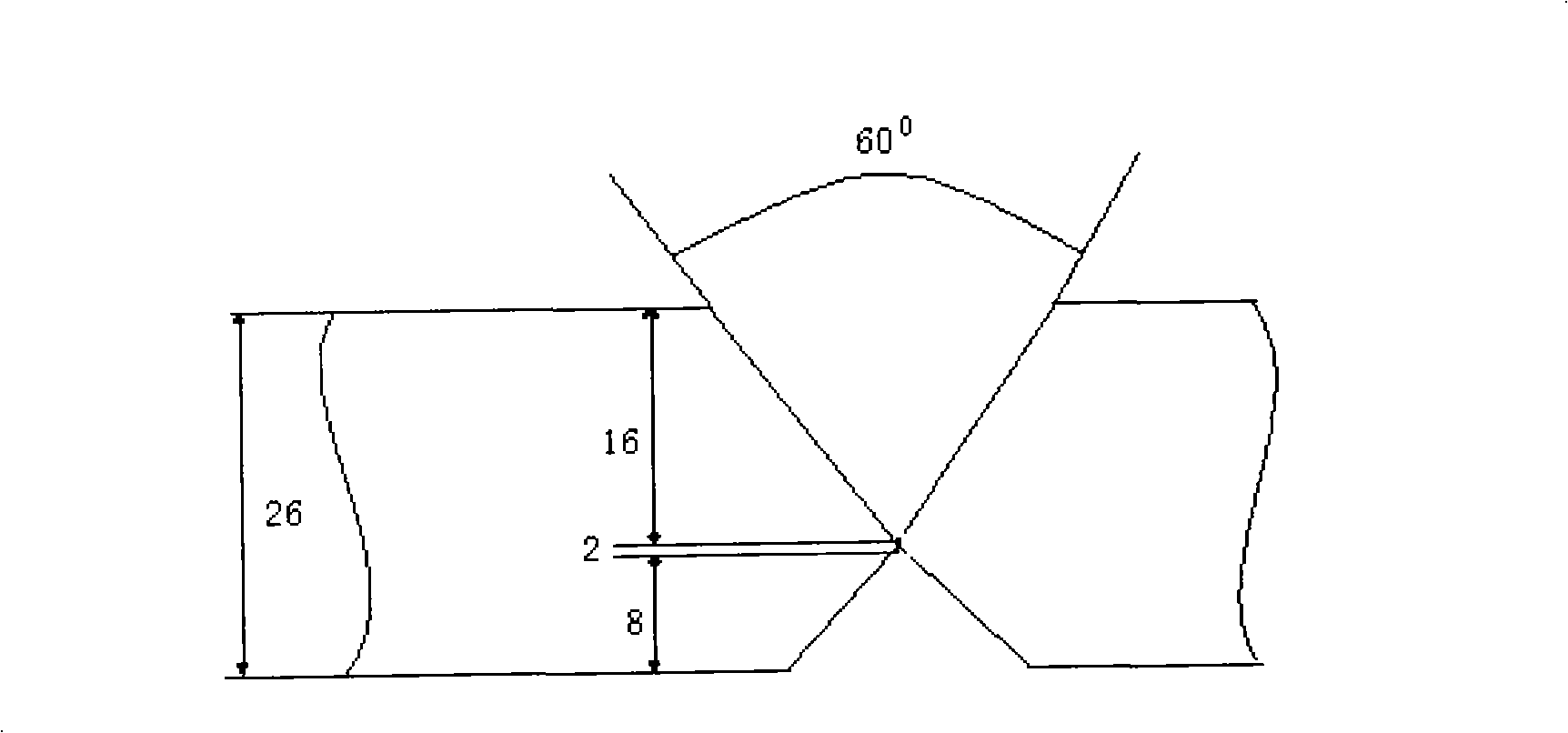

[0016] Base material: WNQ690 steel plate, the size of the test plate is 600mm×300mm×26m. The gas shielded welding groove adopts double V-shaped asymmetric groove, the groove angle is 60°, and the blunt edge is 2mm.

[0017] Welding material matching: the mechanical properties of the deposited metal are R el =665MPa, R m =735MPa, A=20%, Z=68%, average impact energy A of deposited metal KV (-40°C) = 182J, combined with WNQ690 steel (26mm+26mm) thick plate using rich argon (20% CO 2 +80% Ar) welding process welding.

[0018] Welding process specification: The chemical composition of the welding wire used is: C: 0.04, Si: 0.40, Mn: 1.40, P≤0.020, S≤0.015, Ni: 0.40, Cr: 0.20, Ti: 0.06, Cu: 0.30, B: 0.002, Als≤0.02, wire diameter Φ1.2mm, welding current 270(A), welding voltage 27(V), welding speed 29(cm / min), welding heat input 15(kJ / cm), gas flow 18 (L / min); gas shielded welding adopts multi-layer and multi-pass continuous welding, the interlayer temperature is controlled at 1...

Embodiment 2

[0021] Base material: WNQ690 steel plate, the size of the test plate is 600mm×300mm×26m. The gas shielded welding groove adopts double V-shaped asymmetric groove, the groove angle is 60°, and the blunt edge is 2mm.

[0022] Welding material matching: the mechanical properties of the deposited metal are R el =665MPa, R m =735MPa, A=20%, Z=68%, average impact energy A of deposited metal KV (-40°C) = 182J, combined with WNQ690 steel (26mm+26mm) thick plate using rich argon (20% CO 2 +80% Ar) welding process welding.

[0023] Welding process specification: The chemical composition of the welding wire used is: C: 0.12, Si: 0.80, Mn: 2.0, P≤0.020, S≤0.015, Ni: 1.0, Cr: 0.50, Ti: 0.20, Cu: 0.50, B: 0.0079, Als≤0.02. Welding wire diameter Φ1.2mm, welding current 265(A), welding voltage 27(V), welding speed 29(cm / min), welding heat input 15(kJ / cm), gas flow 18(L / min). Gas-shielded welding adopts multi-layer and multi-pass continuous welding, and the temperature between layers is ...

Embodiment 3

[0026] Base material: WNQ690 steel plate, the size of the test plate is 600mm×300mm×26m. The gas shielded welding groove adopts double V-shaped asymmetric groove, the groove angle is 60°, and the blunt edge is 2mm.

[0027] Welding material matching: the mechanical properties of the deposited metal are R el =665MPa, R m =735MPa, A=20%, Z=68%, average impact energy A of deposited metal KV (-40°C) = 182J, combined with WNQ690 steel (26mm+26mm) thick plate using rich argon (20% CO 2 +80% Ar) welding process welding.

[0028]Welding process specification: The chemical composition of the welding wire used is: C: 0.08, Si: 0.6, Mn: 1.6, P≤0.020, S≤0.015, Ni: 0.8, Cr: 0.3, Ti: 0.10, Cu: 0.40, B: 0.004, Als≤0.02.

[0029] Welding wire diameter Φ1.2mm, welding current 270(A), welding voltage 27(V), welding speed 29(cm / min), welding heat input 15(kJ / cm), gas flow 18(L / min). Gas-shielded welding adopts multi-layer and multi-pass continuous welding, and the temperature between layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com